Netting method of superlarge mesh netsheet

A mesh and mesh technology, which is applied to the field of tying of super-large mesh mesh, can solve the problems of large weaving site requirements, poor knot firmness, low weaving efficiency, etc., so as to improve production efficiency and maintain integrity. , the effect of improving the speed of tying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

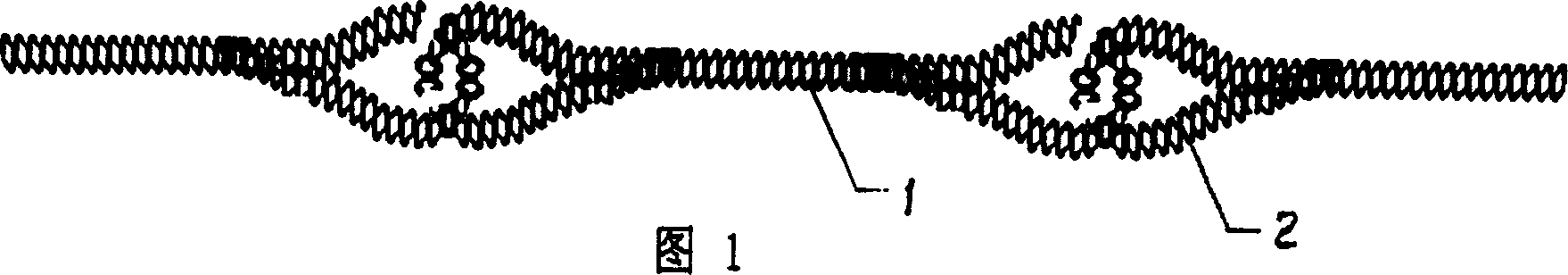

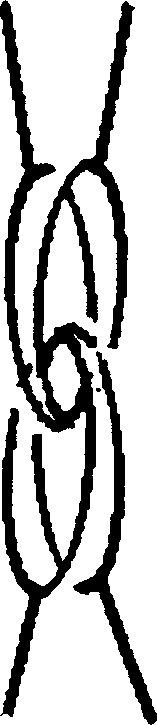

[0012] The best way to implement the present invention is illustrated below in conjunction with the accompanying drawings: at first the mesh is decomposed into mesh pins, and the mesh wire specification and the mesh pin length blanking are used according to the mesh; 2 times the mesh number of the fixed mesh, connect the mesh feet to the long rope, as shown in Figure 1, Figure 4 ; Then arrange the long ropes connected by the 2 mesh foot strings along the W shape, see Figure 5 , Figure 6 According to the set mesh shape, the corresponding mesh feet of the long rope connected by two mesh feet are connected in series with the rope sleeves with added mesh feet 51 or 61 to form a set mesh, such as hexagonal mesh or rhombus mesh Mesh; repeat the above operations to form a woven mesh.

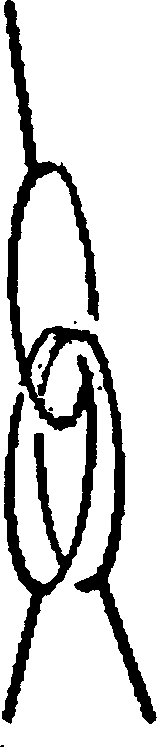

[0013] When the 3 mesh pins are connected to each other, see figure 2 , such as a hexagonal mesh, the noose of each mesh foot is connected in series with the rope casings of the other two mesh fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com