Cloth feeding and fastening mechanism of numerically controlled single heedle quilter

A quilting machine and single-needle technology, which is applied to the cloth feeding mechanism, sewing machine components, and sewing machines for sewing quilts, etc., can solve the problem of not being able to cut fabrics smoothly, and achieve the effect of simple structure, low cost, and good tensioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

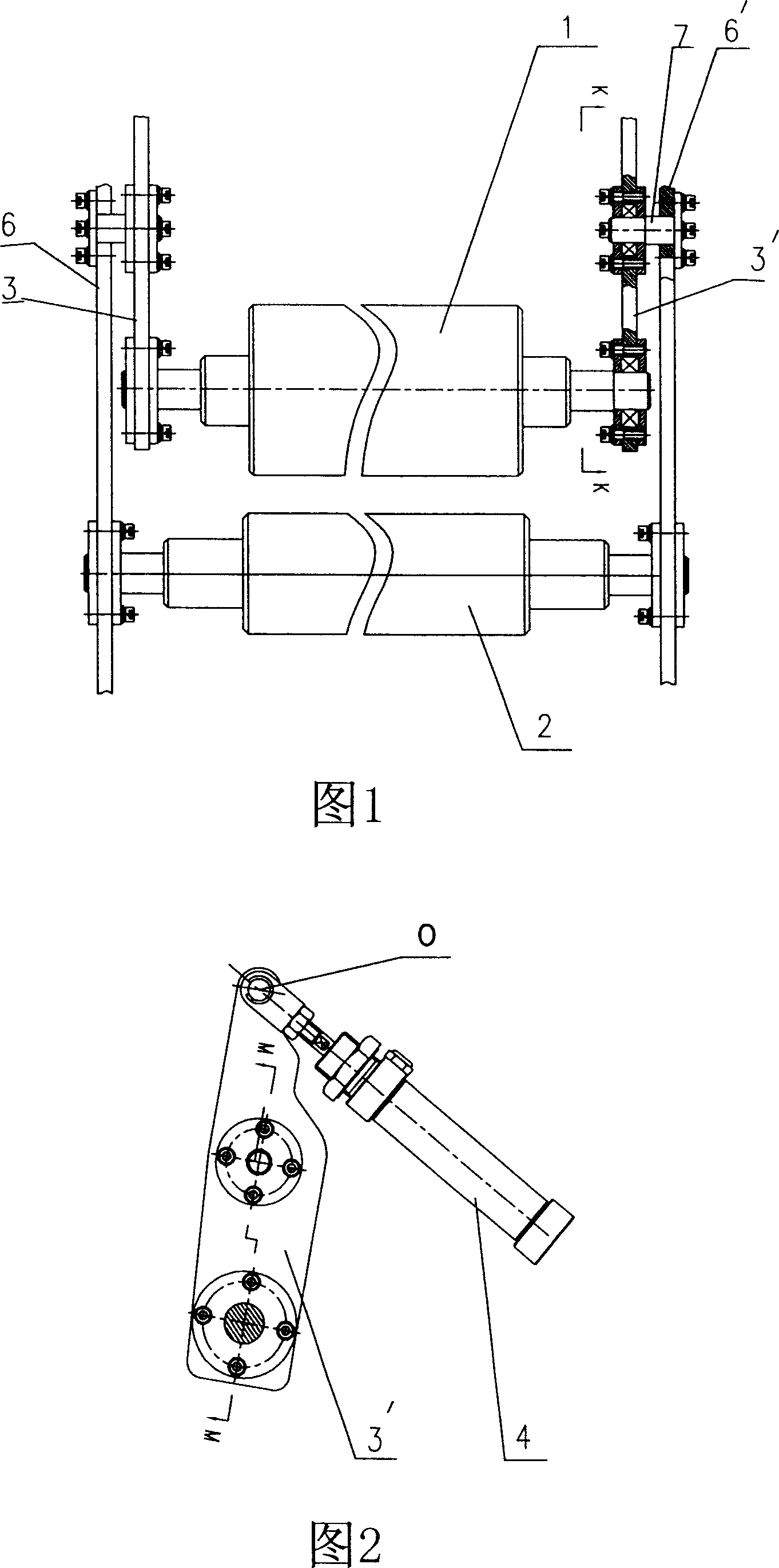

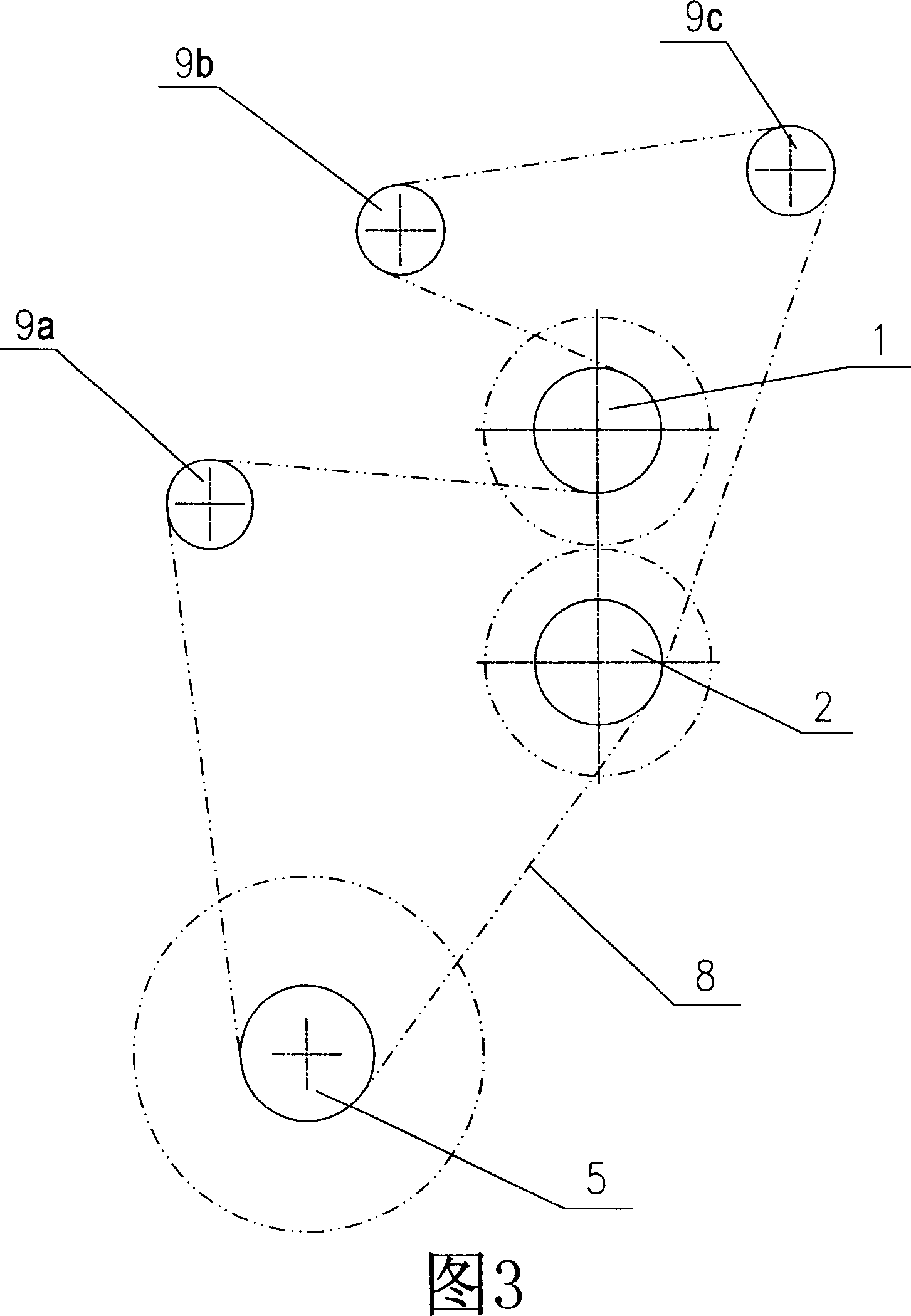

[0009] As shown in Figure 1 and Figure 2, the tensioning mechanism of the CNC single-needle quilting machine is composed of upper roller 1, lower roller 2, left and right swing plates 3, 3', two cylinders 4, left, Right fixed plate 6,6 ' and motor 5, chain 8, tension pulley 9a, 9b, 9c form. The left and right fixing plates 6, 6' and the lower ends of the cylinder 4 are fixed on the box body, the two ends of the upper roller 1 are respectively connected with the left and right swinging plates 3, 3' through the bearing seats, and the left and right swinging plates 3, 3' is respectively connected with the left and right fixed plates 6, 6' through each pin shaft 7. One end of the pin shaft 7 is fixed on the fixed plate 6, the other end is connected with the swing plate 3 through the bearing seat, the telescopic end of the cylinder 4 is hinged with the upper end of the swing plate 3, and the two ends of the lower roller 2 are respectively fixed on the left and right. Plates 6, 6'....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com