Novel lower-bodywork repair welding, positioning and locking device

A technology of positioning and locking, body, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problems of high labor intensity, high operation requirements, large equipment investment, etc., achieve reasonable structure design, improve welding accuracy, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific embodiments.

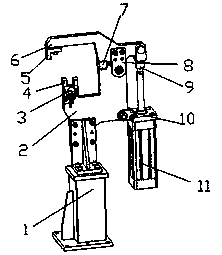

[0016] Such as figure 1 As shown, a new type of repair welding positioning and locking device for the lower body includes a base 1, a bracket 2, a positioning block 4, a pressing block 5, a rocker arm 6, a rocker arm support seat 8, a cylinder guide rod, a cylinder mounting bracket 10, and a cylinder 11. The rocker arm 6 is a sickle "J"-shaped structure, and its front end part is fixedly connected with the pressure block 5; the rocker arm 6 is hinged with the bracket 2 through the connecting plate 8, and the upper end of the connecting plate 8 is fixedly connected with the rocker arm 6, and the lower end It is hinged with the bracket 2; the left side of the connecting plate 8 is provided with an "H"-shaped buffer plate 7; the tail end of the rocker arm 6 is connected with the cylinder guide rod through a "Y"-shaped connecting rod 9, and the "Y"-shaped connecting rod 9 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com