Assembly planetary carrier for wind power

A planet carrier, combined technology, applied in wind power generation, wind turbine, installation/support configuration of wind turbine, etc., can solve the problems of two-disk planetary bearing eccentric load, planetary bearing failure, torque difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

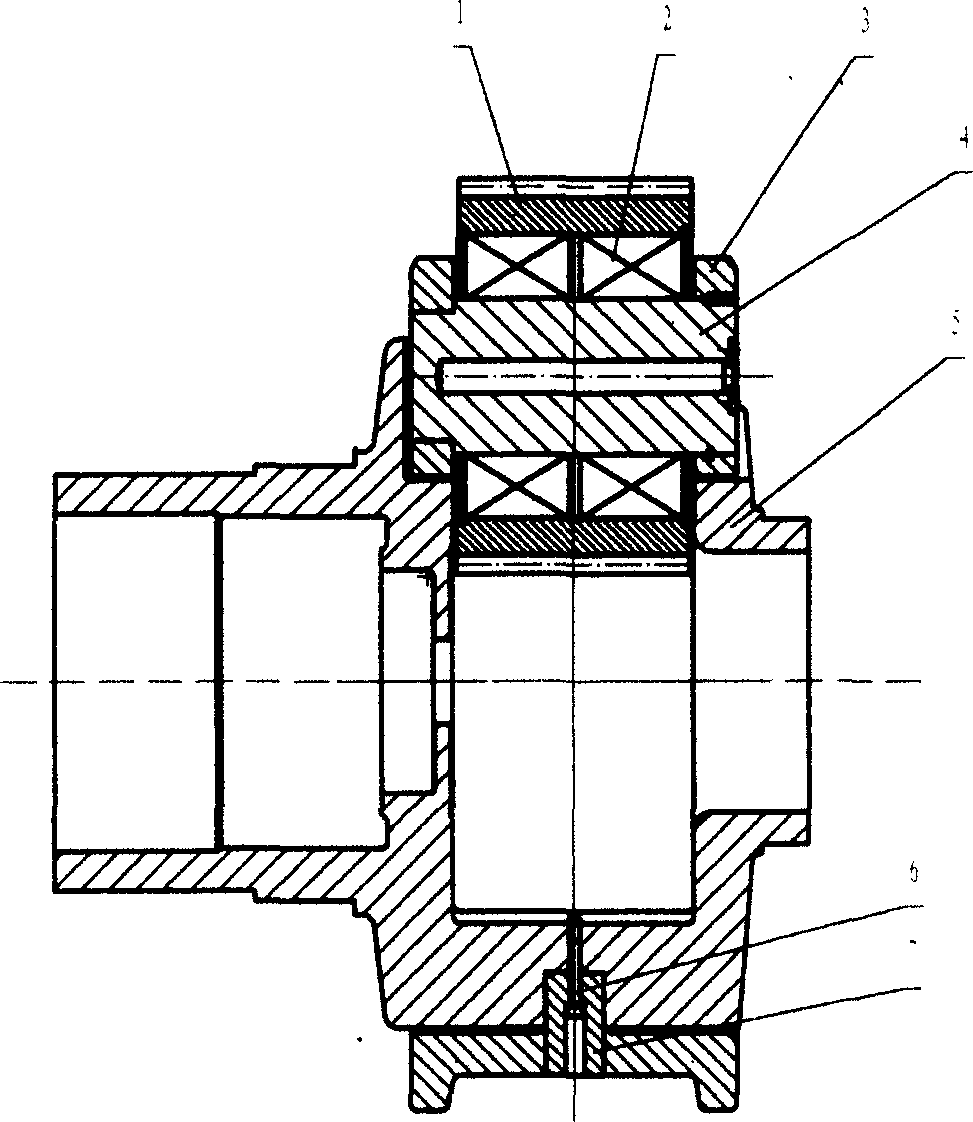

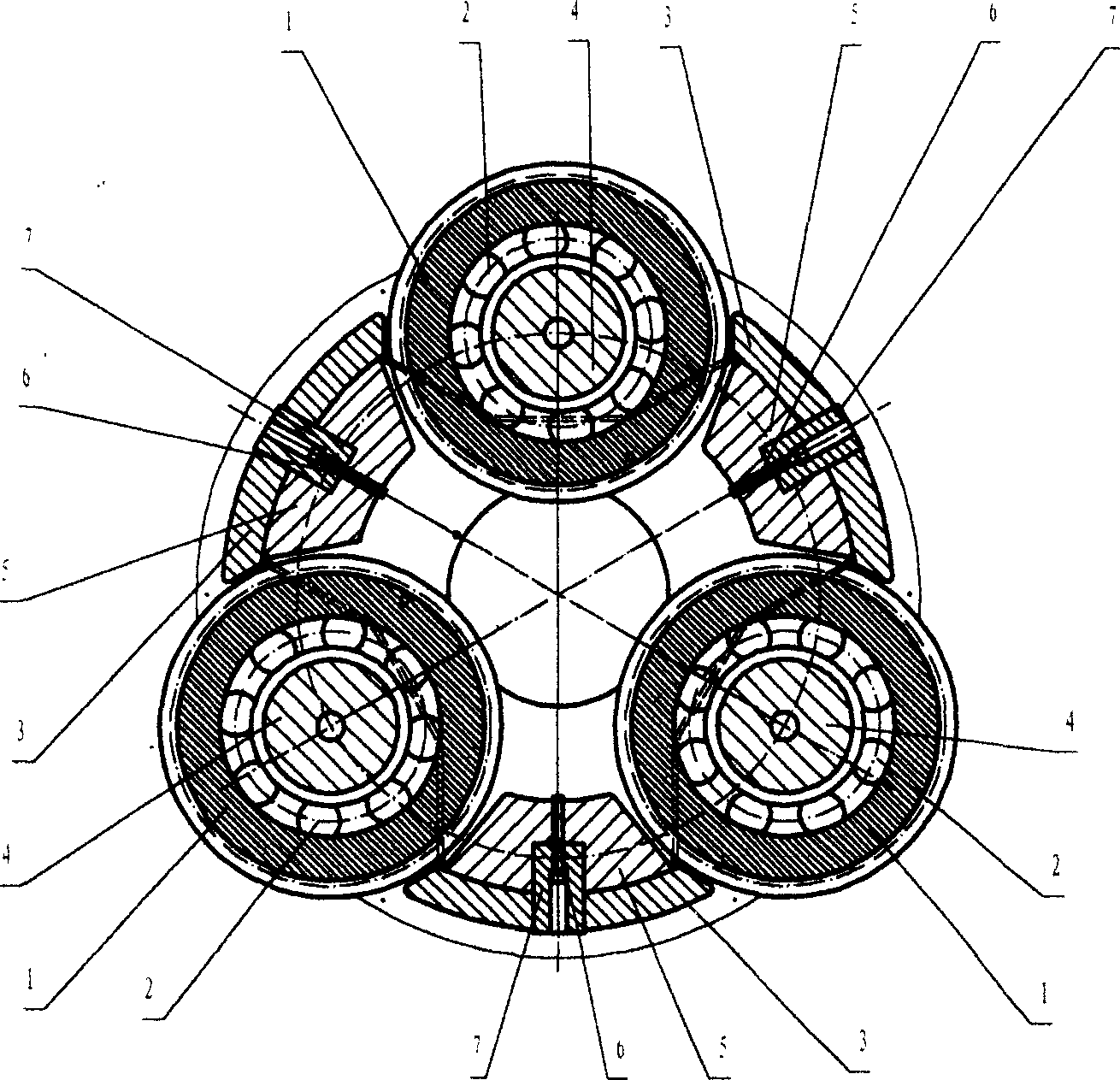

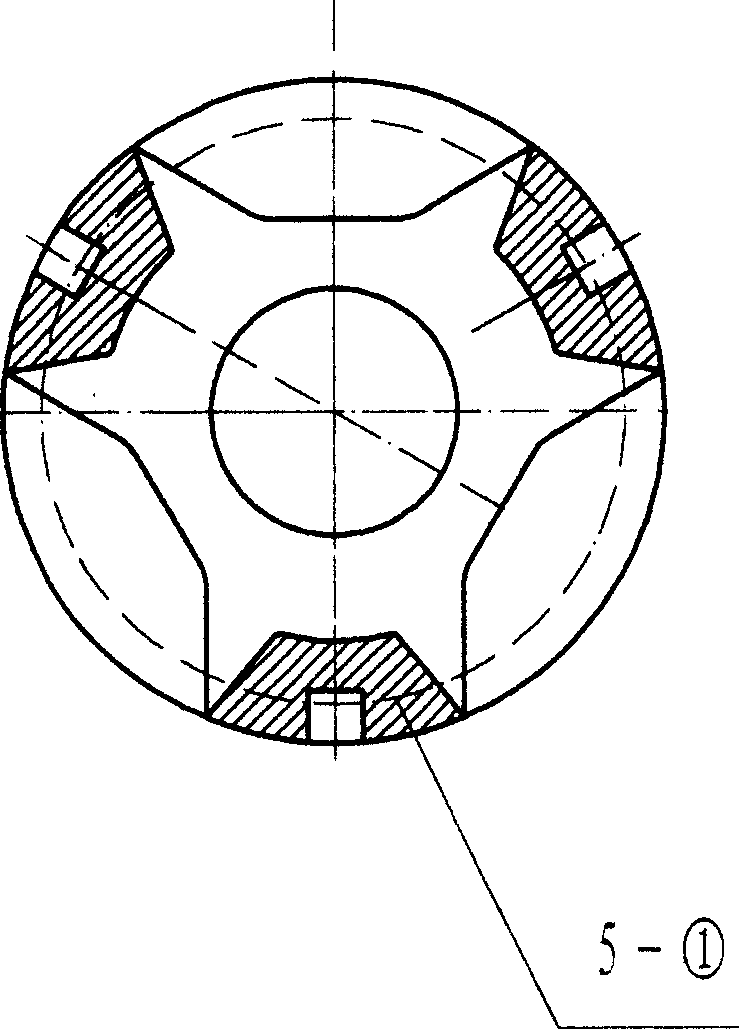

[0020] refer to figure 1 , figure 2 , the present invention is mainly made up of four components, namely the planetary inner frame (5) with connecting plate is socketed with the planetary outer frame (3) with orifice plate, the connecting plate on the planetary inner frame (5) [(5) The middle position of -①] is to install a connecting piece (7) that transmits torque [such as a cylindrical pin or a connecting piece of other shape], and has an annular joint surface with the smallest axial dimension that can closely match the size of the connecting piece (7) [3-②], the inner and outer planetary frames (5, 3) are connected with connectors (7) and fixed with fasteners (6) [such as fastening bolts or other fasteners], the planetary outer frame after assembly (3) contact with the planetary inner frame (5) only at the ring joint surface [3-②], and other positions are suspended in the air. The orifice plate [3-①] of the outer planetary frame (3) is provided with a hole for fixing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com