A method of improving the performance of strip coal pillars by using grouting joint support bolts

A technology of combined support and striped coal pillars, which is applied in the installation of bolts, earthwork drilling, ground mining, etc., can solve problems such as coal pillar instability, inability to adapt to coal pillars, and surface settlement, and achieve improved bearing capacity, The effect of simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

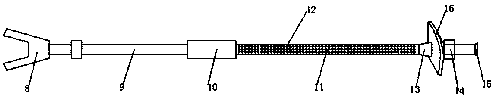

[0018] Such as figure 2 As shown, the grouting joint support anchor includes a drill bit 8, a solid anchor body 9 and a hollow grouting anchor body 11, the drill bit 8 is arranged at the end of the solid anchor body 9, and the solid anchor The rod body 9 is connected with the hollow grouting anchor body 11 through the connecting sleeve 10, and a plurality of grouting holes are uniformly arranged on the hollow grouting anchor body 11, and the end of the hollow grouting anchor body 11 is provided with a grout stop Plug 13, backing plate 16 and slurry plug 15.

[0019] As a preferred manner, the hollow grouting anchor bodies 11 are provided in multiples, and are connected by connecting sleeves 10 .

[0020] According to A.H. Wilson yield zone width formula , where: m is the thickness of the coal seam, h is the mining depth, and the length of the hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com