Yarn guiding device

The technology of a yarn guide and a yarn guide wheel is used in textile and papermaking, weft knitting, knitting and other directions, which can solve the problems that the requirements cannot be met, the yarn tension cannot be adjusted, etc., and achieves a simple structure and good tensioning effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

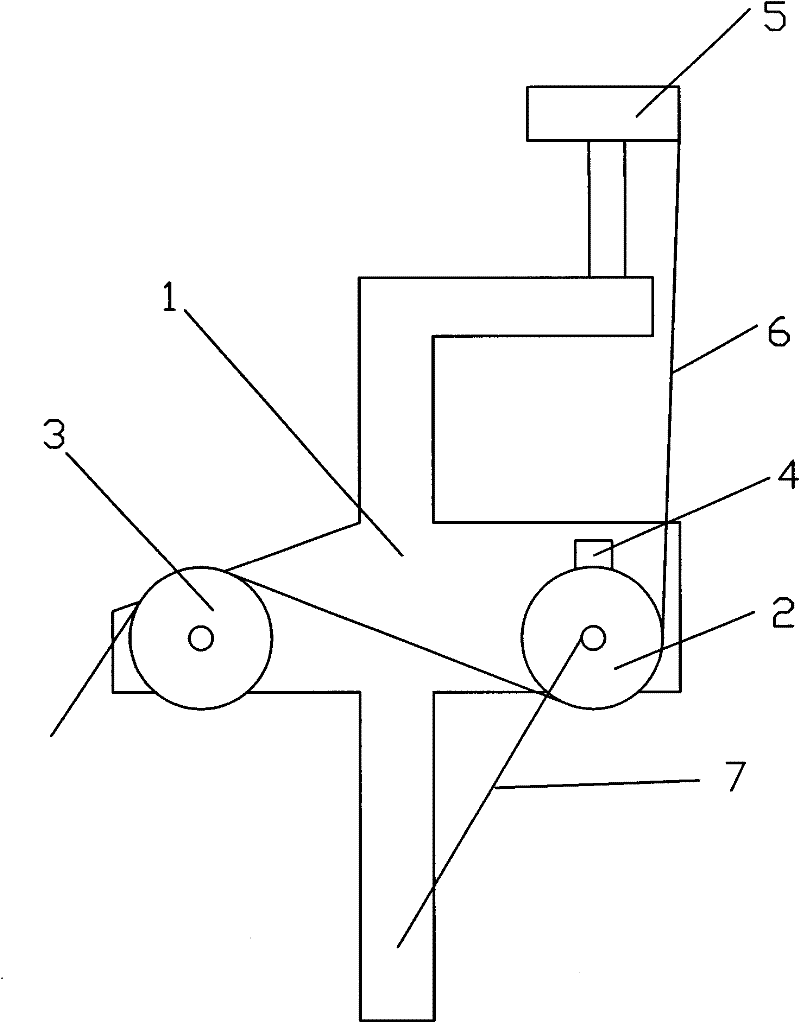

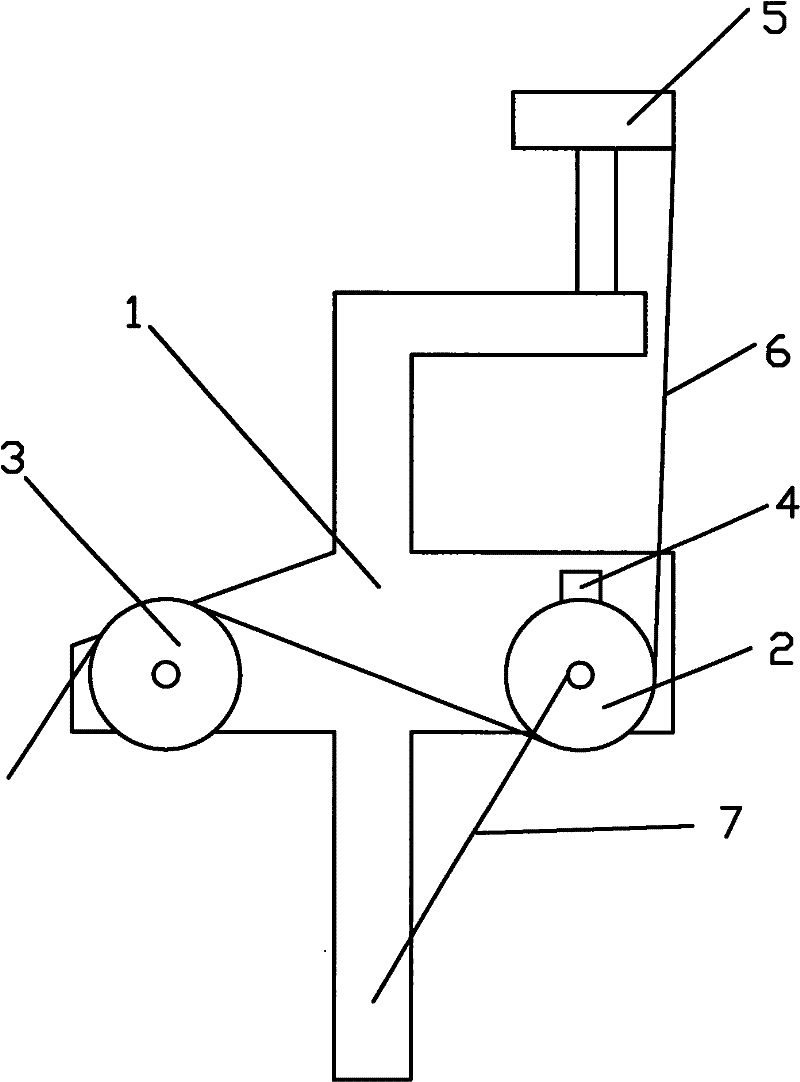

[0009] Below in conjunction with embodiment, the present invention is described in detail: as figure 1 Shown, a kind of yarn guide comprises support 1, and the upper end of support 1 is pay-off reel 5, and the first yarn guide wheel 2 and the second yarn guide wheel 3 in the same horizontal plane are arranged in the middle part of support, the first yarn guide wheel The first yarn guide wheel 2 and the second yarn guide wheel 3 have the same diameter, and a vertical or inclined guide groove 4 is provided at the position where the first yarn guide wheel 2 is installed on the bracket 1, and the first yarn guide wheel 2 is arranged in the guide groove 4 , a spring 7 is connected to the first yarn guide wheel 2, and the other end of the spring 7 is fixed on the lower end of the support 1, and the yarn 6 comes out through the pay-off reel 5 and is wound out from the bottom of the first yarn guide wheel 2 and then from the second yarn guide wheel 2. The upper part of the yarn guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com