Road structure processing method based on reinforced alkaline residue improved soil

A processing method and improved soil technology, applied in roads, roads, buildings, etc., can solve problems such as increased construction costs, inability to realize solid waste resource utilization, and restrictions on large-scale application of alkali slag-improved soil bases, etc., to achieve simple construction, Promote the utilization of resources, the effect of strong bearing capacity and anti-deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

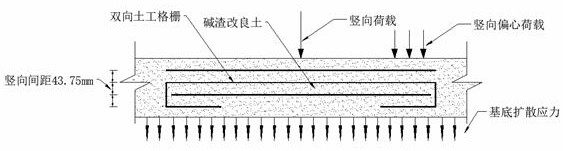

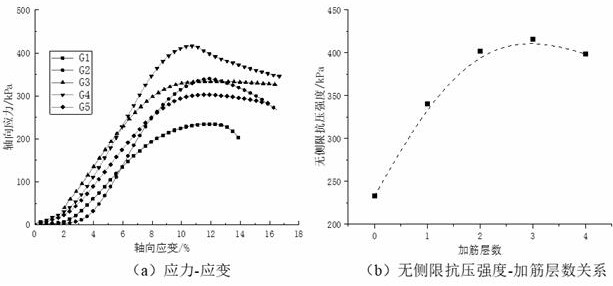

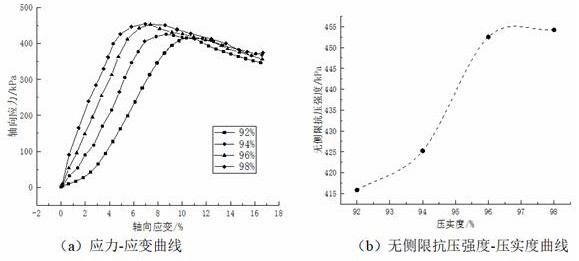

[0030] The invention provides a road structure processing method based on reinforced alkali slag improved soil. The prepared test piece is a cylinder with a diameter of 150mm and a height of 175mm. The waste generated by the process, the main components of alkali slag are CaCO3, CaO, CaCl2 and so on. The main components of the improved soil are: alkali slag, fly ash, and cohesive soil, and the ratio range is (25~35): (2~5): (65~80). The reinforcement adopts two-way geogrid, the width of the longitudinal rib is 5mm, and the width of the transverse rib is 6mm. 5.6mm. Its processing method comprises the following steps:

[0031] Step 1: Prepare alkali slag improved soil, take alkali slag, fly a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com