Deep anchor pull pile supporting system and construction method thereof

An anchor-pull, deep-layer technology, applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve the problem of low horizontal tension of anchor piles, and achieve the effects of improving safety, providing construction efficiency, and high construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

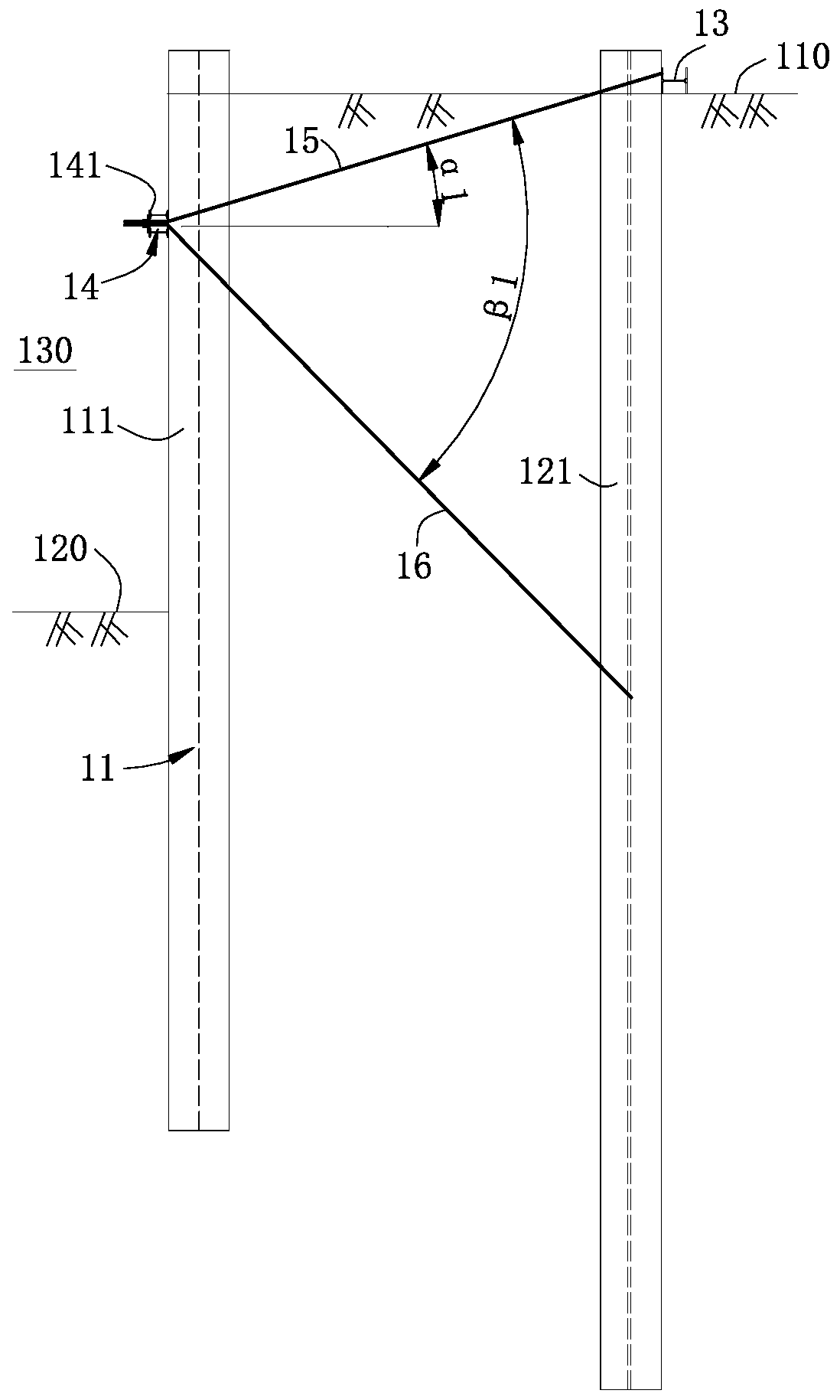

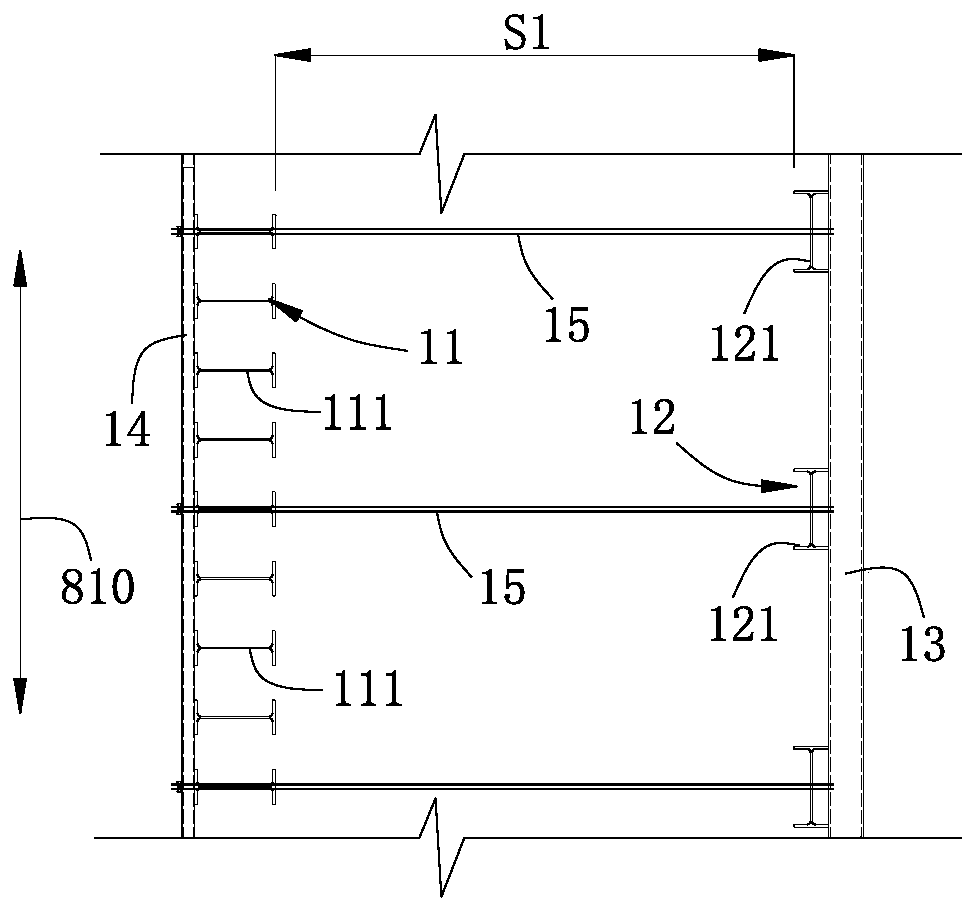

[0069] see figure 1 and figure 2 , the first deep anchor pile support system, which includes several first inner row piles 11 arranged along the first set direction, wherein some of the first inner row piles are formed as first anchor piles 111, corresponding to each Each of the first anchor piles 111 is provided with a first anchor pile 121 , and the first anchor pile 121 is arranged on a side of the corresponding first anchor pile 111 away from the first foundation pit 130 .

[0070] A first inner row of anchor cable purlins A14 is arranged on the inner side of the first inner row of piles 11, and a first outer row of anchor cable purlins 13 is arranged on the outer side of the top of the first anchor pile 121. The anchor cable purlins 13 are pressed against each of the first anchor piles.

[0071] In this embodiment, the first outer row of anchor cable purlins 13 is arranged on the ground 110 . exist figure 2 In , the direction of the arrow 810 indicates the extension...

Embodiment 2

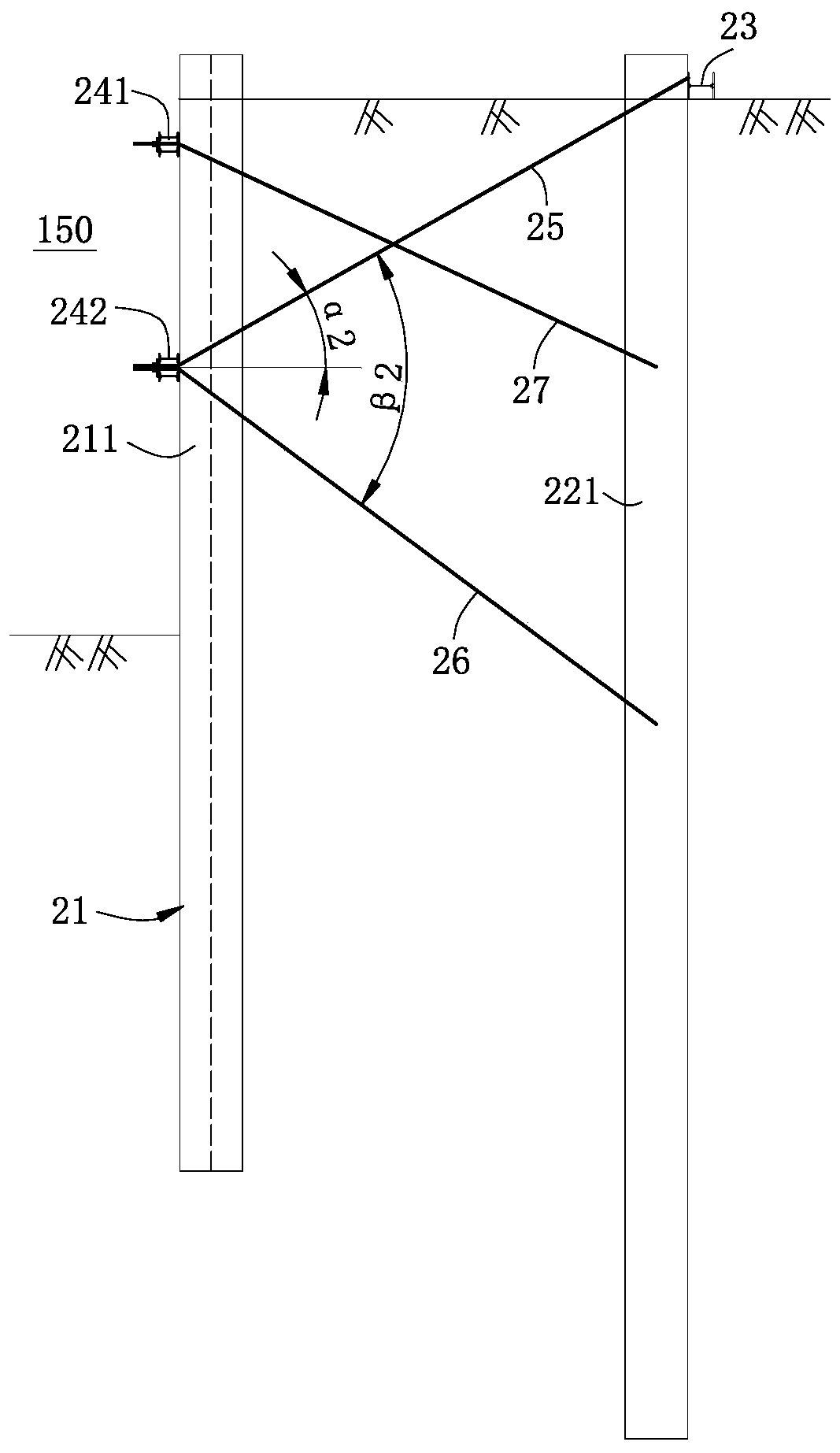

[0107] see image 3 and Figure 4 , the second deep anchor pile support system, which includes several second inner row piles 21 arranged along the first set direction, wherein part of the second inner row piles are formed as second anchor piles 211, corresponding to each Each of the second anchor piles 211 is provided with a second anchor pile 221 , and the second anchor pile 221 is arranged on a side of the corresponding second anchor pile 211 away from the second foundation pit 150 .

[0108] A second inner row of anchor cable purlins A242 is arranged on the inner side of the second inner row of piles 21 . On the outer side of the top of the second anchor pile 221, a second outer row of anchor cable purlins 23 is arranged. In this embodiment, the second outer row of anchor cable purlins 23 is arranged on the ground. exist Figure 4 In , the direction of the arrow 820 indicates the extension direction of the first setting direction in the second embodiment.

[0109] The...

Embodiment 3

[0131] This embodiment is an improvement on the basis of Embodiment 2. Compared with Embodiment 2, this embodiment adds an inner row of anchor cable purlins B, and correspondingly adds a first anchor cable B and a second anchor cable B. This embodiment will be described below.

[0132] see Figure 5 and Figure 6 , the third deep anchor pile support system, which includes several third inner row piles 31 arranged along the first set direction, wherein part of the third inner row piles are formed as third anchor piles 311, corresponding to each Each of the third anchor piles 311 is provided with a third anchor pile 321 , and the third anchor pile 321 is arranged on a side of the corresponding third anchor pile 311 away from the third foundation pit 160 .

[0133] A third inner row of anchor cable purlins A342 is arranged on the inner side of the third inner row of piles 31 . On the outer side of the top of the third anchor pile 321, a third outer row of anchor cable purlins ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com