Rotary shearing and impact linkage single pneumatic anchor bolt drill

A technology of bolt drilling rig and impact coupling, which is applied in the installation of bolts, drilling equipment, earth-moving drilling, etc., can solve the problems of affecting drilling efficiency, coal mining imbalance, slow drilling speed, etc., to improve production and economic benefits. , the effect of alleviating the tension of mining replacement and reducing unilateral wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

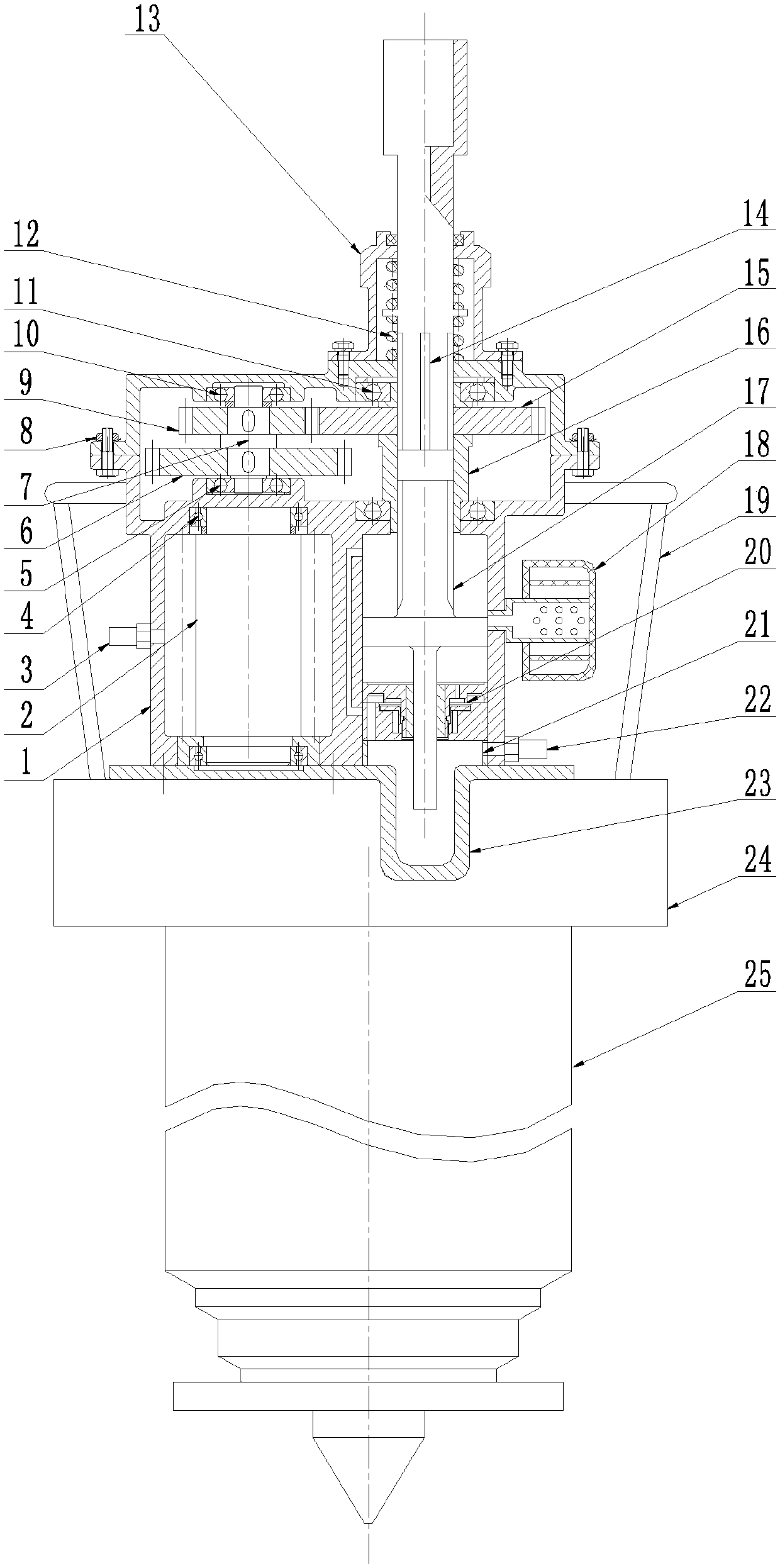

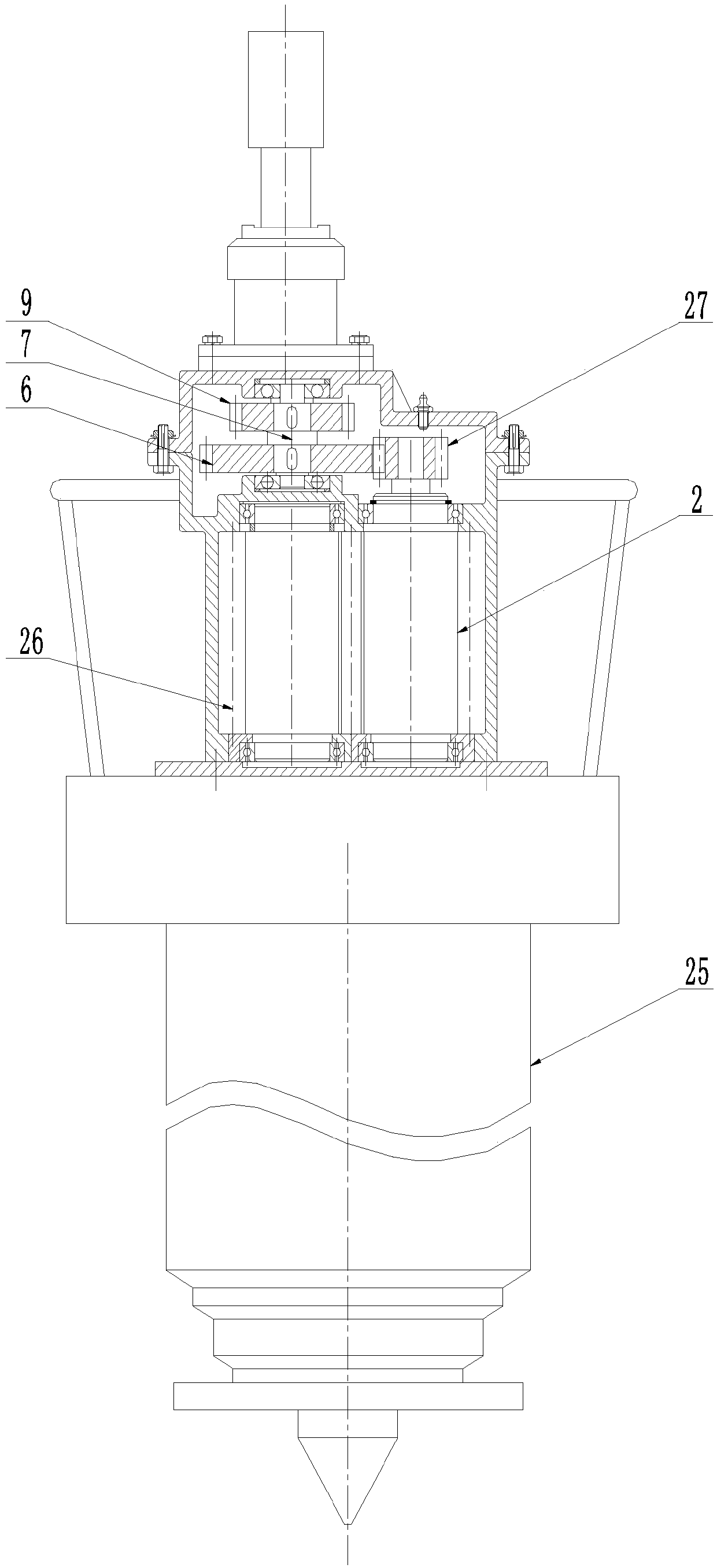

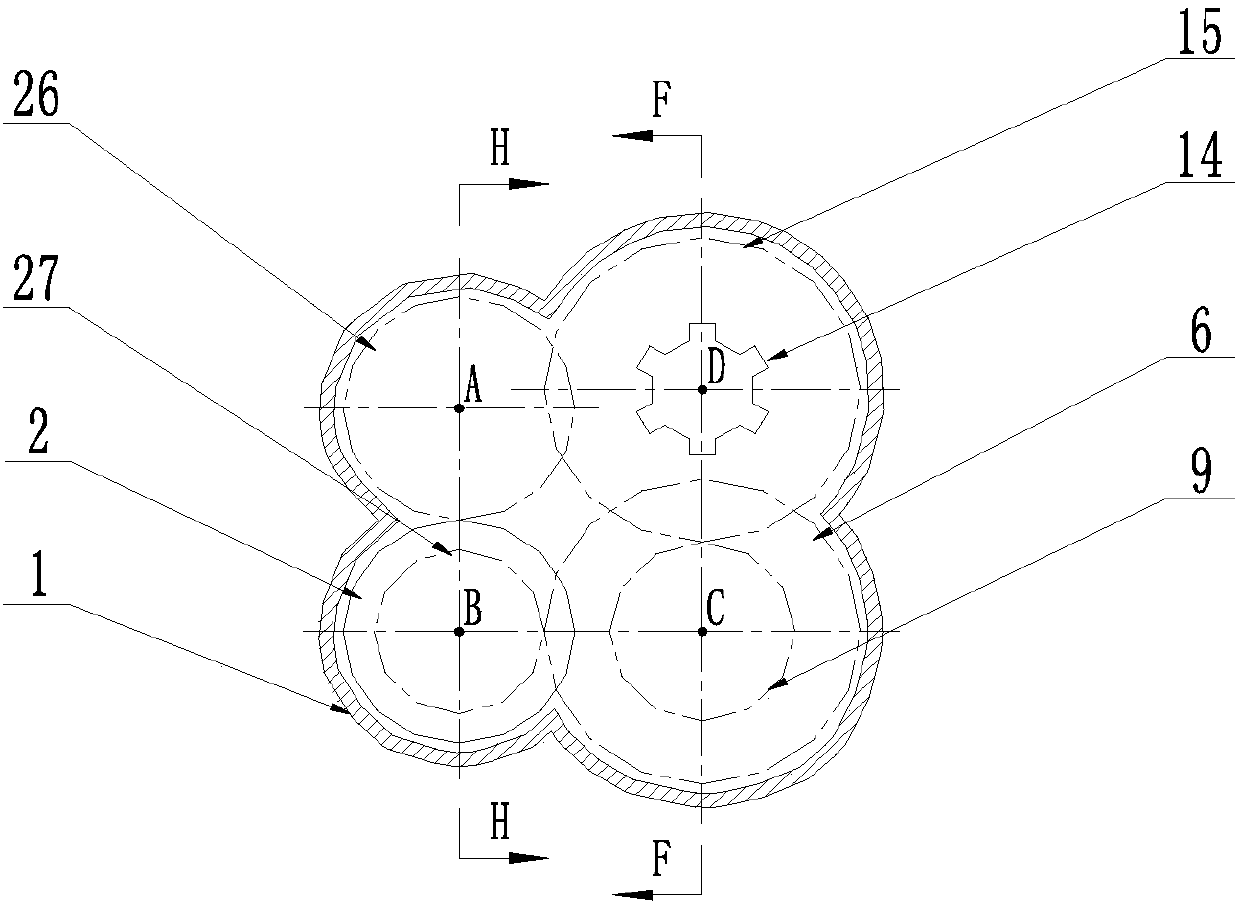

[0019] Such as figure 1 with figure 2 Shown are the F-F cross-sectional view and H-H cross-sectional view of the bolting machine of the present invention, which are image 3 Cut along the F-F line and H-H line. The roof bolter is composed of box body (1), air motor gear I (26), air motor gear II (2), reducer gear I (27), reducer gear II (6), reducer gear III (9) , Reducer gear IV (15), reducer gear shaft (7), main shaft (14), ring valve (20), piston (17), fiberglass leg (25), etc.

[0020] For general rocks, turn on the air intake switch of the pneumatic gear motor, and the compressed air drives the pneumatic gear motor through the compressed air inlet (3) to generate rotational torque, which is transmitted to the splined spindle (14) via gear sets 2, 27, 6, 9, and 15 ), the spindle (14) drives the drill rod and the drill bit to rotate and cut the rock.

[0021] When encountering hard rock formations, open the air inlet switch of the impact device, compressed air enters the air c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com