Method for determining cutter head thickness of full face tunnel boring machine

A tunnel boring machine and a technology for determining methods, which are applied in computer-aided design, special data processing applications, instruments, etc., can solve the problems of uneven force on the tool, no effective method, and prolonging the construction period, so as to reduce the construction cost. Cost reduction, unevenness reduction, and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

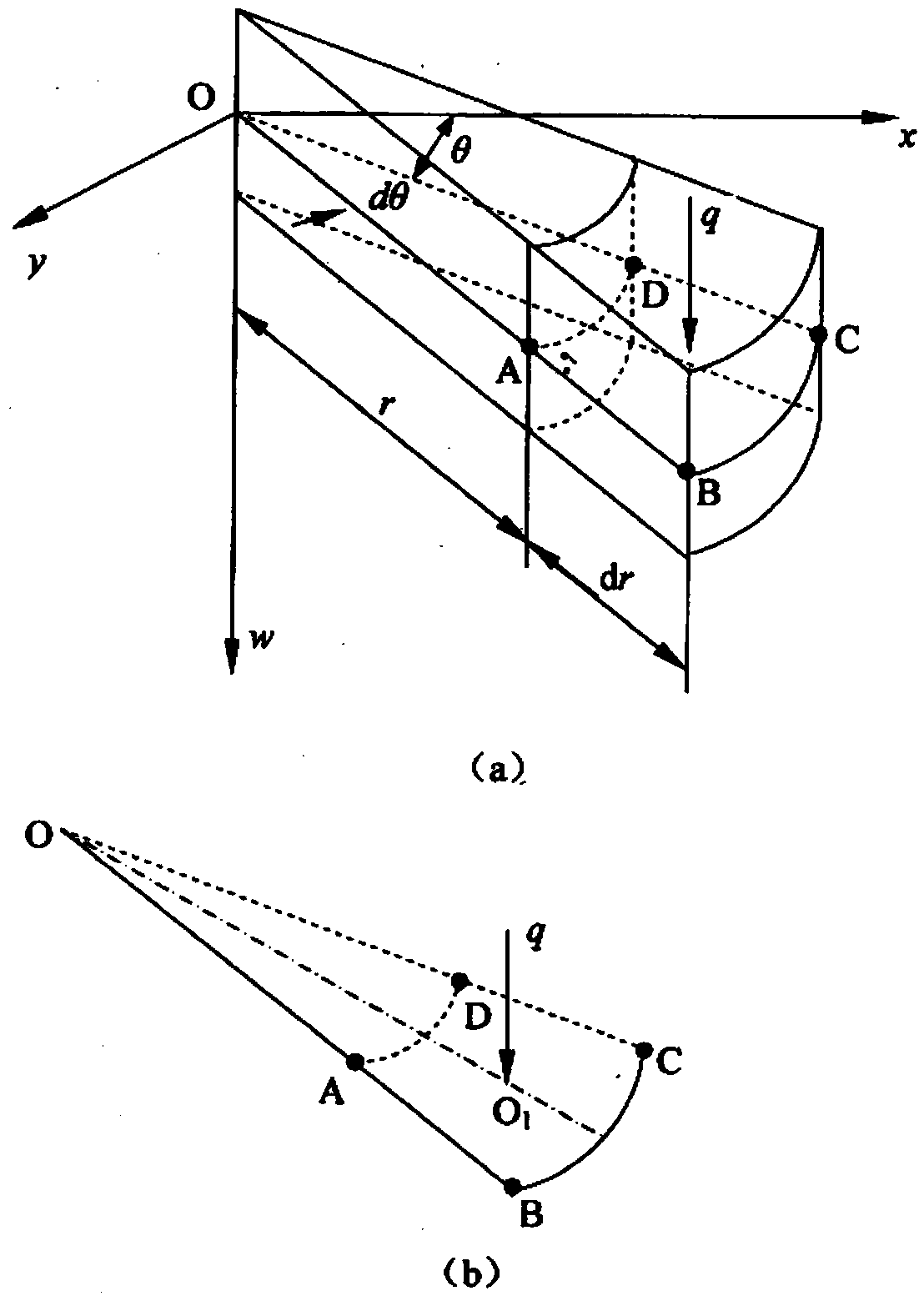

[0031] The method of determining the thickness of the cutter head of the full-face roadheader is based on the elastic mechanics theory. The deflection w(r,θ) of the TBM cutter head under the action of its lateral load q is:

[0032]

[0033] In the formula: D is the bending stiffness of the TBM cutter head, Among them, E is the Young's modulus of elasticity of the TBM cutterhead material, t is the thickness of the TBM cutterhead, μ is the Poisson's ratio of the TBM cutterhead material; to simplify the formula, introduce Among them, r and θ are polar coordinates; when w and q are in the same direction, take positive, otherwise take negative; figure 1 The surface load acting on the polar coordinate (r, θ) unit of the TBM cutterhead unit is shown, (a) the TBM cutterhead unit body, (b) the unit block of the TBM cutterhead unit body midplane.

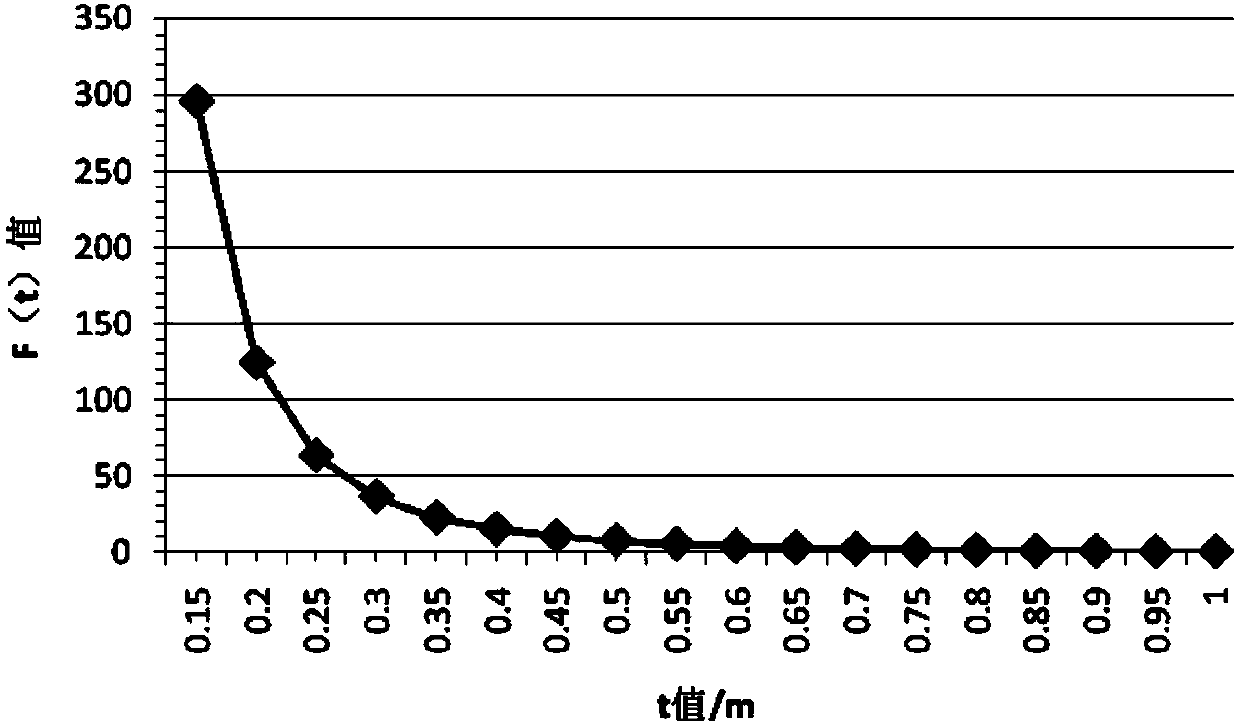

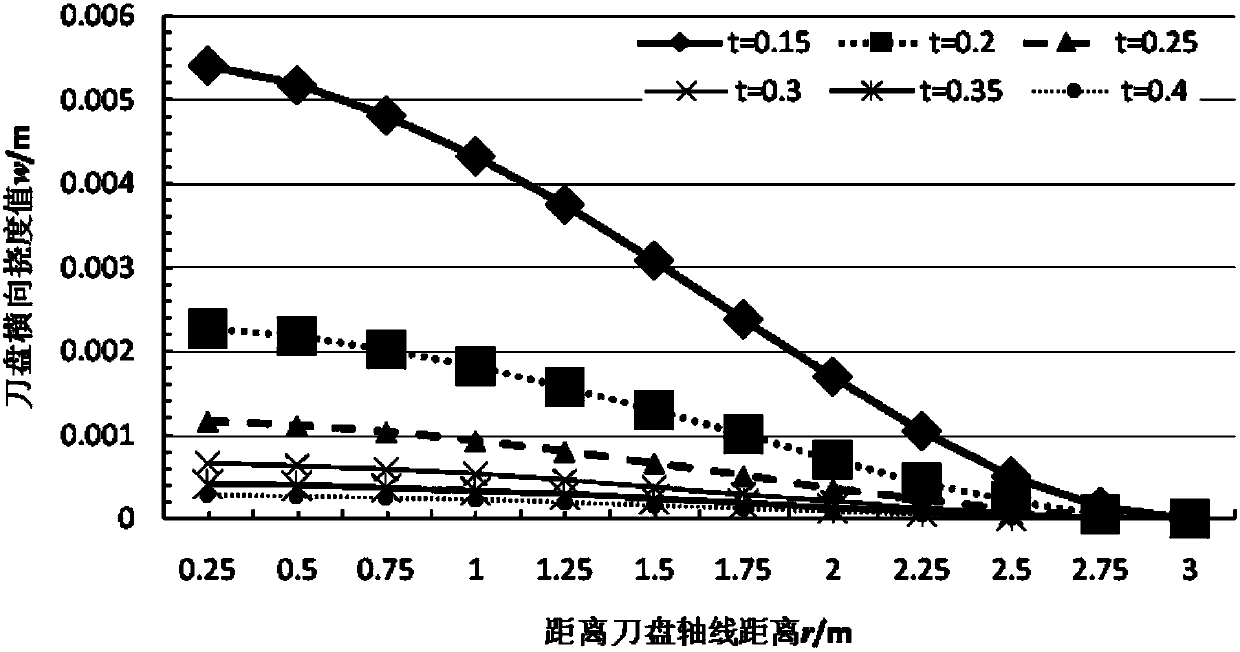

[0034] According to the above calculation and analysis, the material parameter of a certain type of full-face rock boring machine cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com