Construction method of steel-section-concrete T-shaped section column

A construction method and concrete technology, applied in the directions of columns, piers, pillars, etc., can solve the problems of complex and difficult construction, and achieve the effects of avoiding welding or drilling, improving seismic performance and easy construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawings and examples.

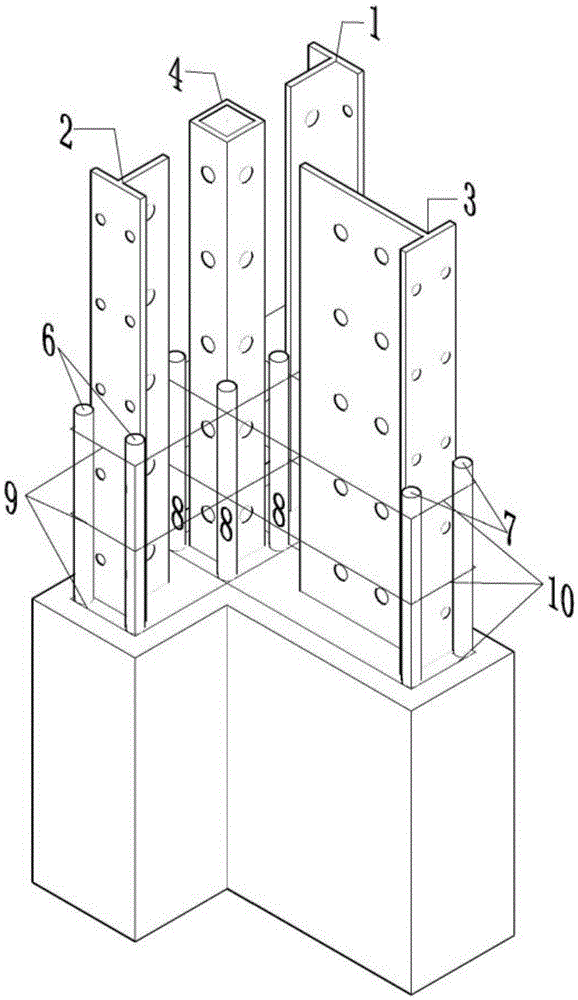

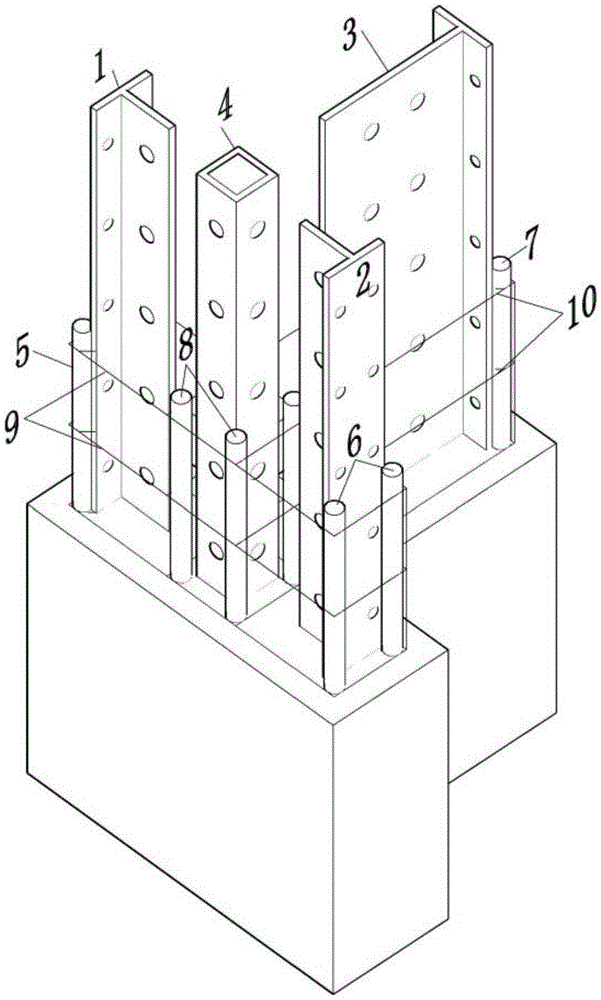

[0024] The present invention provides a construction method for steel concrete T-shaped cross-section columns for side columns in special-shaped column frame structures, including T-shaped cross-section concrete columns, T-shaped steel, square steel pipes, longitudinal bars, and stirrups. Configure T-shaped steel, square steel pipes, longitudinal bars and stirrups.

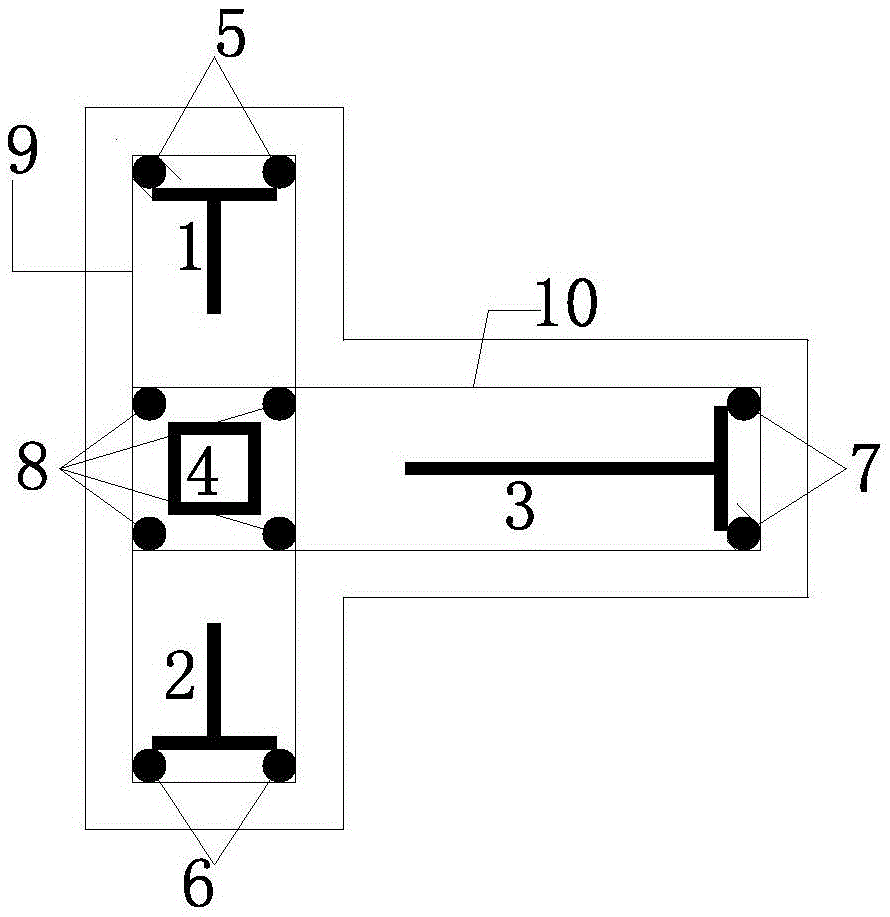

[0025] T-shaped section steels 1, 2, 3 are arranged in each column limb of the T-shaped cross-section column, and square steel pipes 4 are arranged in the core area. In order to strengthen the bond between the steel and concrete and ensure that the two work together, the symmetrical positions of the flange steel plates on both sides of the T-shaped steel, the symmetrical positions of the web and the steel pipe walls on the four sides of the square steel pipe are punched at a certain distance, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com