A tool magazine control system and its control method

A control system and control method technology, applied in manufacturing tools, metal processing machinery parts, positioning devices, etc., can solve problems such as affecting processing efficiency, poor surface processing effect of workpiece, machine vibration, etc., to avoid damage to tool magazines , The effect of reducing the eccentric load of the tool magazine and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]The preferred embodiments of the present invention will be described in detail below.

[0050] The following descriptions of various embodiments refer to the accompanying drawings to illustrate specific embodiments according to which the present invention can be implemented. The directional terms mentioned in the present invention, such as "up", "down", "front", "rear", "left", "right", "inside", "outside", "side", etc., are only for reference Attached directions. Therefore, the directional terms used are used to illustrate and understand the application, but not to limit the application. Also, in the specification, the word "comprise" or "comprising" should be understood as meaning including the element, but not excluding any other element, unless it is clearly described to the contrary.

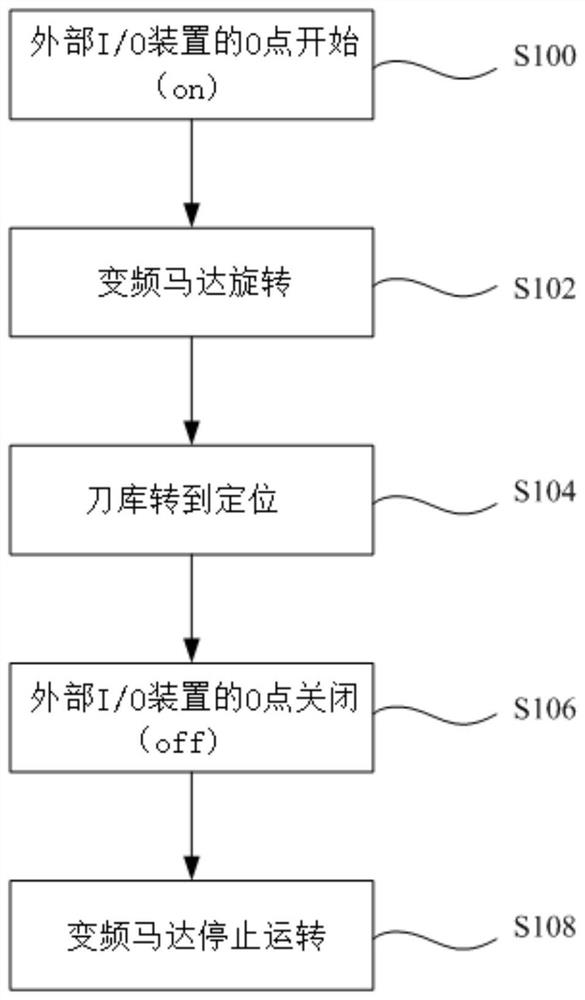

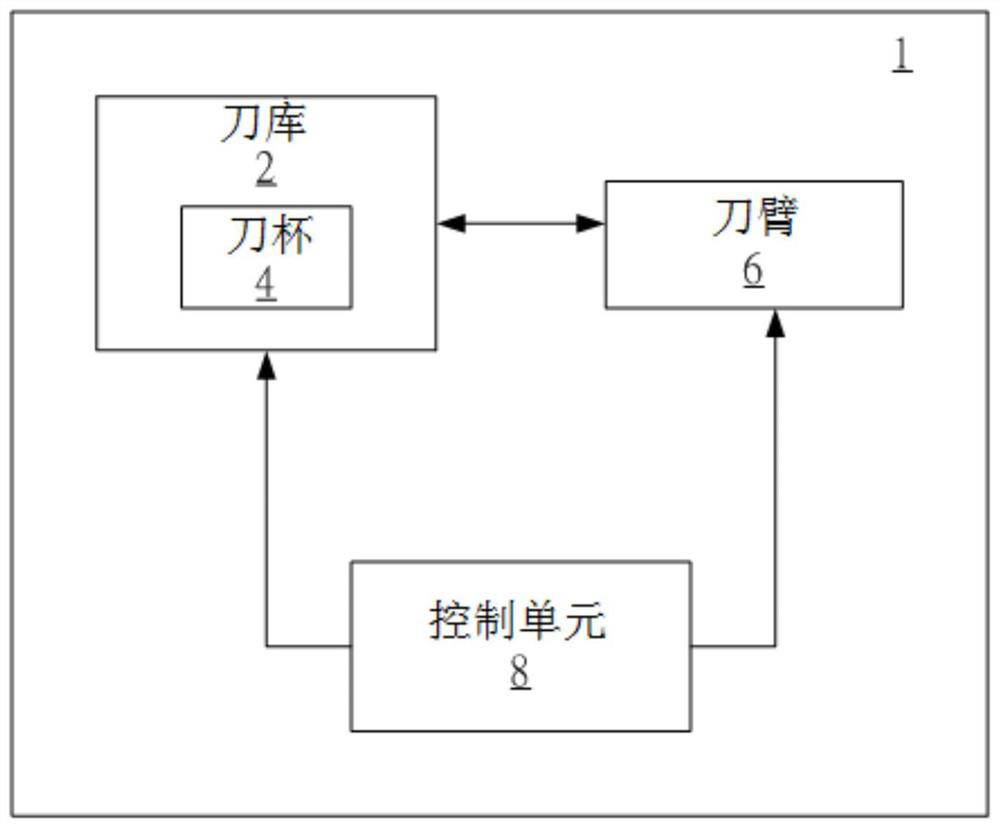

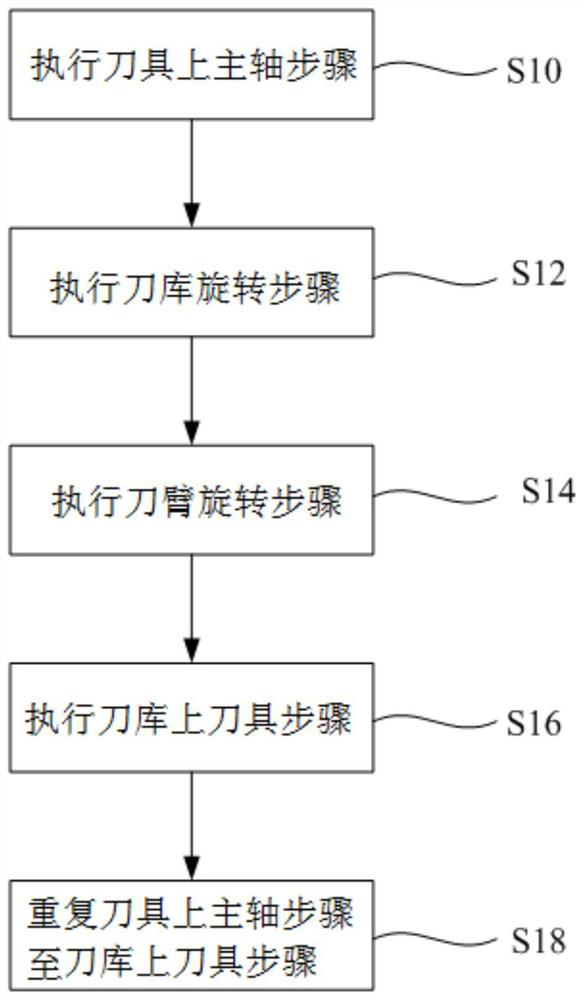

[0051] first reference figure 2 . figure 2 It is a block diagram showing the tool magazine control system according to the technology disclosed in the present invention.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com