A method for producing screws, and the screws thereby

A screw and ultra-high-strength technology, applied in the field of screw manufacturing, can solve the problems of high cost and high consumption, and achieve the effect of avoiding weak parts and good strength characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

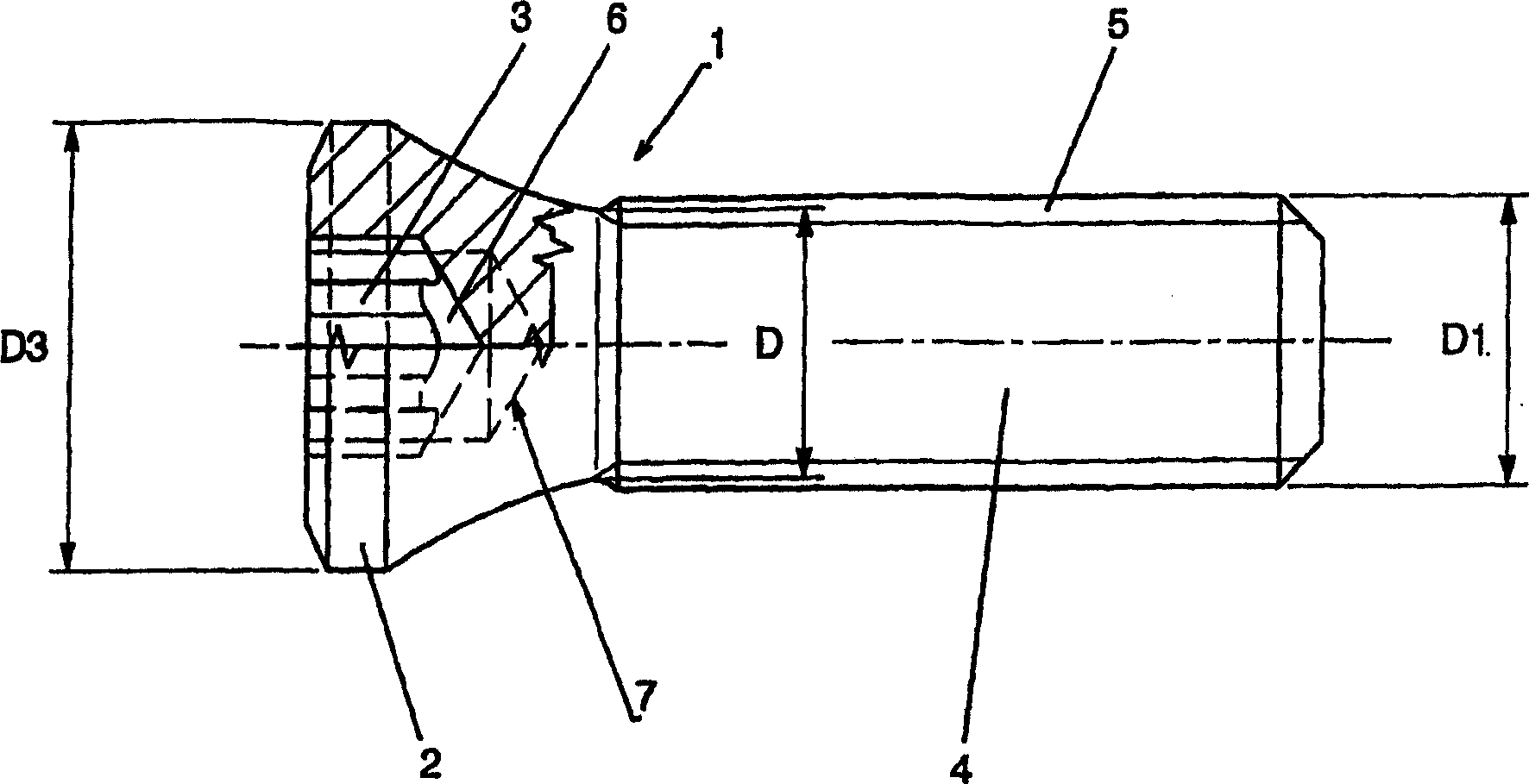

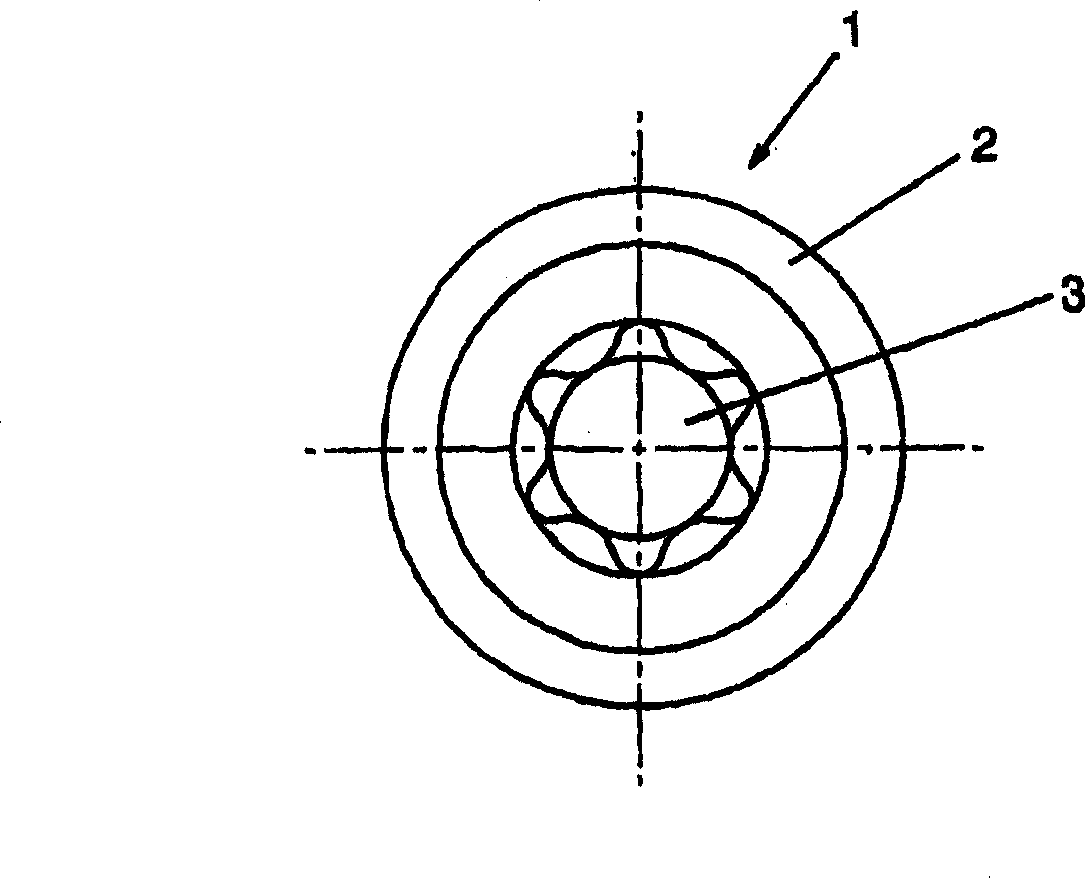

[0012] The drawing shows an exemplary embodiment of a screw, as it is used to fasten indexable inserts. Of course, the measures according to the invention for screws can be applied in the same way in other fields. Precisely for such screws, which have to be produced with close tolerances and are mainly subjected to torque and tensile forces, it has been shown that screws produced by cold pressing are clearly superior to screws produced by machining. However, since screws made precisely of ultra-high-strength steel are the best raw material for such screws, they have so far been produced as turned parts, because experts skilled in the art believe that the method of cold pressing Manufacturing is impossible for finishing.

[0013] A screw 1 shown in the drawing, in particular for fastening indexable inserts, has a screw head 2 and a threaded shaft 4 provided with a thread 5 . A flight 5 having an outer diameter D1 is wound around the screw 4 having a diameter D. The screw hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com