Connection joint of concrete column and steel beam

A technology for concrete columns and connecting nodes, which is applied to buildings and building structures, can solve problems such as complex operations and difficult repairs, and achieve the effects of improving construction progress, simplifying construction difficulties, and reducing matching gaps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

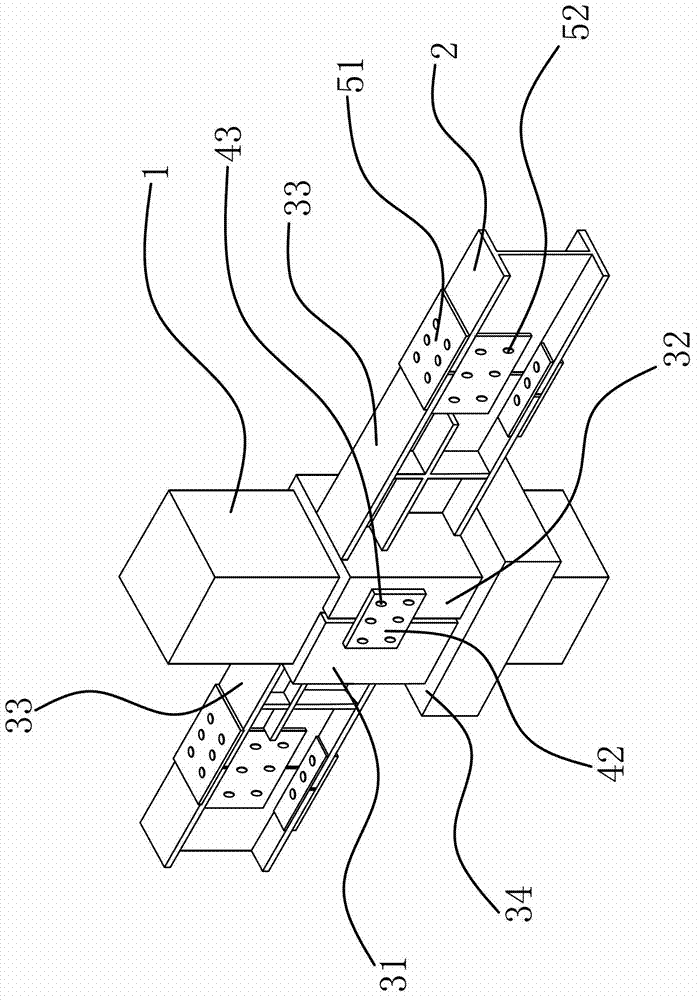

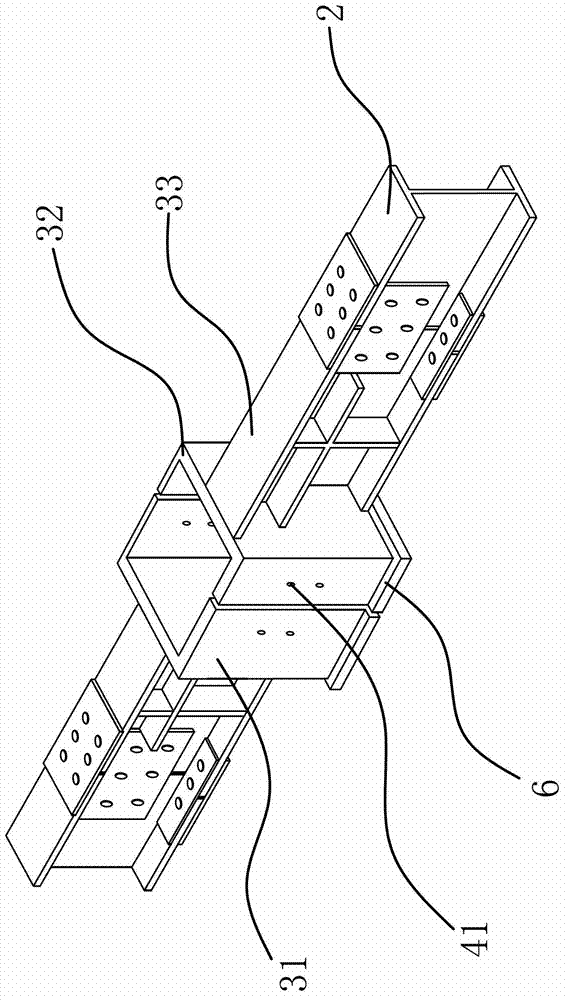

[0030] Such as figure 1 , figure 2 , image 3 with Figure 5 As shown, a connection node between a concrete column and a steel beam includes a concrete column 1 and a steel beam 2. This node includes a half-steel jacket 31 and a half-steel jacket 2 32, and the half-steel jacket 31 and the half-steel jacket 2 32 can be After the connection is disassembled and connected, it can be set on the concrete column 1; the first half-steel sleeve 31 and / or the second half-steel sleeve 32 are welded and fixedly connected with the connecting arm 33, and the first half-steel sleeve 31 and the second half-steel sleeve 32 are connected to the connecting arm 33 are fixedly connected by double-sided fillet welds, and the connecting arm 33 is detachably connected to the steel beam 2; the concrete column 1 is provided with a shoulder 34, and the first half steel sleeve 31 and the second half steel sleeve 32 can lean against the On the shoulder 34, the first half steel sleeve 31 and the second h...

Embodiment 2

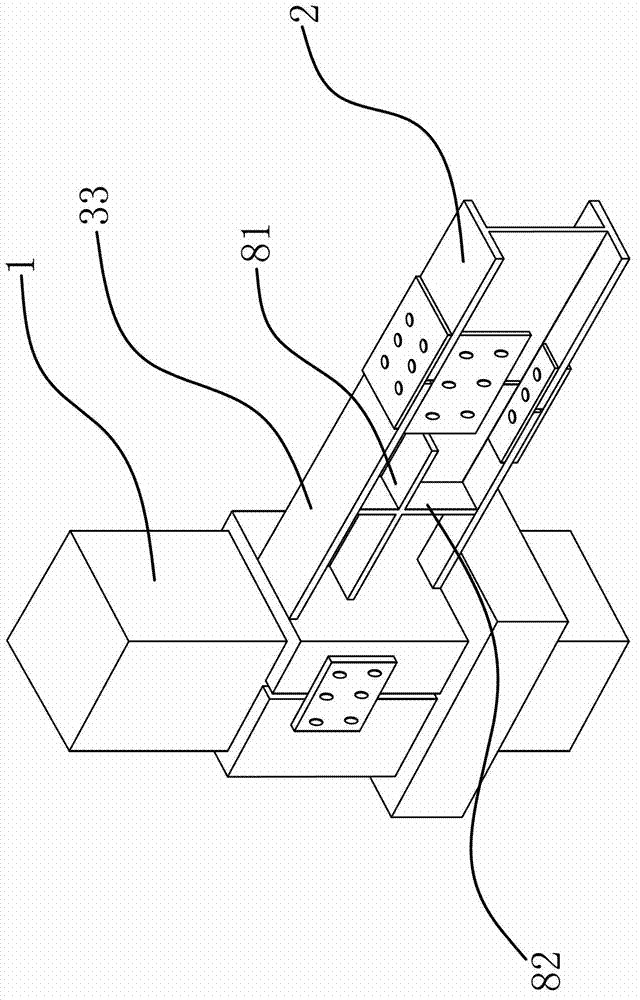

[0037] Such as Image 6 As shown, the content of the present embodiment is roughly the same as that of the first embodiment, the difference being that: the half-steel sleeve-31 is fixedly provided with several connecting plates-42, and the connecting plates-42 connect with the semi-steel through several connecting bolts-43. Set 2 32 is connected, in order to better reduce construction difficulty and improve installation accuracy, one end of connecting plate 1 42 can be welded with semi-steel sleeve 1 31, and the other end and half-steel sleeve 2 32 can be fixed with connecting bolt 1 43 Even, what is different from the previous scheme is that the through hole on the connecting plate 42 can be opened in advance, first connect one end of the connecting plate to the half steel sleeve 32 through the connecting bolt 1 43, and then connect the other end to the half steel sleeve 32. The steel sleeve is welded at 31, and its construction is easier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com