Profile forming device and method for heat dissipation element with micro-channel offset layout

A technology of heat dissipation elements and micro-channels, applied in the direction of metal extrusion dies, etc., can solve the problems of die wear or cracking, affecting the shape and dimensional accuracy of profiles, and die core deflection, reducing die core offset and improving die. Longevity, reduced wear and eccentric loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

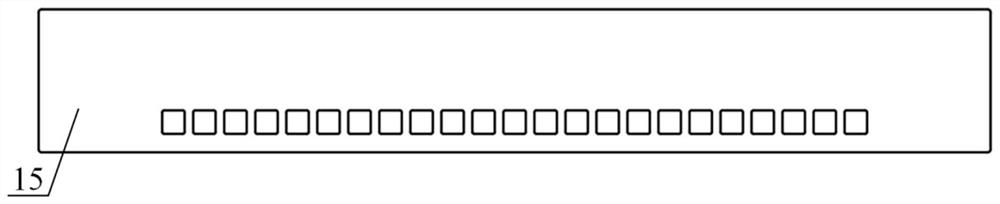

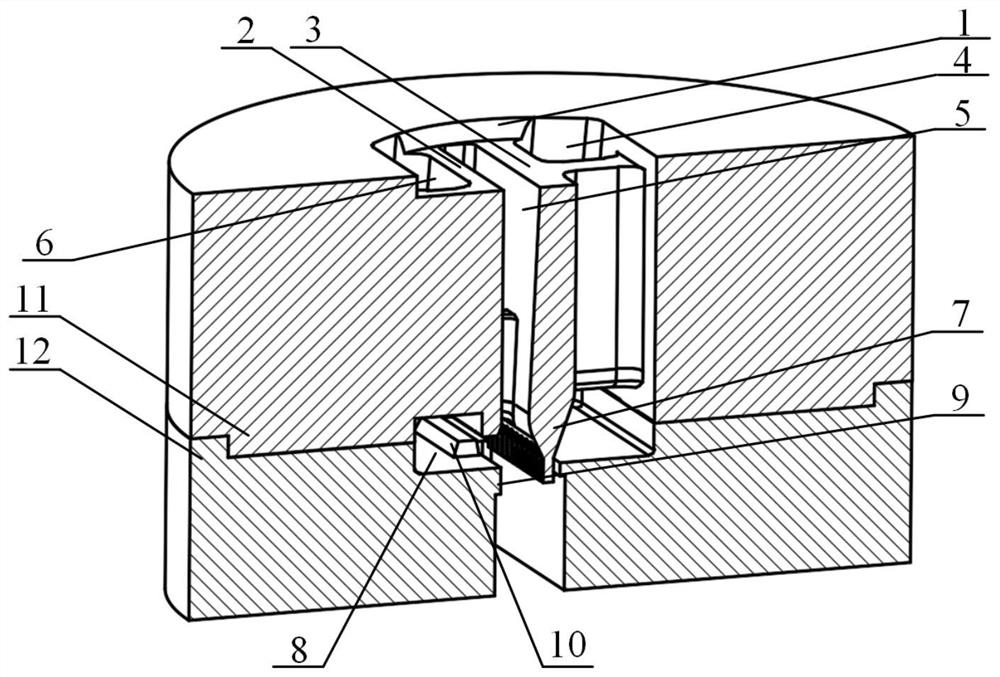

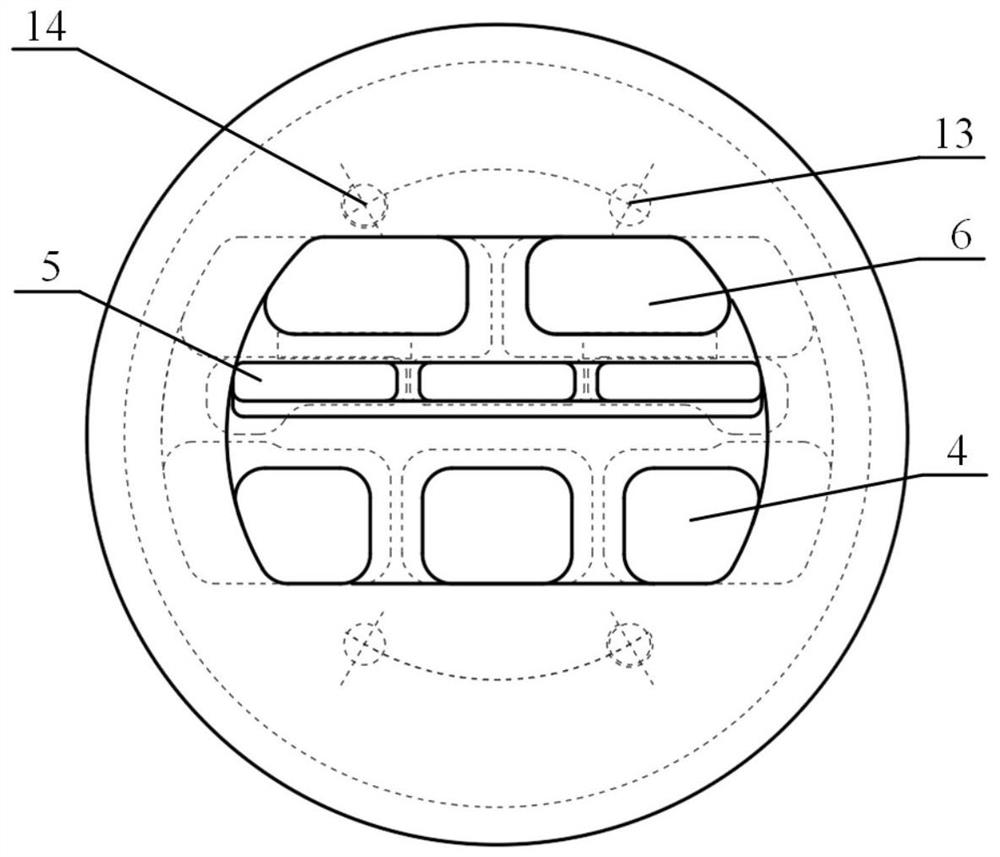

[0032] In a typical embodiment of the present invention, such as Figure 1 to Figure 5 As shown, a profile forming device for heat dissipation elements with a microchannel offset layout is given.

[0033] Such as figure 2 The profile forming device for the heat dissipation element of the microchannel offset layout shown is used for processing the profile for the heat dissipation element of the microchannel offset layout, such as figure 1 The profile 15 for the heat dissipation element with the microchannel offset layout is processed by the forming device to obtain the microchannel flat tube profile, and the profile 15 for the heat dissipation element with the microchannel offset layout is obtained after straightening and sawing. And through further machining, heat dissipation elements with micro-channel bias layout can be obtained, which can be applied to the heat dissipation of components inside the equipment, such as air conditioner inverters, diodes, etc., as a heat dissi...

Embodiment 2

[0060] In another typical embodiment of the present invention, such as Figure 1 to Figure 5 As shown, a profile forming method for a heat dissipation element with an offset layout is given, using a profile forming device for a heat dissipation element with an offset microchannel layout as in Example 1.

[0061] Include the following steps:

[0062] Homogenize the melted and cast bars, then saw and cut them as required to obtain a certain length of billet for extrusion, and then heat and keep the billet warm;

[0063] Preheat the mold and keep it warm, and send the heat-insulated extrusion billet into the material inlet of the mold;

[0064] The ingot for extrusion passes through the counterbore 1, the split hole, the welding chamber 8, the core drainage groove and the forming cavity sequentially in the mold, and is finally formed by the end of the working belt into a heat dissipation element profile 15 with a microchannel offset layout;

[0065] Cooling, straightening and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com