Ceramic cutting and conveying device with automatic correction function

A conveying device and automatic correction technology, applied in the direction of conveyor, transportation and packaging, etc., can solve the problems of lower product rate, limited effect, drop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

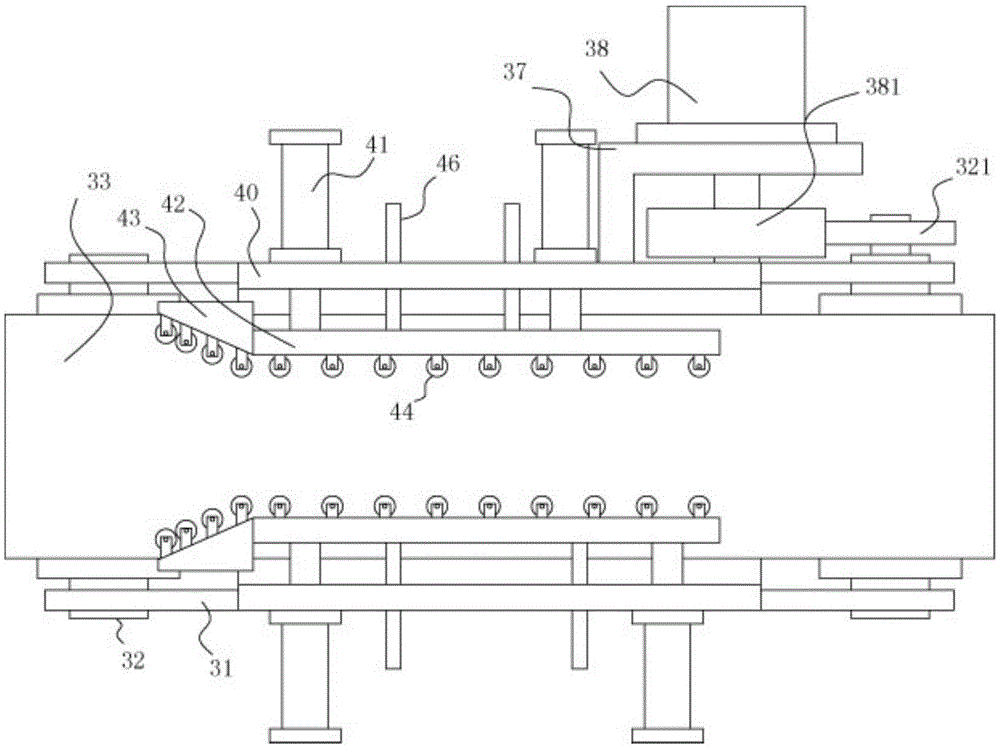

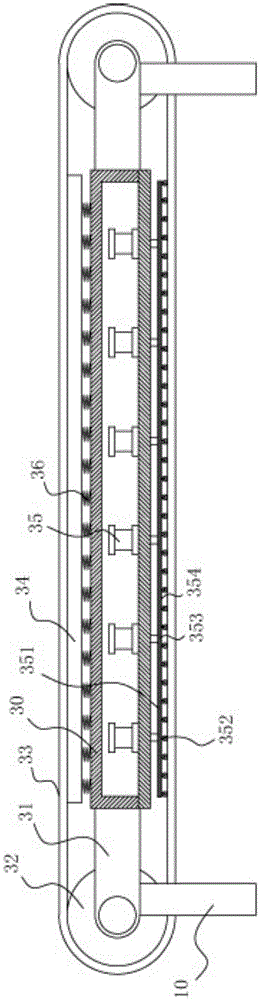

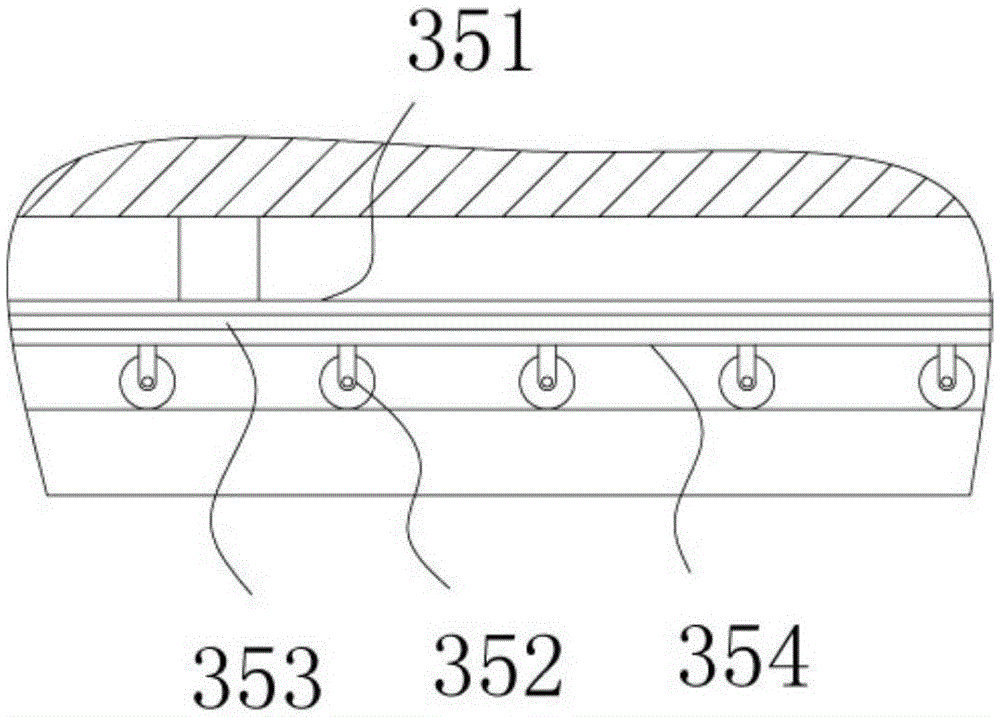

[0019] Example: see Figure 1 to Figure 3 As shown, a ceramic cutting and conveying device with automatic correction includes a frame 10, and the frame 10 includes a middle casing 30, and support plates 31 are fixed at the front and rear ends of the left and right outer walls of the middle casing 30. , the two ends of the drive roller 32 are hinged on the corresponding two support plates 31, the conveyor belt 33 is tensioned on the two drive rollers 32, and the legs are fixed on the bottom surface of the support plate 31;

[0020] The top surface of the middle casing 30 is provided with an upper support plate 34, which presses against the inner wall surface of the upper part of the conveyor belt 33, and the top front and rear sides of the middle casing 30 are also fixed with vertical plates 40. , two vertical boards 40 are located on both sides of the conveyor belt 33, a plurality of guide cylinders 41 are fixed on the vertical boards 40, and the push rods of the guide cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com