Breaking and cleaning machine for plastic bags

A technology for plastic bags and cleaning machines, which is applied in the fields of plastic recycling, mechanical material recycling, cleaning methods and utensils, etc. It can solve the problems that plastic bags cannot be effectively broken, improve processing quality, facilitate subsequent processing, and improve cleaning quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

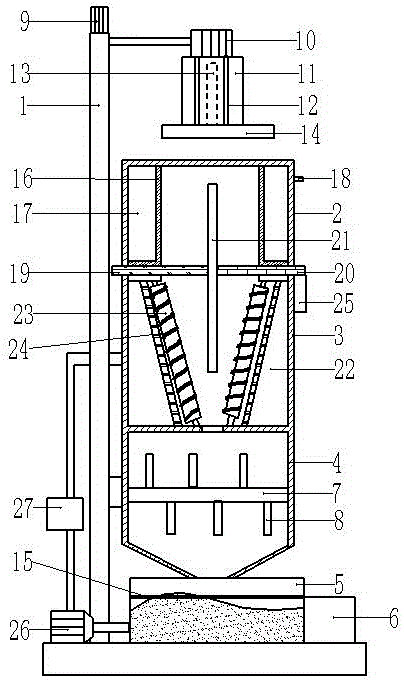

[0019] The reference signs in the drawings of the description include: frame 1, material handling chamber 2, extrusion chamber 3, crushing chamber 4, sedimentation chamber 5, cleaning pool 6, crushing knife 7, rotating blade 8, first cylinder 9, second Two cylinders 10, pressure caps 11, telescopic shafts 12, slide rails 13, pressure plates 14, leaking screens 15, compression cylinders 16, filling chambers 17, filling ports 18, left bottom plates 19, right bottom plates 20, insert rods 21, interlayers 22 , Roller 23, freezing pipe 24, freezer 25, water pump 26, heater 27.

[0020] The embodiment is basically as figure 1 Shown: Plastic bag crushing and washing machine, including frame 1, frame 1 is provided with material handling chamber 2, extrusion chamber 3, crushing chamber 4 and sedimentation chamber 5 in order from top to bottom, and the crushing chamber 4 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com