Patents

Literature

31results about How to "Limit lateral deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

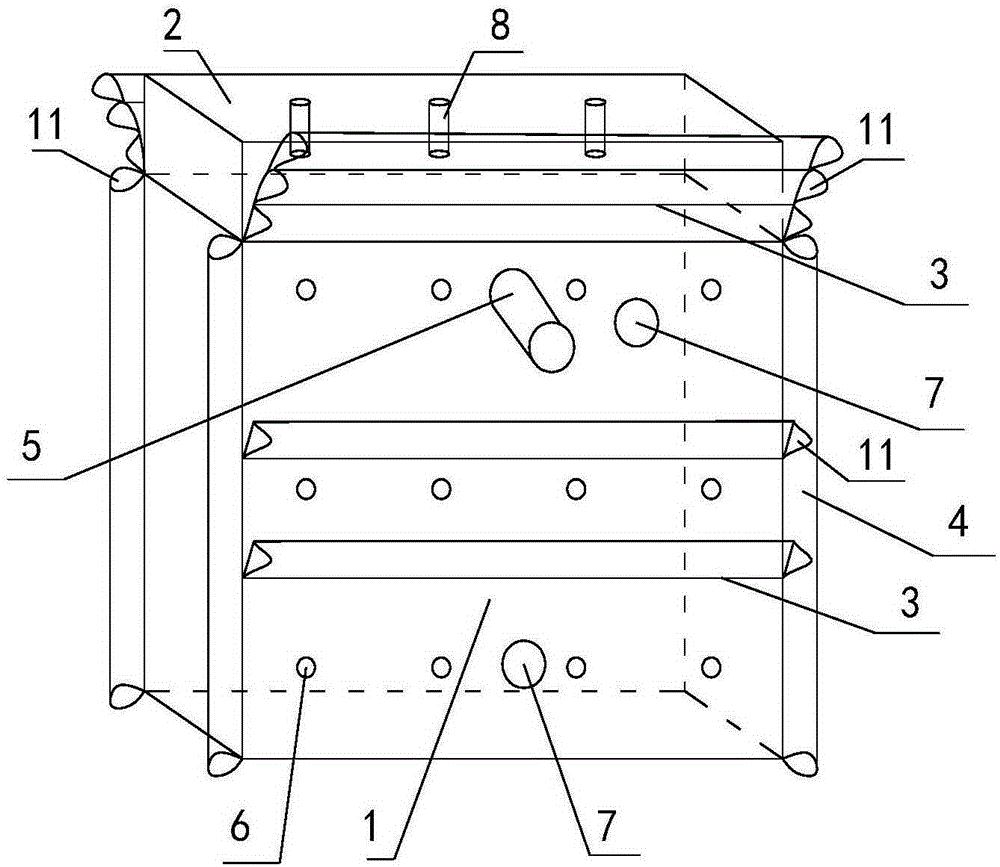

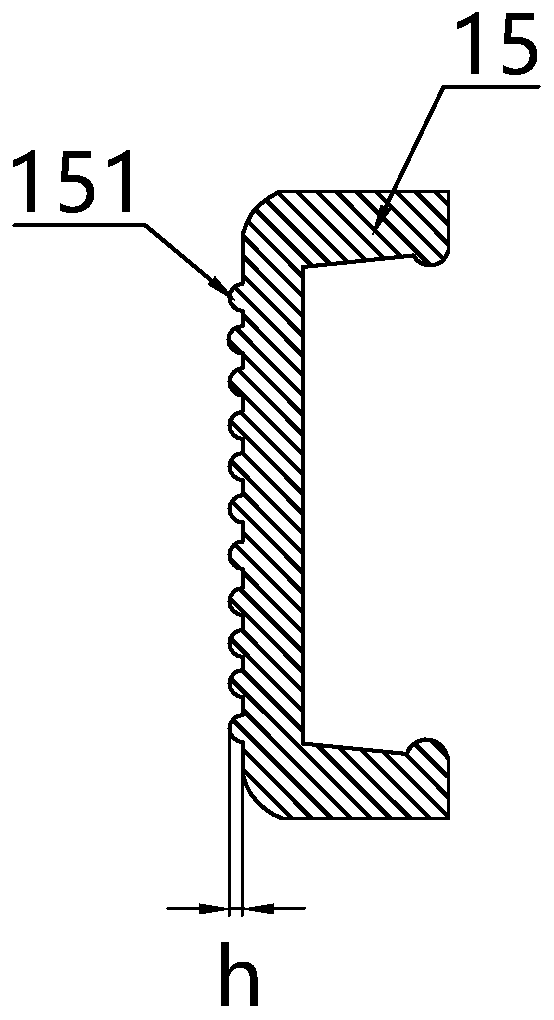

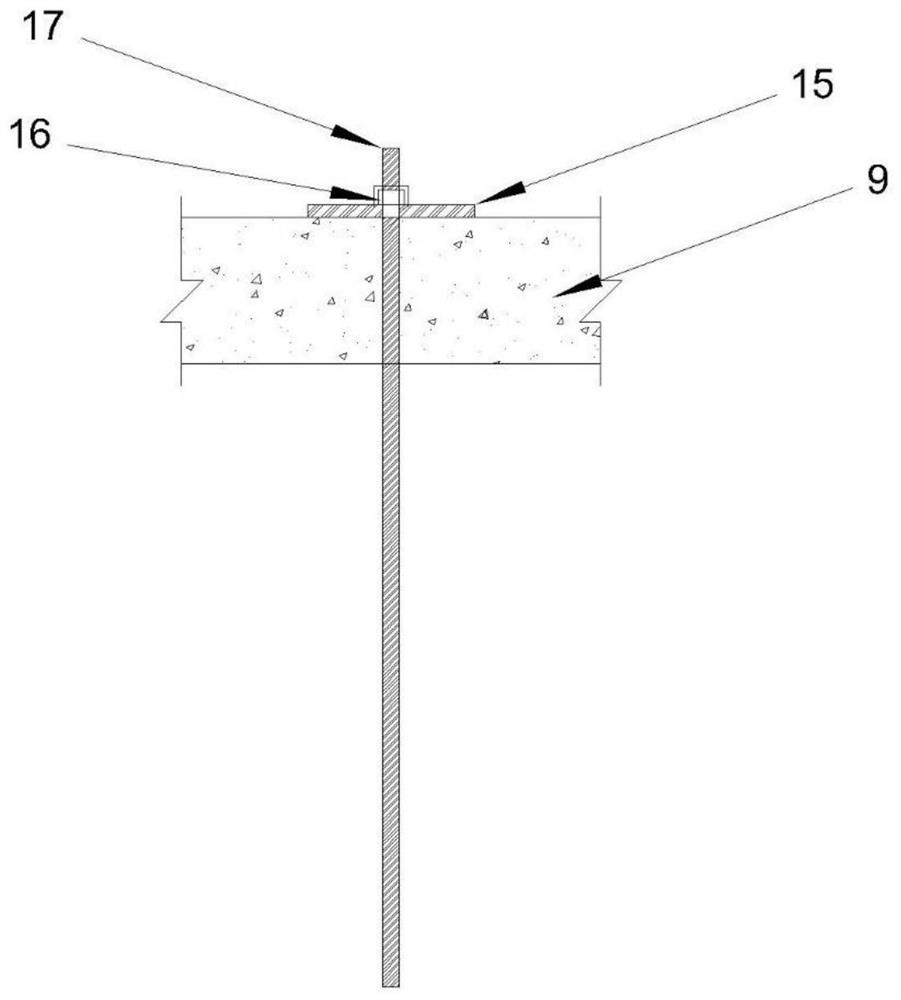

Connection joint of concrete column and steel beam

InactiveCN103243818AHigh precisionFit clearance is smallBuilding constructionsUltimate tensile strengthMaterials science

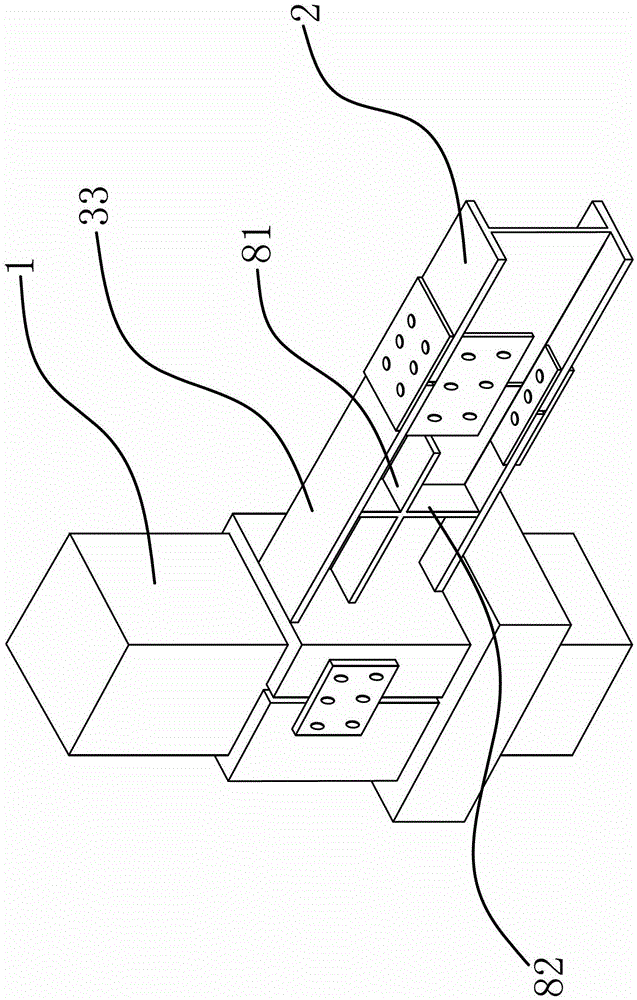

The invention provides a connection joint of a concrete column and a steel beam, belongs to the technical field of construction engineering, and solves the technical problems of low strength, construction difficulty and the like of an existing connection joint of the concrete column and the steel beam. The connection joint of the concrete column and the steel beam comprises the concrete column, the steel beam, a half steel sleeve I and a half steel sleeve II. The half steel sleeve I and the half steel sleeve II are detachably connected and can be sleeved on the concrete column after being connected; the half steel sleeve I or the half steel sleeve II is fixedly connected with a connection arm which is detachably connected with the steel beam; and the concrete column is provided with a projecting shoulder, and the half steel sleeve I and the half steel sleeve II can abut against the projecting shoulder. The connection joint of the concrete column and the steel beam has the advantage of being high in bearing capacity and simple in construction.

Owner:汪洋 +1

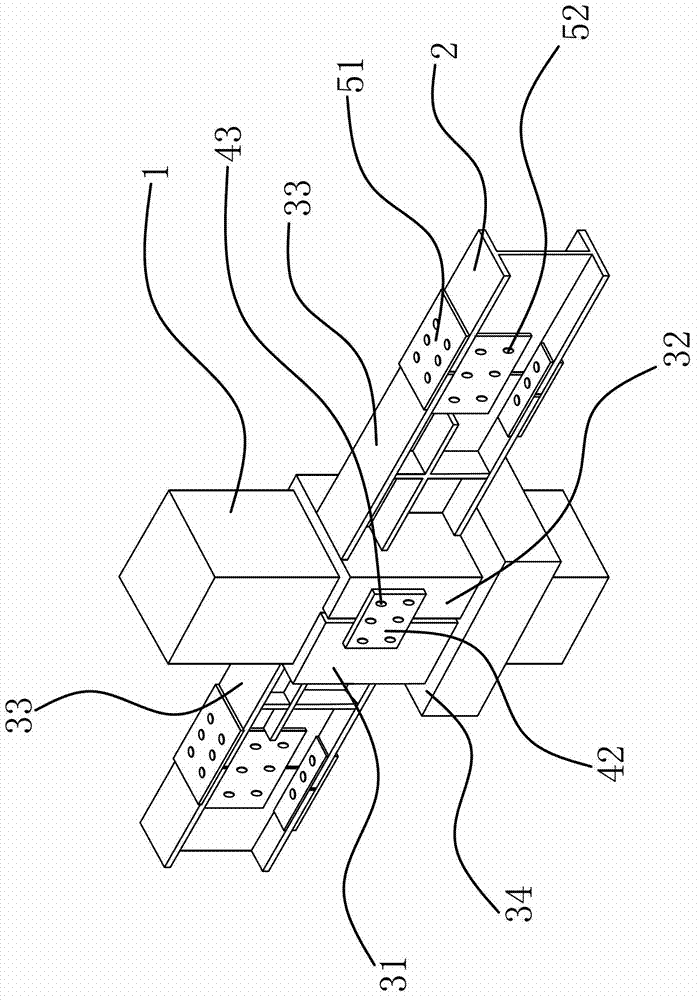

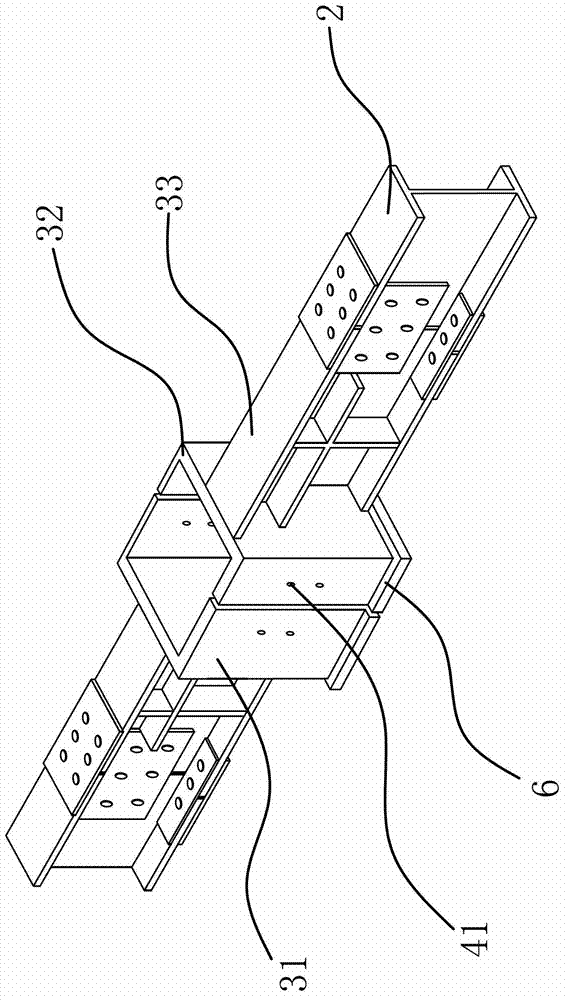

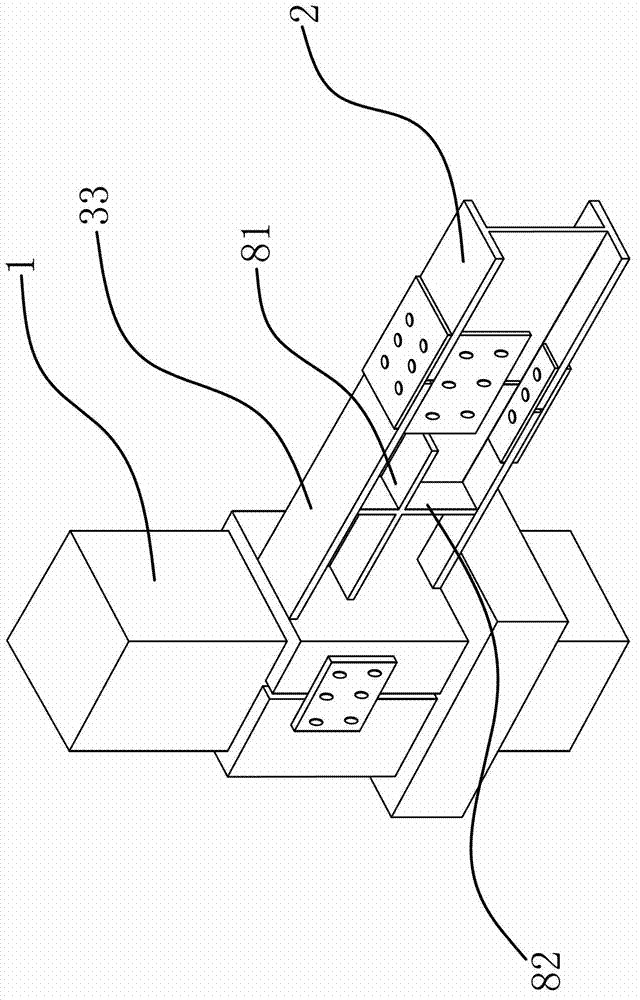

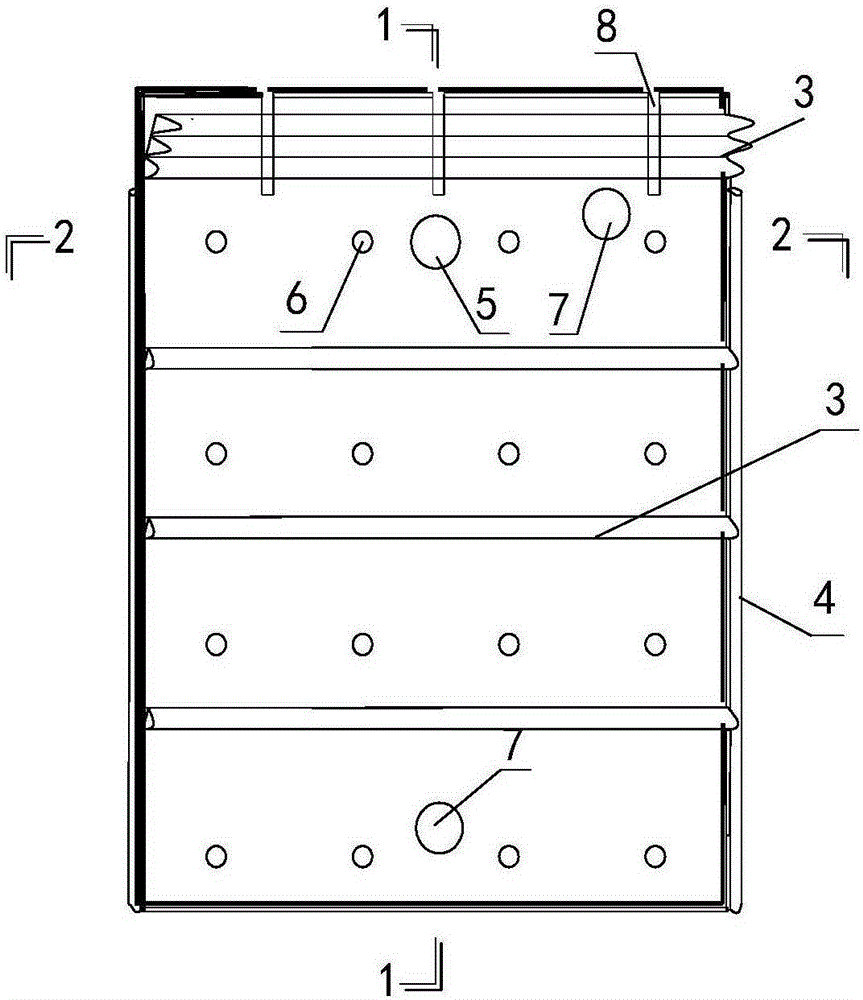

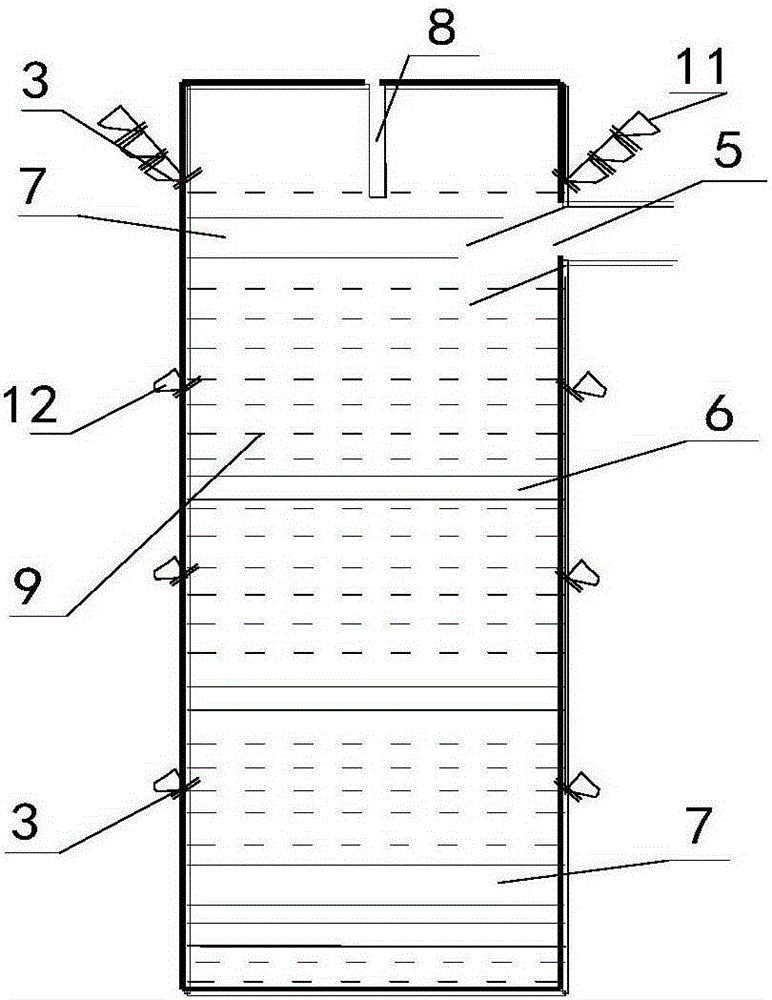

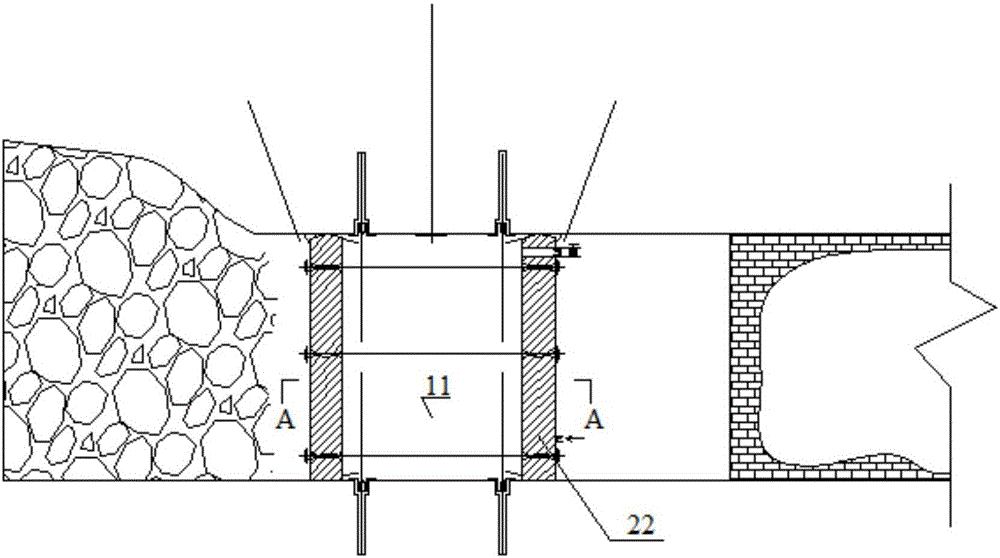

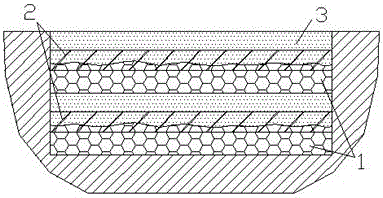

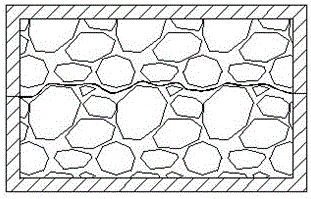

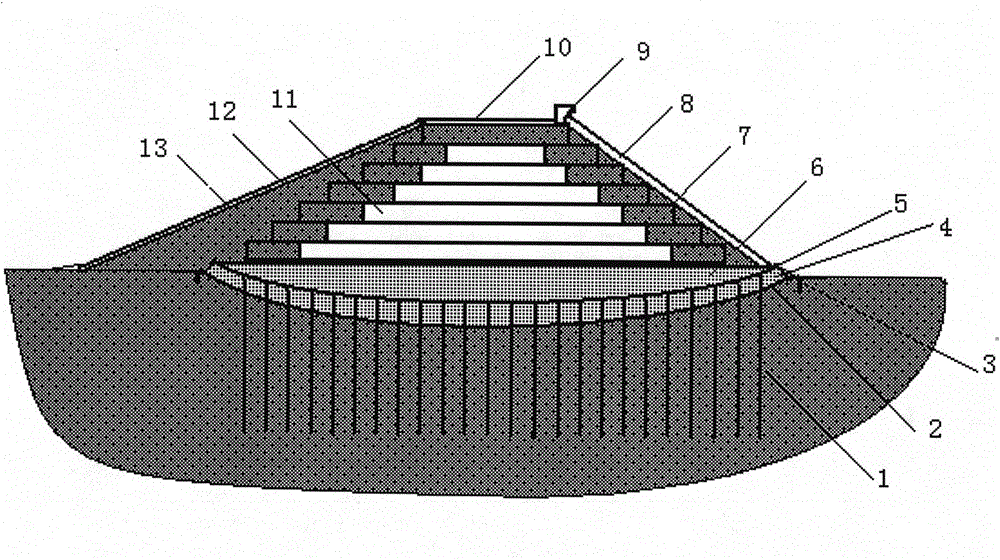

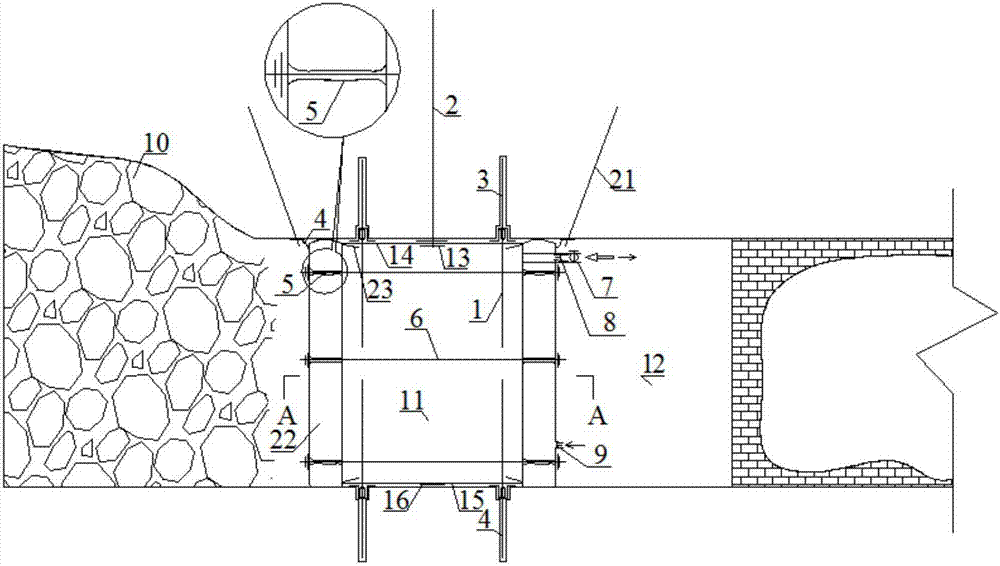

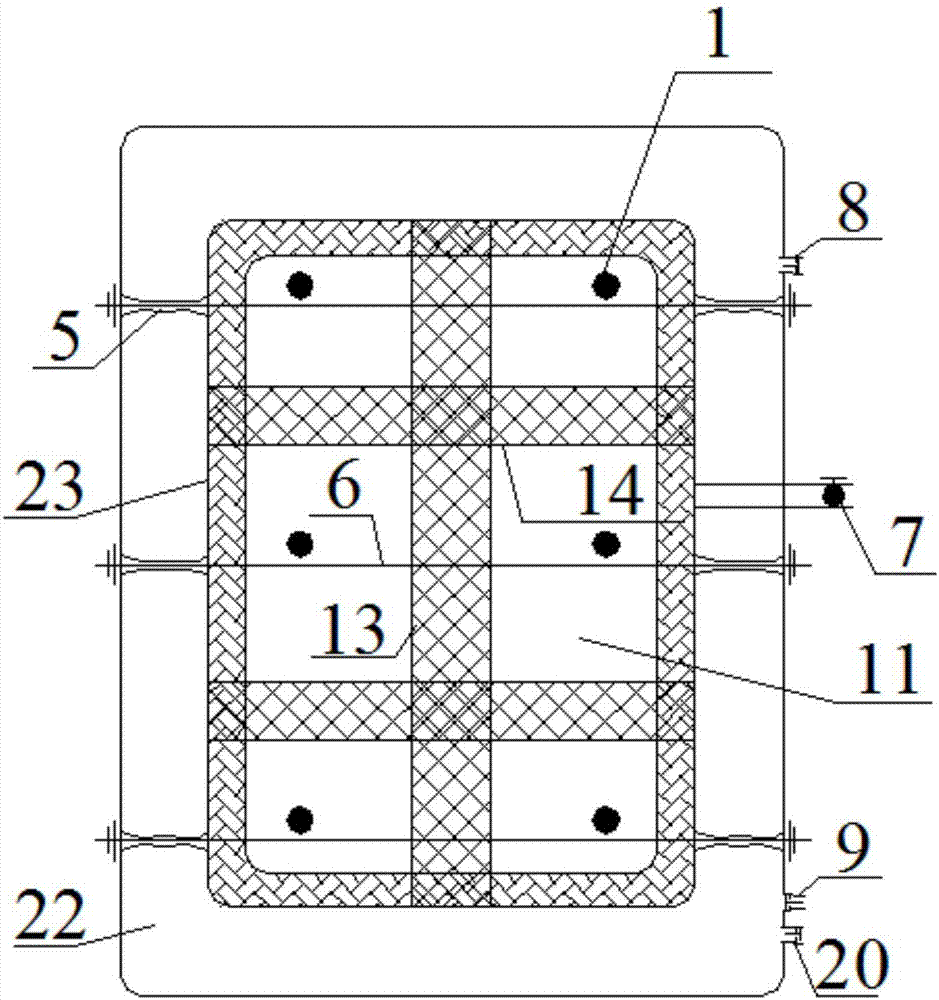

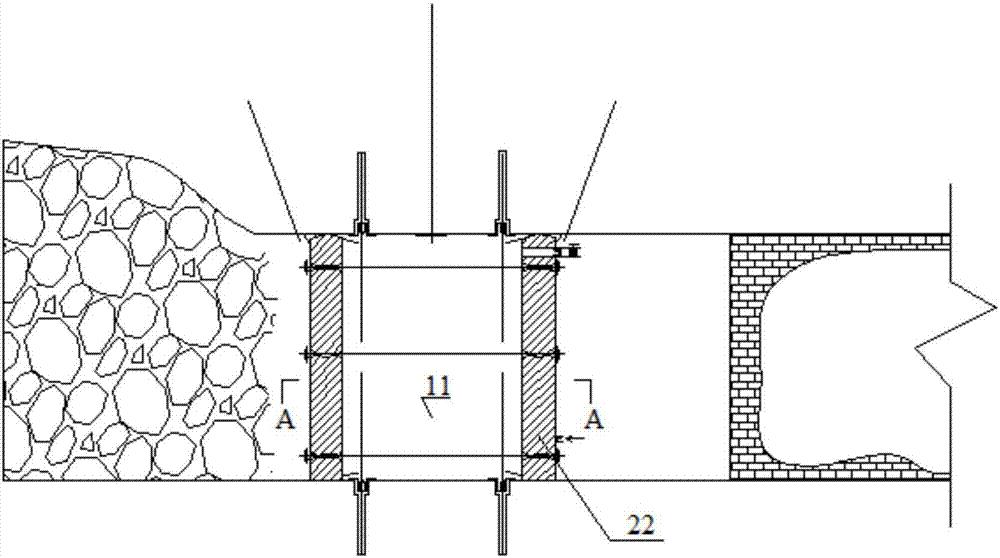

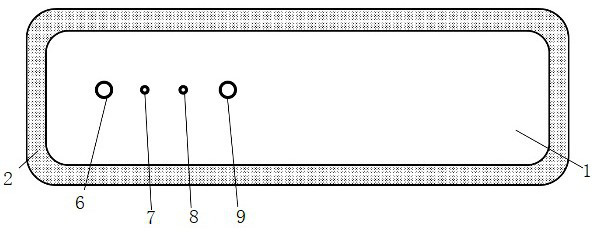

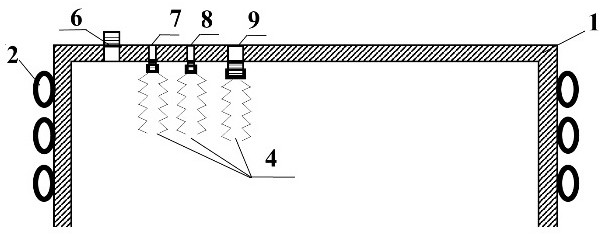

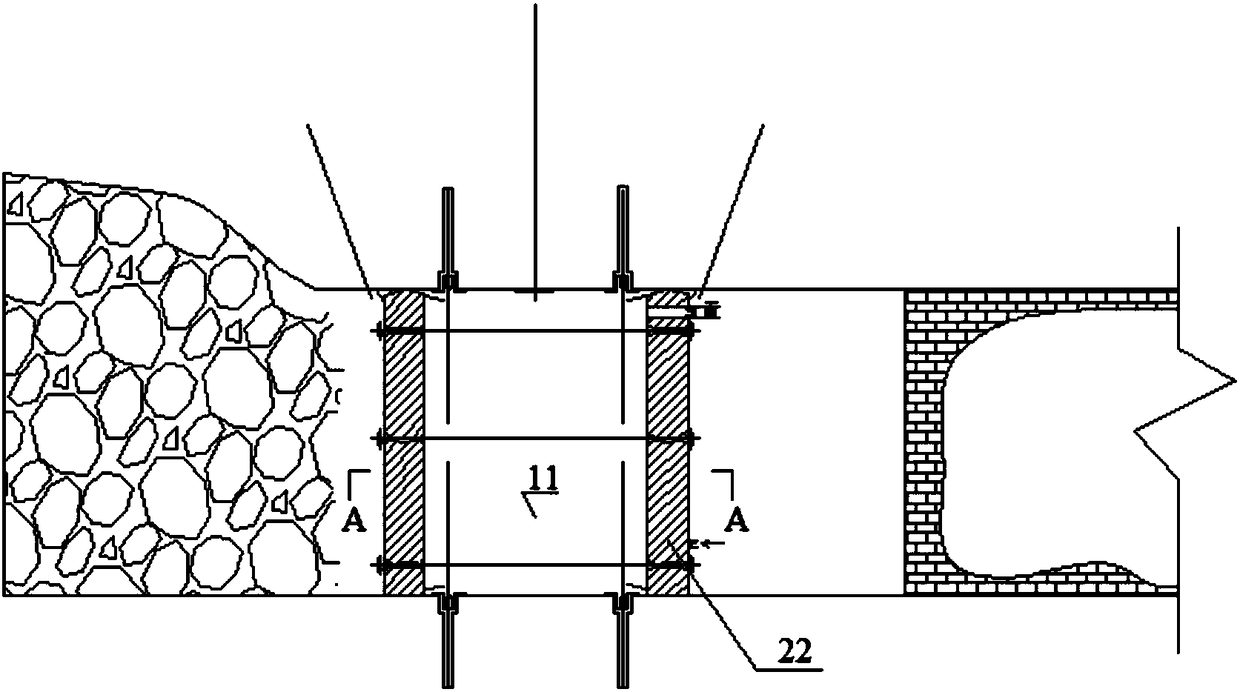

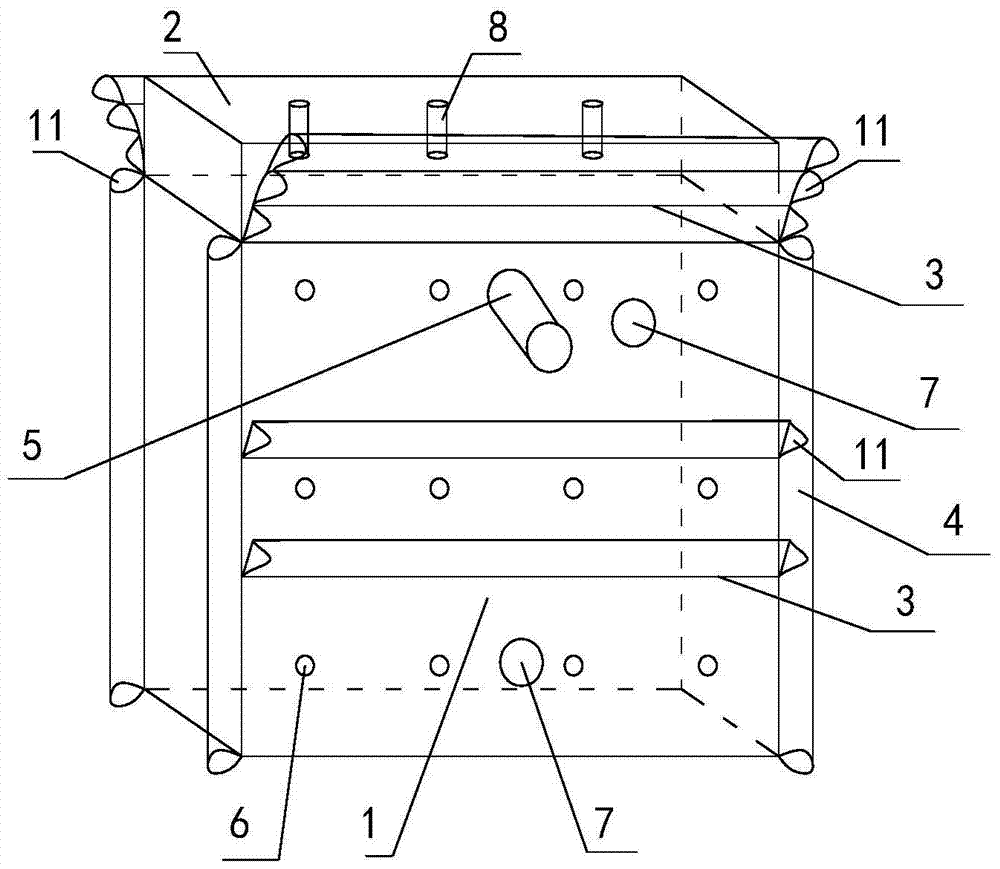

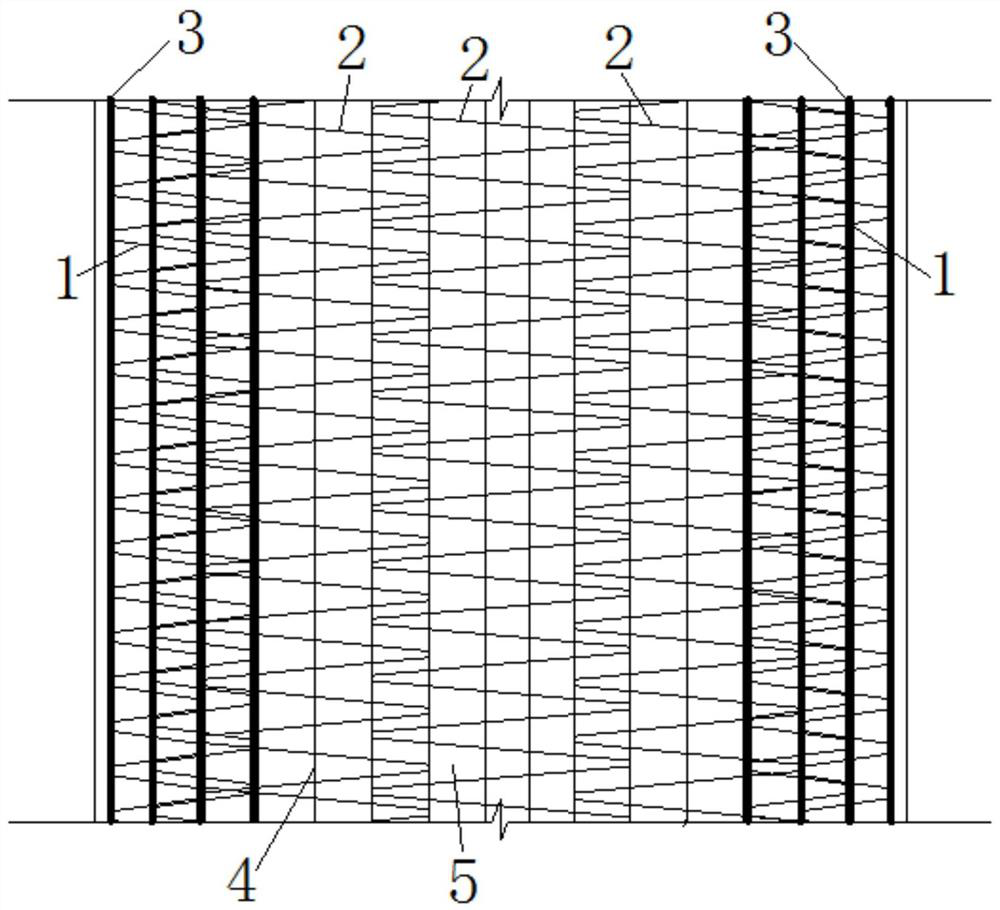

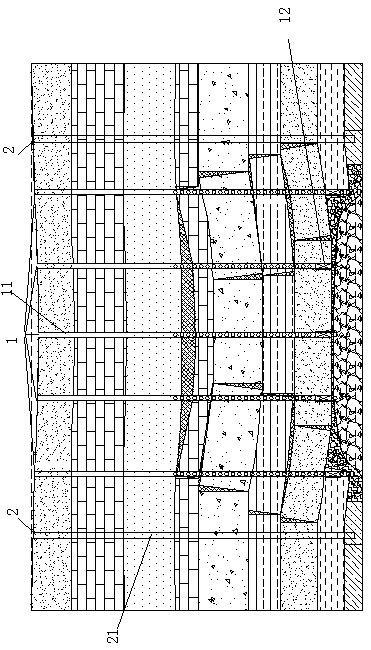

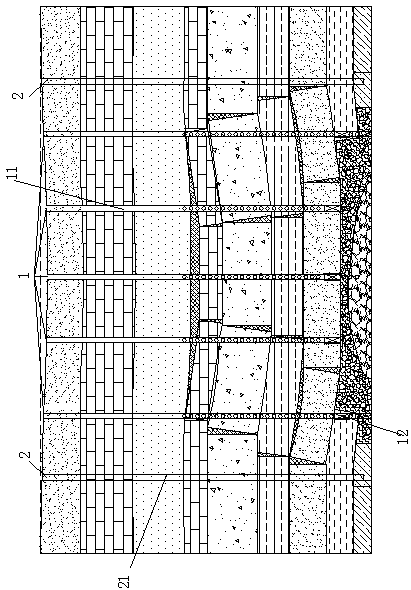

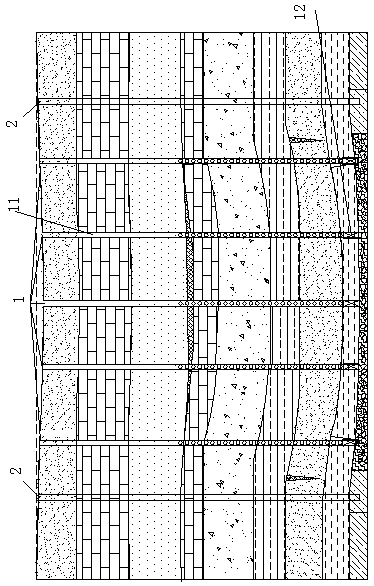

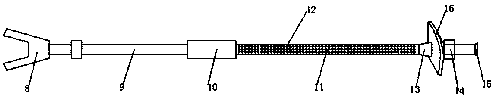

Gob-side-entry-retaining transverse-slant-dual-pulling fiber flexible template and filling method thereof

ActiveCN105201529ALimit lateral deformationEven by forceUnderground chambersTunnel liningFiberCrack resistance

The invention discloses a gob-side-entry-retaining transverse-slant-dual-pulling fiber flexible template. The fiber flexible template comprises a template body. A top connecting template body is connected to the template body. The template body is provided with filling openings, anchor bolt holes, transverse flanges and vertical flanges. Sleeves are connected to the transverse flanges. Bar embedding holes are formed in the top connecting template. A plurality of transverse tying bars and a plurality of slant tying bars are arranged in the template body. The two ends of the transverse tying bars are fixed to the two opposite faces inside the template body through bar arranging rings respectively. The two ends of the slant tying bars are slantly fixed to the two connected faces on the inner side of the template body through bar arranging rings respectively. Reserved holes are further formed in the template body and are of cylindrical structures made of flexible template cloth in advance. By means of the template, lateral deformation generated after filling of the flexible template can be limited, the flexible template is evenly stressed during filling accordingly, and a filling body is high in strength and crack resistance accordingly. The invention further discloses a method for carrying out flexible template concrete construction through the gob-side-entry-retaining transverse-slant-dual-pulling fiber flexible template. According to the method, a pipe is convenient to install, and the construction speed is high.

Owner:SHAANXI PIONEERING ARCHITECTURAL TECH

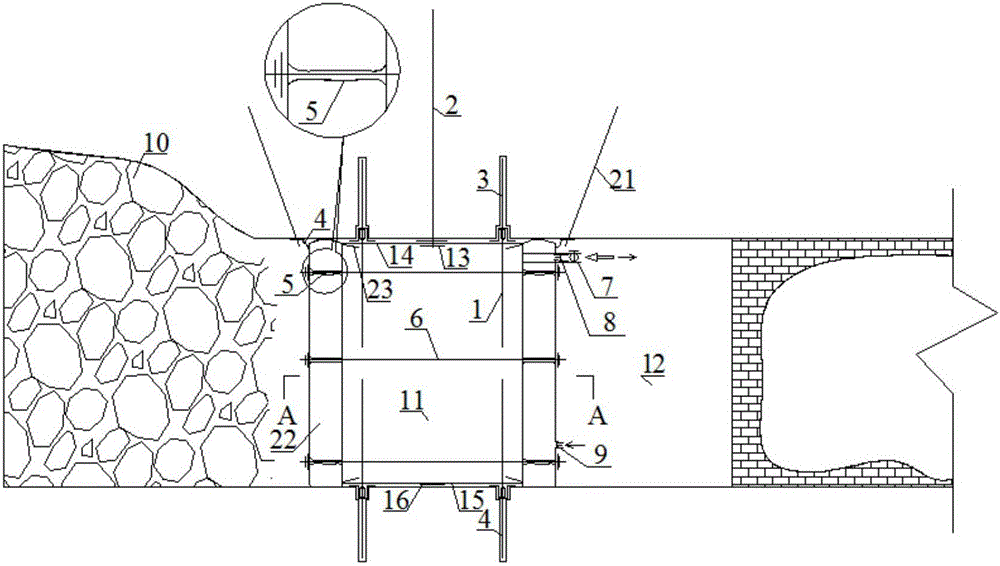

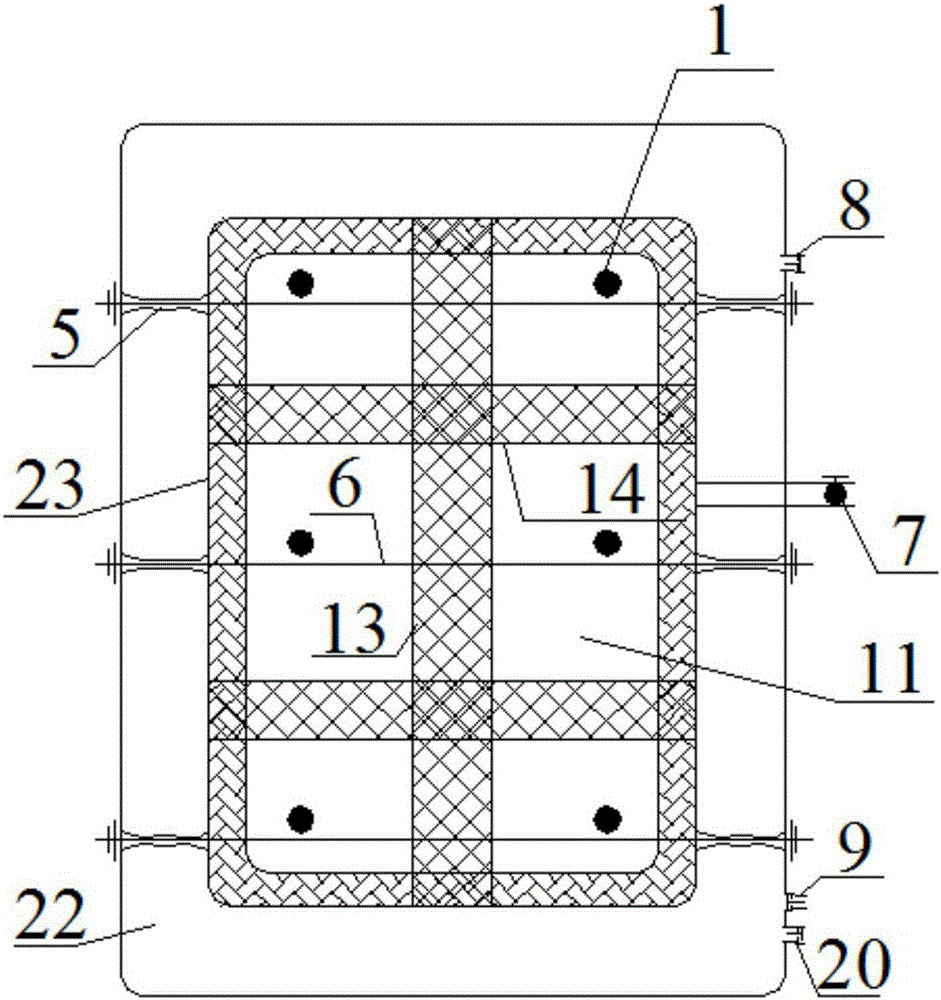

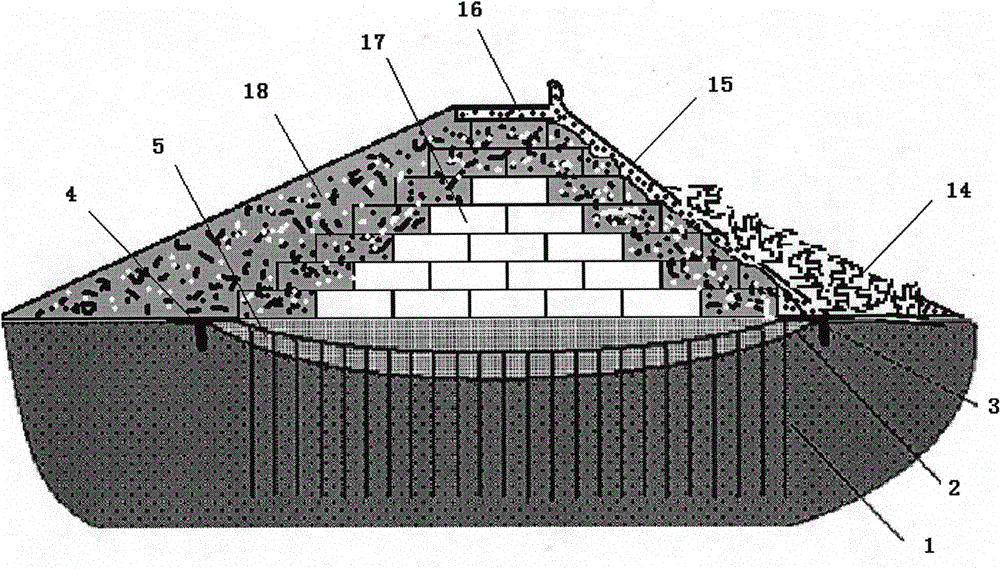

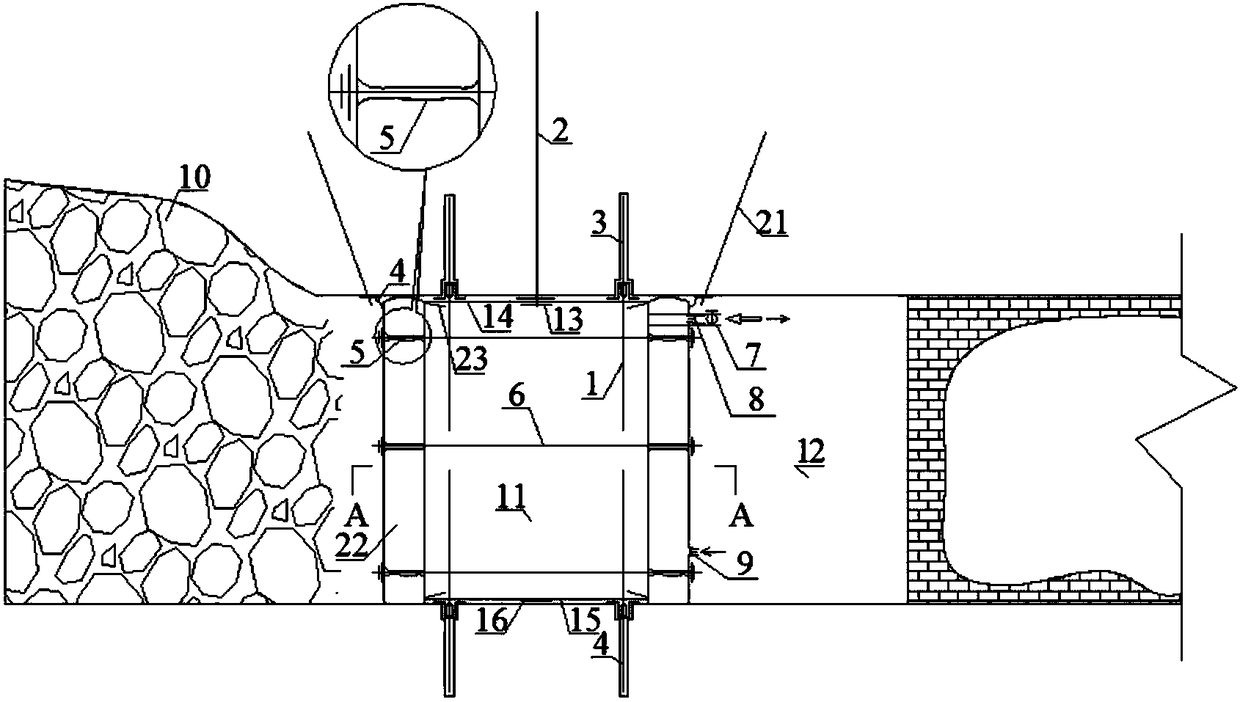

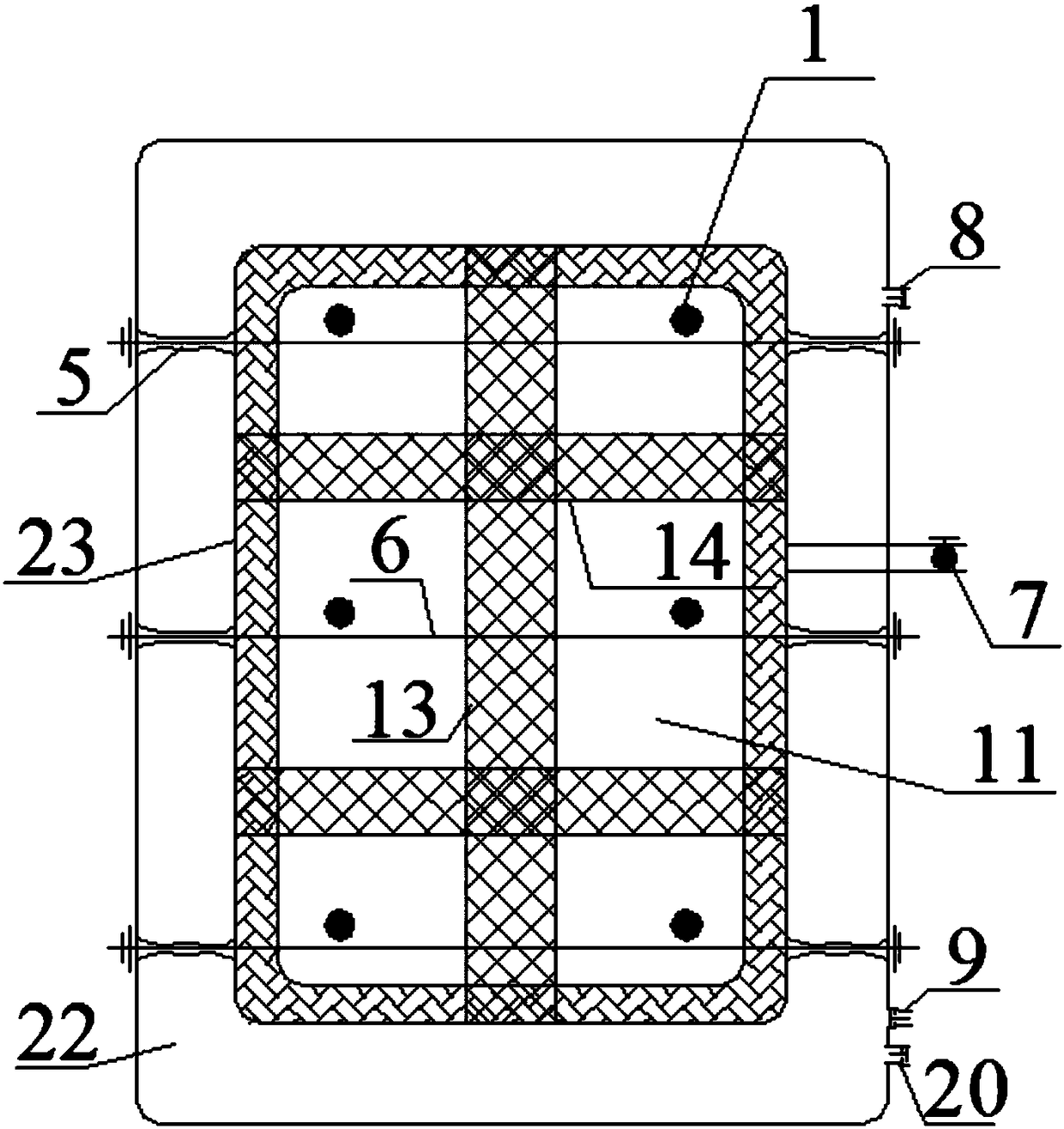

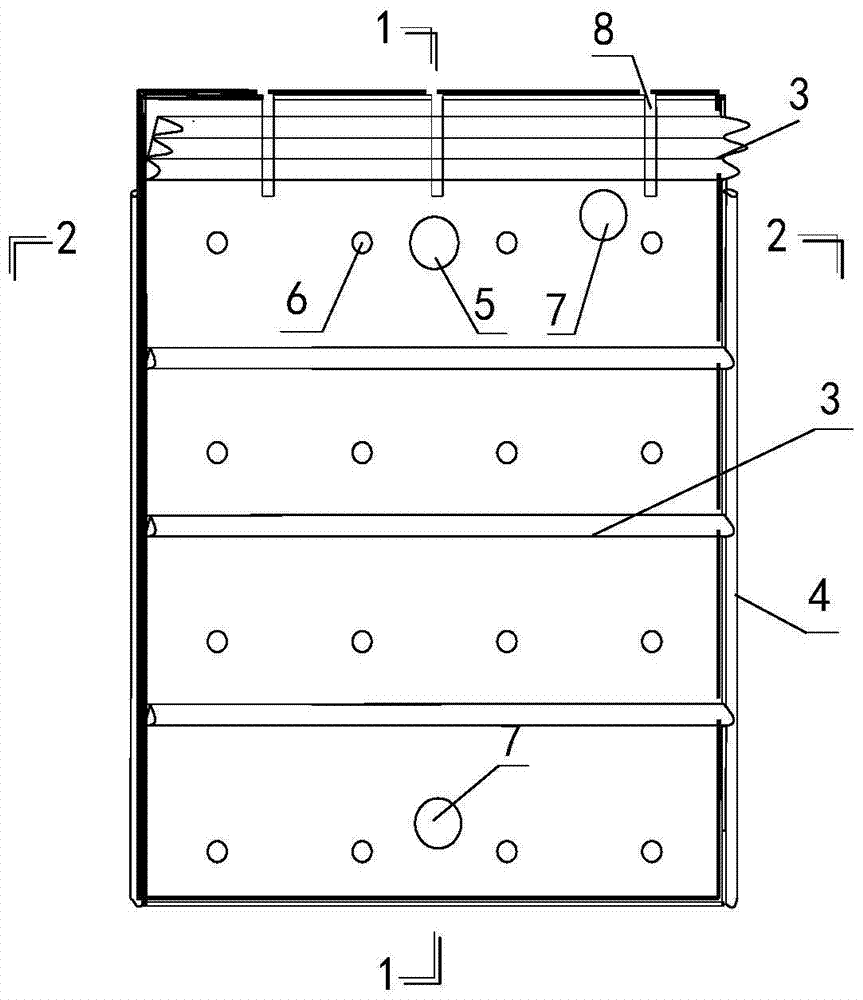

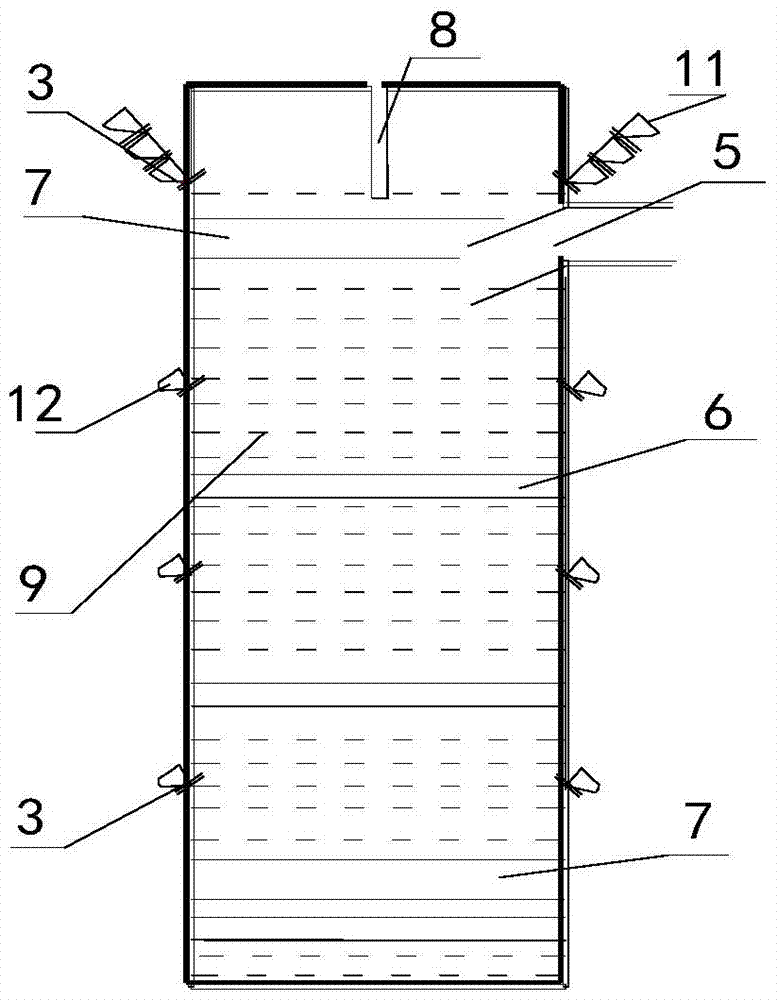

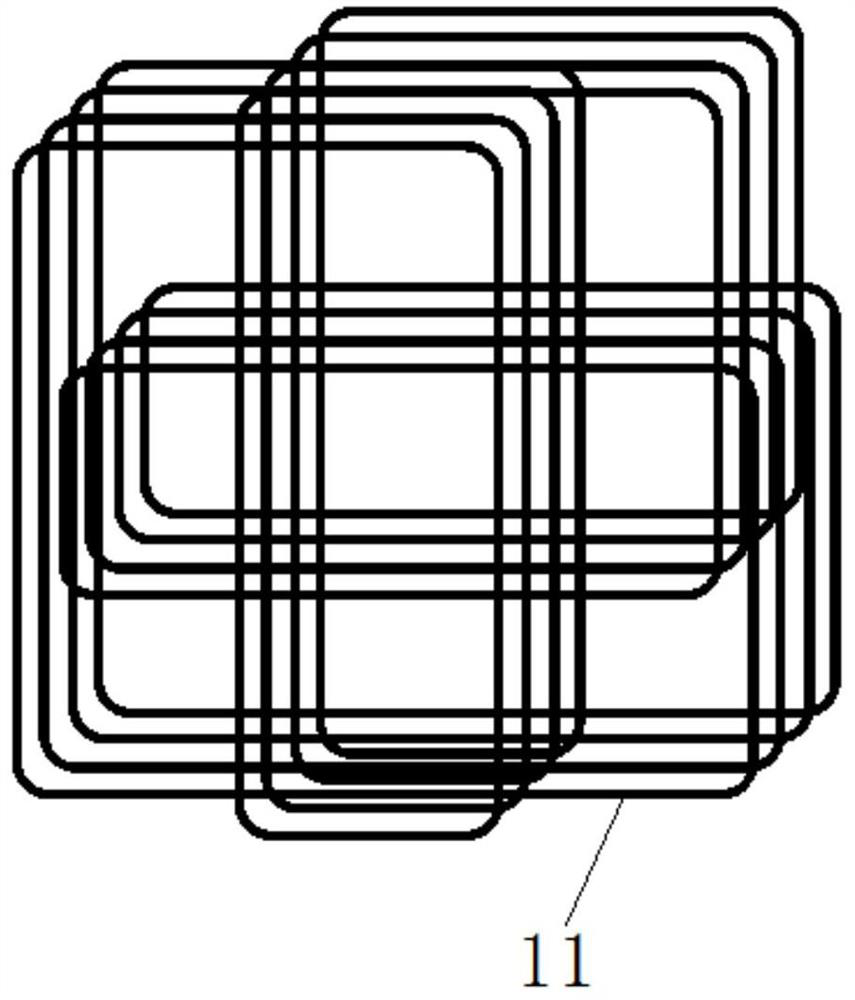

Gob-side entry retaining concrete filled wall annular air bag construction method

ActiveCN105937407AImprove longitudinal shear resistanceAvoid destructionMaterial fill-upStructural engineeringAirbag deployment

The invention discloses a gob-side entry retaining concrete filled wall annular air bag construction method. The construction method adopts an annular air bag pressure bag mode, and an annular air bag pressure bag is fixed through anti-displacement anchorage devices and horizontal lateral confinement reinforcement devices. The anti-displacement anchorage devices make annular air bag formworks and top and bottom plates integrated to form a whole. The horizontal lateral confinement reinforcement devices can effectively limit transverse deformation of a filled wall body, ensure successive gob-side entry retaining, can resist multiple times of pressure from the top plate and improve the overall stability of the concrete wall body. Before concrete is cast into a filling cavity, inflation is needed, the annular air bag pressure bag structure bear rigid and flexible formwork supports for usage. After the annular air bag pressure bag is deflated, the bag is filled with concrete, the bag and the concrete jointly form a gob-side entry retaining lateral filled wall, the links of steel formwork erection and steel formwork dismounting are omitted in the whole process, a middle grouting process is not needed to be waited, the labor intensity of workers is reduced, continuous and rapid filling operation is achieved, and the face advancing speed can be improved.

Owner:XIAN UNIV OF SCI & TECH

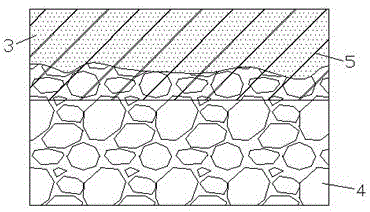

Building waste-doped geogrid cell reinforced sand blanket and construction method

The invention discloses a building waste-doped geogrid cell reinforced sand blanket and a construction method. The geogrid cell reinforced sand blanket mainly consists of a plurality of building waste layers and reinforced structure layers which are crossly arranged in a ground foundation from bottom to top; each building waste layer is formed by compacting and paving the crushed waste concrete; each reinforced structure layer is a geogrid cell; the bottom part of each geogrid cell is partially crossed with the building waste layer thereunder, sand is charged to the middle part and upper part of each geogrid cell, and a sand layer is formed above each geogrid cell; another building waste layer is arranged on each sand layer. The geogrid cell reinforced sand blanket has the advantages that the main body materials are building wastes and geogrid cells, so that the problem of building waste filling is solved, the resource is saved, and the manufacturing cost of project is reduced; the building waste is compacted, and a tight engaged skeleton is formed and is combined with the three-dimensional geogrid cells, so that the bearing capacity of the ground foundation is improved, and the damage due to overlarge deformation of the ground foundation is overcome.

Owner:HUBEI UNIV OF TECH

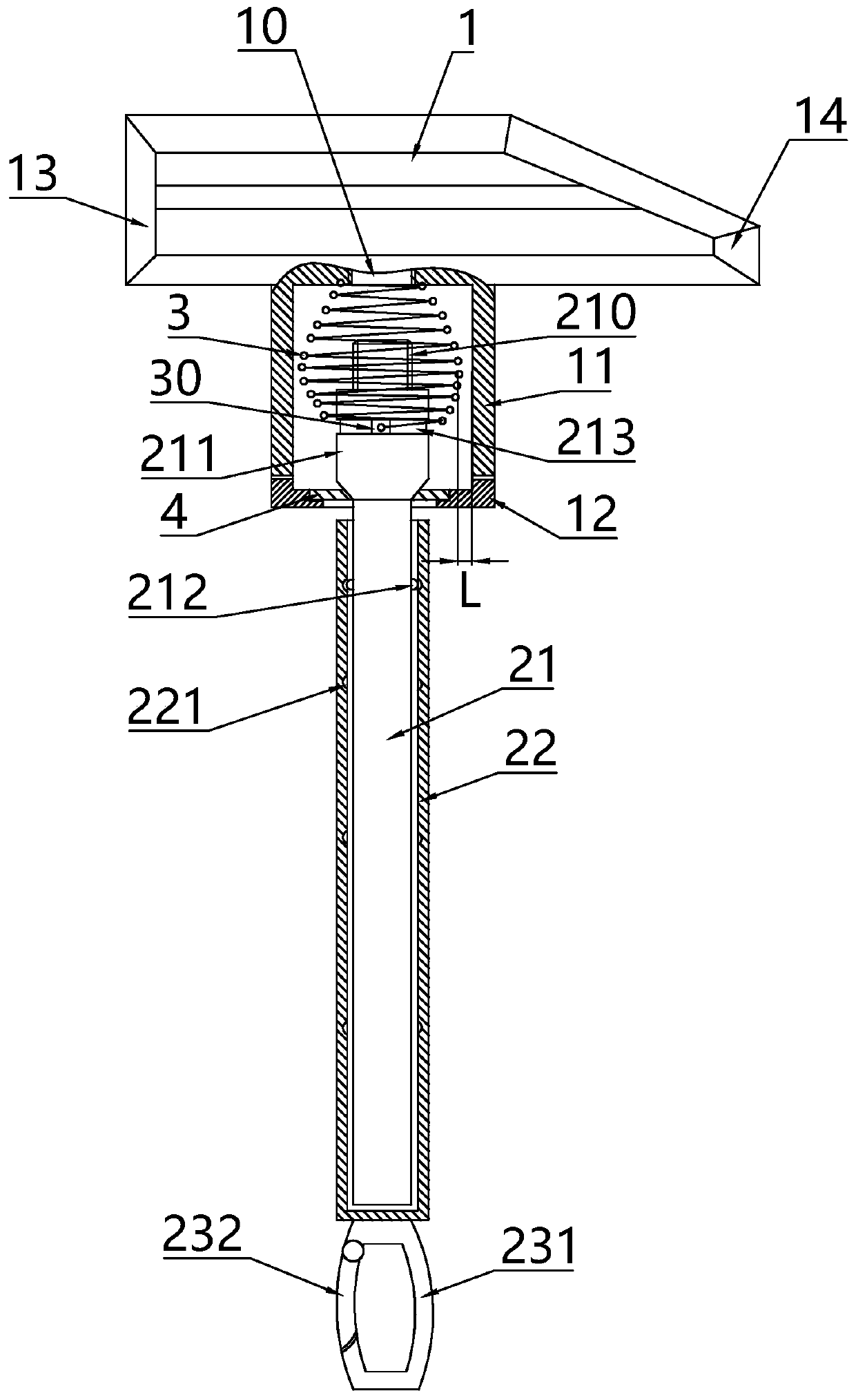

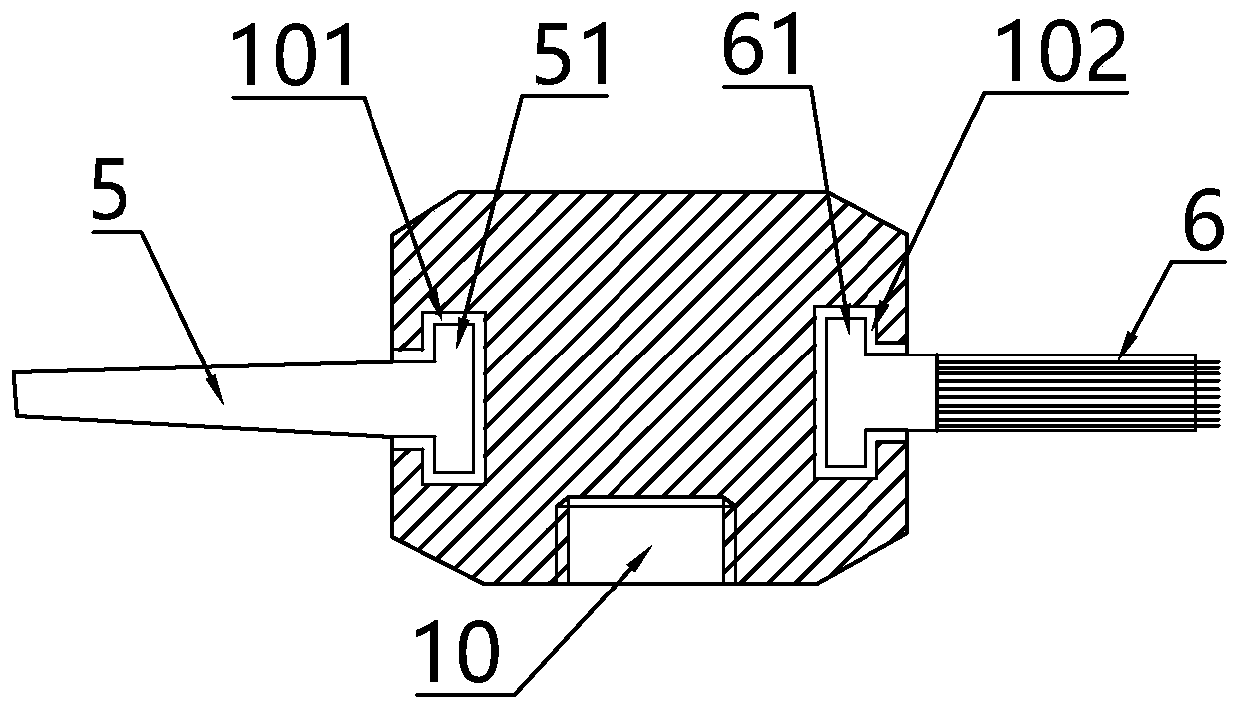

Deicing tool for electric equipment

PendingCN110328197AGood for storageSoft touchCleaning using toolsHand hammersPower equipmentEngineering

The invention discloses a deicing tool for electric equipment. The deicing tool for electric equipment solves the problem that the hand numb of operators is caused by the transmission of vibration between a hammer body and a hammer handle. According to the technical scheme for solving the problem, the deicing tool mainly comprises a hammer body and a hammer handle, the hammer handle comprises a telescopic rod, the telescopic rod comprises an inner rod and an outer rod sleeved on the outer side of the inner rod, an anti-skid holding surface is arranged on the outer side surface of the outer rod, a connector is arranged at the end, close to the hammer body, of the inner rod, a threaded column is arranged at the top end of the connector, a connecting cylinder for extending the connector is arranged on the hammer body, a threaded hole is formed in the bottom wall of the connecting cylinder, the connector and the hammer body are detachably connected with the threaded hole through the threaded column, the connector is sleeved with a spring and is elastically connected with the connecting cylinder through the spring, the spring is of a drum-shaped structure, the minimum distance L betweenthe spring and the side wall of the inner cylinder of the connecting cylinder is 2-5 mm. The deicing tool is suitable for mild knocking and deicing of valuable electric equipment, and the operation comfort degree of operators is high.

Owner:国网浙江兰溪市供电有限公司 +1

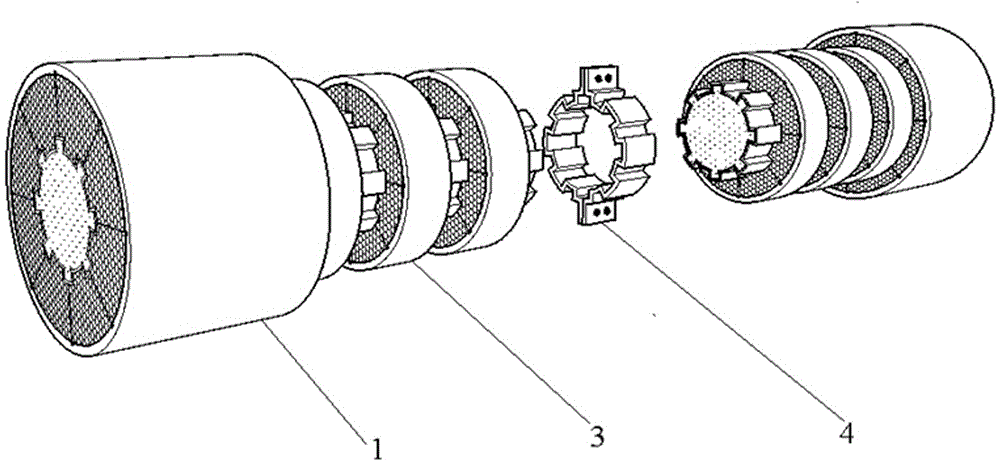

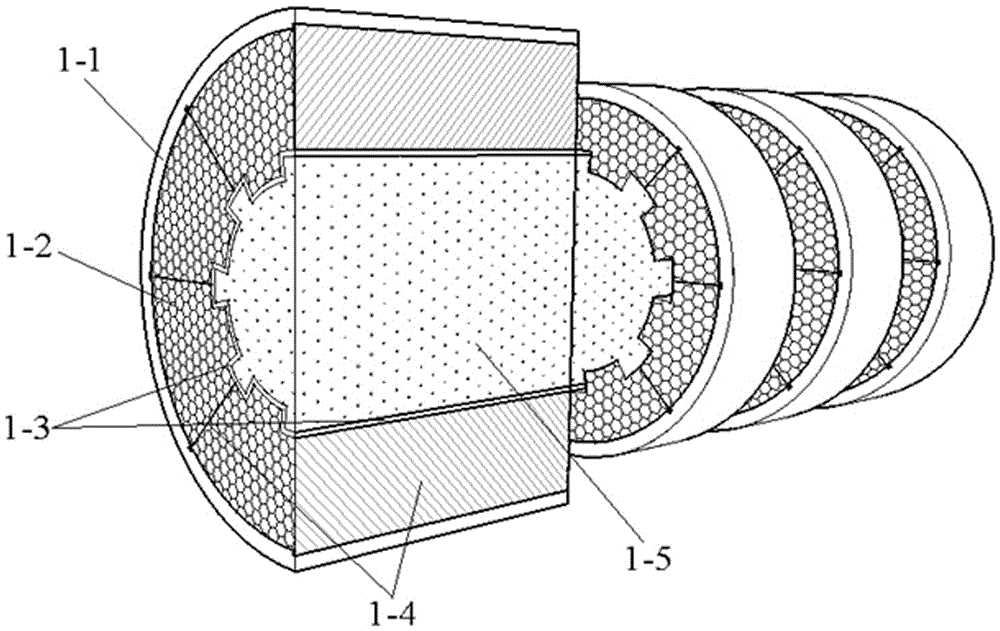

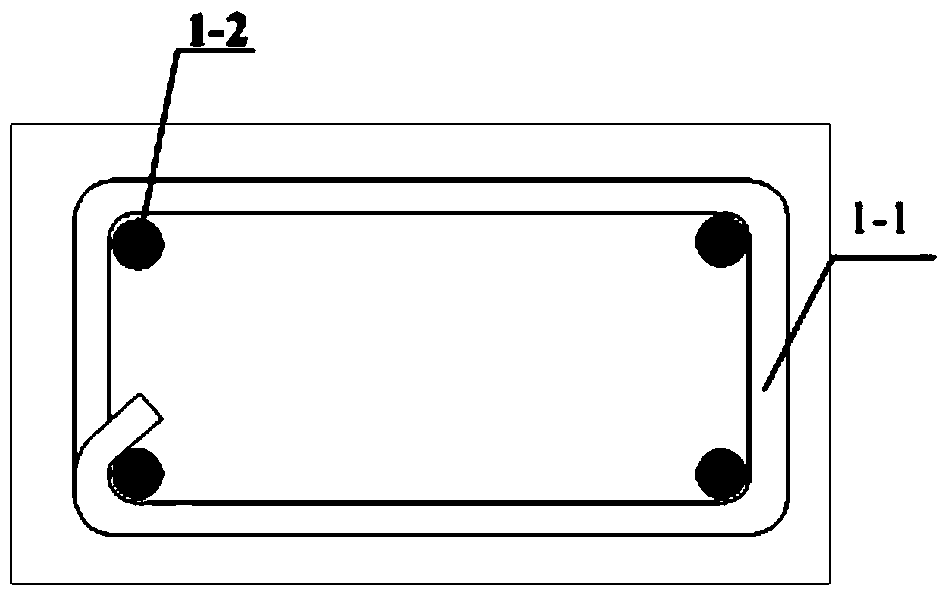

Novel composite sandwich crash barrier on road

InactiveCN105568897AReduce weightGuaranteed stiffnessRoadway safety arrangementsFilling materialsMetallic materials

The invention relates to a composite sandwich crash barrier member on a road, in particular to a novel composite sandwich crash barrier on the road. A plurality of crash bar units are connected through connectors, and each crash bar unit comprises an outer casing, an inner casing and a filling material body located in the inner casing. Metal ribs are arranged on the outer wall of the inner casing and rapidly transmit part of automobile impact loads from the outer casing to the inner casing, so that the inner casing and the outer casing share the load together, and the impact load on an automobile is effectively dispersed; the connectors comprise gear connecting and fastening elements and curved-surface cover plates, and the gear connecting and fastening elements and the curved-surface cover plates are made of composites or metal materials. The composite sandwich crash barrier can achieve multifunctional safety fortification, solves problems of traditional barrier fortification, and has the characteristics of corrosion resistance, ageing resistance, low weight, high strength, easiness of maintenance, speediness and convenience for construction, easiness of repair after damage and the like.

Owner:SHANXI UNIV

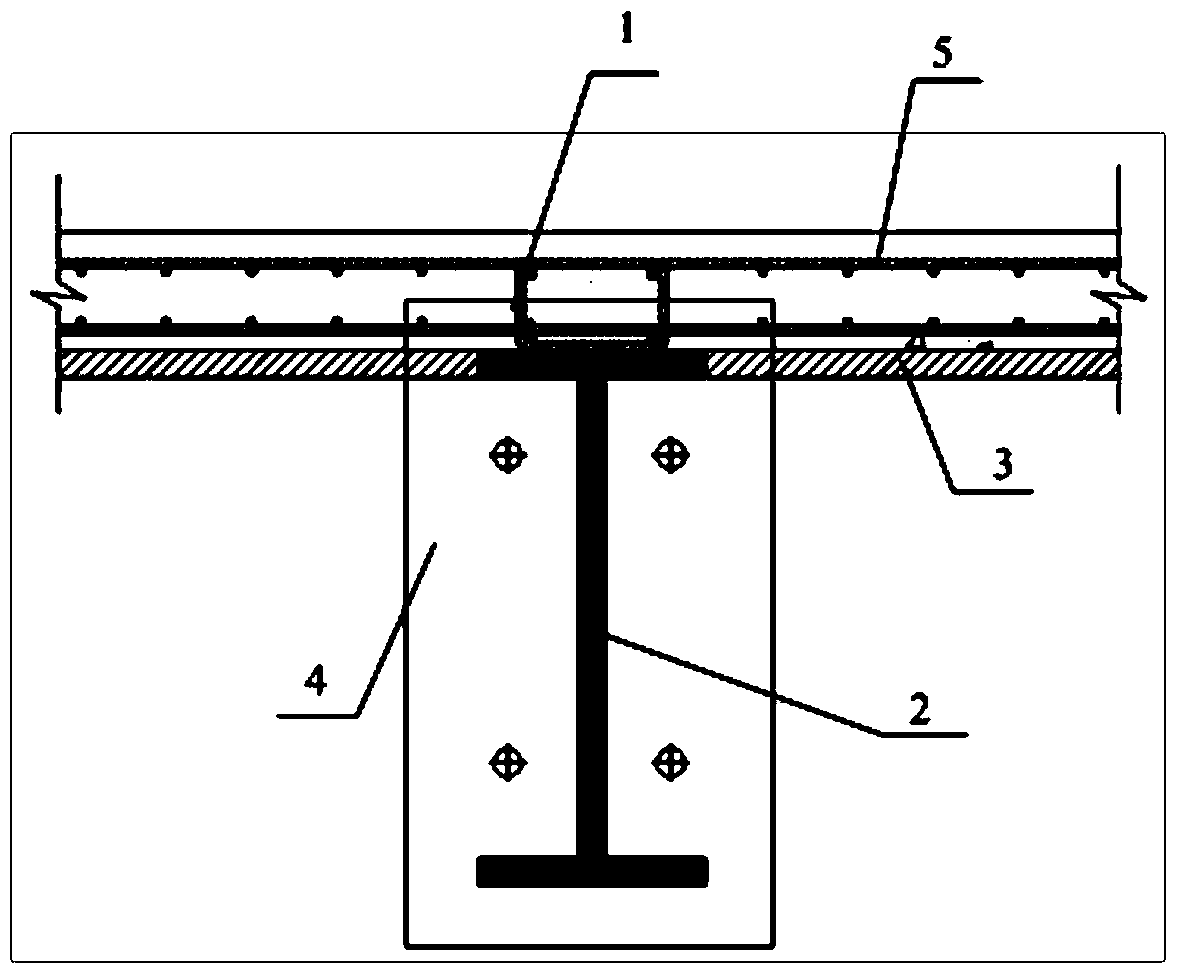

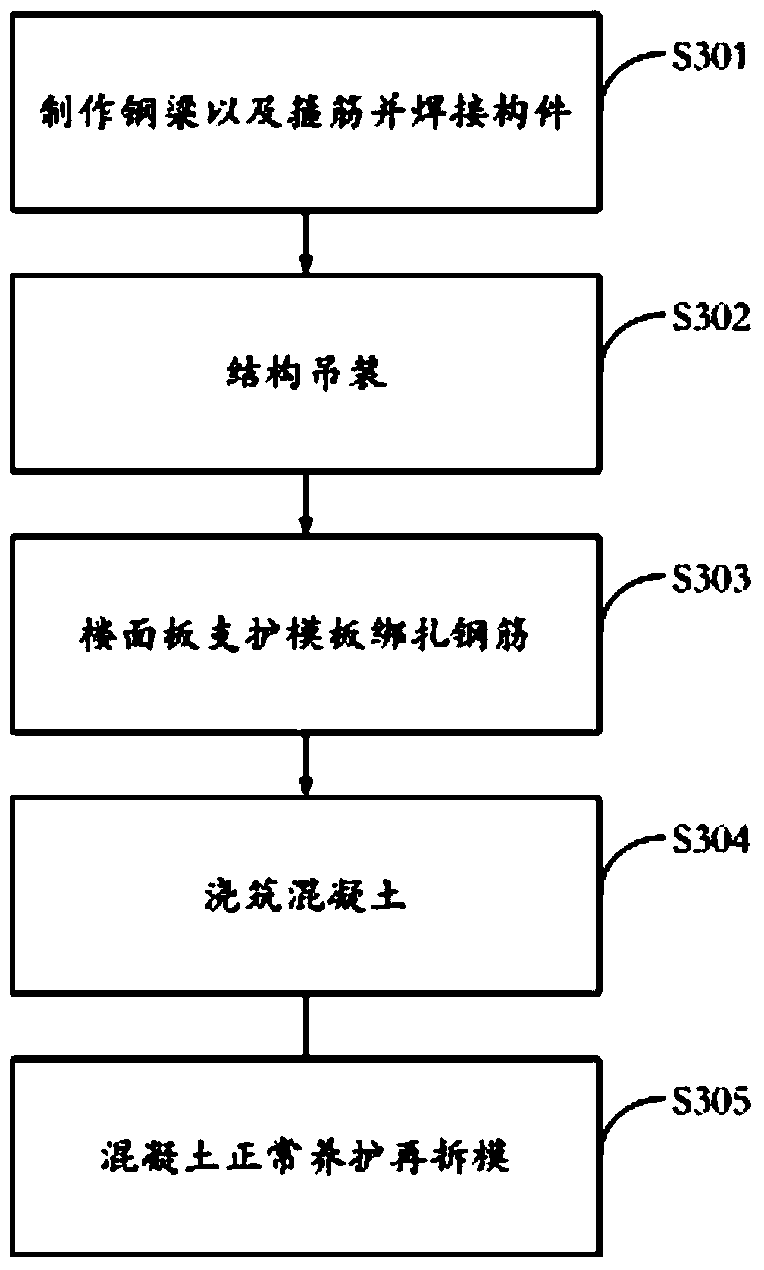

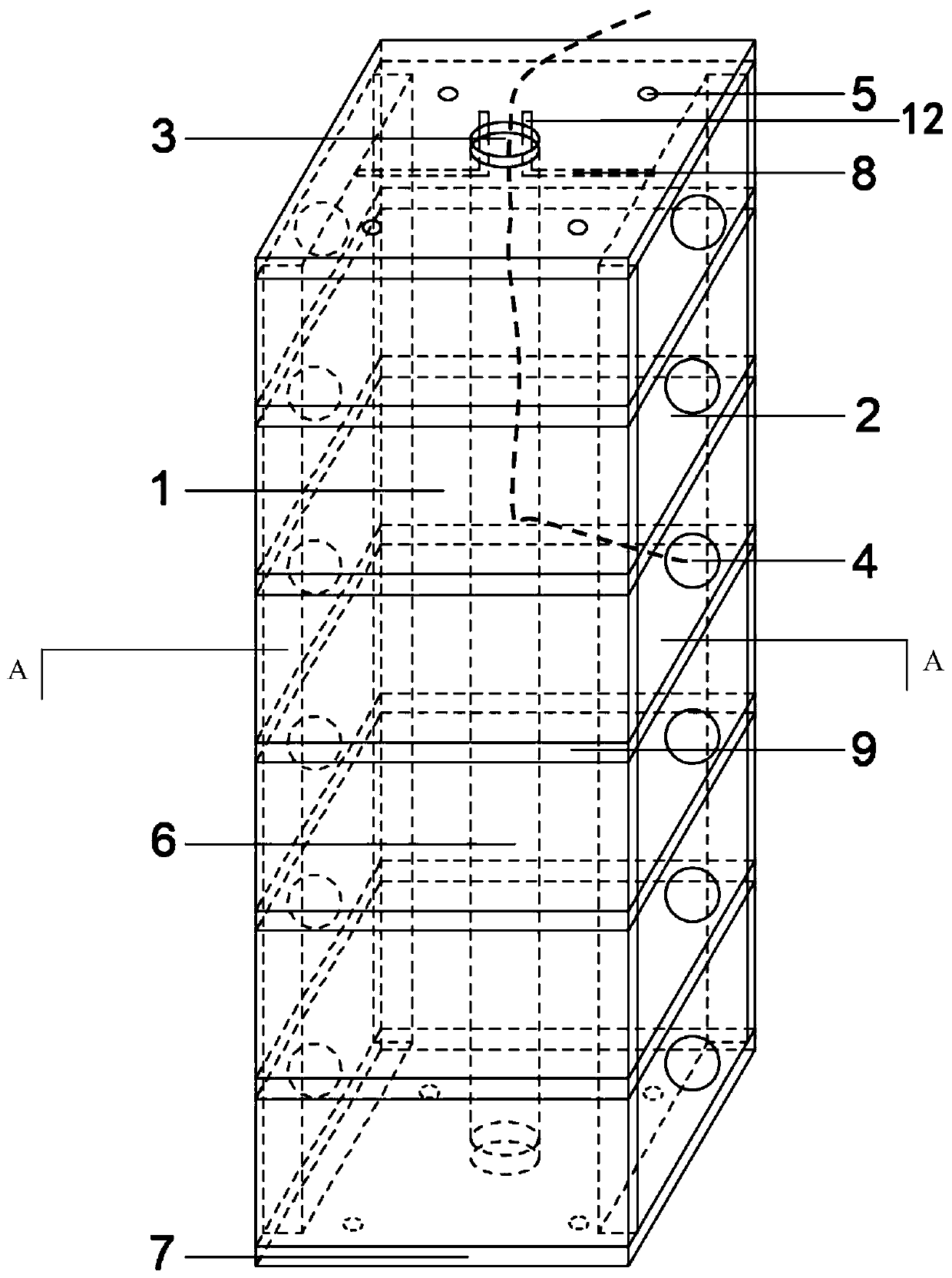

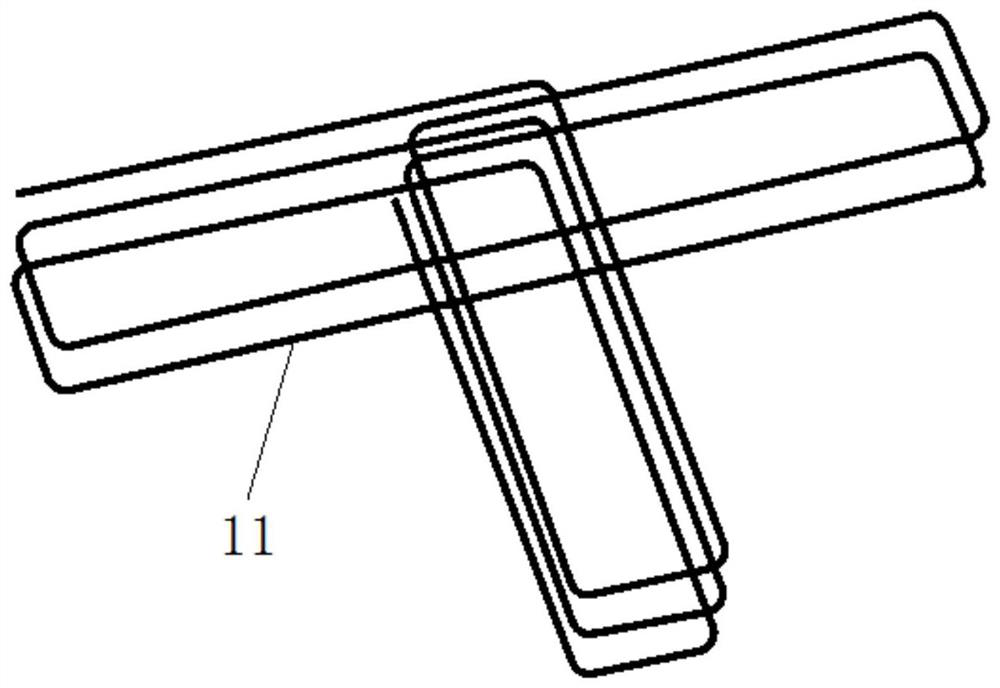

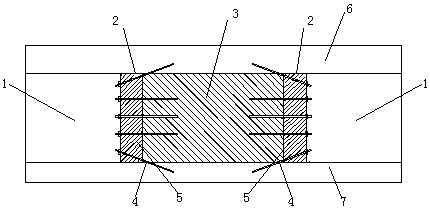

Novel stirrup shearing connector as well as manufacturing and installing methods thereof

InactiveCN103437474AIncreased shear strengthIncrease stiffnessFloorsBuilding material handlingEngineeringRebar

The invention discloses a novel stirrup shearing connector as well as manufacturing and installing methods of the novel stirrup shearing connector. The connector comprises a stirrup shearing connector, a stirrup, longitudinal reinforcing steel bars, a steel beam, a template, end plates and transverse reinforcing steel bars. The manufacturing and installing methods comprise the following steps: manufacturing the steel beam and the stirrup and welding the component, placing the longitudinal reinforcing steel bars at four corners inside the stirrup to complete binding; hoisting the structure; binding the reinforcing the steel bars by a floorboard supporting and protecting template; casting concrete; normally maintaining the concrete and then dismounting the template. According to the invention, a steel reinforcement cage which is bound by the longitudinal reinforcing steel bars and the stirrup is welded with the upper wing edge of the steel beam, and then bound with the transverse and the longitudinal reinforcing steel bars in a concrete plate to form an integer, so that the shearing resistance and rigidity of the steel beam-concrete combined component are effectively improved, thereby achieving cooperative stress of the concrete and the steel beam, a simple structure and convenience in construction, restricting lifting deformation, increasing plasticity (i.e., deformable capacity) of the concrete and the steel beam, and improving the stability and the reliability of the concrete and the steel beam.

Owner:NANJING TECH UNIV

Prefabricated high-pressure airbag isolation pile structure with grouting function and construction method

PendingCN110144901AMake up for displacement deformationControlled Diffusion RangeExcavationsBulkheads/pilesEngineeringHigh pressure

The invention relates to a prefabricated high-pressure airbag isolation pile structure with a grouting function and a construction method. The structure comprises a prefabricated high-pressure airbagpile body, an automatic adjusting system and a grouting system. The structure has the following beneficial effects: the prefabricated high-pressure airbag isolation pile is adopted to replace a traditional isolation pile; a high-pressure airbag is distributed in soil near the bottom of a foundation pit by a certain depth range, high-pressure gas is injected in the high-pressure airbag to form expansion pressure to change a peripheral stress field to cut off a stress transfer path, so that the horizontal traction effect of the rigid isolation pile is eliminated, and the displacement deformationgenerated by self deformation of the traditional isolation pile is made up; and the inflation expansion of the prefabricated high-pressure airbag is used for assisting the prefabricated pile to resist the deformation of the soil to realize real-time adjustment of the displacement of deep soil, so that the effect is better compared with the traditional isolation pile, the displacement deformationof the traditional isolation pile due to insufficient rigidity is made up, and the displacement of the deep soil on the outer side of an active area is reduced.

Owner:NINGBO UNIV

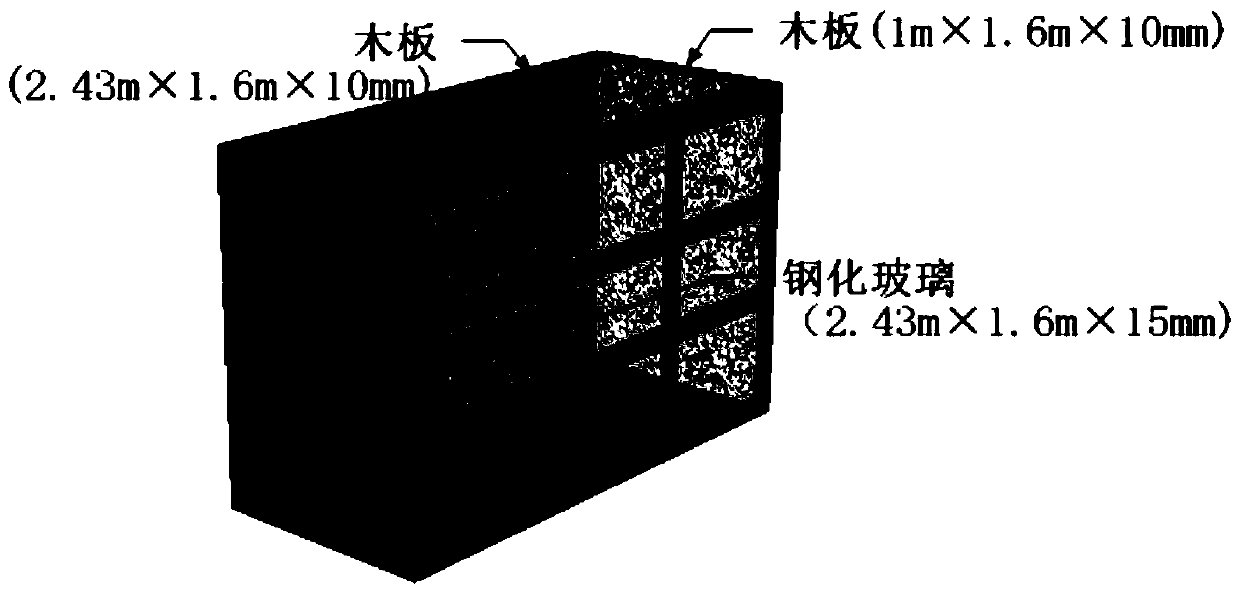

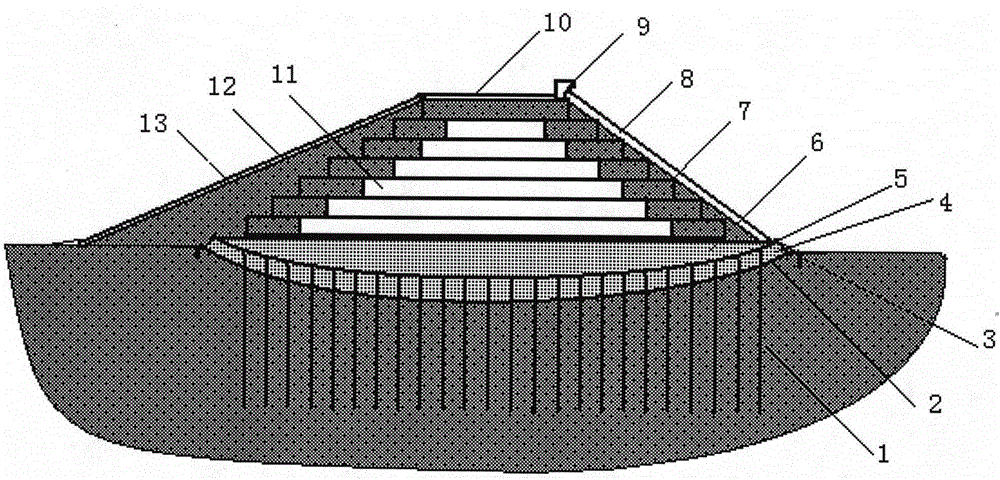

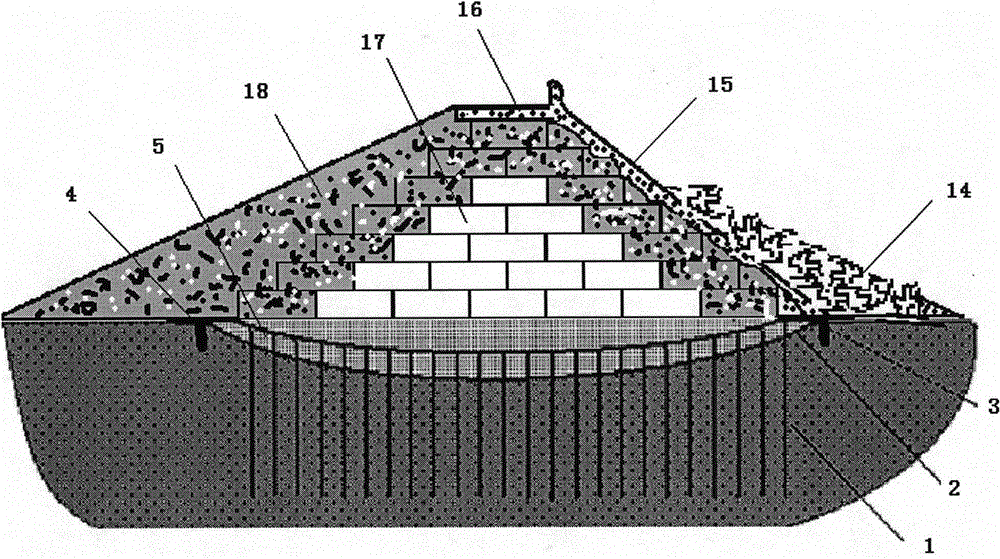

Industrially-manufactured dam component and method for quickly building dams

InactiveCN103938581AOvercome the stack can't go upTo overcome the slow increase in the degree of consolidationDamsClimate change adaptationVacuum pumpingLandslide

The invention provides an industrially-manufactured dam component and a method for quickly building dams, and belongs to the technology of dam building. The method comprises the steps that a foundation is quickly processed by the means of a plastic water drainage plate, geofabric, a sand cushion laye, a vacuum pumping combined pre-pressing means and the like; the mode that vacuum pumping is conducted under a sealing film is used, a secondary sand cushion layer is poured on a covered thin film, and an earthwork is input on a prefabricated part; combined prepressing of the water level, sand cushion layer earthwork heaping and vacuum pumping is formed; the method that a prefabricated dam component is built on a processed embankment foundation, the prefabricated dam component and the processed embankment foundation are connected with each other to form a dam framework, and a light cushion layer is laid is used. The stress balance of the dam is adjusted, and differential settlement and landslide are avoided. The problems of foundation strength and earthwork heaping are fundamentally solved, and mechanical and mass construction is facilitated. The advantages of saving cost due to the fact that stones are replaced by earth, increasing the construction speed, being stable and reliable and the like are achieved.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

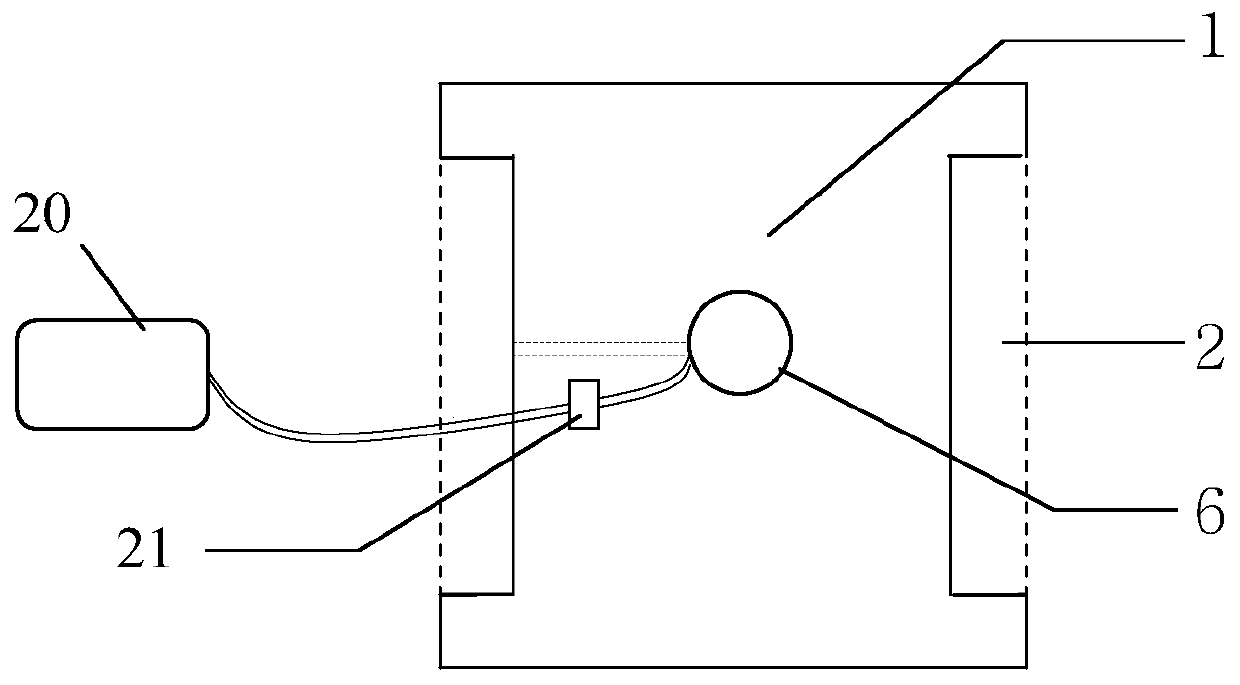

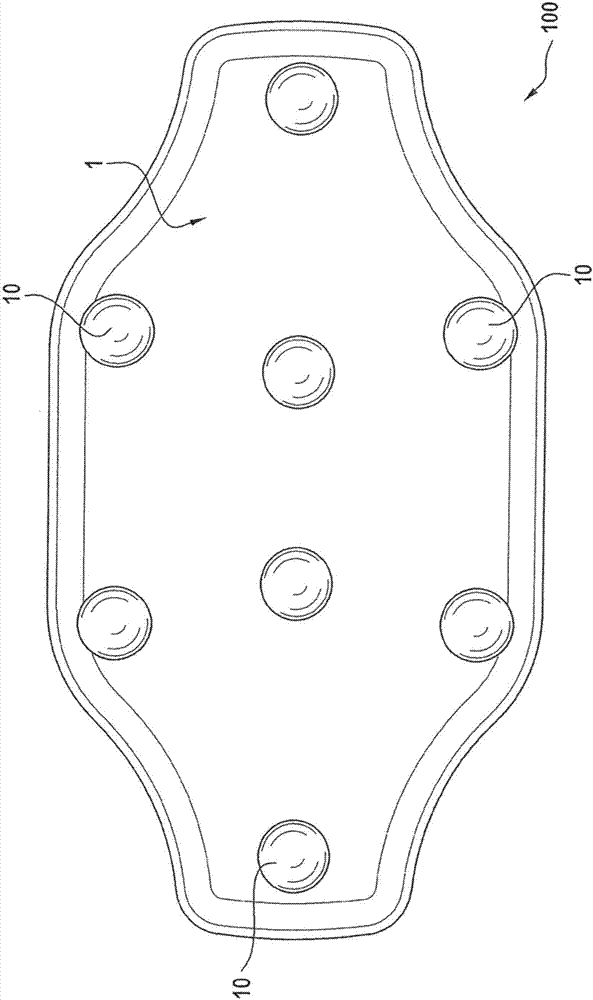

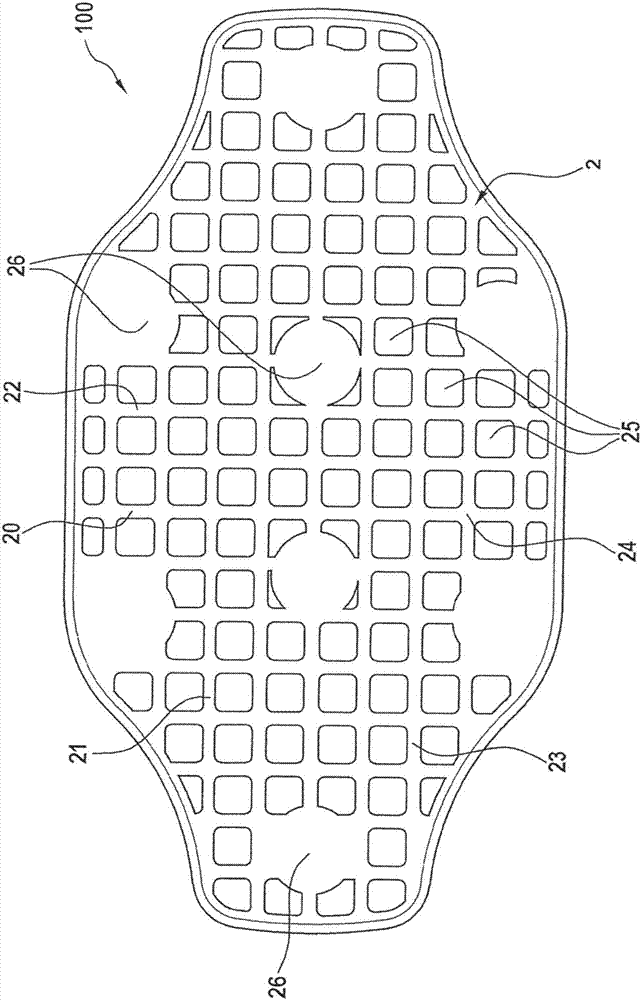

Pad

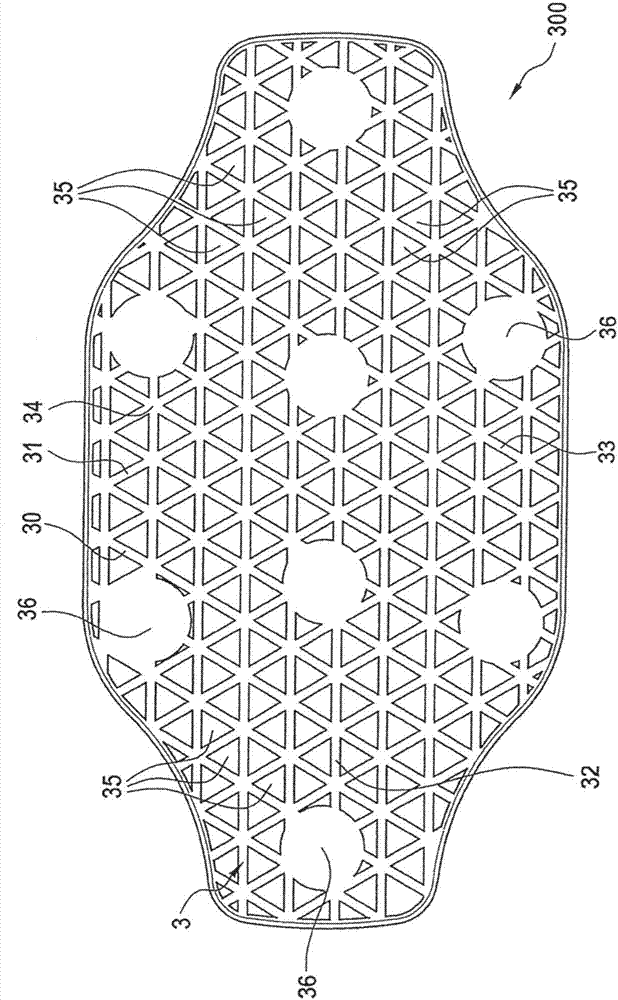

ActiveCN107106318ALimit lateral deformationSimple implementationOrthopedic corsetsOrthotic deviceBiomedical engineering

The invention relates to a pad (100, 300) for a bandage (101) or orthosis; said pad (100) has a front surface (1) and a rear surface (2); at least a subarea of the rear surface (2) has connection pieces (20, 21, 22, 23, 30, 31, 32, 33) which form a mesh structure with interstices (25, 35).

Owner:BAUERFEIND GMBH & CO

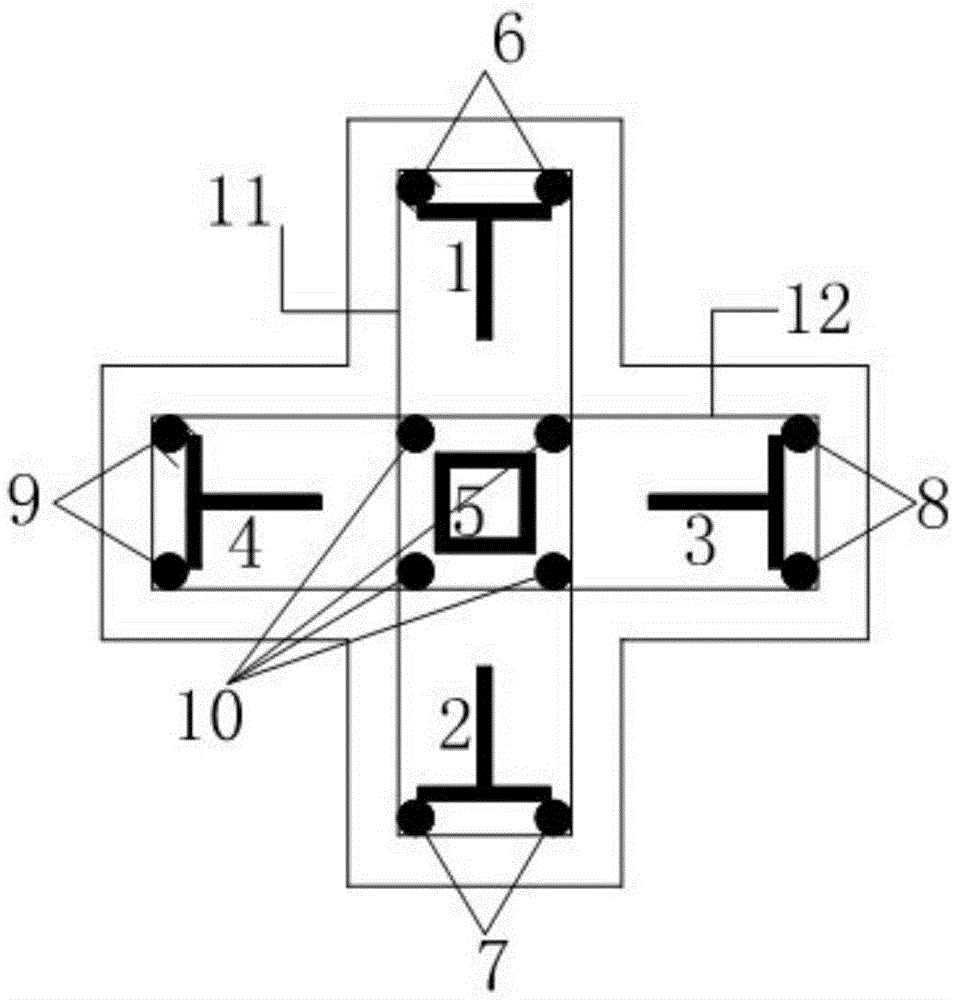

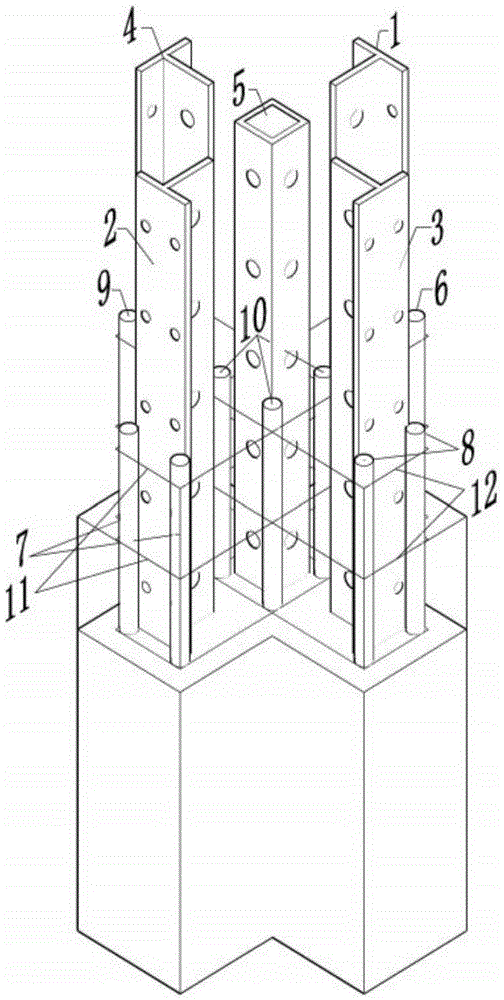

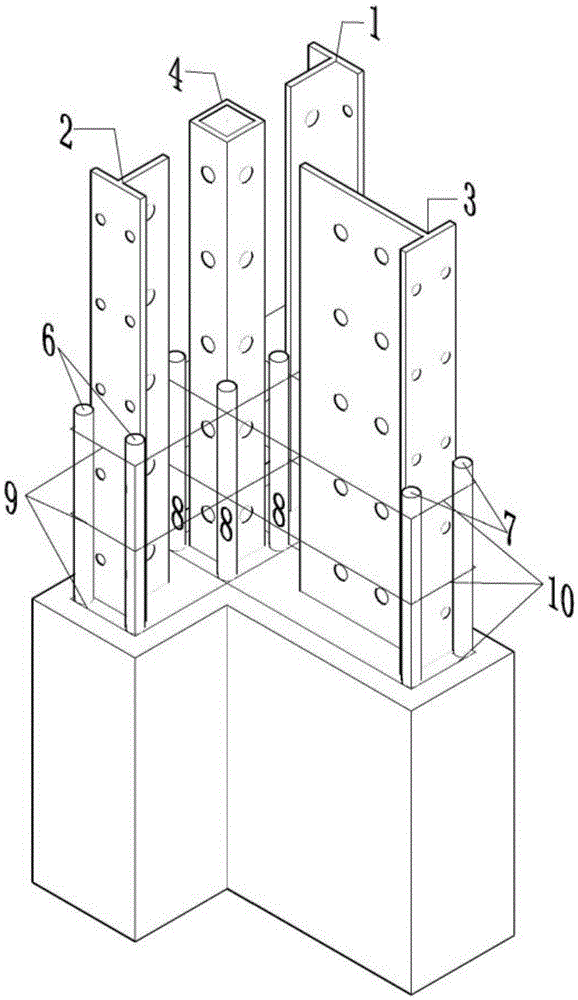

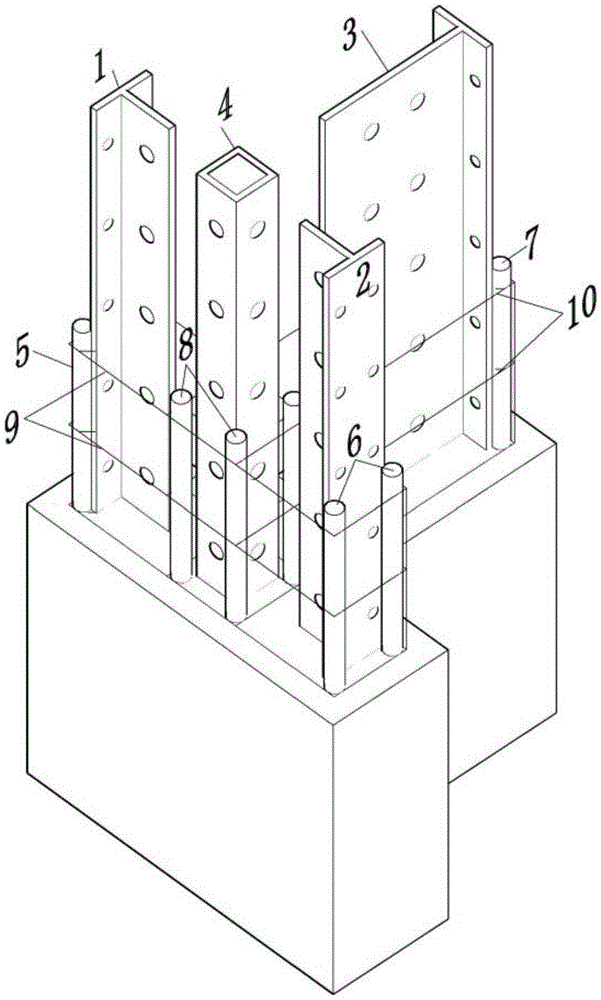

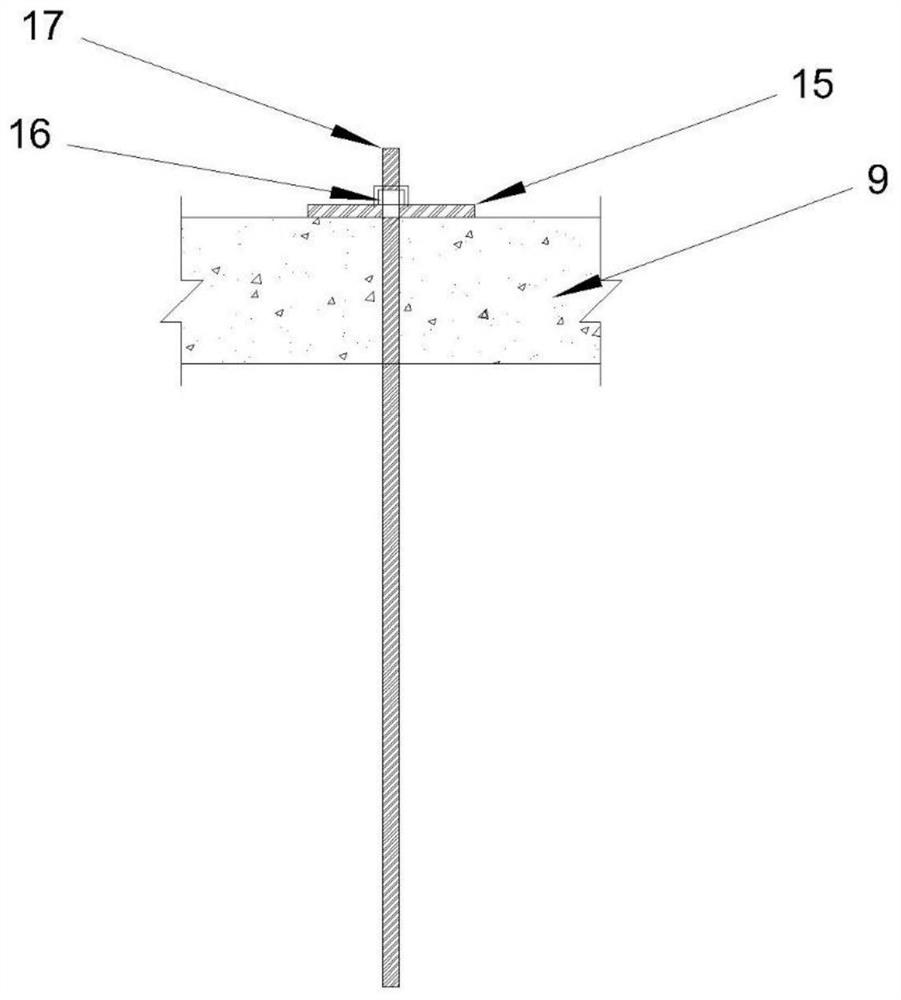

Production method of steel-section-concrete +-shaped section column

The invention relates to a production method of a steel-section-concrete +-shaped section column. The produced +-shaped section column comprises a steel-concrete composite core zone and four column limbs. The production method comprises the following steps: producing T-shaped steel sections and square steel tubes; punching holes in flanges and web plates of the T-shaped steel sections and in tube walls of four sides of the square steel tubes at intervals; vertically mounting the T-shaped steel section in each column limb respectively, wherein the flange of each T-shaped steel section is positioned at an outward position of the corresponding column limb; vertically mounting the square steel tube steel sections in the core zone, wherein all the steel sections are anchored at the top of a foundation, and welding end plates to strengthen anchoring; arranging steel bars; arranging transverse stirrups; mounting a moulding plate; pouring concrete. By the production method of the steel-section-concrete +-shaped section column, provided by the invention, a specially-shaped column structure can be popularized and applied to high-rise buildings and buildings in a region with high seismic fortification intensity.

Owner:TIANJIN UNIV

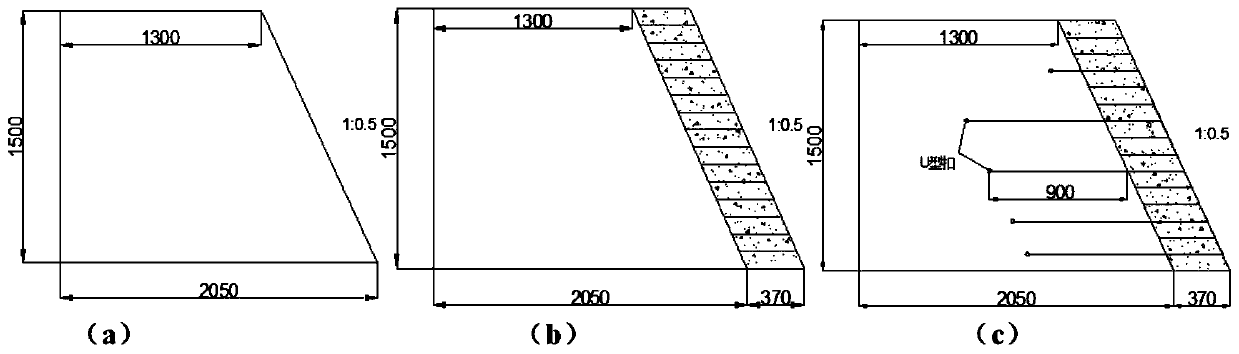

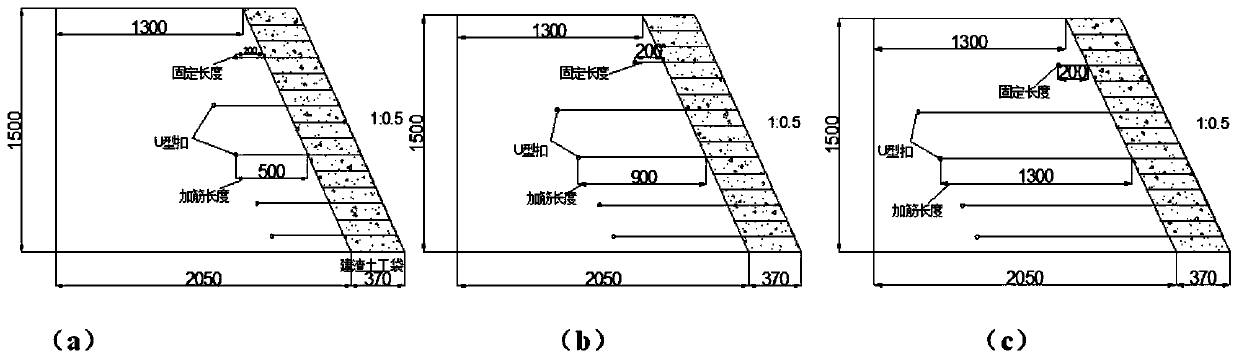

Reverse-bag type building slag geobag retaining wall, construction method and application

PendingCN110644529AReduce demandReduce dependenceArtificial islandsUnderwater structuresArchitectural engineeringGeogrid

The invention discloses a reverse-bag type building slag geobag retaining wall, a construction method and application and aims at solving the problems that in the construction process of a reinforcedretaining wall, the geobag retaining wall can achieve a certain reinforcing effect, but geobags are independent bodies and lack connectivity, and integrality is poor in engineering application. A retaining wall assembly is formed by sequentially connecting a reinforced section, a reverse bag section and a fixed section. The reverse-bag type building slag geobag retaining wall comprises a bottom layer and a protection unit arranged on the bottom layer. The protection unit is composed of N retaining wall assemblies, and N is larger than or equal to 1. Geobags, a geogrid and building slag are combined, the reverse-bag type building slag geobag retaining wall structure is provided, a slope reinforcement effect of the reverse-bag type building slag geobag retaining wall is explored, thus the building slag is recycled, bearing capacity and integrality of the retaining wall are improved, and a basis is provided for application of the reverse-bag type building slag geobag retaining wall in practical engineering.

Owner:西南科技大学城市学院

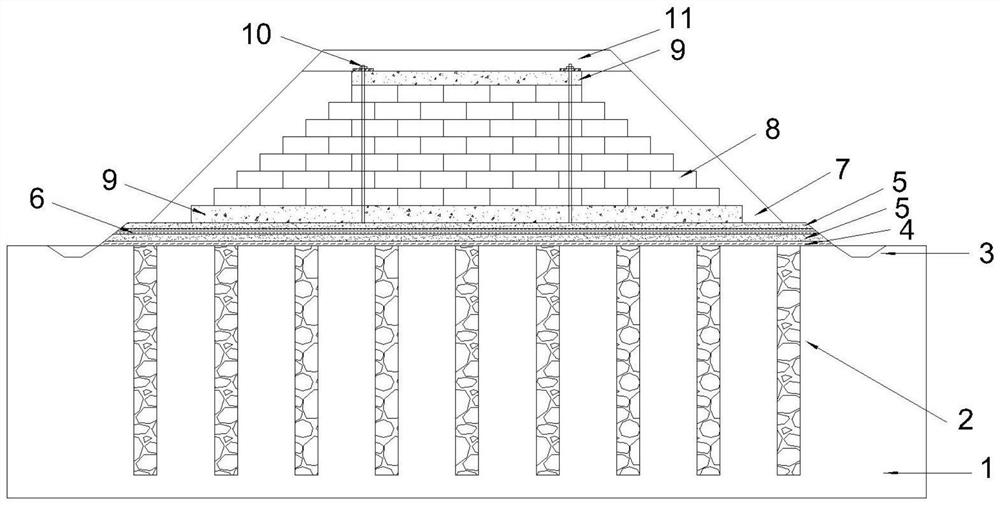

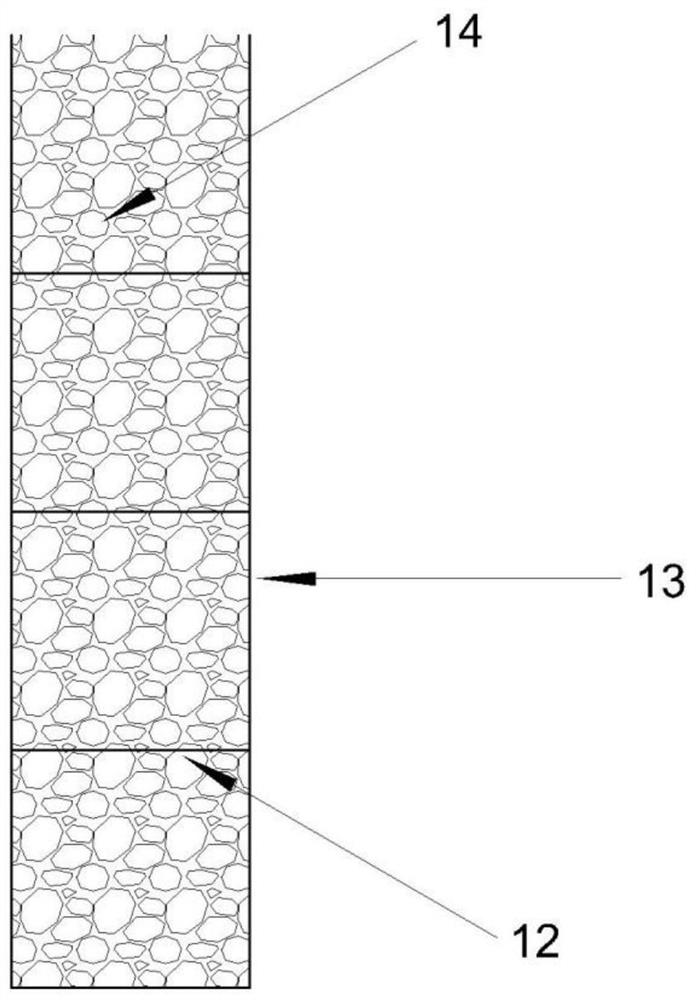

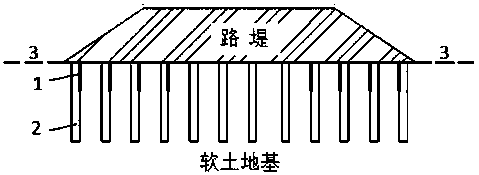

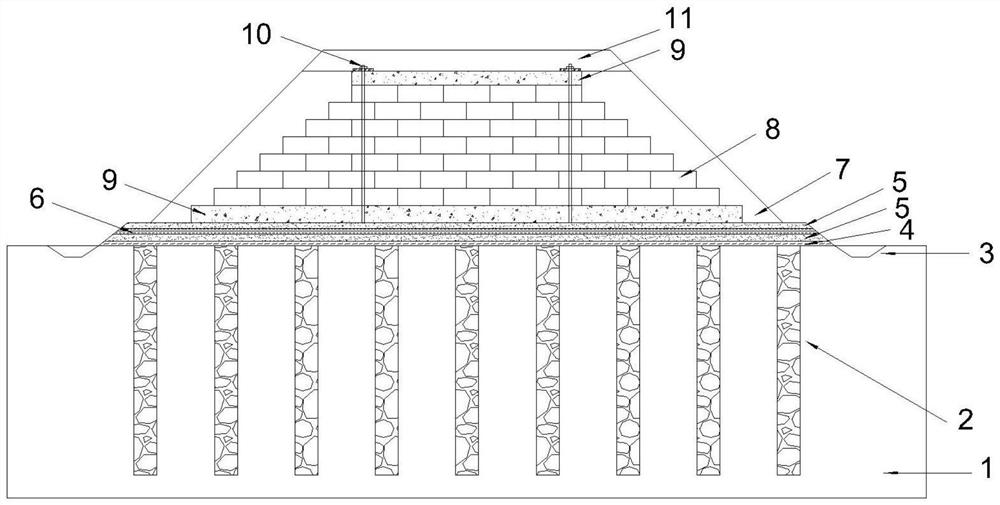

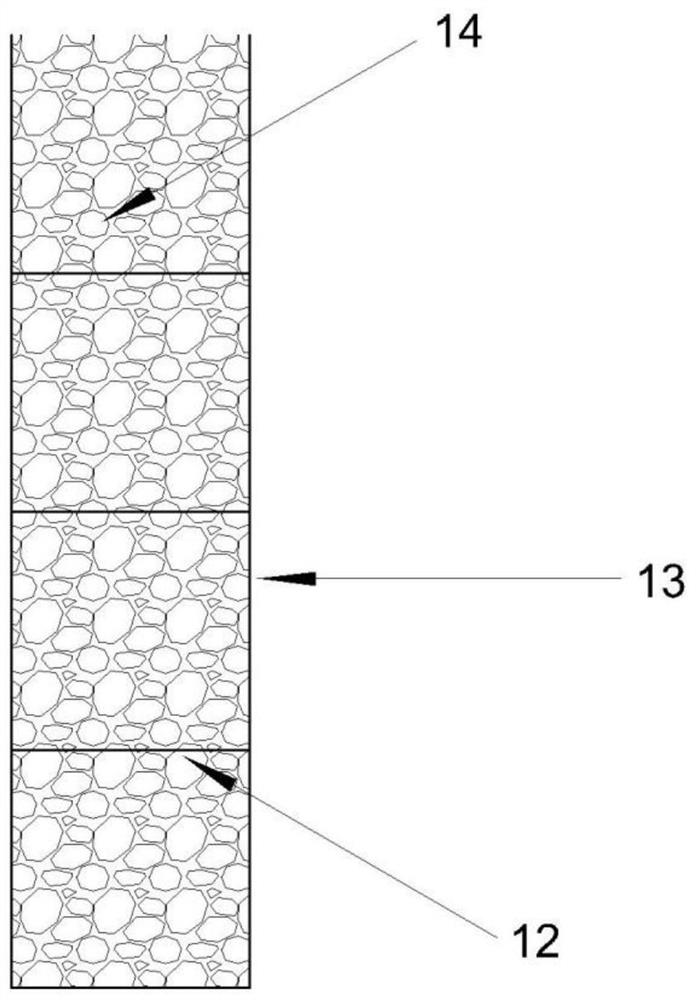

Soft soil area reinforced gravel pile supporting EPS light embankment structure and construction method thereof

ActiveCN112921731AAccelerated consolidationLow costRoadwaysSoil preservationSoil scienceCrushed stone

The invention belongs to the field of roadbed engineering, and relates to a soft soil area reinforced gravel pile supporting EPS light embankment structure and a construction method thereof, wherein the soft soil area reinforced gravel pile supporting EPS light embankment structure comprises bidirectional reinforced gravel piles, a drainage ditch, a geotechnical cloth cushion layer, a high-strength load transmission platform, a waterproof roll, edge covering soil, EPS foam blocks and a pavement structure layer; the bidirectional reinforced gravel piles are arranged in a pile group mode, are distributed in a square mode and are longitudinally arranged in a soft soil foundation; and the geotechnical cloth cushion layer, the high-strength load transfer platform, the waterproof roll and a second high-strength load transfer platform are sequentially laid on the top of the bidirectional reinforced gravel pile from bottom to top, the EPS foam blocks are filled in a layered mode, and finally a pavement structure layer is laid. The strength of the foundation is improved, the EPS foam block is used as the embankment filler, the dead weight of the embankment and the overlying load of the foundation soil are remarkably reduced, the overall stability of the structure is remarkably enhanced through the high-strength load transfer platform, and the defects that the foundation of the embankment built on the soft soil foundation is large in settlement, poor in stability and the like can be effectively overcome.

Owner:WUHAN UNIV

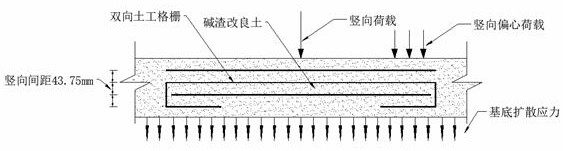

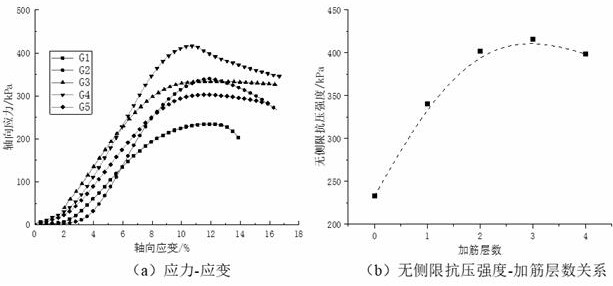

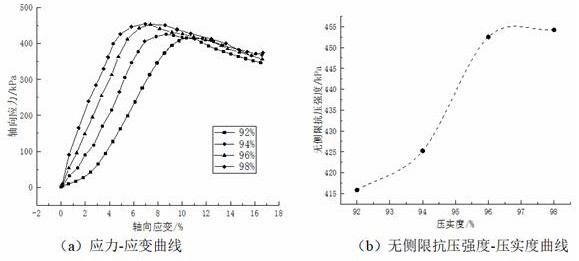

Road structure processing method based on reinforced alkaline residue improved soil

The invention relates to the technical field of road traffic construction, and discloses a road structure processing method based on reinforced alkaline residue improved soil, which comprises the following steps: taking a proper amount of alkaline residue, fly ash and cohesive soil, adding water for mixing by adopting the optimal water content of 23%, and then conducting sealing for 14 days to promote volcanic ash reaction; smearing engine oil in a road structure mold cylinder for lubrication, and packing the mixture into the alkaline residue improved soil in a multi-layer volume-controlled manner; after each layered volume is filled, laying a layer of reinforced material, laying 8-12 cm of alkaline residue improved soil for rolling compaction, and after compaction, sequentially packing the upper-layer mixture until a next-layer reinforcing layer is reached; and circulating and repeating the steps to form the reinforced road structure. Compared with the prior art, the reinforced alkaline residue improved soil is reasonably designed, geogrids and the alkaline residue improved soil are used as raw materials according to the optimal grid spacing, the base layer structure for the solid waste regeneration road is constructed, the design requirements of roads at or below a second level can be met, and resource utilization of alkaline residue solid waste is greatly promoted.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY +1

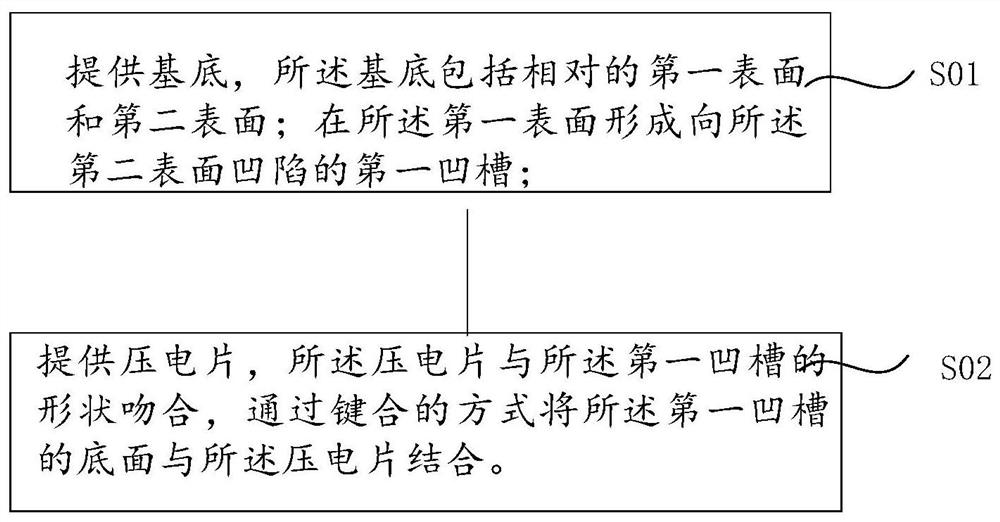

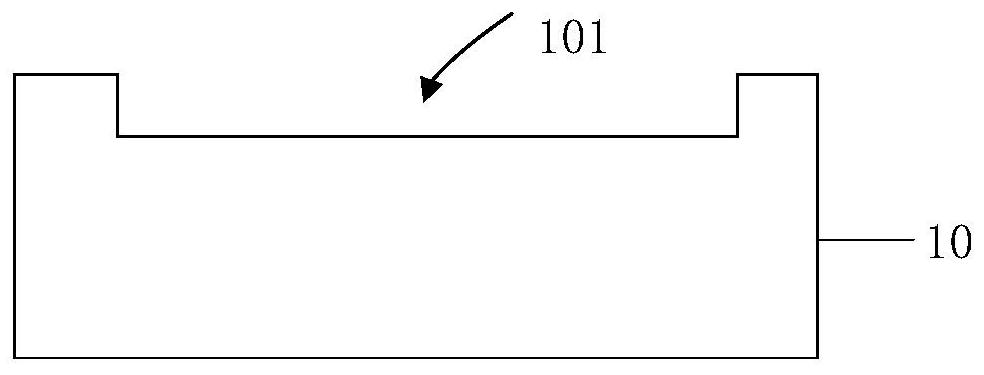

Composite substrate for manufacturing acoustic wave resonator, surface acoustic wave resonator and manufacturing method

PendingCN113098431AInhibit sheddingLimit lateral deformationImpedence networksComposite substrateEngineering

The invention discloses a composite substrate for manufacturing an acoustic wave resonator, a surface acoustic wave resonator and a manufacturing method, and the manufacturing method of the composite substrate comprises the steps: providing a substrate which comprises a first surface and a second surface which are opposite to each other; forming a first groove which is recessed towards the second surface on the first surface; and providing a piezoelectric plate, wherein the piezoelectric plate is matched with the first groove in shape, and the bottom face of the first groove is combined with the piezoelectric plate in a bonding mode. The composite substrate comprises a substrate, wherein the first substrate comprises a first surface and a second surface which are opposite; the first surface is provided with a first groove which is recessed towards the second surface; a piezoelectric plate is embedded in the first groove, and the top surface of the piezoelectric plate is higher than the first surface or is flush with the first surface.

Owner:NINGBO SEMICON INT CORP

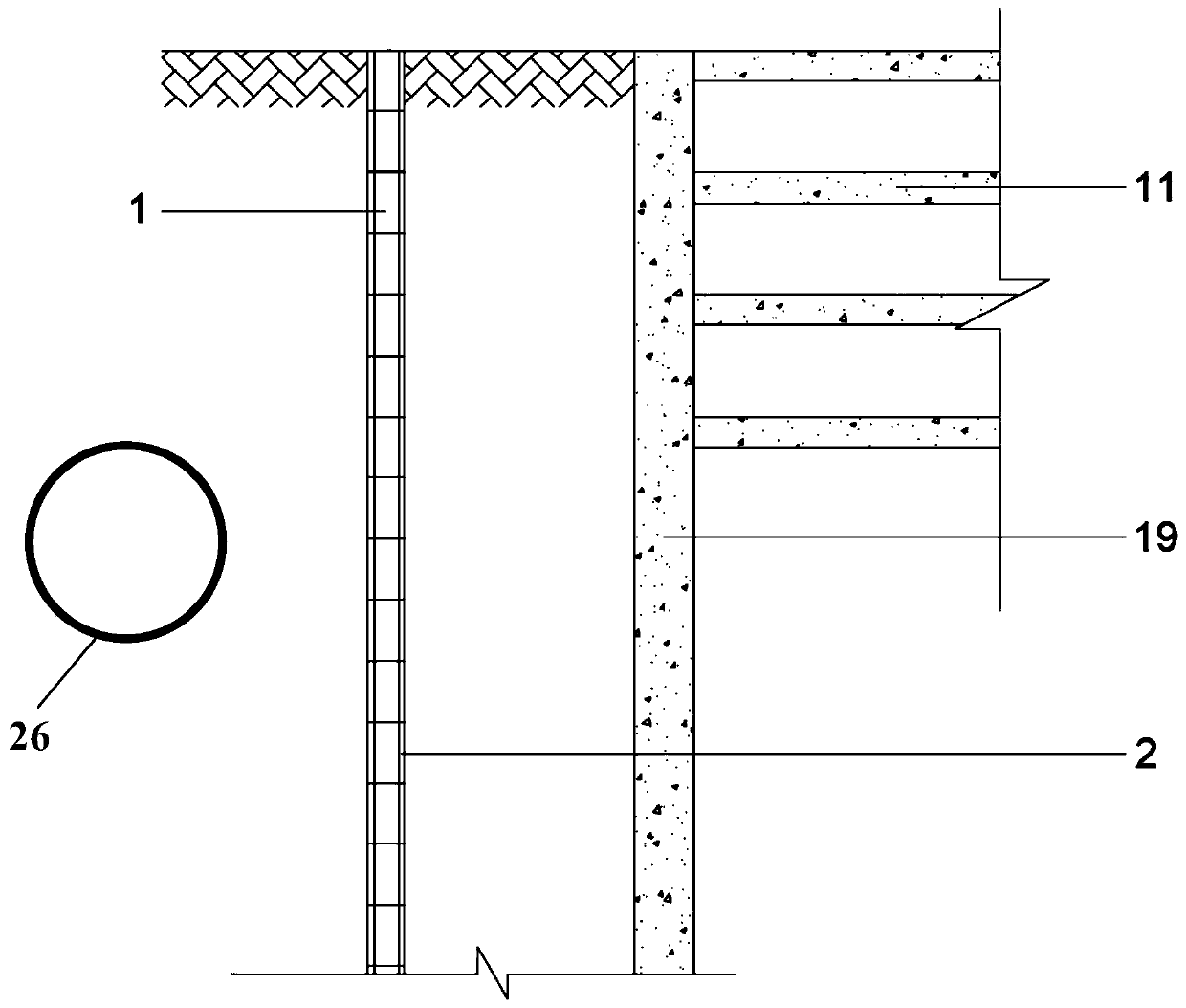

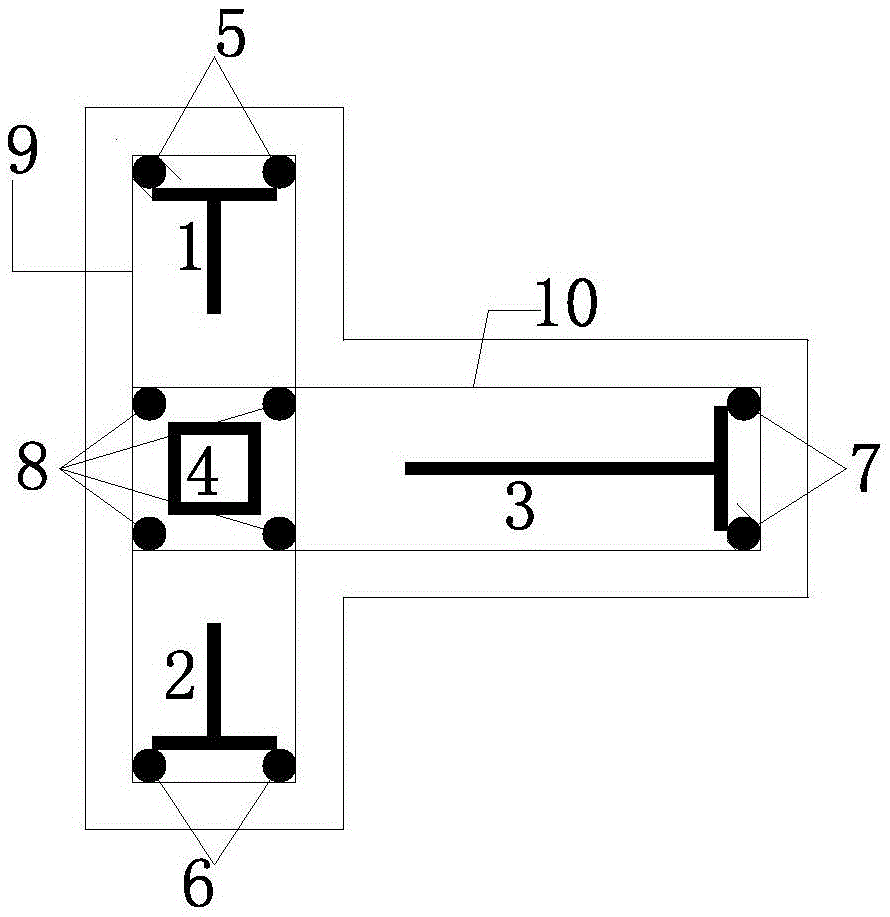

Construction method of steel-section-concrete T-shaped section column

The invention relates to a construction method of a steel-section-concrete T-shaped section column. The construction method comprises the following steps: 1) producing T-shaped steel sections and square steel tubes; 2) punching holes in steel flange plates and web plates on two sides of the T-shaped steel sections and in tube walls of four sides of the square steel tubes; 3) mounting the vertical T-shaped steel sections in each column limb of the T-shaped column respectively, and mounting vertical square steel tubes (4) in the core zone of the T-shaped section column, wherein all the steel sections (1-4) are anchored at the top of a foundation, and welding end plates to strengthen anchoring; 4) arranging longitudinal force-bearing steel bars; 5) arranging stirrups (9, 10) at certain intervals in directions parallel to the flange and the web plate of the T-shaped section column respectively by tightly adhering to the outer surfaces of the longitudinal force-bearing steel bars; 6) mounting a moulding plate; 7) pouring concrete. By the construction method of the steel-section-concrete T-shaped section column, provided by the invention, a specially-shaped column structure can be popularized and applied to high-rise buildings and buildings in a region with high seismic fortification intensity.

Owner:TIANJIN UNIV

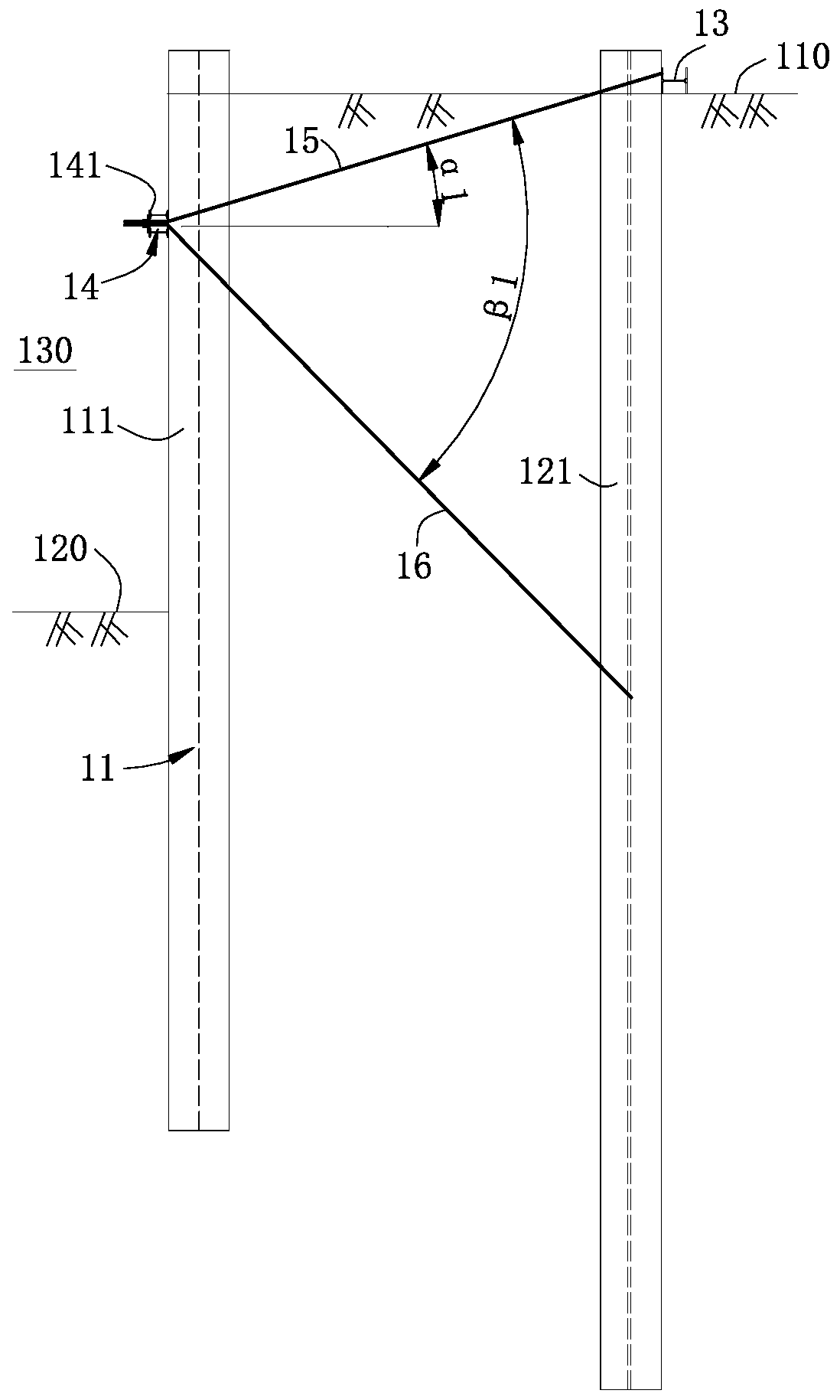

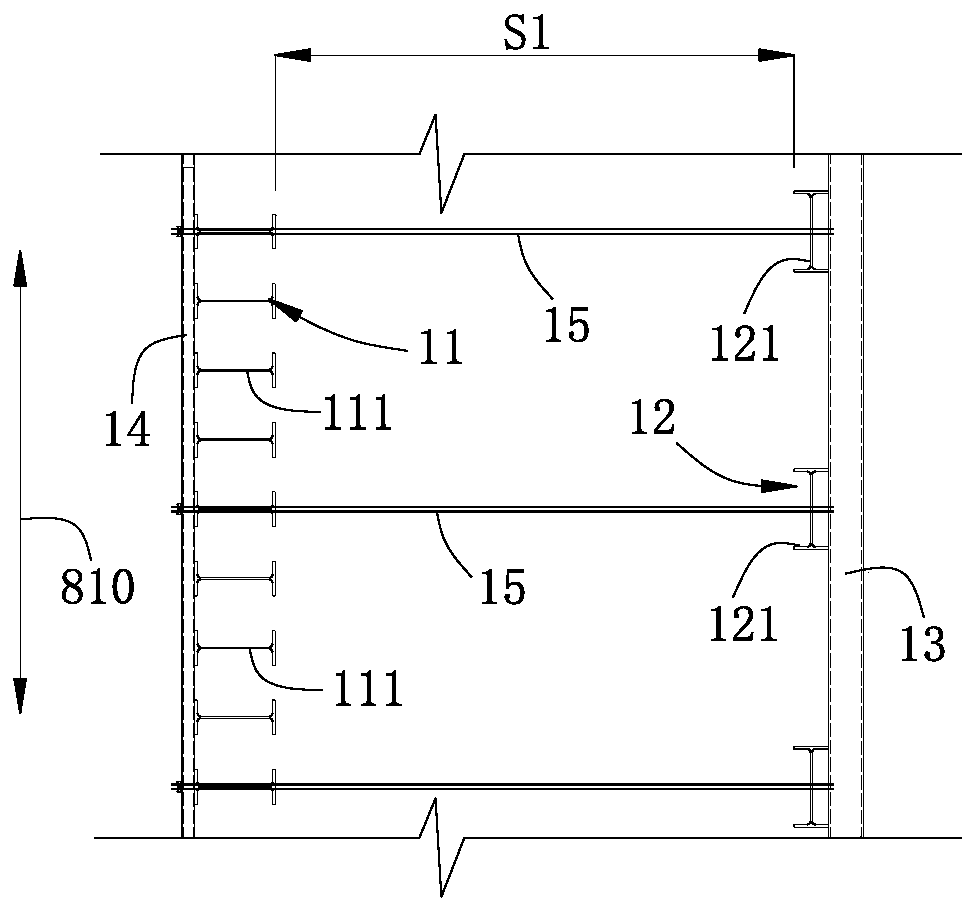

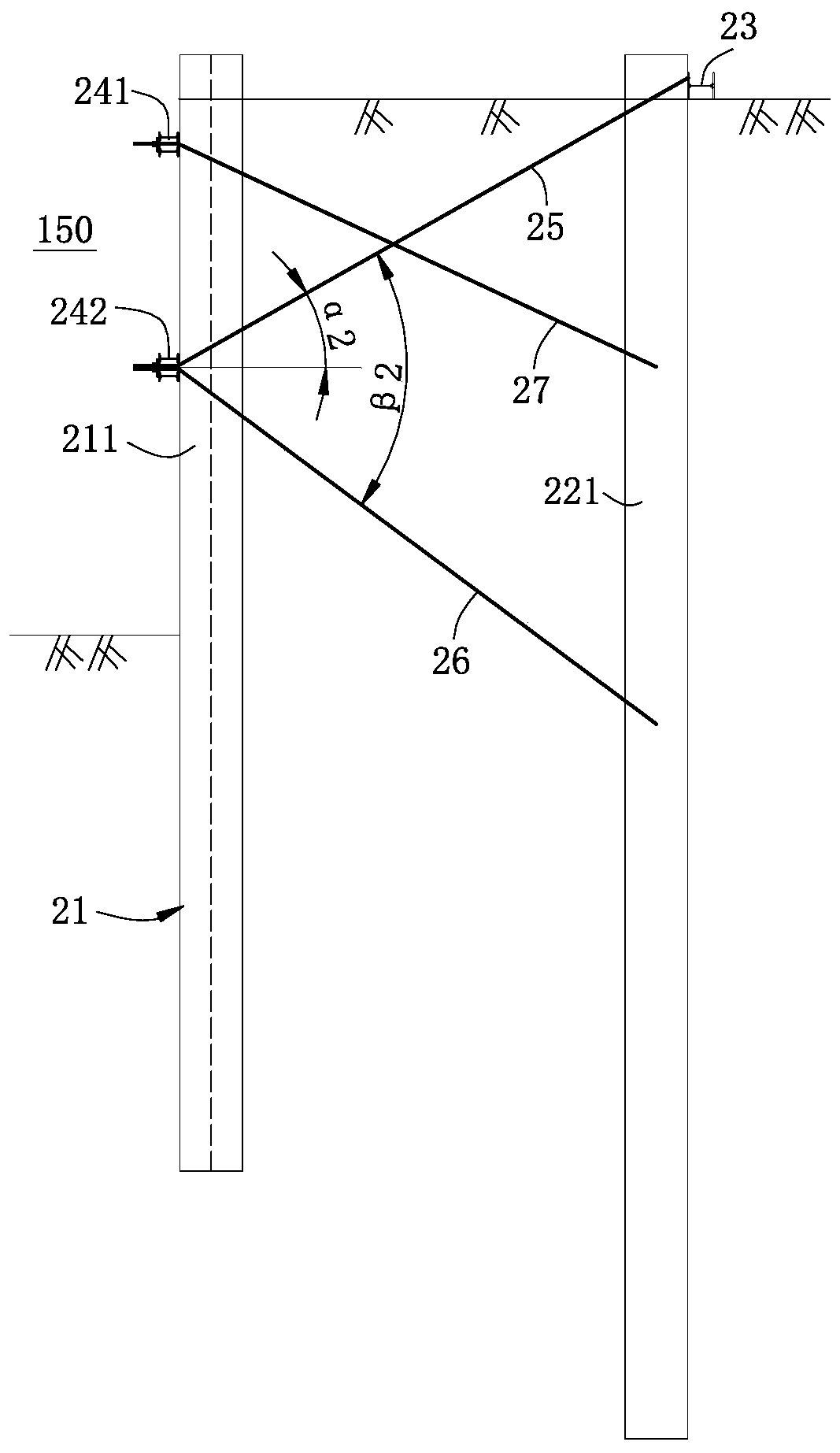

Deep anchor pull pile supporting system and construction method thereof

PendingCN111335327ASmall footprintIncrease construction costsExcavationsBulkheads/pilesSupporting systemPurlin

The invention discloses a deep anchor pull pile supporting system. The deep anchor pull pile supporting system comprises anchor rope piles and anchor piles arranged on the sides, away from a foundation pit, of the anchor rope piles, first anchor ropes A and second anchor ropes A are arranged between the anchor rope piles and the anchor piles; an inner row anchor rope surrounding purlin A is arranged on the inner sides of the anchor rope piles; an outer row anchor rope surrounding purlin is arranged on the outer sides of the tops of the anchor piles; one end of each first anchor rope A penetrates through the corresponding anchor rope pile and then is connected to the inner row anchor rope surrounding purlin A, and the other end of each first anchor rope A extends upwards in the inclined direction, penetrates through the corresponding anchor pile and then is connected to the outer row anchor rope surrounding purlin; and one end of each second anchor rope A penetrates through the corresponding anchor rope pile and then is connected to the inner row anchor rope surrounding purlin A, and the other end of each second anchor rope A extends downwards in the inclined direction and is connected to the corresponding anchor pile. The invention further discloses a construction method of the deep anchor pull pile supporting system. The deep anchor pull pile supporting system and the construction method thereof can be carried out within a limited construction range and can improve construction efficiency.

Owner:JIANGSU DONGHENAN GEOTECHNICAL TECH CO LTD

A construction method of annular airbag in gob-side entry retaining concrete filling wall

ActiveCN105937407BImprove longitudinal shear resistanceAvoid destructionMaterial fill-upStructural engineering

The invention discloses a gob-side entry retaining concrete filled wall annular air bag construction method. The construction method adopts an annular air bag pressure bag mode, and an annular air bag pressure bag is fixed through anti-displacement anchorage devices and horizontal lateral confinement reinforcement devices. The anti-displacement anchorage devices make annular air bag formworks and top and bottom plates integrated to form a whole. The horizontal lateral confinement reinforcement devices can effectively limit transverse deformation of a filled wall body, ensure successive gob-side entry retaining, can resist multiple times of pressure from the top plate and improve the overall stability of the concrete wall body. Before concrete is cast into a filling cavity, inflation is needed, the annular air bag pressure bag structure bear rigid and flexible formwork supports for usage. After the annular air bag pressure bag is deflated, the bag is filled with concrete, the bag and the concrete jointly form a gob-side entry retaining lateral filled wall, the links of steel formwork erection and steel formwork dismounting are omitted in the whole process, a middle grouting process is not needed to be waited, the labor intensity of workers is reduced, continuous and rapid filling operation is achieved, and the face advancing speed can be improved.

Owner:XIAN UNIV OF SCI & TECH

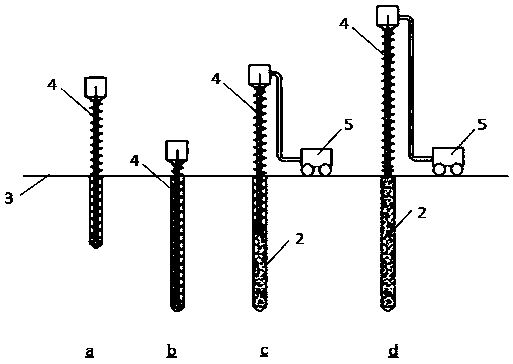

A construction method for comprehensively applying piles and vertical geotechnical materials to treat soft foundations of highways

ActiveCN106120523BGive full play to the characteristics of materialsLimit lateral deformationFoundation engineeringRoads maintainenceStructural engineeringImplant

The present invention disclosed a construction method of the soft base of comprehensive application piles and vertical geomorphous materials, and introduced the construction process in detail.The implantation position of geomorphology materials is marked with the location of the material; 2) Pile construction setting set setting in the step 1) is performed;Materials and pile connection; 5) The construction of the cushion and the embankment is performed.The invention implants vertical geographical materials in the ground base so that the vertical geographical materials and piles work together. On the basis of the vertical sinking of the ground soil, the vertical geomorphous material is achieved.Further improve the effect of foundation treatment.

Owner:HOHAI UNIV

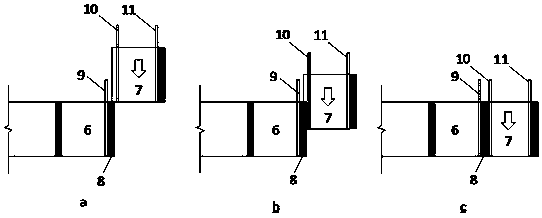

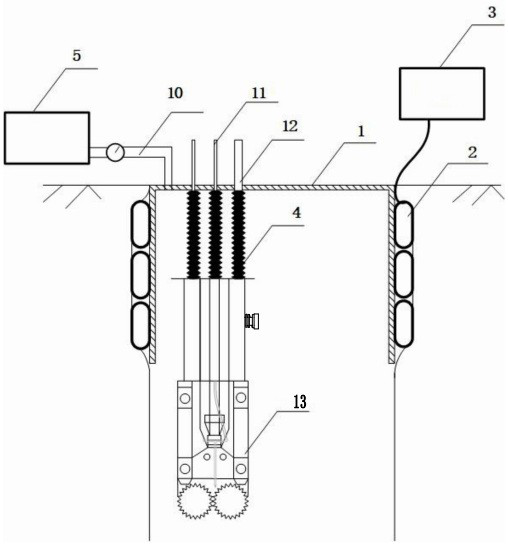

Construction method of high pressure mud retaining wall with underground diaphragm wall forming groove

ActiveCN113279415BImprove reliabilityLimit lateral deformationSoil-shifting machines/dredgersExcavationsSlurry wallHydraulic pump

The invention discloses a method for constructing a high-pressure mud retaining wall for forming a groove into an underground continuous wall, comprising the following steps: forming a guide wall; installing a groove milling machine; ; until the entire groove section is grooved. The advantages of the invention are that it can control the pressure of the mud in the groove, and use the sealing device of the groove and the hydraulic pump to realize the high-pressure retaining wall of the mud during the forming of the groove, so as to limit the lateral deformation of the soil body of the groove wall, thereby reducing the construction of the underground continuous wall. The construction cost of milling into the groove is simple and efficient; the sealing reliability of both ends of the telescopic sealing sleeve is high, which further improves the reliability of the high-pressure protective wall.

Owner:江苏中车城市发展有限公司 +2

An annular airbag formwork for gob-side entry retaining concrete filling wall

ActiveCN106194250BImprove longitudinal shear resistanceAvoid destructionMaterial fill-upFast fillingAirbag

The invention discloses an annular air bag formwork of a gob-side entry retaining concrete filling wall. By using an annular air bag pressure bag mode, an annular air bag pressure bag is fixed through a displacement-resistant anchoring device and a horizontal lateral limit reinforcing device; the displacement-resistant anchoring device combines an annular air bag formwork with top and bottom plates into a whole; the horizontal lateral limit reinforcing device can effectively limit the transverse deformation of a filling wall body to ensure the successful retaining of the gob-side entry retaining, and can resist multiple times of top plate coming pressure, so that the integral stability of a concrete wall body is improved; the annular air bag pressure bag structure needs to be inflated before concrete filling into a filling cavity, and is used for carrying a rigid and flexible formwork support frame; after the annular air bag pressure bag is deflated, the annular air bag pressure bag is filled with concrete; and the annular air bag pressure bag and the concrete jointly form the filling wall body beside the gob-side entry retaining. A link of mounting and dismounting a steel formwork is omitted in the whole flow process; the waiting is not needed in the middle grouting flow process; the work intensity of workers is reduced; the continuous and fast filling operation is realized; and the close following with the work face advancing speed can be realized.

Owner:XIAN UNIV OF SCI & TECH

EPS light embankment structure and construction method supported by reinforced gravel piles in soft soil area

ActiveCN112921731BAccelerated consolidationLow costRoadwaysSoil preservationCrushed stoneStructural engineering

The invention belongs to the field of subgrade engineering, and relates to an EPS light embankment structure supported by reinforced gravel piles in soft soil areas and a construction method, including two-way reinforced gravel piles, drainage ditch, geotextile cushion, high-strength load transfer platform, waterproof Coiled material, edge-wrapped soil, EPS foam block, pavement structure layer; two-way reinforced gravel piles are arranged in groups of piles, distributed in a square, and longitudinally arranged in soft soil foundation; the top of two-way reinforced gravel piles is laid sequentially from bottom to top Geotextile cushion, high-strength load transfer platform, waterproof membrane and the second layer of high-strength load transfer platform are filled with EPS foam blocks in layers, and finally the pavement structure layer is laid. The invention improves the strength of the foundation, uses the EPS foam block as the embankment filler, significantly reduces the self-weight of the embankment and the overlying load of the foundation soil, and significantly enhances the overall stability of the structure through the high-strength load transfer platform, which can effectively solve the problem of soft The embankment built on the soil foundation has the disadvantages of large foundation settlement and poor stability.

Owner:WUHAN UNIV

A gob-side entry retaining method and its filling method

ActiveCN105201529BLimit lateral deformationEven by forceUnderground chambersTunnel liningFiberCrack resistance

The invention discloses a flexible formwork for gob-side retaining with double-stretched fibers, which comprises a main formwork connected with a top formwork, and the main formwork is provided with pouring ports, anchor bolt holes, transverse flanges and vertical wings. There is a sleeve connected to the transverse flange, and a reinforcement hole is provided on the top formwork, and a plurality of transverse ties and oblique ties are arranged in the main formwork, and both ends of the transverse ties are fixed to the main body by reinforcing rings. On the two opposite sides of the formwork, the two ends of the diagonal stays are obliquely fixed on the two connected surfaces inside the main formwork through the reinforcement ring. The main formwork is also provided with reserved holes, which are flexible molds. The cloth is prefabricated into a tubular structure. The template can limit the lateral deformation of the flexible template after filling, so that the flexible template is evenly stressed during filling, and the filling body has high strength and strong crack resistance. The invention discloses a method for soft-formed concrete construction by adopting cross-inclined double-stretched fiber flexible formwork in gob-side entry retention. The method is convenient for pipeline installation and fast in construction speed.

Owner:SHAANXI PIONEERING ARCHITECTURAL TECH

Factory-like manufacturing of dam components and method for rapid construction of dams

InactiveCN103938581BFast constructionShorten the construction periodDamsClimate change adaptationLandslideRapid construction

The invention relates to a method for industrially manufacturing embankment components and quickly constructing an embankment, which belongs to embankment construction technology. The joint preloading of plastic drainage boards, geotextiles, sand cushions and vacuuming is used to quickly treat the foundation; vacuuming is used under the sealing film, and a secondary sand cushion is thrown on the covering film, and the prefabricated components Input the earthwork from above; form the joint preloading of water level, sand cushion earthwork pile-up and vacuum; adopt the prefabricated embankment components to be placed on the treated embankment foundation, and connect each other to form the embankment skeleton, light cushion method, adjust The force balance of the embankment is improved, and uneven settlement and landslides are avoided; the problems of foundation strength and earthwork height are fundamentally solved, which is conducive to mechanized and large-scale construction. It also has the characteristics of replacing stone with soil, saving costs, increasing construction speed, and being stable and reliable.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Composite spiral stirrup confined concrete shear wall structure and construction method thereof

PendingCN112627392AImprove restraintGuarantee the construction qualityWallsBuilding reinforcementsEarthquake resistanceRebar

The invention discloses a composite spiral stirrup confined concrete shear wall structure and a construction method thereof. The composite spiral stirrup confined concrete shear wall structure comprises continuous composite spiral stirrups, wherein continuous composite spiral horizontal distribution bars are evenly distributed in concrete; on the same horizontal plane, the adjacent continuous composite spiral horizontal distribution bars are fixedly connected together; the continuous composite spiral stirrups are symmetrically arranged at the positions of confined edge components at the two ends of the concrete; and longitudinal bars are evenly arranged in the overlapping areas of the continuous composite spiral stirrups and the continuous composite spiral horizontal distribution bars, and vertical distribution bars are evenly arranged in the continuous composite spiral horizontal distribution bars. According to the composite spiral stirrup confined concrete shear wall structure and the construction method thereof, the continuous composite spiral stirrups are arranged on the edge of a wall, core concrete can be effectively confined, the effective confined area of the concrete is increased, and the compressive strength and the ultimate compressive strain of the concrete are improved; and a stable steel reinforcement framework is formed by the continuous composite spiral horizontal distribution bars and the vertical distribution bars, the overall stability of the wall is enhanced, transverse deformation of the wall concrete is confined, and the anti-seismic property of the wall is improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Construction method of integrated comprehensive treatment of strip mining goaf

ActiveCN108798769BImprove stabilityLighten the loadUnderground miningSurface miningMining engineeringSlurry

The invention discloses a construction method for integrated and comprehensive treatment of strip mining goafs, which relates to the field of coal mine goaf management. Firstly, the gobs are filled with gangue, and then grouted and filled. The solidified gangue cemented body has strong stability , so that the goaf after strip mining has the bearing capacity again, enhances the overall strength, and reduces the bearing load of the coal pillars on both sides; grouting the cracks and separation layers on the goaf, making the overlying It is solidified and cemented with the grout, so that the rock formations that originally had cracks are reconnected together, thereby preventing the overlying strata from continuing to collapse into the goaf; finally, the grouting treatment of the yield zone of the coal pillar further enhances the strength of the coal pillar and prevents the collapse of the coal pillar. The deformation of the coal pillar; the construction method is simple, the operation is convenient, the integrated comprehensive construction, the cost is low, the overall stability and bearing capacity of the goaf are ensured, the effect of settlement reduction is remarkable, and it is suitable for large-scale promotion and application.

Owner:SHANDONG UNIV OF SCI & TECH

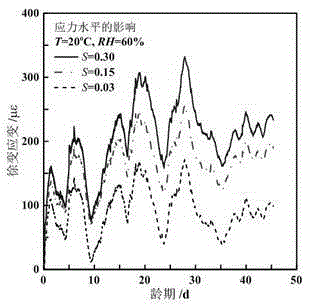

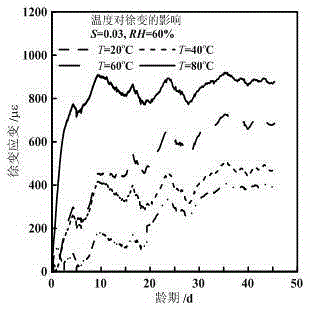

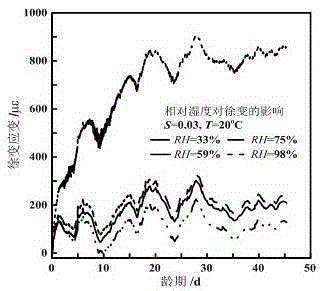

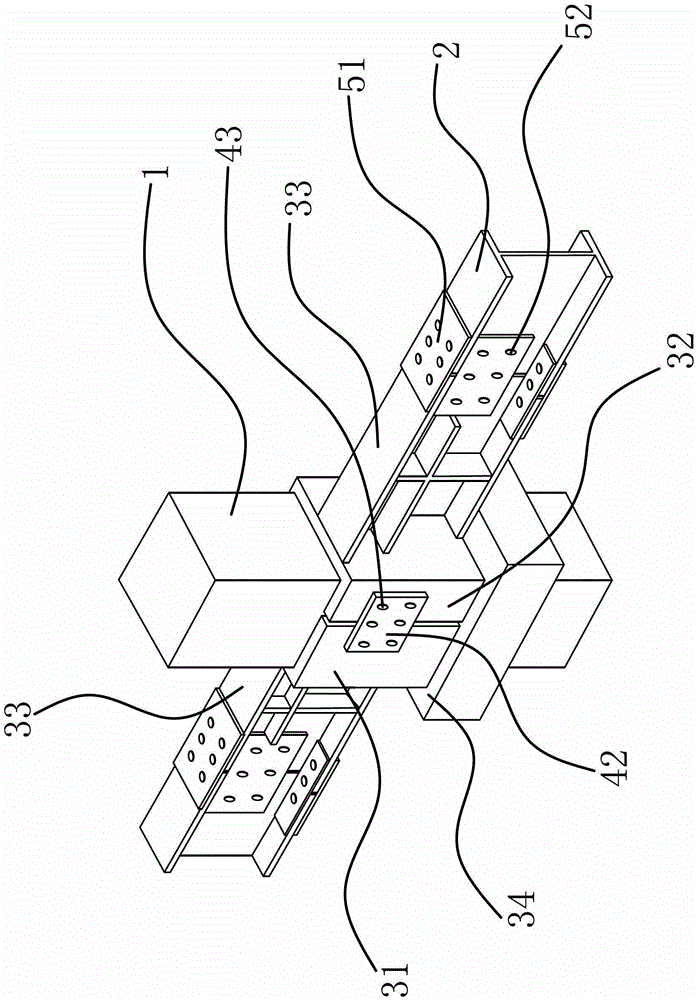

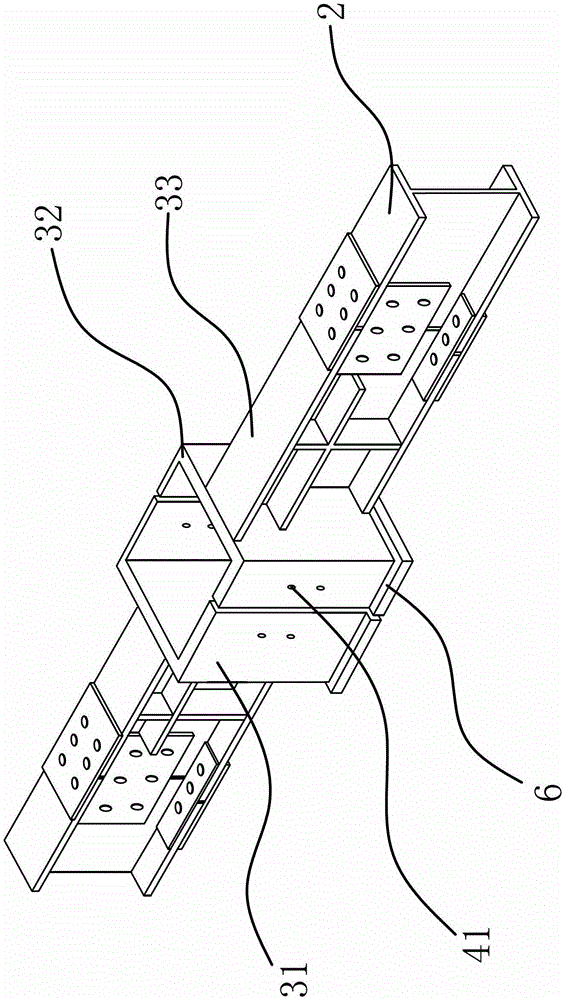

Test device and test method for material creep under the coupling action of tensile stress and environment

InactiveCN103267682BUniform stressUniform stress distributionMaterial strength using tensile/compressive forcesStress relaxationEngineering

The invention discloses a device for testing material creep under the coupling action of tensile stress and the environment. The device comprises a support, a weight, a heating jacket, a container containing a saturated inorganic salt solution, a strain demodulator, a power supply, a temperature controller, a strain sensor and a test piece, wherein the support comprises a positioning plate, an upper spherical hinge, an upper clamping head, a supporting rod, a bearing plate, a base plate, a lower clamping head and a lower spherical hinge; the supporting rod is connected with the bearing plate through a sliding bearing; the test piece is embedded in a groove in the upper clamping head and a groove in the lower clamping head; the weight is positioned on the bearing plate; the heating jacket covers on the outer side of the support; the container is positioned between the support and the heating jacket; the strain sensor is adhered to the outer wall surface of the test piece; and the temperature controller is connected with the ring-shaped heating jacket. By adopting the device, the reliability of the test process can be improved, and the accuracy of results is ensured. Meanwhile, the invention also discloses a test method for the test device. The method is simple and easy to operate, and can keep that the test piece does not generate stress relaxation in the process of long-term load application, and the stress is uniformly distributed.

Owner:SOUTHEAST UNIV

A connection node between a concrete column and a steel beam

InactiveCN103243818BHigh precisionFit clearance is smallBuilding constructionsUltimate tensile strengthMaterials science

The invention provides a connection joint of a concrete column and a steel beam, belongs to the technical field of construction engineering, and solves the technical problems of low strength, construction difficulty and the like of an existing connection joint of the concrete column and the steel beam. The connection joint of the concrete column and the steel beam comprises the concrete column, the steel beam, a half steel sleeve I and a half steel sleeve II. The half steel sleeve I and the half steel sleeve II are detachably connected and can be sleeved on the concrete column after being connected; the half steel sleeve I or the half steel sleeve II is fixedly connected with a connection arm which is detachably connected with the steel beam; and the concrete column is provided with a projecting shoulder, and the half steel sleeve I and the half steel sleeve II can abut against the projecting shoulder. The connection joint of the concrete column and the steel beam has the advantage of being high in bearing capacity and simple in construction.

Owner:汪洋 +1

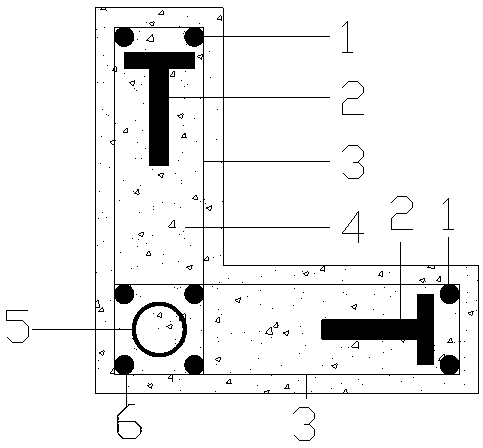

Profile steel-concrete combined L-shaped column with internal FRP ribs

The invention relates to a profile steel-concrete combined L-shaped column with internal FRP ribs. The profile steel-concrete combined L-shaped column with the internal FRP ribs comprises an L-shapedconcrete column body, the corner portion of the concrete column body serves as a core area, and a round steel pipe is vertically arranged in the core area; T-shaped profile steel is vertically arranged in two column limbs of the concrete column body separately, and the flanges of the T-shaped profile steel are both located on the outer portions of the column limbs; and first longitudinally-stressed FRP ribs are arranged on the outer sides of the flanges of the T-shaped profile steel in the concrete column body, second longitudinally-stressed FRP ribs are arranged on the four outer side cornersof the round steel pipe in the concrete column body, and the first longitudinally-stressed FRP ribs and the second longitudinally-stressed FRP ribs are bound and connected through stirrups separately. The profile steel-concrete combined L-shaped column with the internal FRP ribs is simple in structure.

Owner:FUZHOU UNIV

A method of improving the performance of strip coal pillars by using grouting joint support bolts

ActiveCN104847354BSimple structureImprove carrying capacityUnderground miningSurface miningEngineeringCoal pillar

The invention discloses a method for improving the performance of striped coal pillars by using grouting combined support bolts, relates to the technical field of strip coal pillar mining, designs the structure of grouting combined support bolts, and uses grouting combined support The method of improving the performance of the strip coal pillar by the protective bolt realizes the dual functions of grouting in the yield zone of the strip coal pillar and bolt support in the yield zone and elastic zone of the strip coal pillar. On the one hand, the bearing capacity of the yield zone is improved, and on the other hand On the one hand, the grouting combined with the supporting bolts gives the coal pillar a certain lateral restraint force, and the coal pillar is transformed from a two-way stress state to a three-way stress state, and the strength and performance of the coal pillar are improved; The top and bottom of the grouting combined support bolts are obliquely drilled. After grouting, the coal pillar is connected with the roof and the floor as a whole, which limits the lateral deformation of the coal pillar. The structure of the grouting combined support bolt is simple and can be The column width adjusts the length of the hollow grouting bolt body, which is easy to install, ensures the improvement of the bearing capacity in the yield zone, and is low in cost. It is suitable for large-scale promotion and application in mining areas.

Owner:SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com