Turnover type billboard transmission mechanism

A transmission mechanism and billboard technology, applied in the direction of instruments, identification devices, etc., can solve the problems of fracture of the transmission spindle, accelerated wear of the mechanism, and accelerated wear of the mechanism, and achieve the effect of avoiding movement and wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following is the best embodiment of the reversible billboard transmission mechanism of the present invention, which does not limit the protection scope of the present invention.

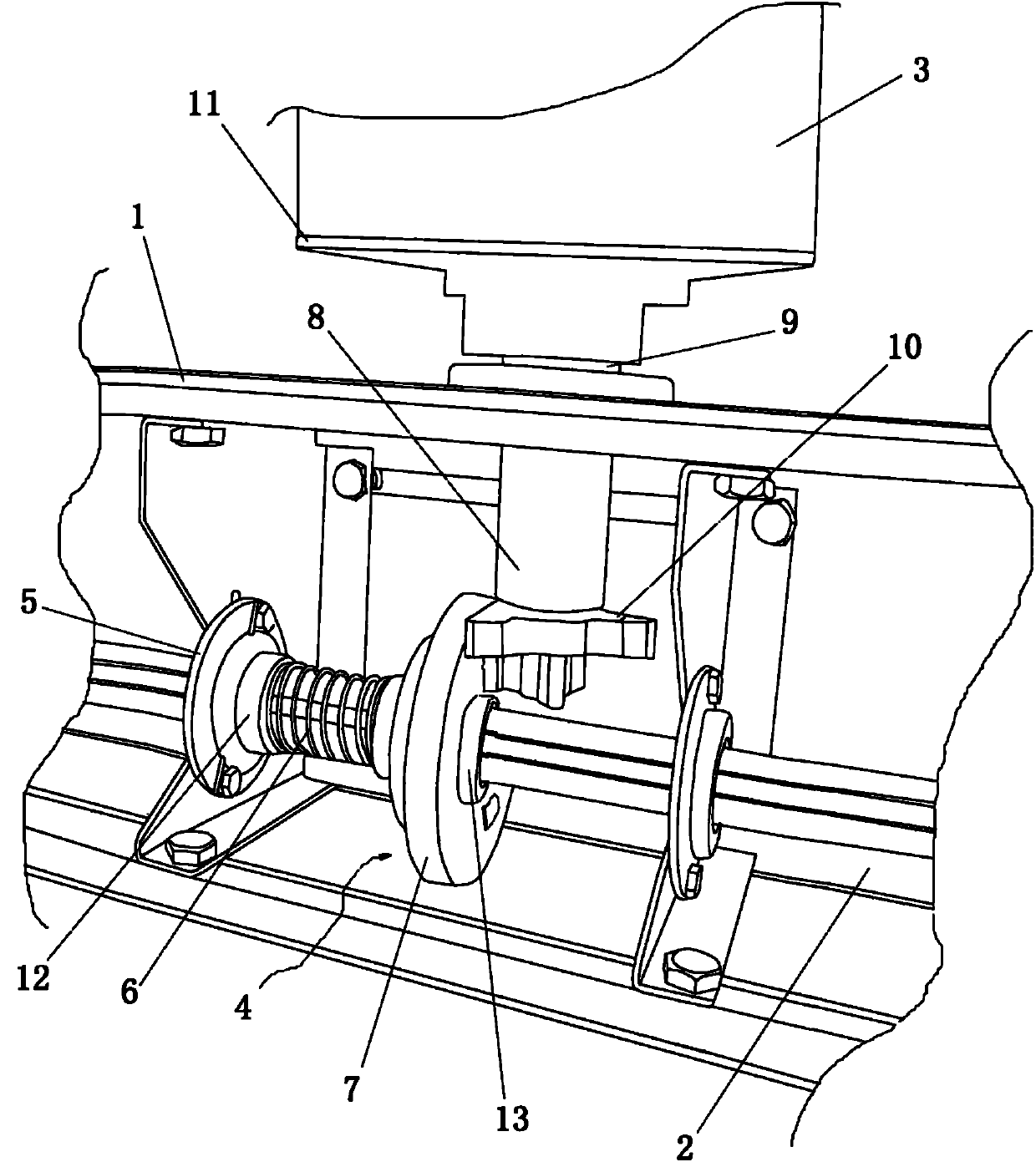

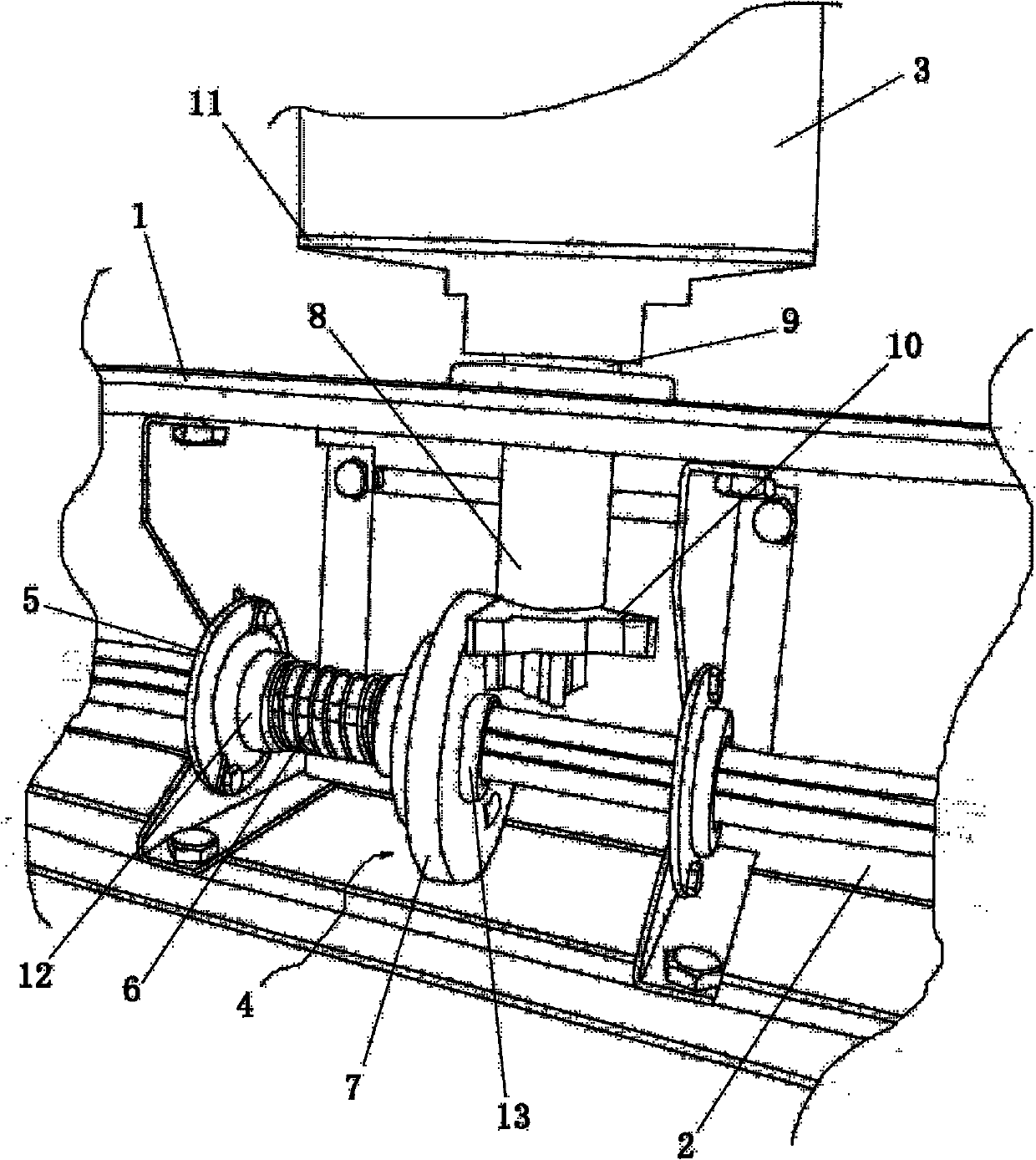

[0017] refer to figure 1 , to provide a flip-type billboard transmission mechanism, including a casing 1, a drive shaft 2 is arranged laterally in the casing 1, and a plurality of transmissions for driving the billboard triangular prism 3 to turn over are installed at intervals in the casing 1. Device 4, the transmission device 4 is composed of a compression spring seat 5, a compression spring 6, and a cam 7 that are sleeved on the transmission main shaft 2, a fixed seat 8 installed on the casing 1, and a transmission rod installed in the fixed seat 8. 9. The small triangular transmission plate 10 installed at the lower end of the transmission rod 9 is composed of the large triangular connection plate 11 installed at the upper end of the transmission rod 9. The small triangular transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com