Power assembly suspended torsion bar and mounting structure thereof

A technology of power assembly and installation structure, applied in power plant, transportation and packaging, jet propulsion, etc., can solve the problems of large diameter size and large installation structure space, so as to reduce installation space and facilitate installation and disassembly or maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0035] In the present invention, unless stated to the contrary, the used orientation words such as "up, down, left, right" are usually used to describe the mutual positional relationship of the components in terms of the directions shown in the drawings.

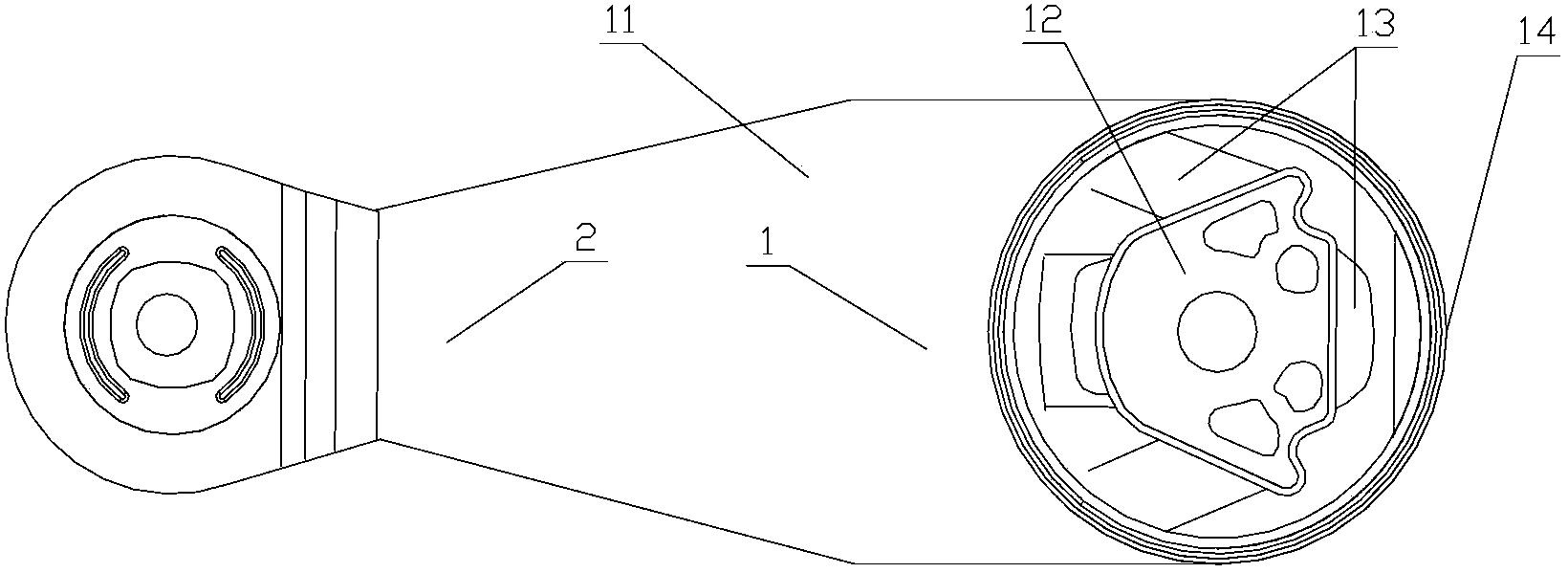

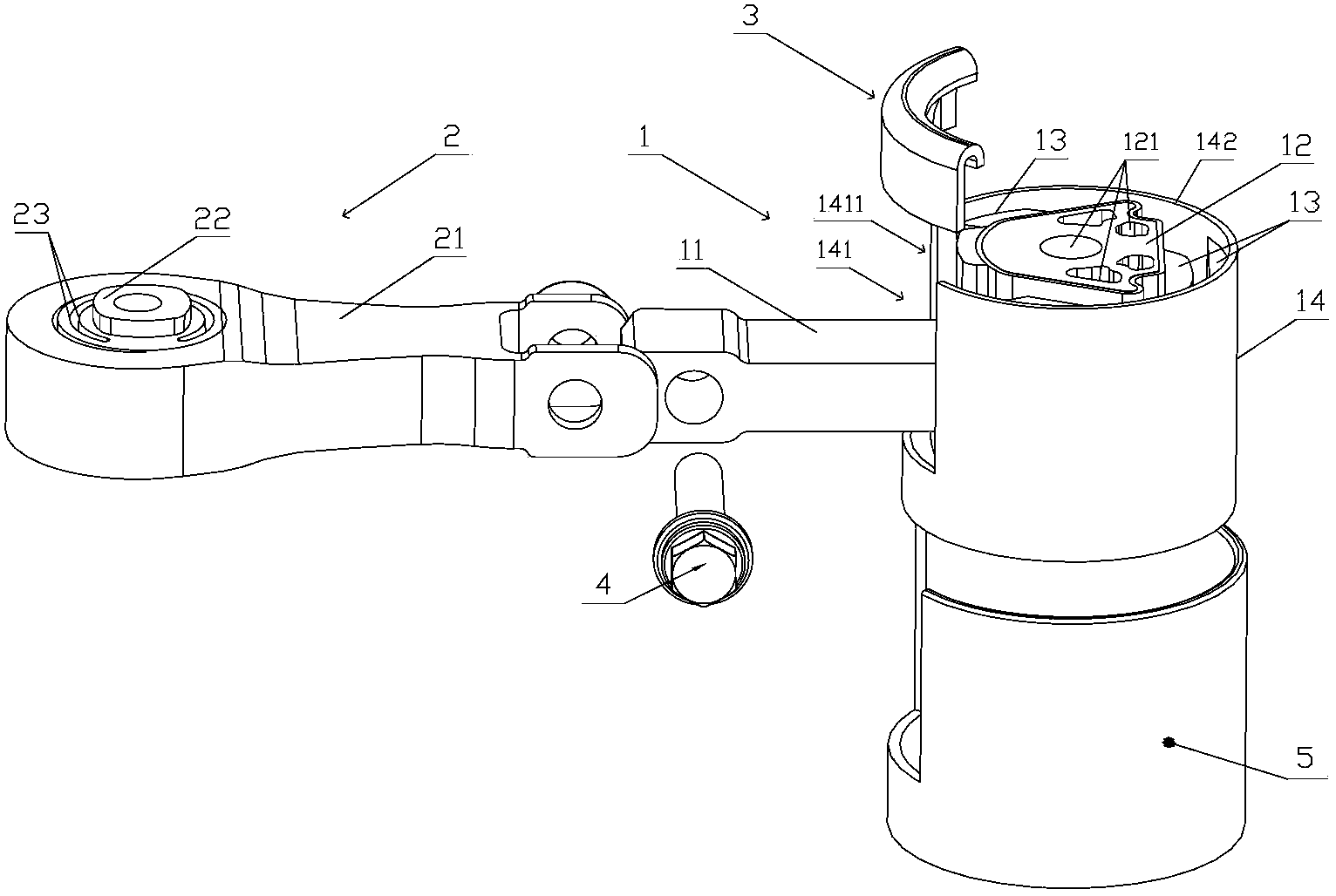

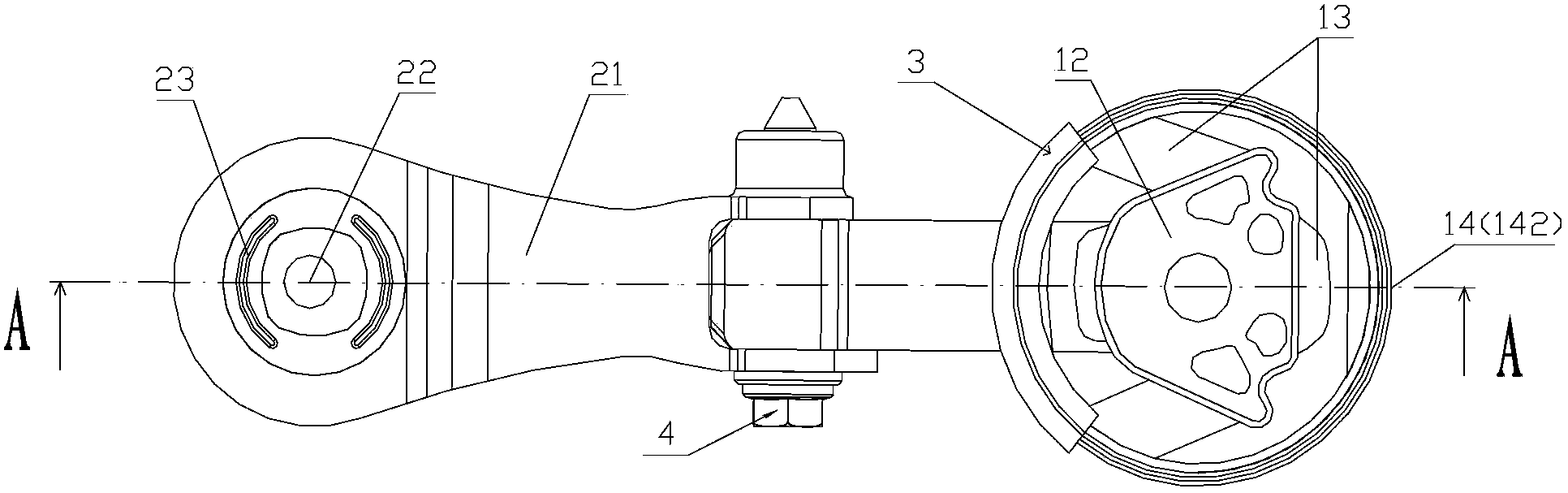

[0036] Such as Figure 2 to Figure 4 As shown, the present invention provides a powertrain suspension torsion bar, the suspension torsion bar includes a first part 1 and a second part 2 for connecting the powertrain, the first part 1 and the second part 2 are detachable The first part 1 includes a first connecting arm 11, a first inner core 12, an outer sleeve 14, and a first shock absorber 13 arranged betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com