Factory-like manufacturing of dam components and method for rapid construction of dams

A kind of technology of building dams and industrialization, which is applied in the field of dam construction and dam construction, which can solve the problems of long construction period, poor reliability, and shortage of stone materials, and achieve the effects of saving materials, improving stability, and speeding up construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

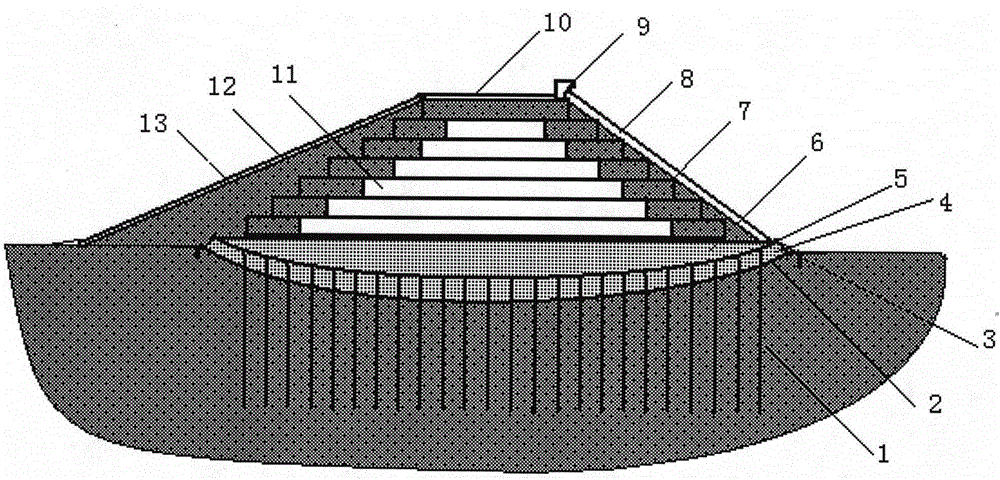

[0031] Embodiment 1 is a coastal soft foundation dam construction project, which is divided into 16 construction unit blocks, and its dam section is as follows: figure 1 As shown, the method includes the following steps:

[0032] A. Lay 500g / m on the embankment that has been measured and set out 2 Needle-punched non-woven geotextiles (2), throwing medium-coarse sand with a thickness of 2m and a mud content of less than 5% on the geotextile (2) as a sand cushion (4), interspersed in a triangular arrangement with a spacing of 1.5m, A vertical plastic drainage board (1) with a depth of 16m forms horizontal and vertical drainage channels; B. Buried instruments, set signs, and laid vacuum drainage pipes for filtration and drainage; covered with three layers of PVC sealing film (5), and excavated Vacuum preload the sealing membrane groove, lay the sealing membrane and backfill it with silt, and seal the surrounding sealing groove (3); install a vacuum pump, connect the main branch...

Embodiment 2

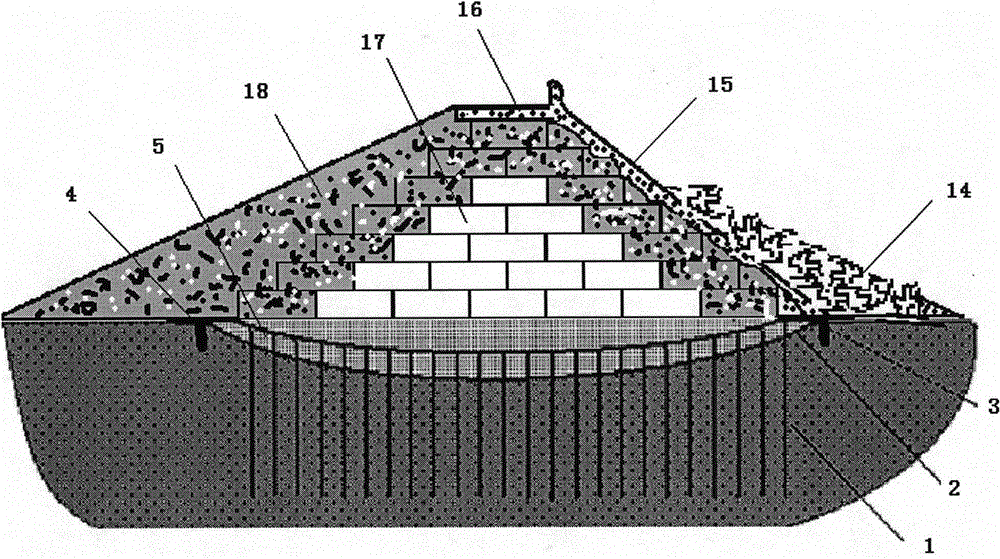

[0033] Embodiment 2 is the sea reclamation project of a certain soft foundation dam, and its dam section is as follows figure 2 Shown, its method is similar with embodiment 1, and difference is: F. fill the easy subsidence position of embankment core (11) with light material (17), mix with light material (17) in filling earthwork ( 18). G. After the embankment is stable, do a good job of laying the surface of the embankment top surface (10); use the top concrete (16) on the dike top, and adopt concrete (15) to form slope protection and masonry anti-wave walls (9) on the upper part of the embankment, With prefabricated 8 tons of twisting " king " block body wave-dispelling face protection, lay artificial face protection block body (14) from bottom to top.

[0034] Through the comparative analysis of various dams, the advantages of the present invention have been fully reflected: the added dam components are connected with each other to form the dam skeleton, which improves th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com