Deicing tool for electric equipment

A technology for power equipment and tools, which is applied in the field of deicing tools for power equipment, can solve problems such as hand numbness, reduce the work efficiency of deicing personnel, leakage and short circuit, etc., and achieve the effect of facilitating storage, improving user experience, and soft contact mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

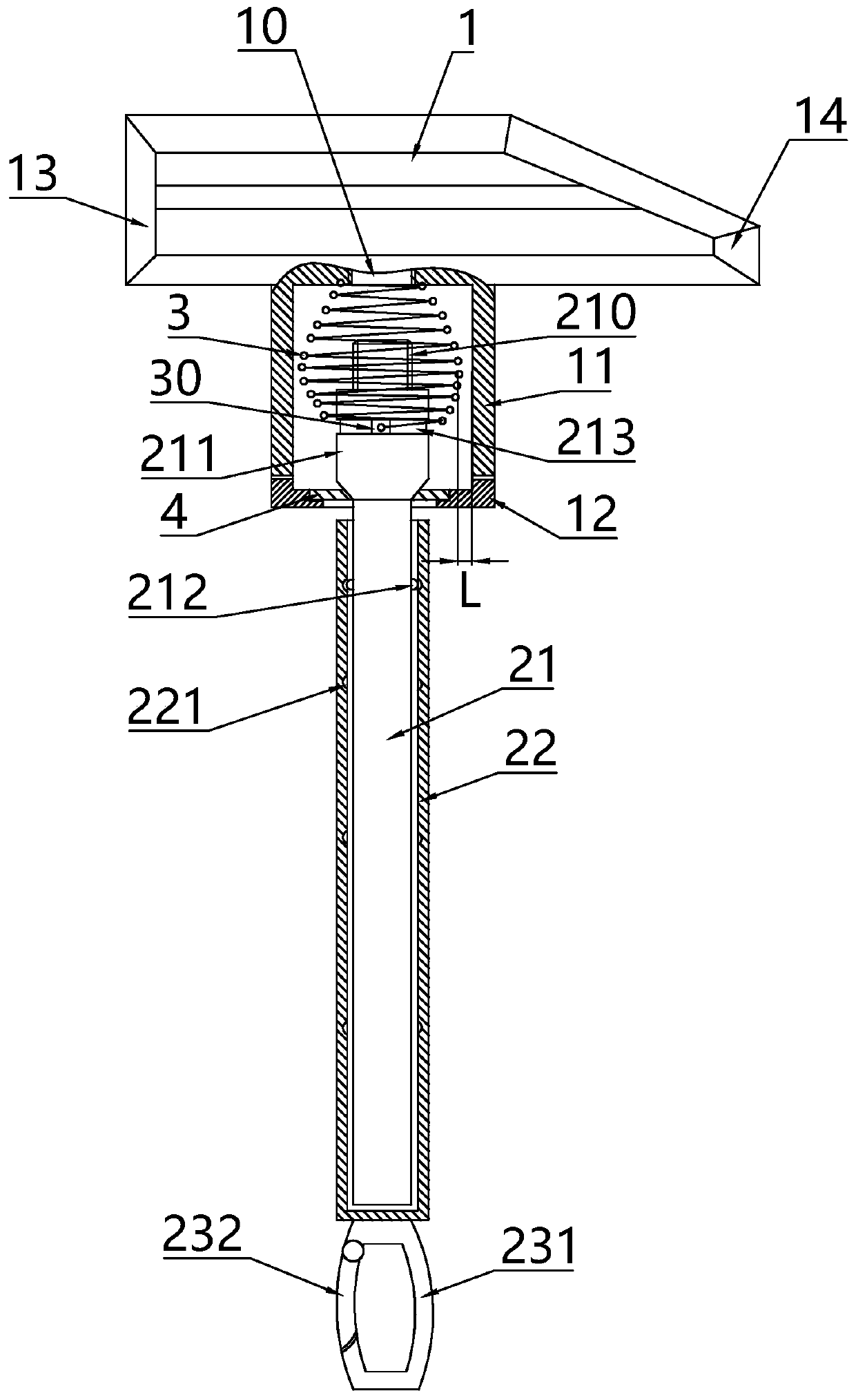

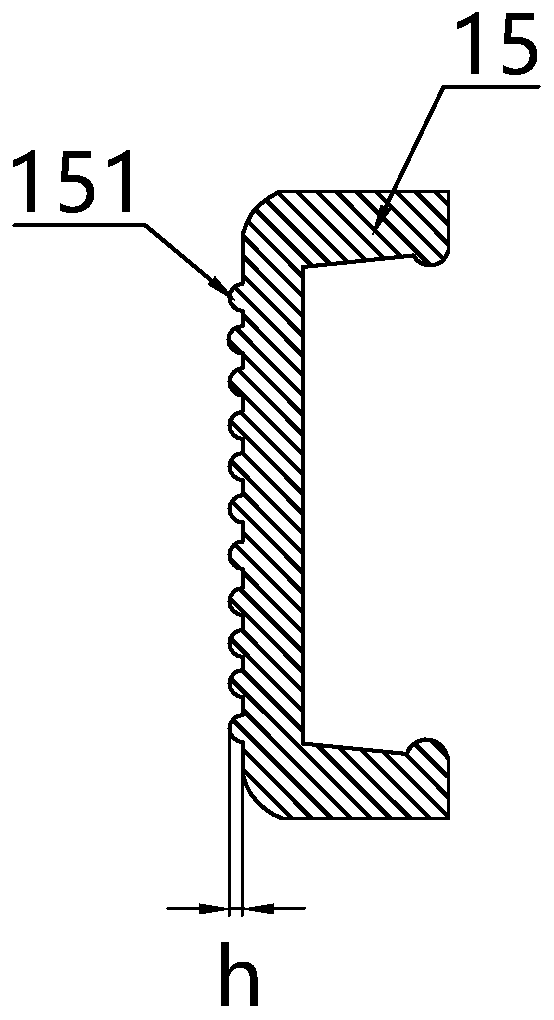

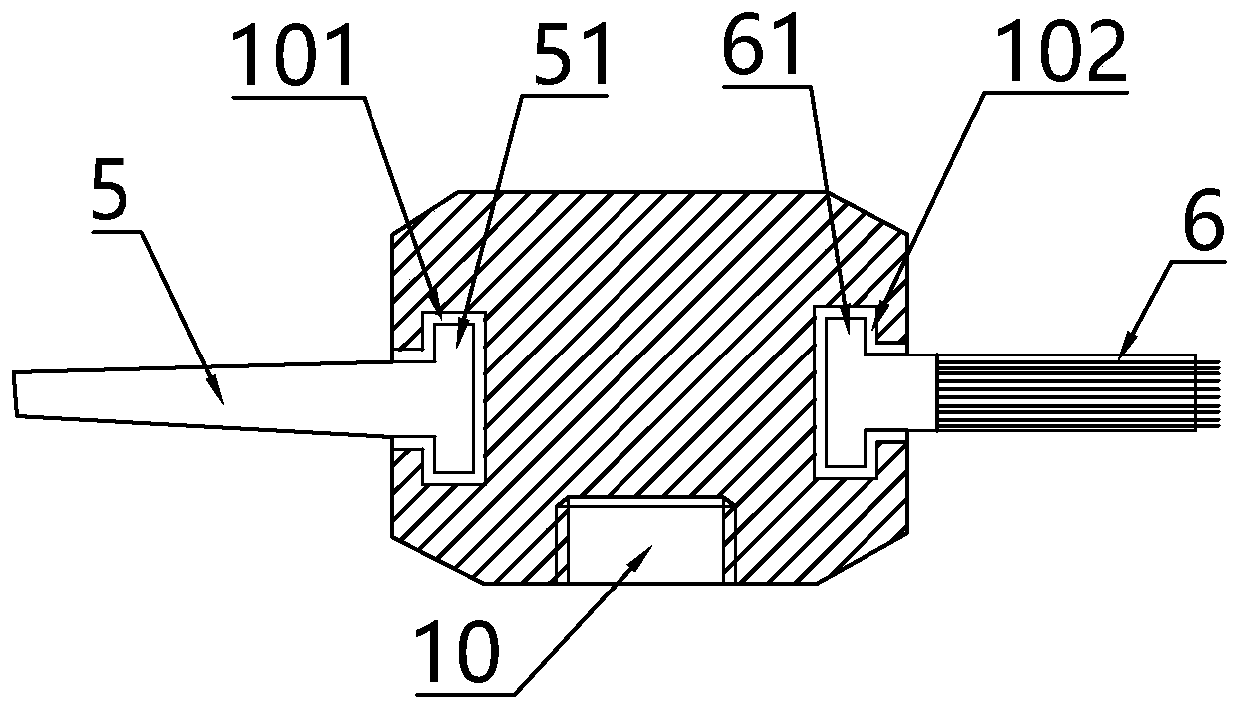

[0019] The invention provides a deicing tool for electric equipment, such as figure 1 As shown, it includes a hammer body 1 and a hammer handle. The hammer handle includes a telescopic rod. The telescopic rod includes an inner rod 21 and an outer rod 22 sleeved on the outside of the inner rod 21. The outer surface of the outer rod 22 is provided with a non-slip grip surface. , the end of the inner rod 21 near the hammer body 1 is provided with a connector 211, the top of the connector 211 is provided with a threaded post 210, the hammer body 1 is provided with a connecting cylinder 11 for the connector 211 to extend into, and the bottom wall of the connecting cylinder 11 is provided There is a threaded hole 10, the connecting head 211 and the hammer body 1 are detachably connected to the threaded hole 10 through the threaded column 210, the connecting head 211 is covered with a spring 3 and elastically connected to the connecting cylinder 11 through the spring 3, the spring 3 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com