Filter upper bearing shell, filter and method for manufacturing filter upper bearing shell

A filter and bearing pad technology, which is applied in the field of manufacturing upper bearing pads of filters, can solve problems such as being unable to withstand high loads, damage to filters or filter housings, etc., to avoid component failure and simplify fixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

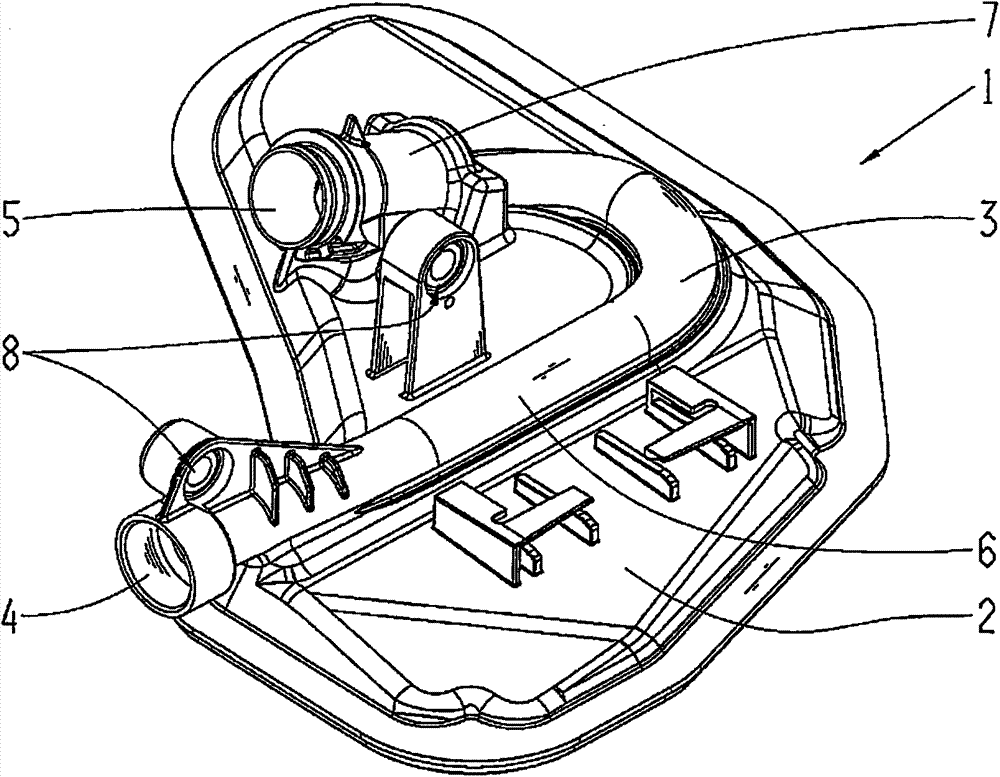

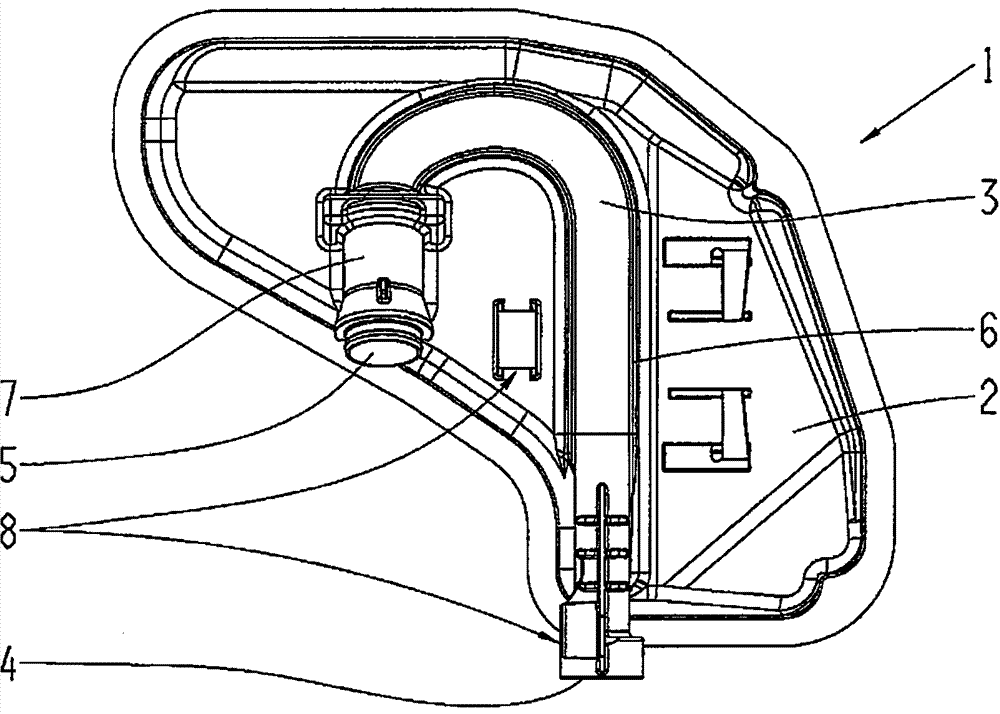

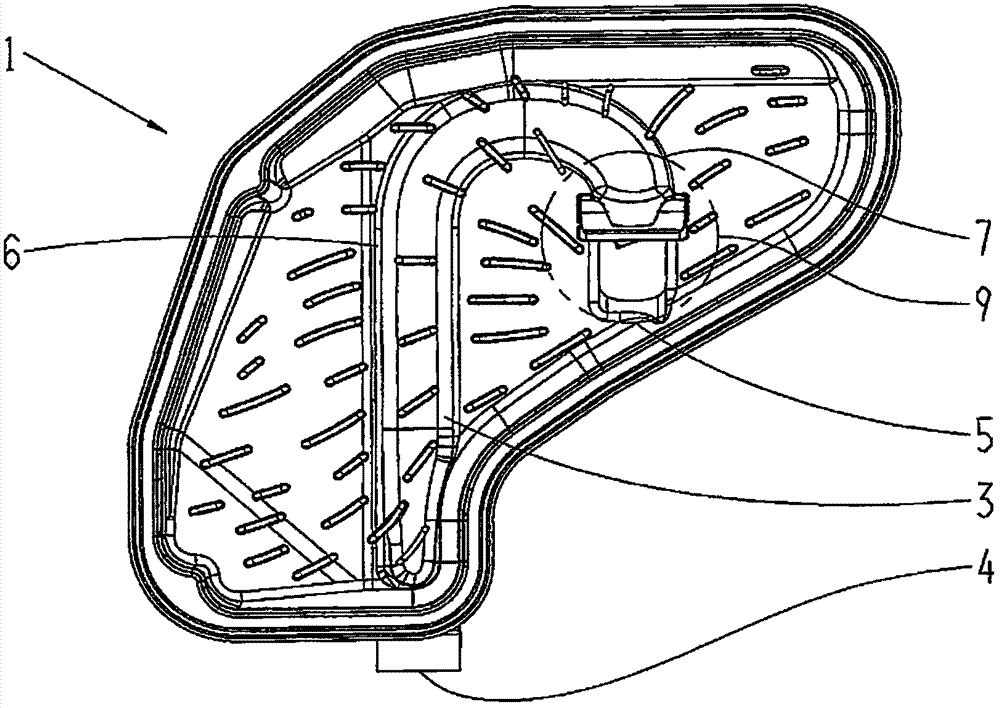

[0038] Figures 1A-1E Various views of a filter top shell 1 for a transmission oil filter according to one embodiment are shown. Figure 1A is an isometric view of bearing pad 1 on the filter, Figure 1B is the top view of bearing bush 1 on the filter, Figure 1C It is the bottom view of bearing bush 1 on the filter, Figure 1D is the side view, and Figure 1E It is a partially cut-away front view of the upper bearing bush 1 of the filter. The filter top shell 1 is produced from a plastic material, preferably from glass-fibre-reinforced polyamide (PAGF). A pressure duct 3 with a circular cross section is formed integrally with the filter top shell 1 on the top surface 2 of the filter top shell 1 . The pressure line 3 provides suction boosting to improve the filtering effect and for this purpose has an inlet 4 at which fluid or transmission oil enters the pressure line 3 and an outlet 5 at which the transmission oil delivered via the pressure line 3 flows out again or It f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com