Construction method of high pressure mud retaining wall with underground diaphragm wall forming groove

A technology for underground diaphragm walls and mud retaining walls, which is applied in excavation, infrastructure engineering, construction, etc., can solve problems such as increased consumption, difficult separation of formation particles, and limited reinforcement depth, so as to achieve improved reliability, high sealing reliability, and reduced The effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

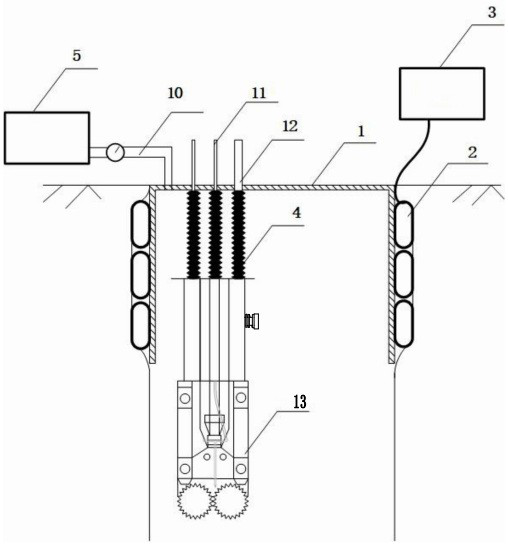

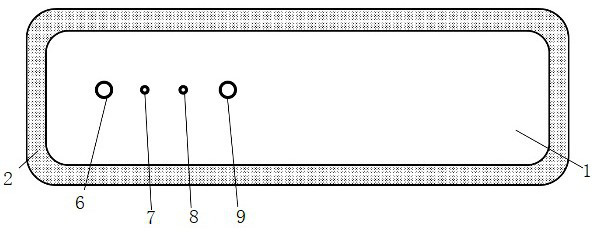

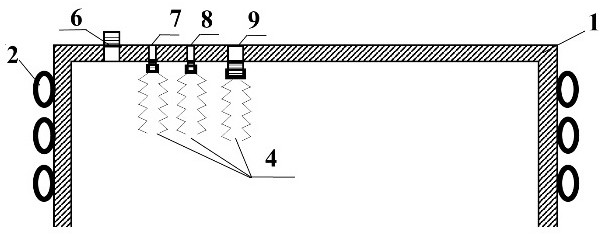

[0031] like Figure 1 to Figure 3 As shown in the figure, a method for constructing a high-pressure mud retaining wall in which an underground diaphragm wall is formed into a groove is characterized by comprising the following steps:

[0032] A. Forming the guide wall; before the underground continuous wall is constructed into a groove, the guide wall shall be constructed according to the specification requirements; if the deformation modulus of the soil body within 2 meters below the guide wall is low, the soil body shall be carried out along the guide wall before the guide wall is constructed. reinforcement.

[0033] B. Install the slot milling machine 13; both the suspension line 11 and the pulp outlet pipe 12 of the slot milling machine 13 pass through the reserved holes of the sealing device, and the suspension wire and the pulp outlet tube of the slot milling machine are placed on the slot milling machine 13 to guide The upper part of the frame; the suspension wire 11 p...

Embodiment 2

[0042] A method for constructing a high-pressure mud retaining wall in which an underground diaphragm wall is formed into a groove, such as Figure 4 As shown, the difference between Embodiment 2 and Embodiment 1 is that the end of the telescopic sealing sleeve 4 is provided with an annular connecting convex portion, and the annular connecting convex portion is connected with the corresponding equipment through screws. The annular connecting convex portion includes an annular folded surface 41 integral with the upper end of the telescopic sealing sleeve 4 , and the shape of the axial cross-section of the annular folded surface 41 is “M” shape. The outer end of the annular folding surface 41 is provided with a sealing edge 42 arranged around the outer end of the annular folding surface 41, and the shape of the sealing edge 42 is an "S" shape in cross-section; 4. The sealing lip 43 of the plane where the upper end is located.

Embodiment 3

[0044] A method for constructing a high-pressure mud retaining wall in which an underground diaphragm wall is formed into a groove, such as Figure 5 As shown, the difference between Embodiment 3 and Embodiment 1 is that: the slurry pipe 14 of the slot milling machine 13 is provided with a flat pressing hole 141, the flat pressing hole 141 is provided with an elastic film 142, and the flat pressing hole 141 is provided with a peripheral There is a flat pressure pipe 143 , a flat pressure column 144 is arranged in the flat pressure pipe 143 , a limit cap 145 is arranged at the outer end of the flat pressure column 144 , and an elastic reset member is arranged between the limit cap 145 and the slurry outlet pipe 14 . There is a flow cycle of slurry inlet and outlet in the groove, and the flowing slurry will cause the pressure difference between the slurry inlet and the slurry outlet. The slurry outlet pipe 14 of the milling machine 13 is located between the slurry inlet hole 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com