Trolley lifting mechanism used for carrying surgical tools

A lifting mechanism and trolley technology, applied in the field of medical devices, can solve the problems of poor stability and large eccentric load, and achieve the effects of reducing force, running smoothly, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 provides a trolley lifting mechanism for carrying surgical tools, and its structure will be described in detail below.

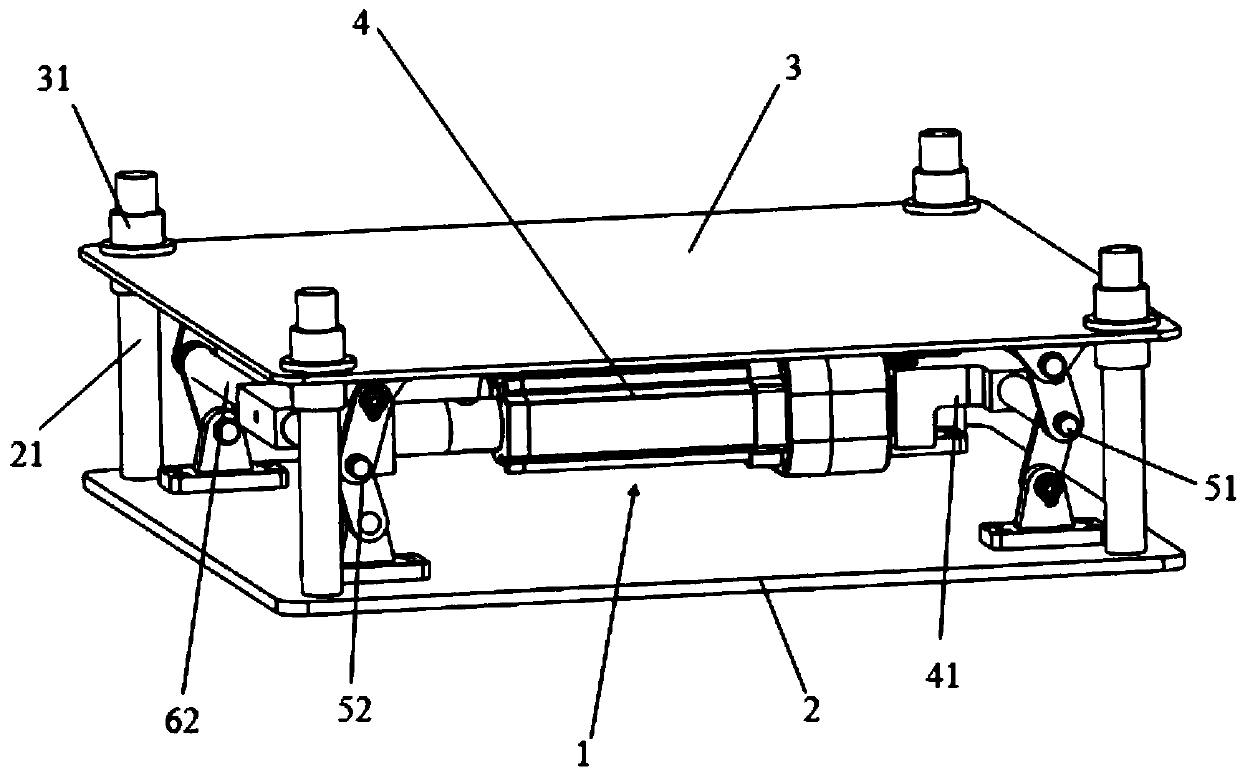

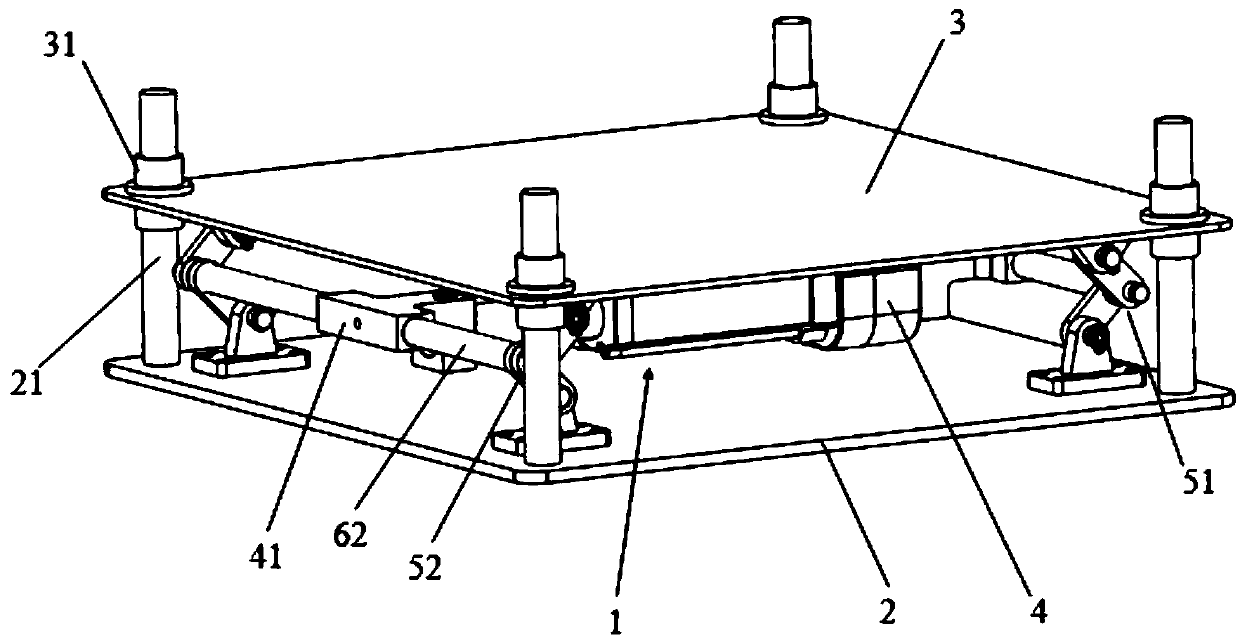

[0031] refer to figure 1 and figure 2 , the trolley lifting mechanism includes a connecting rod lifting mechanism 1, a lower plate 2, an upper plate 3 and an electric push rod 4, and the lower plate 2 is set on a support plane, which can be a flat ground, a floor surface, a desktop, etc. The lower plate 2 is parallel to the upper plate 3, four guide rods 21 are vertically fixed on the lower plate 2, and the connection lines of the projection points of the four guide rods 21 on the lower plate 2 are rectangular, and four guide rods 21 are vertically fixed on the upper plate 3. Cover 31, the connection line of the projection points of four guide sleeves 31 on the upper plate 3 is a rectangle, the guide rod 21 is a straight rod, the two ends of the guide sleeve 31 are open, and the four guide rods 21 are respectively installed on the four ...

Embodiment 2

[0041] In order to further improve the stability of the trolley lifting mechanism, on the basis of Embodiment 1, Embodiment 2 improves the hinge 80 and its connection relationship. The improvements are as follows:

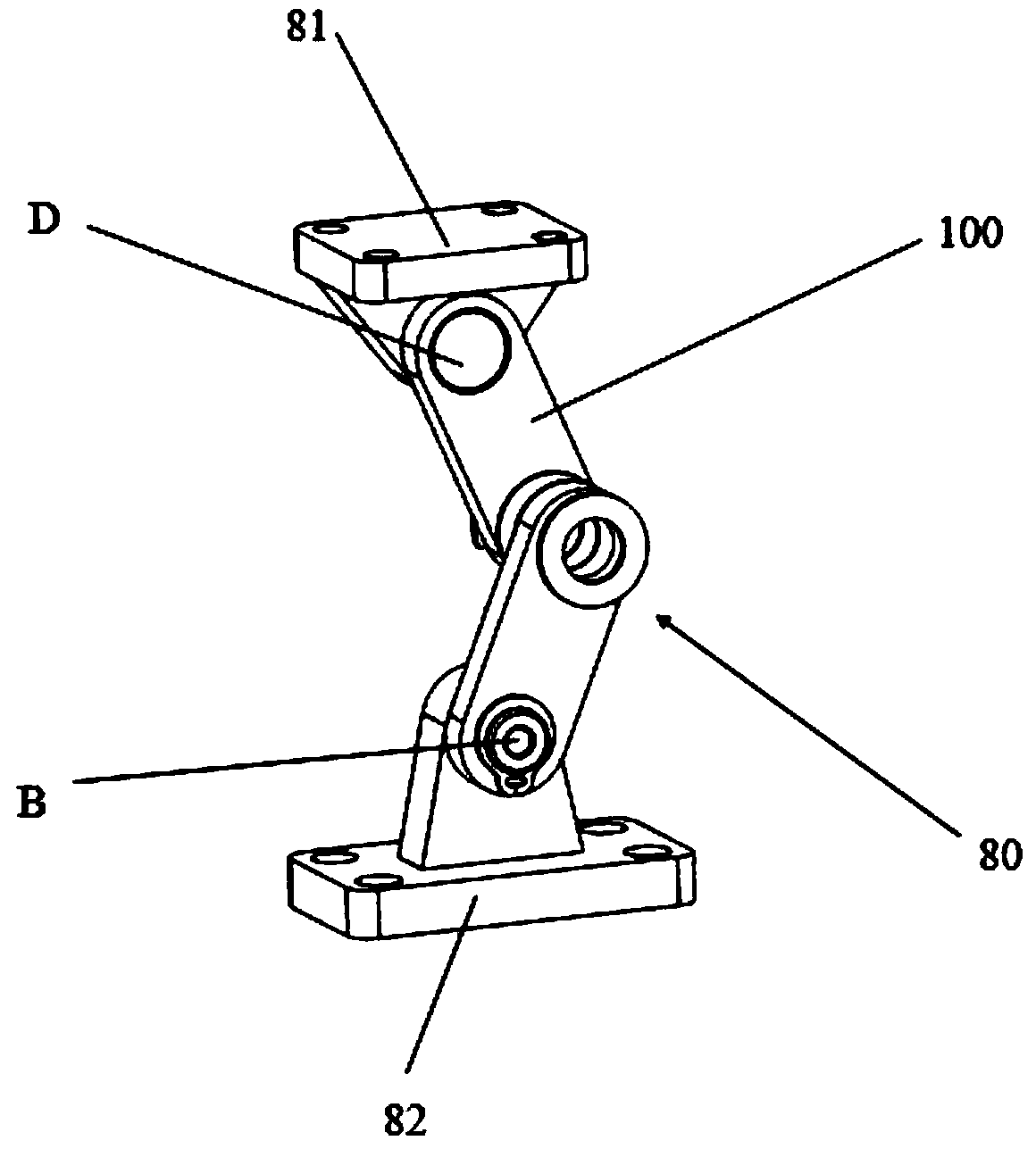

[0042] refer to Figure 6 , the hinge 80 includes four jacking rods 100, the hinge 80 is connected end to end by the four jacking rods 100 to form a parallelogram, and the two adjacent jacking rods 100 at the upper part are hinged through the upper hinge hole D, and the two lower Adjacent jacking rods 100 are hinged through lower hinge holes B, two adjacent jacking rods 100 on the left are hinged through outer hinge holes A, and two adjacent jacking rods 100 on the right are hinged through inner hinge holes C.

[0043] refer to Figure 7 , the settings of the left force beam 62 and the right force beam 61 are selected from one of the following two ways:

[0044] In the first type, the two ends of the right force transmission beam 61 are respectively penetrated in...

Embodiment 3

[0047] In order to further improve the stability of the lifting mechanism of the trolley, on the basis of Embodiment 2, Embodiment 3 improves the connection relationship between the hinges. The improvements are as follows:

[0048] refer to Figure 8 to Figure 11 , the link lifting mechanism 1 also includes a first front stabilizer bar 71, a second front stabilizer bar 72, a first rear stabilizer bar 73 and a second rear stabilizer bar 74,

[0049] The inner hinge hole C of the first hinge part 51 on one side is connected with the outer hinge hole A of the second hinge part 52 through the first front stabilizer bar 71, and the outer hinge hole A of the first hinge part 51 on the same side is connected with the second hinge hole A. The inner hinge hole C of the member 52 is connected through the second front stabilizer bar 72;

[0050] The inner hinge hole C of the first hinge part 51 on the other side is connected with the outer hinge hole A of the second hinge part 52 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com