Straight pipe end clamping device of pipe expanding machine

A technology of a clamping device and a tube expander, which is applied in the field of clamping devices, can solve the problems of poor clamping consistency, difficult control, and unstable clamping, and achieves compact structure, improved consistency, and uniform force distribution. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

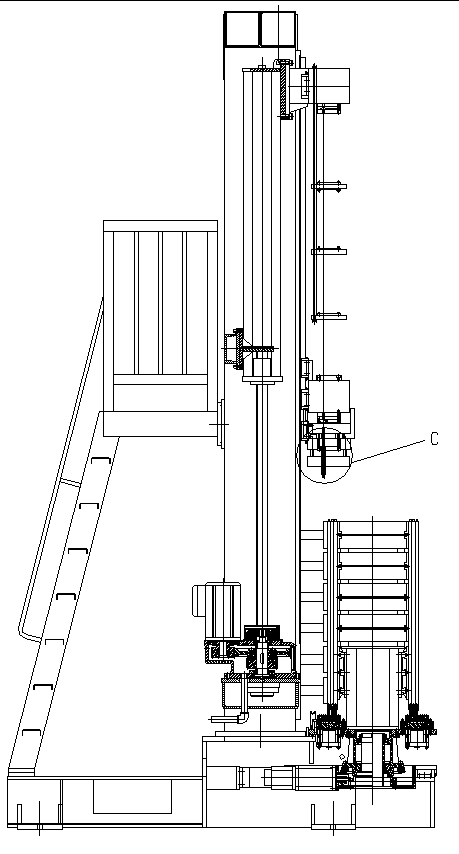

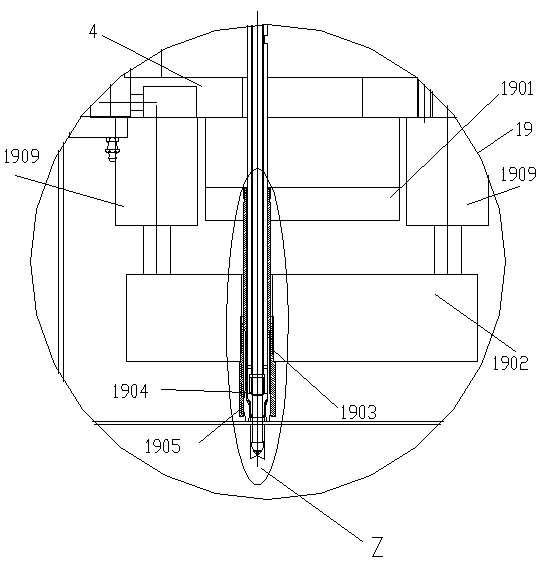

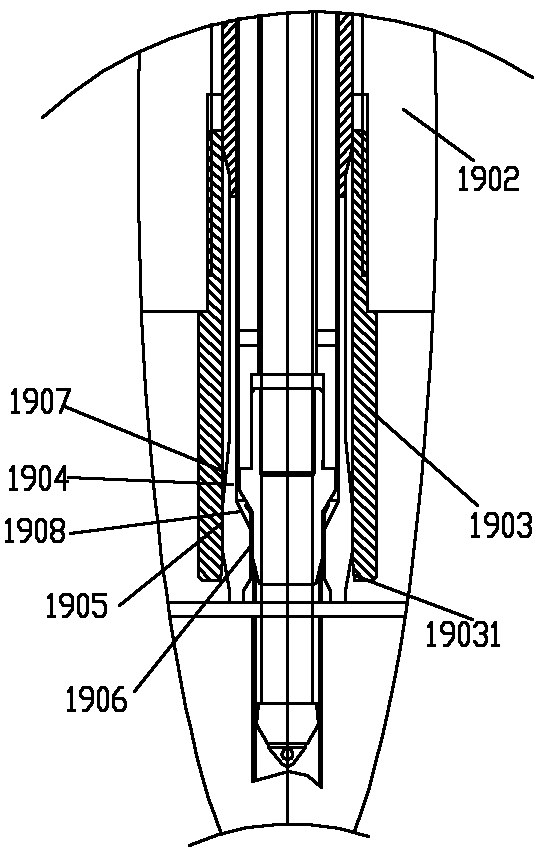

[0021] Such as figure 1 , 2 As shown, the straight pipe end clamping device 19 of the tube expander includes a clamping jaw mounting plate 1901 and a clamping sleeve mounting plate 1902 installed on the ejector base 4, and a clamping jaw 1904 is mounted on the clamping jaw mounting plate 1901. The tight sleeve 1903 is installed on the clamping sleeve mounting plate 1902, the head of the clamping jaw 1904 is provided with a cylindrical surface 1905 behind the largest conical surface, and there are several slits along the axial direction, and the clamping sleeve 1903 passes through The clamping sleeve mounting plate 1902 moves up and down to realize the opening and closing of the jaw 1904 head, thereby realizing the clamping and loosening of the straight pipe end of the workpiece. The driving mechanism oil cylinder 1909 drives the clamping slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com