High pressure resistant and impact resistant roller bit with high rotating speed

A roller cone bit, high-pressure-resistant technology, applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve the problem of reducing the contact area between the large journal 41 of the tooth palm and the large shaft hole 21 of the cone, poor impact resistance, no Locking function and other issues to achieve the effect of reducing overload, improving lubrication conditions, and increasing the bearing capacity of rollers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

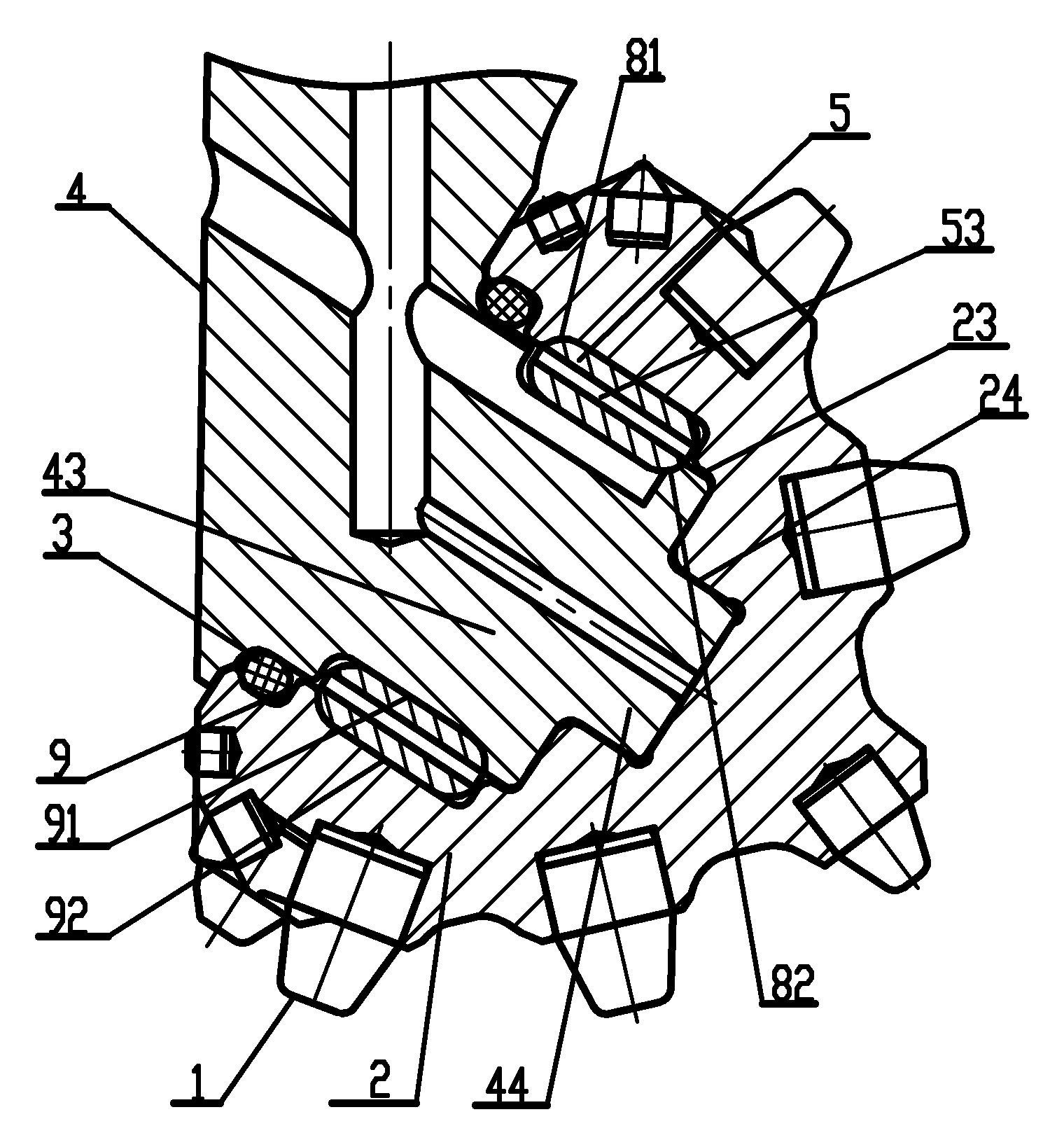

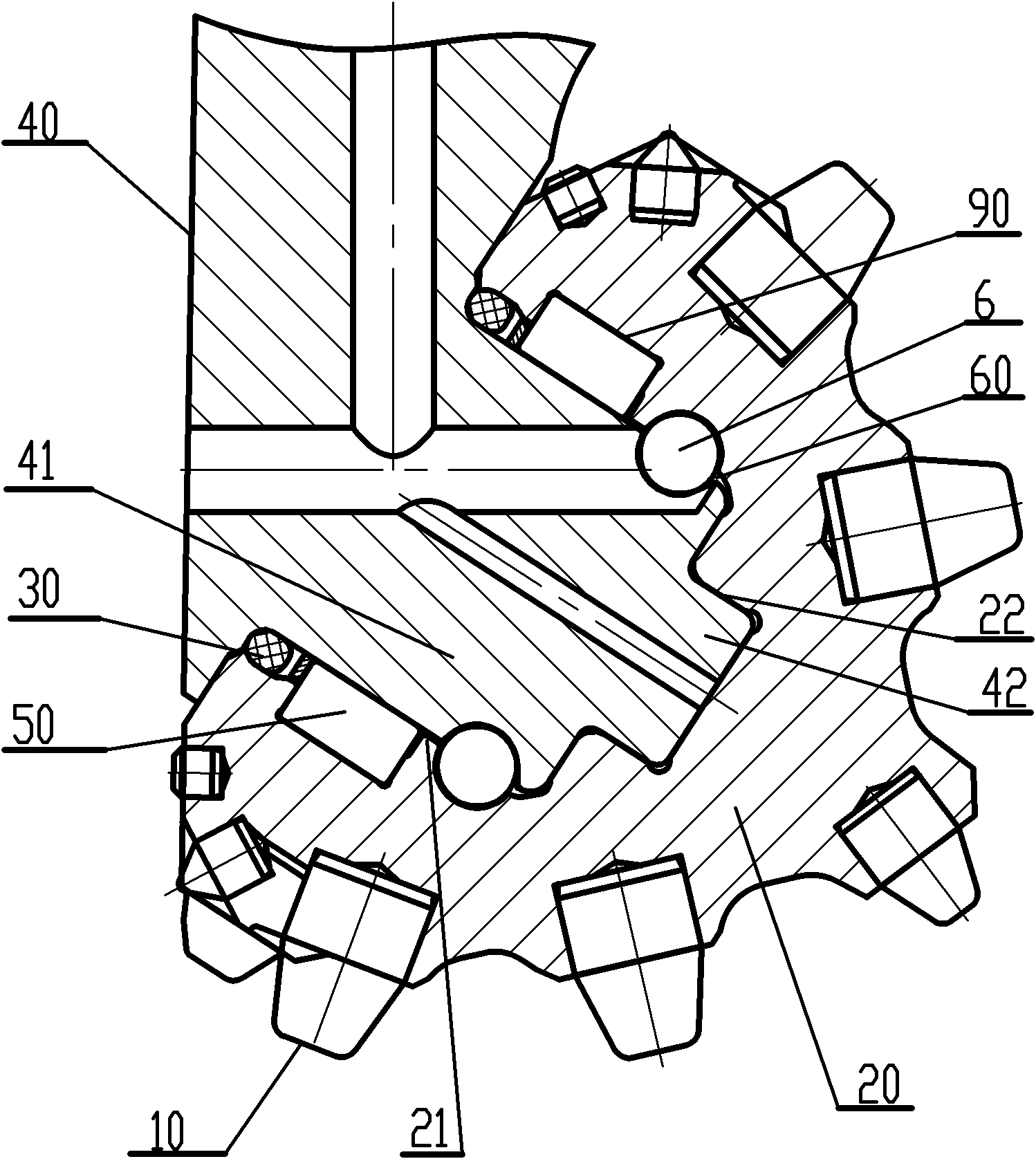

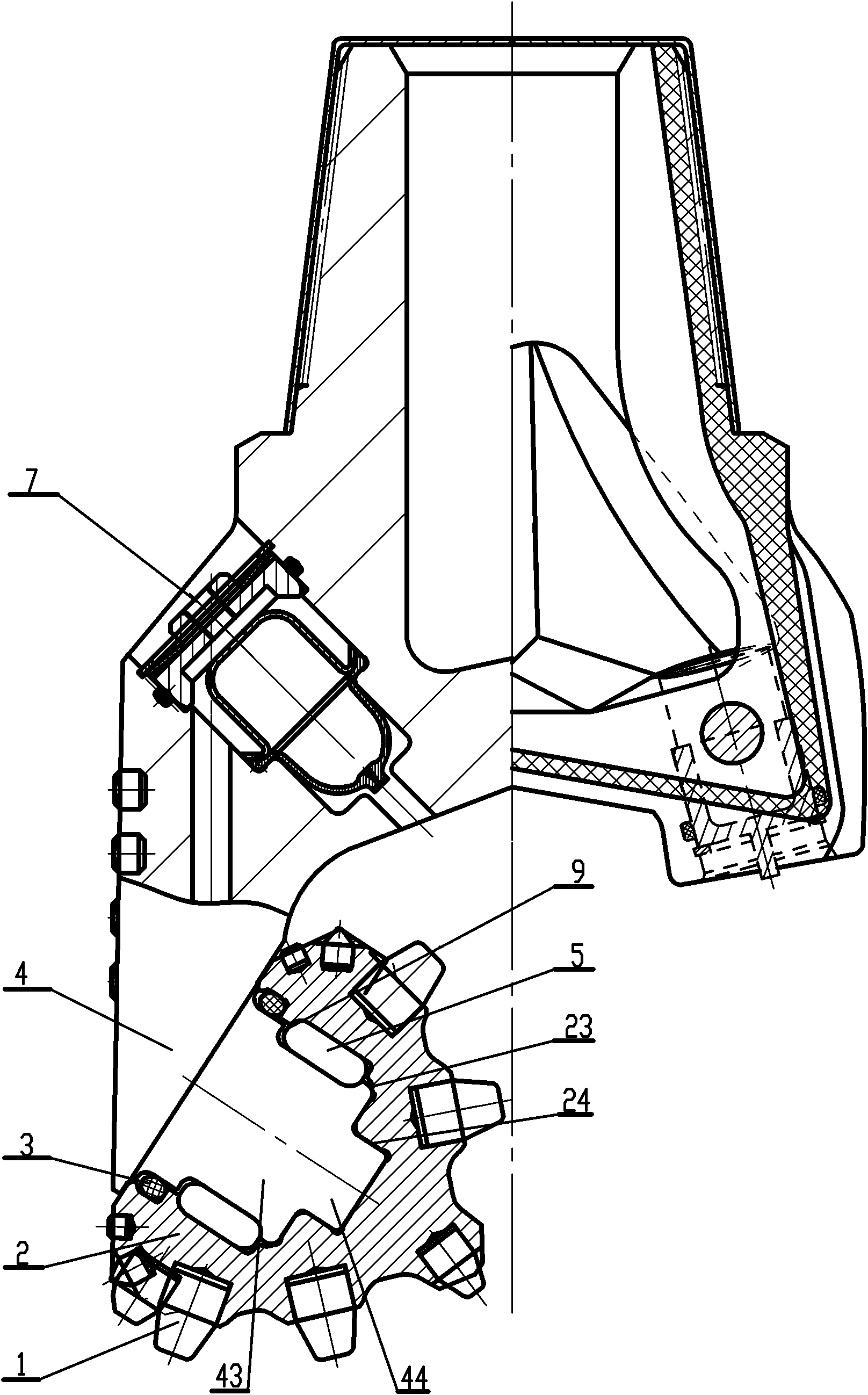

[0019] Figures 2 to 4 show a high-speed impact-resistant roller cone bit, including a cone 2 inlaid with an alloy tooth 1, a tooth palm 4, and the tooth palm 4 is provided with a large journal 43 and a small journal 44, and the cone 2 The large shaft hole 23 and the small shaft hole 24 are correspondingly provided. The large shaft hole 23 and the small shaft hole 24 of the cone are respectively set on the large journal 43 and the small journal 44 of the tooth palm, and are embedded in the raceway 9 The roller 5 in the middle is in rolling friction connection with the tooth palm 4, and the tooth palm 4 is also provided with an oil supply system 7 and a rubber sealing ring 3.

[0020] As shown in Fig. 2 and Fig. 3, the present invention is characterized in that the outer surface of the above-mentioned large journal 43 is provided with a journal half formed by a journal ring-shaped groove whose width extends to the end of the large journal 43. The raceway 91 is provided with a sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com