Numerical control diamond abrasive wire sawing machine

A wire cutting machine tool, diamond sand technology, applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc. The problem of inflexible rotation of the guide wheel has achieved the effect of wide application, saving raw materials and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

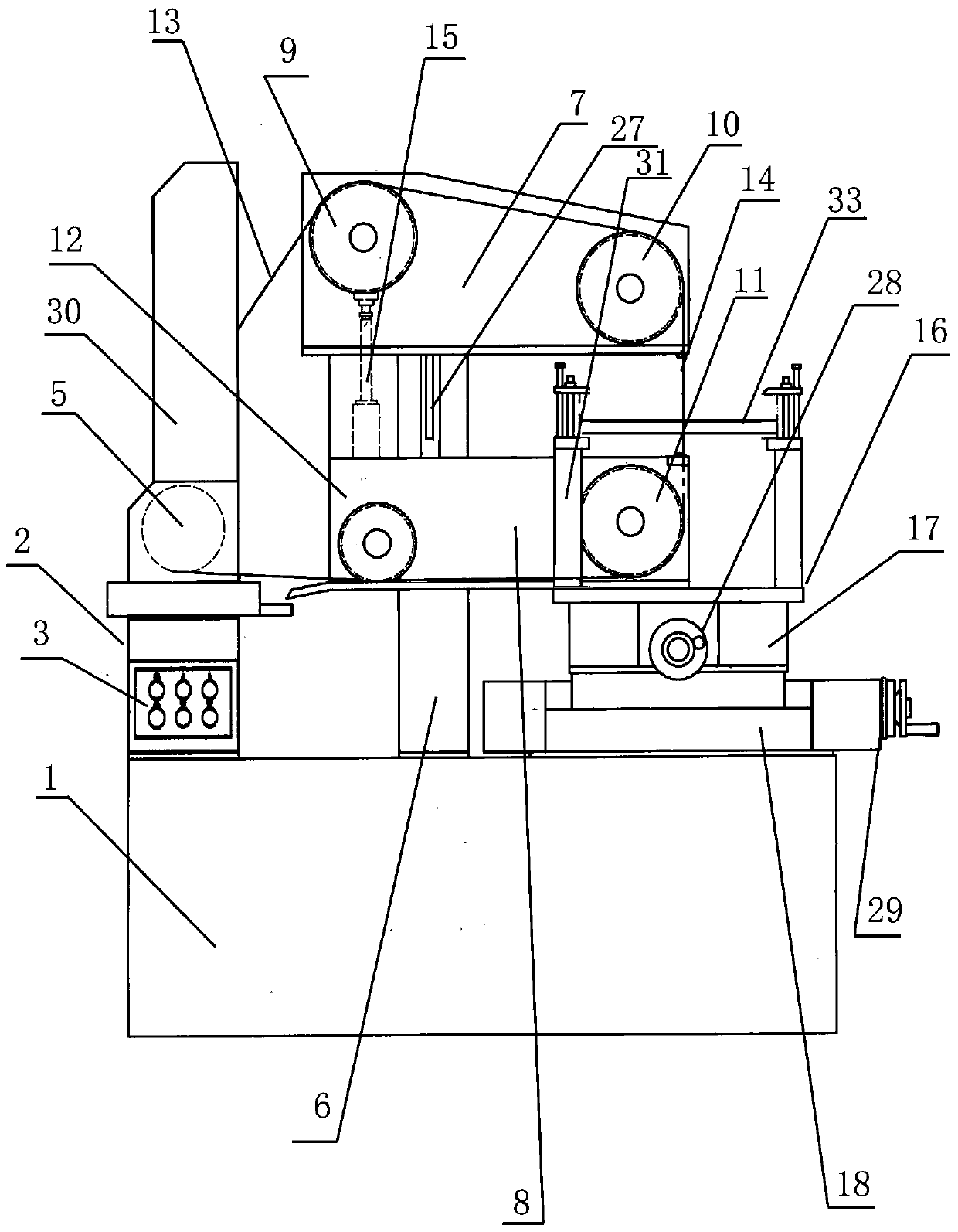

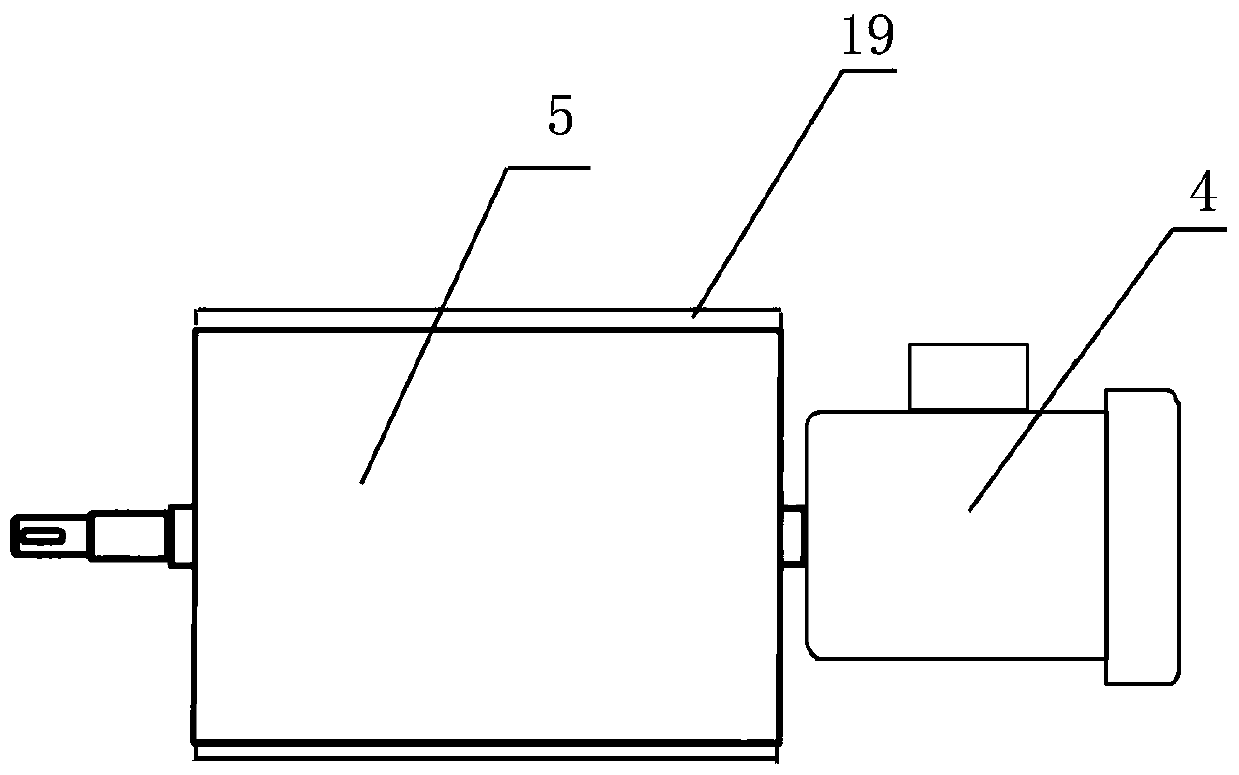

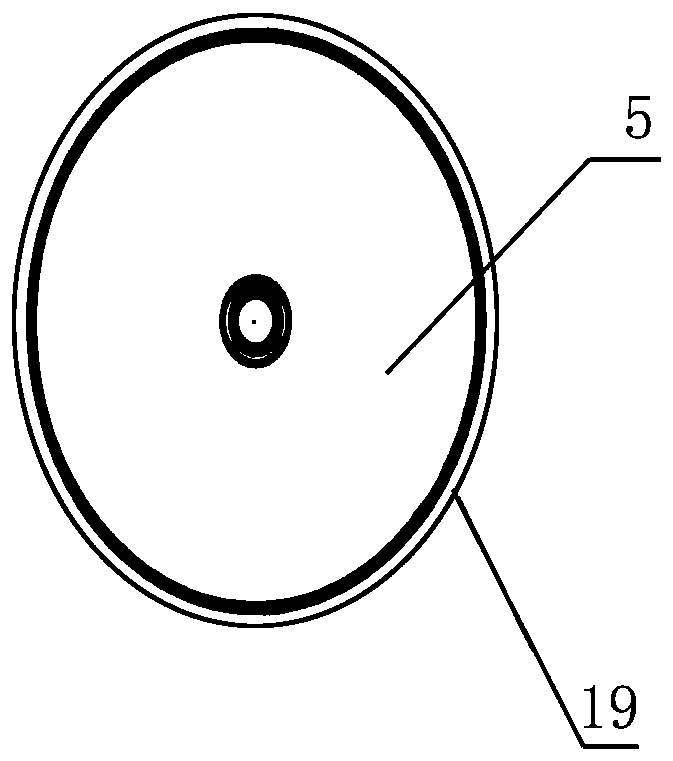

[0023] exist figure 1 Among them, the present invention provides a CNC diamond sand wire cutting machine tool, which is provided with a bed 1, one side of the bed 1 is provided with a mounting table 2, the mounting table 2 is arranged on the upper surface of the bed 1, and the front of the mounting table 2 An operation panel 3 is provided, and a wire feeding mechanism is placed on the installation table 2, and the figure 2 and image 3 Among them, the wire feeding mechanism includes a driving motor I4 and a wire storage drum 5, the outer surface of the wire storage drum 5 is covered with a protective rubber layer for the outer ring of the wire drum, and the protective rubber layer for the outer ring of the wire drum is a polyurethane rubber layer 19 , one end of the wire storage drum 5 is in transmission connection with the drive motor I4, and the drive motor I4 is in transmission connection with the rotating shaft of the wire storage drum 5 through a coupling. The bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com