Three-axis high-speed cutting machine capable of detecting fracture of diamond wires

A diamond wire and cutting machine technology, which is applied to metal sawing equipment, metal processing equipment, sawing machine accessories, etc., can solve the problems of safety accidents, failure to adhere to the diamond wire, clamping and installation position adjustment difficulties, etc., to achieve The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

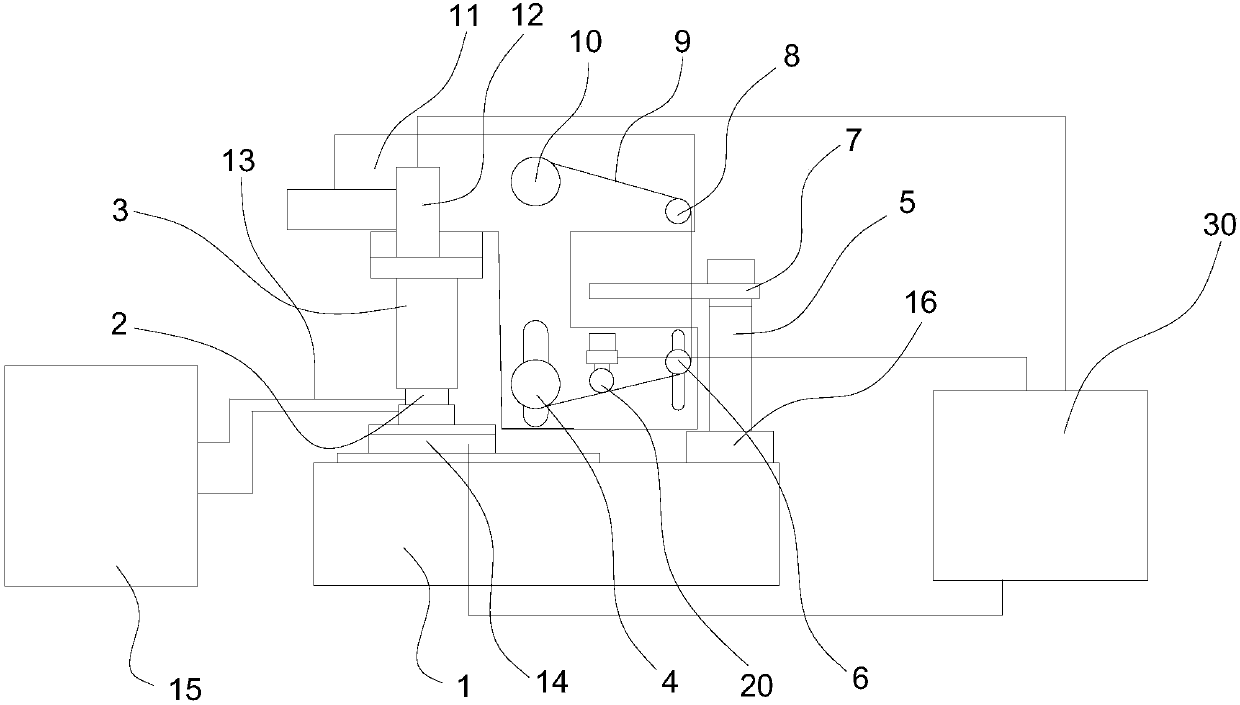

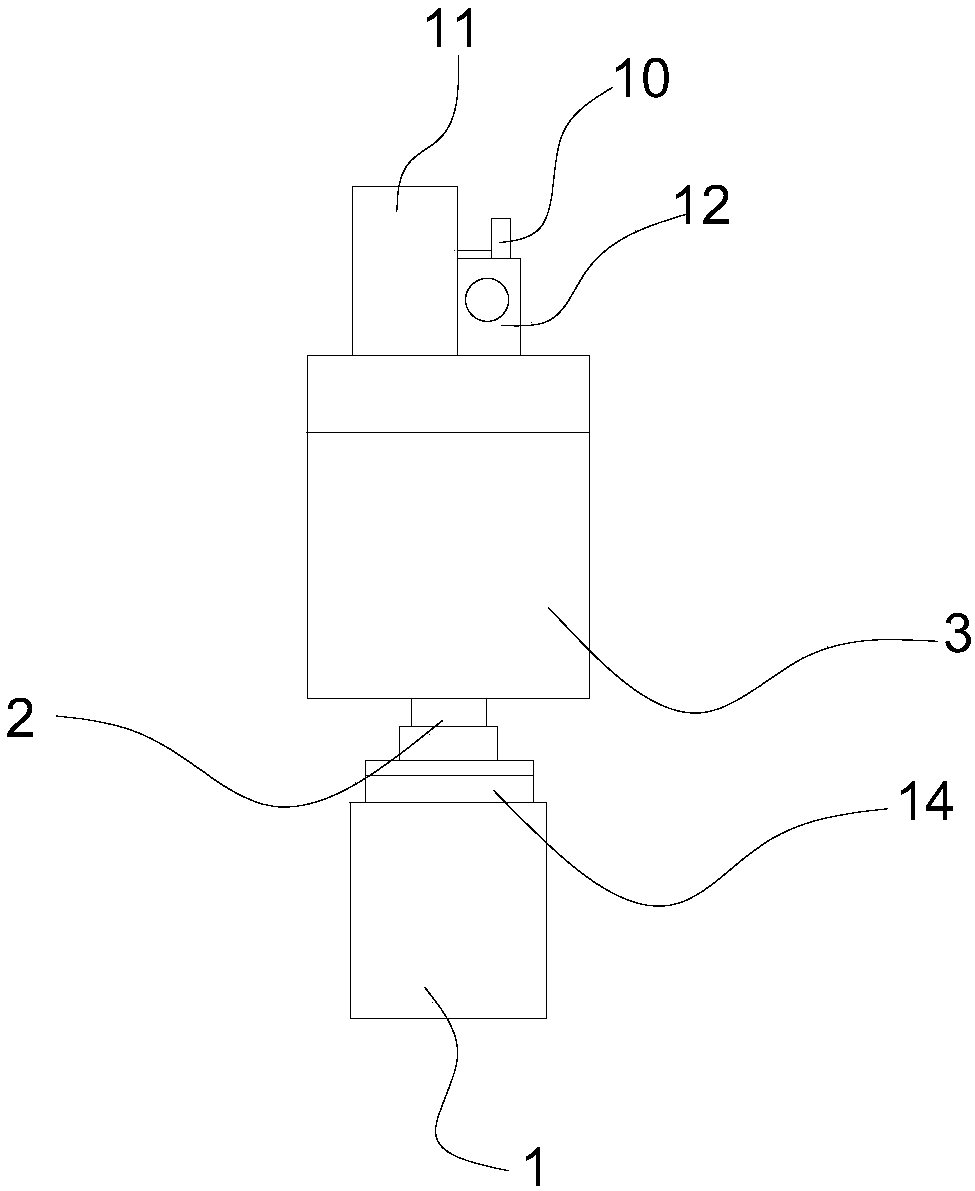

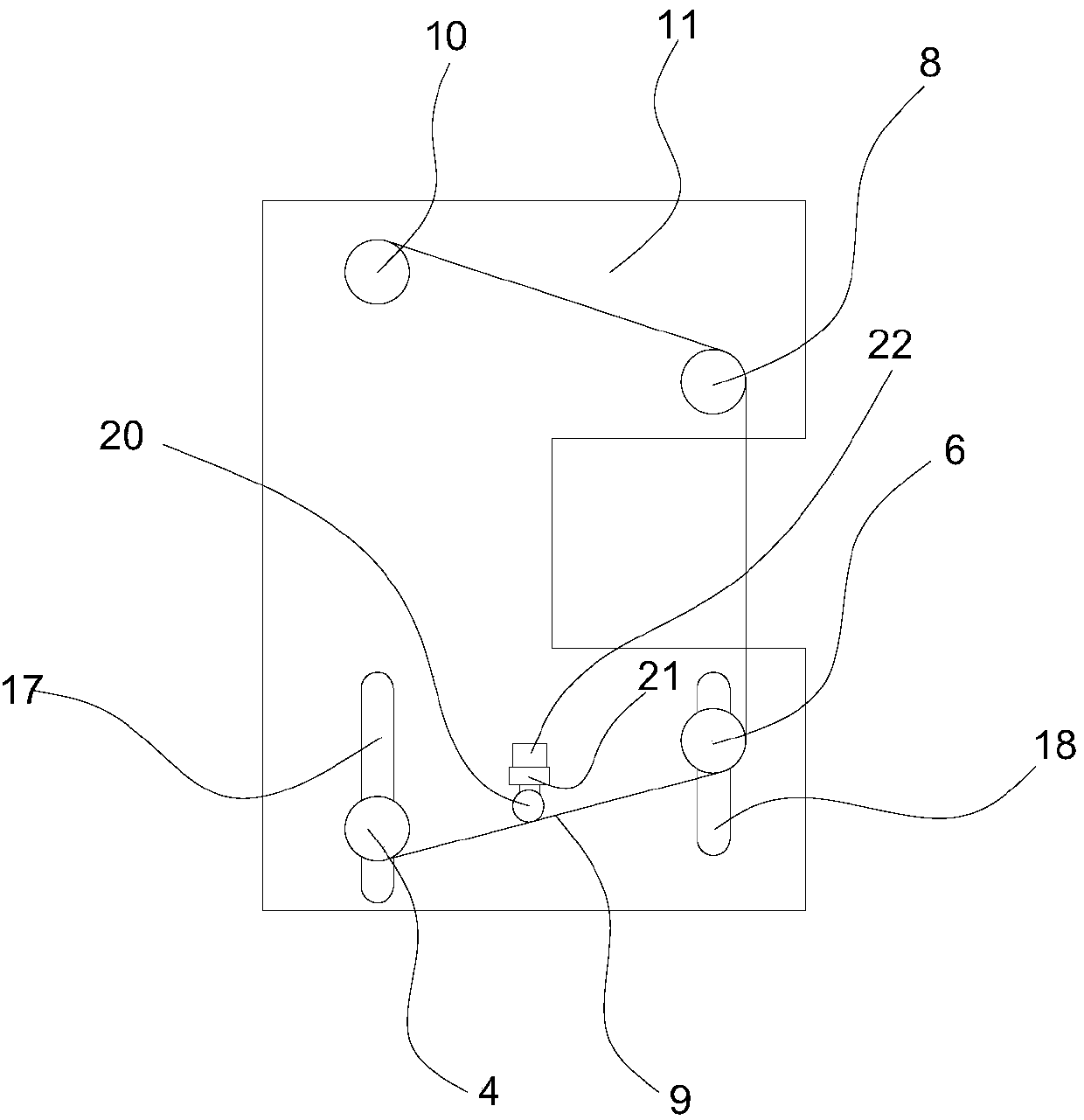

[0037] Such as Figure 1 to Figure 6 As shown, the three-axis high-speed cutting machine capable of detecting diamond wire breakage according to the present invention includes a base 1 and a servo control cabinet 30, and the base 1 is provided with a support platform 3; between the support platform 3 and the base 1 A horizontal linear drive device 14 that drives the support platform 3 to move horizontally on the base 1 is provided; a support block is provided on the horizontal linear drive device 14, and a vertical telescopic device 2 is provided on the support block. The supporting platform 3 is installed on the upper end of the vertical telescopic device 2; the longitudinal working platform 11 is slidably installed on the supporting platform 3 through the longitudinal linear drive device 12; the longitudinal working platform 11 is provided with a cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com