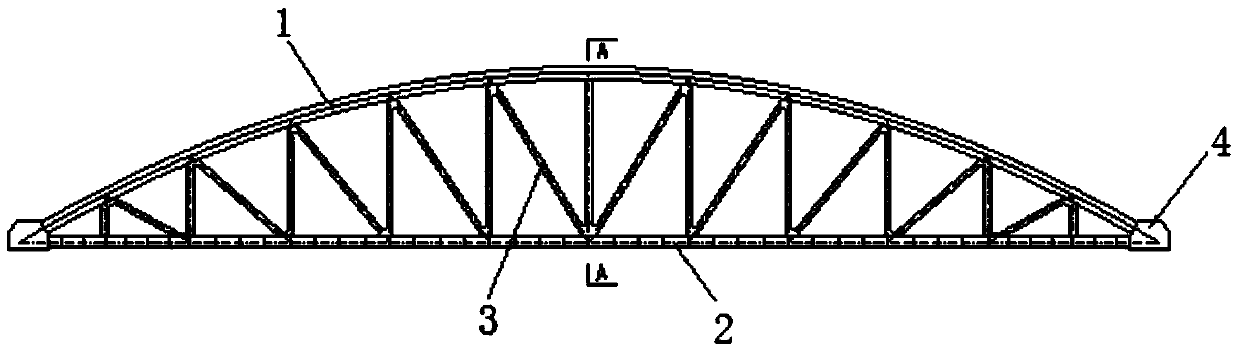

Steel tube truss arch bridge

A technology for steel pipe trusses and arch bridges, applied in the field of bridge structures, can solve the problems of increased steel consumption, high requirements for construction machinery, and difficult construction, and achieves the effects of low steel consumption, low construction machinery requirements, and project cost savings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

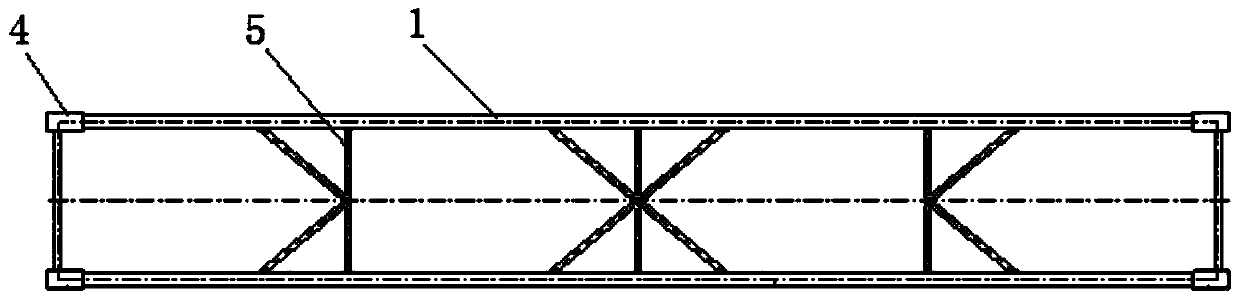

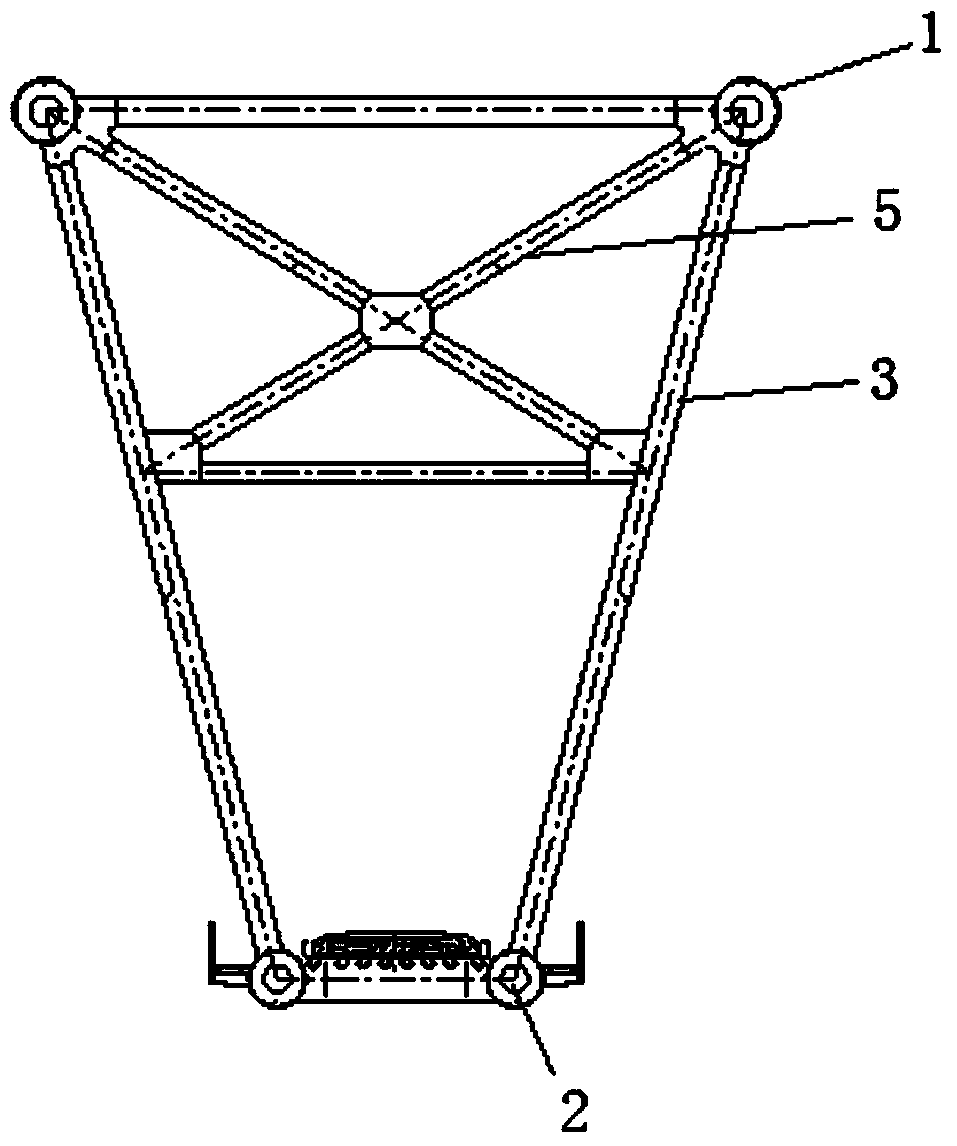

[0019] Embodiment: The present invention includes two hollow round steel pipe arch ribs 1, hollow round steel pipe tie beams 2 and cross braces 5, the cross braces 5 are welded between the two hollow round steel pipe arch ribs 1, and the hollow round steel pipe tie beams 5 The beam 2 is welded with a crossbeam 6 and also includes an arch foot connection device 4. The two ends of the hollow circular steel pipe arch rib 1 and the two ends of the hollow circular steel pipe tie beam 2 form a rigid knot through the arch foot connecting plate. A truss type web member 3 is connected between the belly of the steel pipe arch rib 1 and the hollow circular steel pipe tie beam 2 . A steel bridge deck 9 is continuously laid vertically and horizontally across the entire bridge above the crossbeam 6, and the steel bridge deck 9 is welded to the tie beam 2 longitudinally, and an I-shaped rib beam 7 is vertically arranged between the crossbeam 6 and the steel bridge deck 9. A U-shaped rib beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com