Pipe alignment machine

A technology of pipe arranging machine and righting arm, which is applied to drilling pipes, casings, drilling equipment, etc., can solve the problems of high labor intensity of operators, large workload of receiving and unloading ports, long time for tripping and drilling, etc. The effect of easy synchronization control, uniform force and labor intensity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

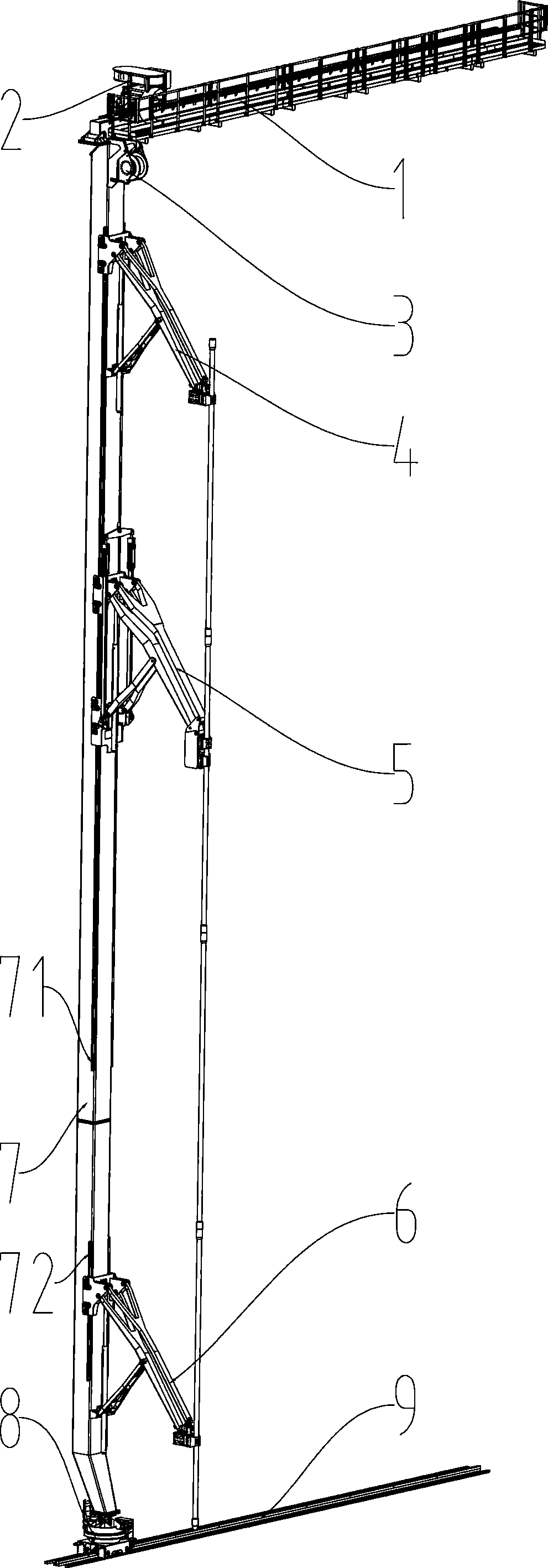

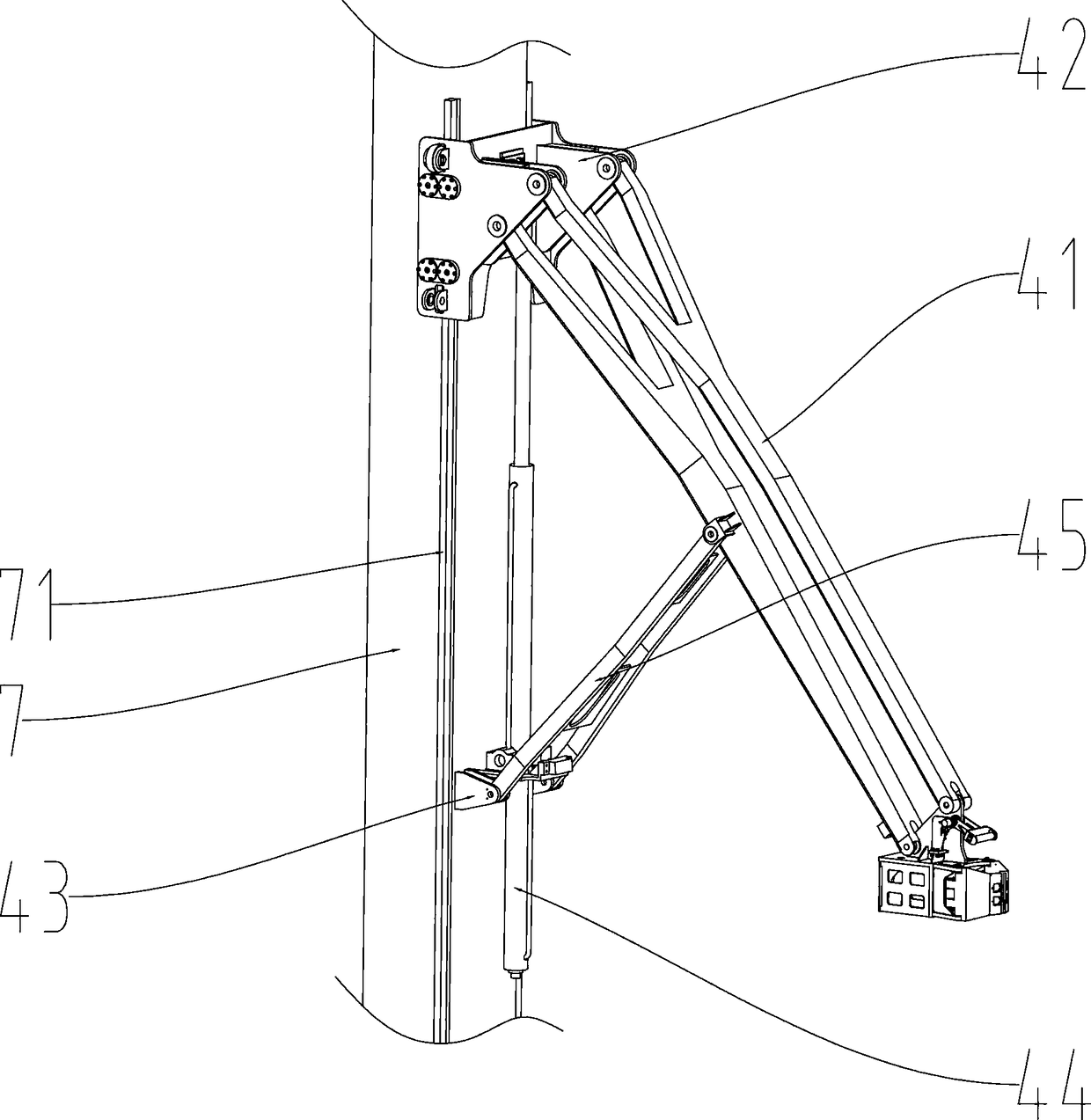

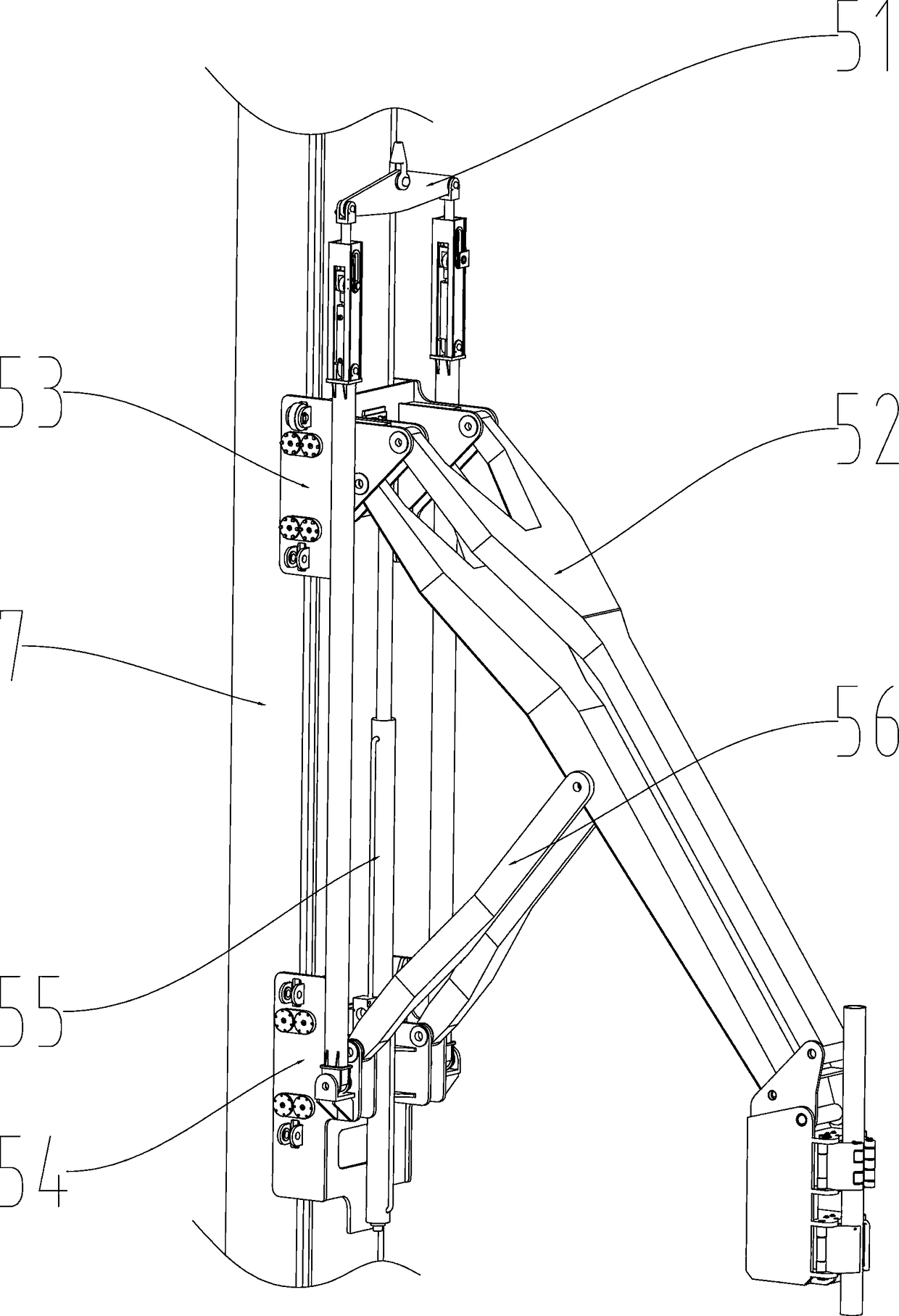

[0031] Such as figure 1 As shown, the pipe row machine is composed of an upper track 1, an upper driving trolley 2, a lifting winch 3, an upper righting arm 4, a lifting arm 5, a lower righting arm 6, a column 7, a lower driving trolley 8 and a lower track 9, and an upper driving trolley 2 Slidingly connected with the upper rail 1, the top of the column 7 is hinged with the bottom of the upper driving trolley 2, the lifting winch 3 is fixedly connected with the upper part of the column 7, the upper righting arm 4 is fixedly connected with the column 7, and the lifting arm 5 is connected with the column 7 Sliding connection is carried out, the lifting arm 5 is also movably connected with the lifting winch 3, the lower righting arm 6 is fixedly connected with the column 7, the lower end of the column 7 is hinged with the lower driving trolley 8, and the upper driving trolley 2 and the lower driving trolley 8 are simultaneously driven The column 7 moves along the upper track 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com