Double-station grabbing mechanism

A grasping mechanism and dual-station technology, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of increased cost, interference, and limited space occupation, so as to reduce production costs, reduce movement space, and avoid interference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

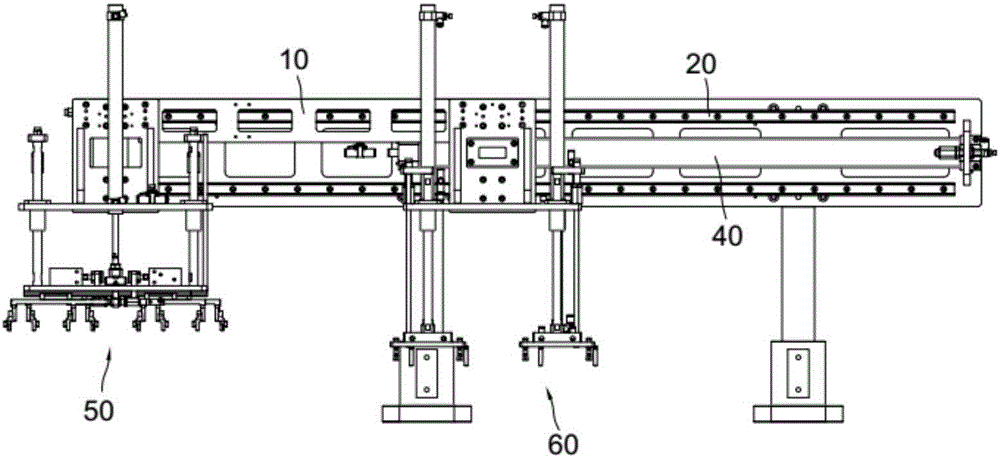

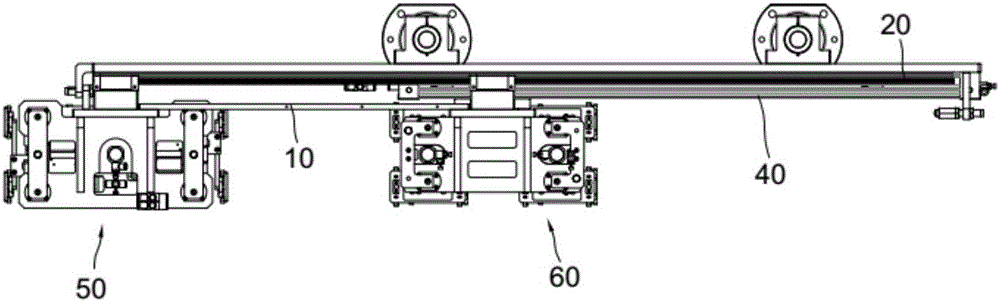

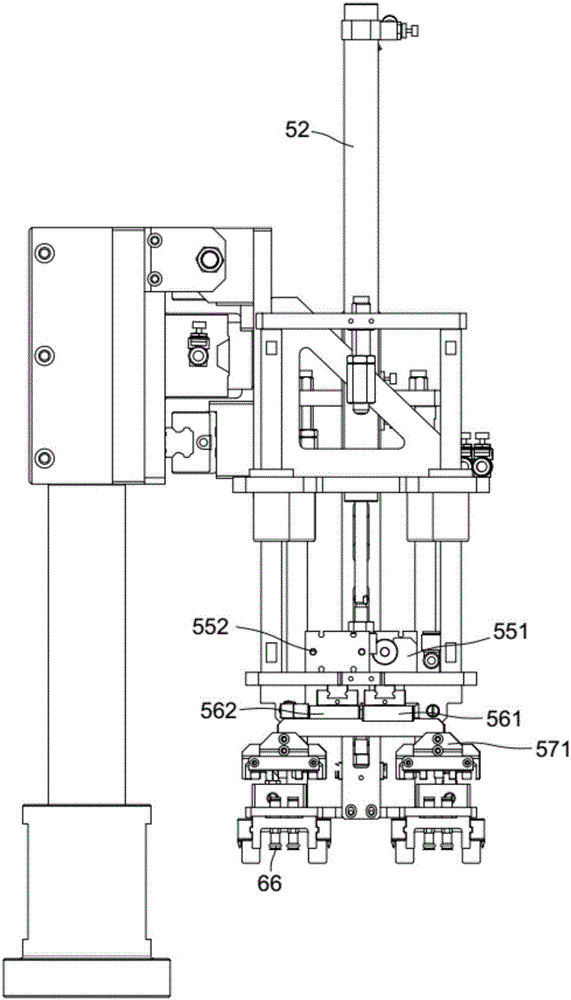

[0025] combine figure 1 , figure 2 , a double-station grabbing mechanism, including two grabbing mechanisms slidably installed on the frame, which are respectively a left grabbing mechanism 50 and a right grabbing mechanism 60, and three grabbing mechanisms are arranged below the two grabbing mechanisms. Work station; the two grabbing mechanisms are fixedly connected by the connecting rod 10, the three stations are arranged in a line, and the distance between two adjacent stations is equal to the distance between the two grabbing mechanisms. Among them, the middle station among the three stations is the product assembly station, and the stations on both sides of the middle station are the component loading stations for the assembled products.

[0026] The two grabbing mechanisms slide and fit on the slide rail 20 through the slide block, and the slide rail is fixed on the frame; the number of slide rails is a pair, and a pair of slide rails are arranged in parallel up and do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com