Patents

Literature

39results about How to "Guaranteed not to loosen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

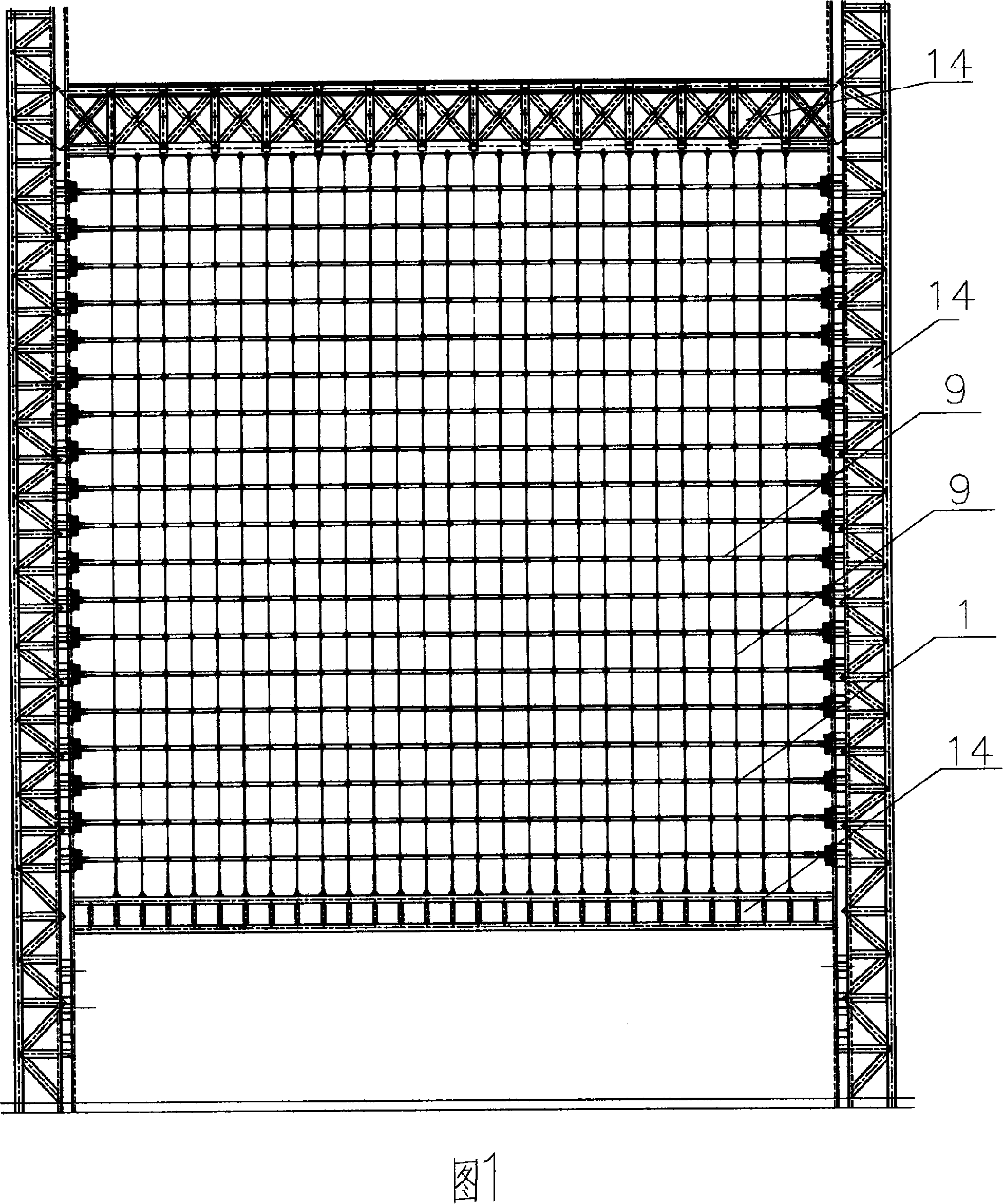

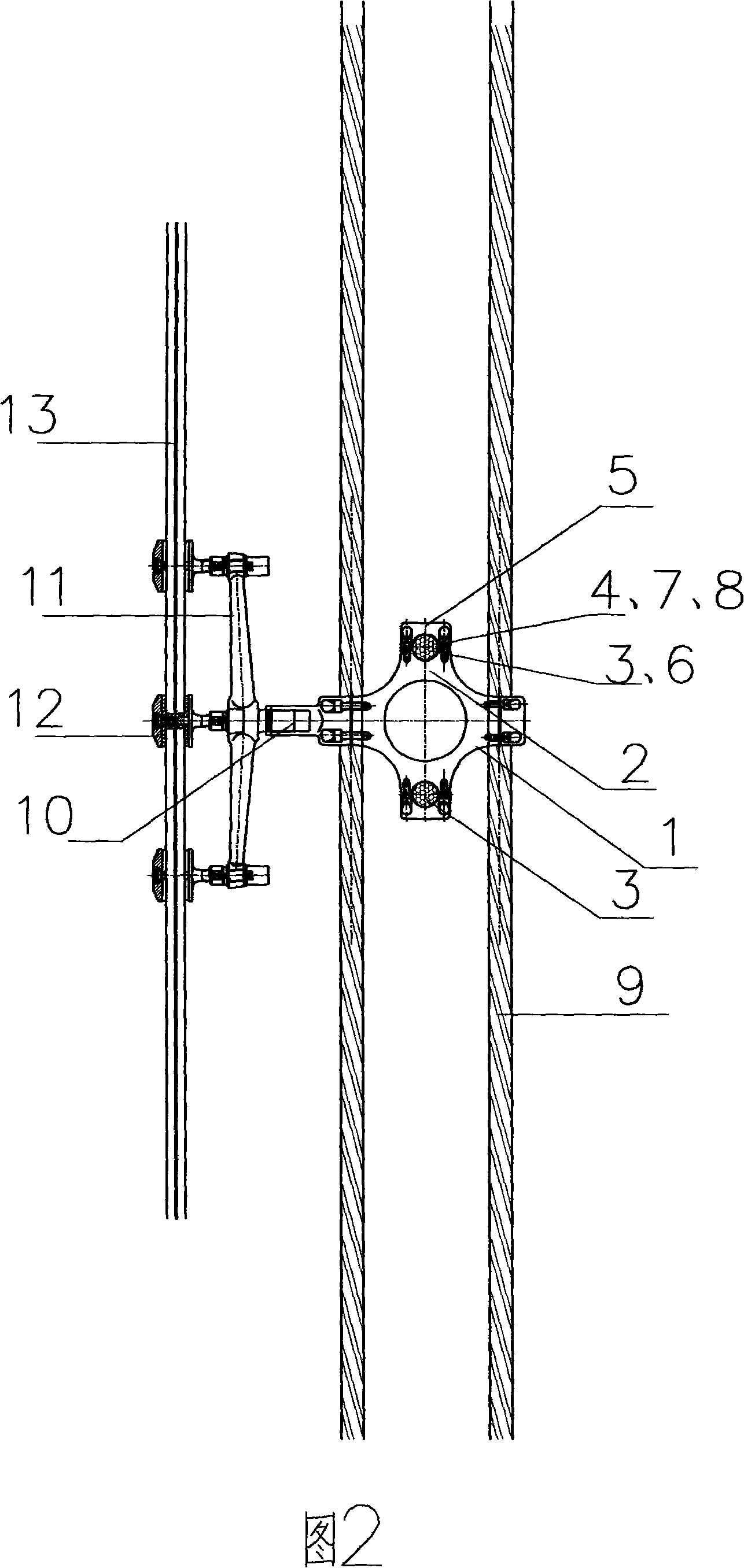

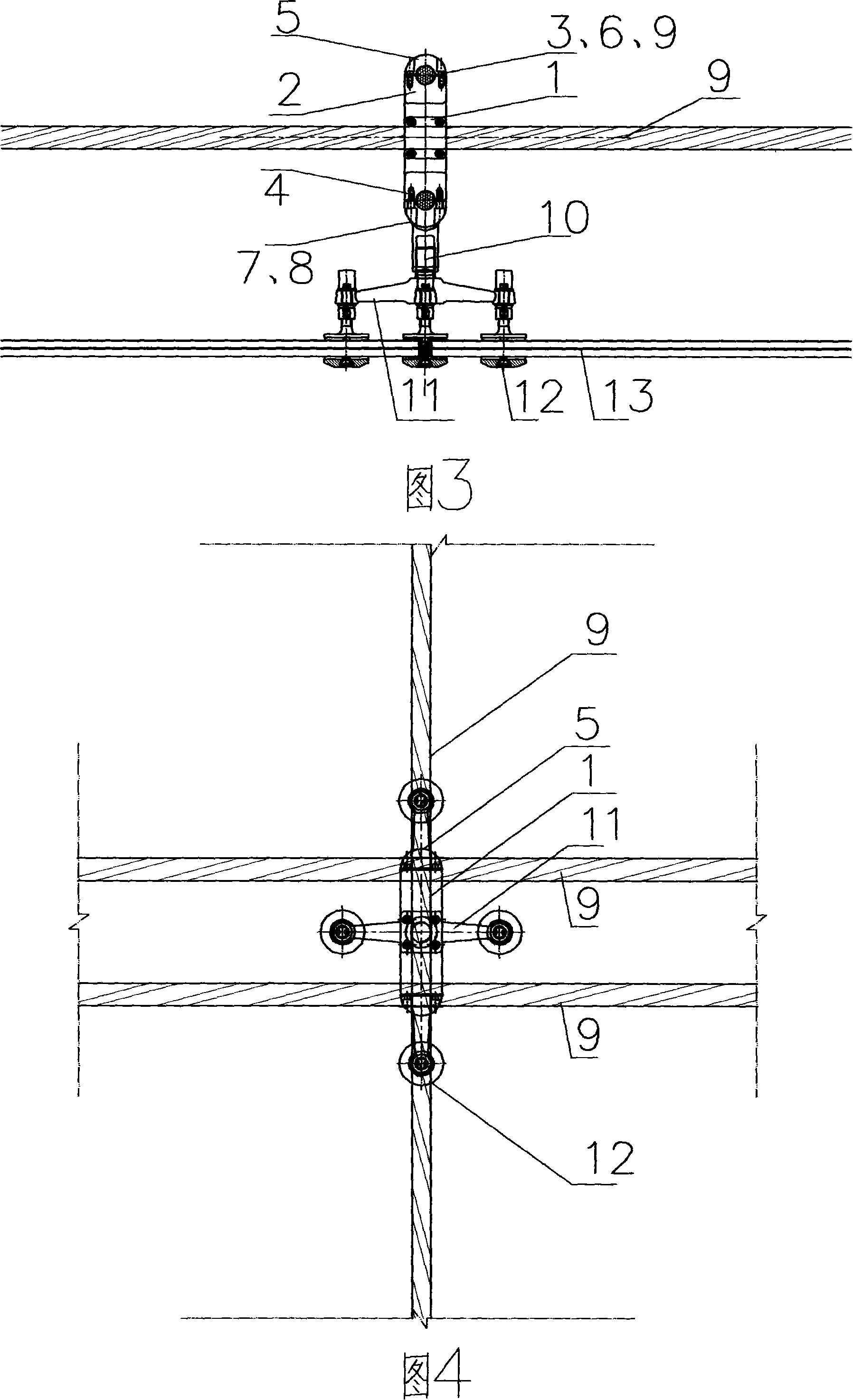

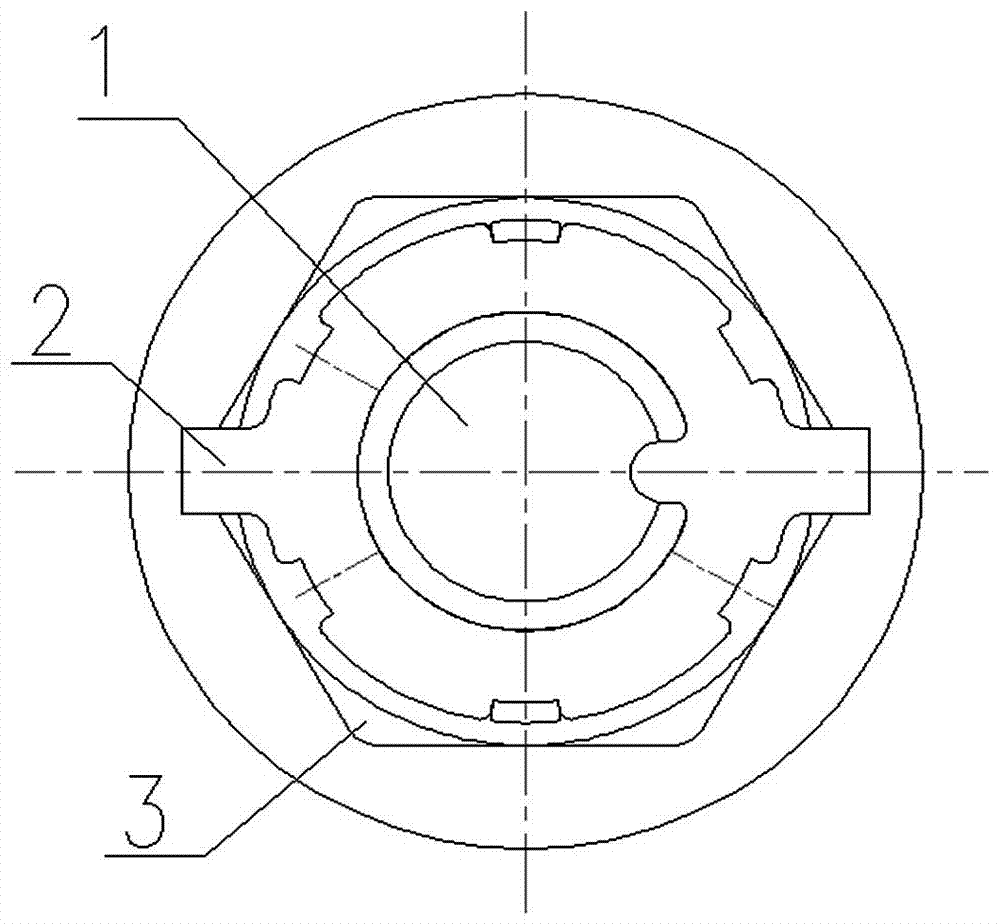

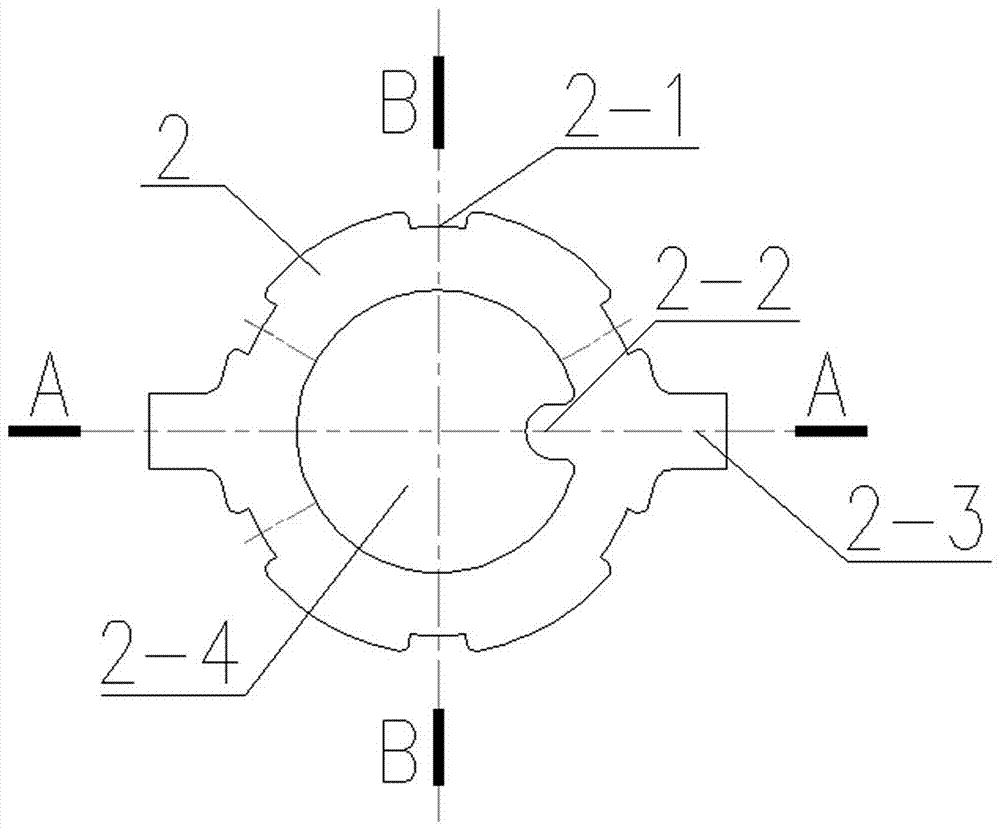

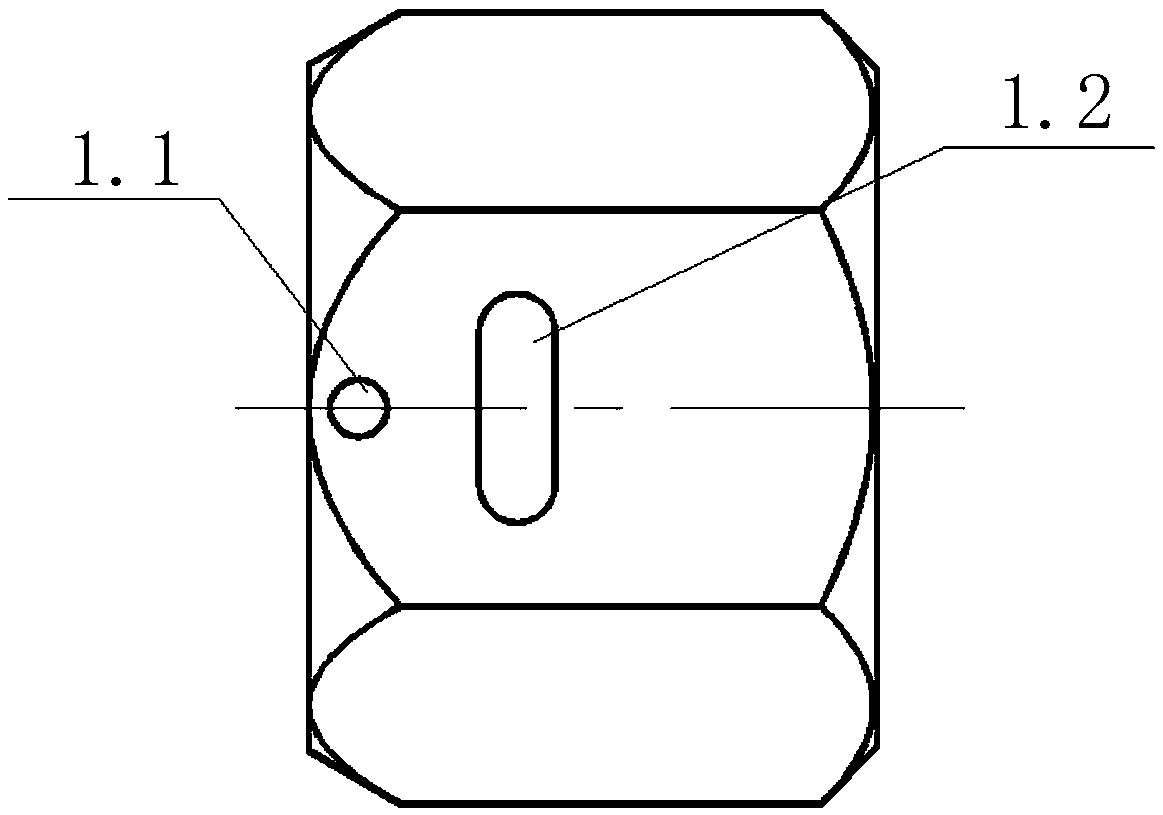

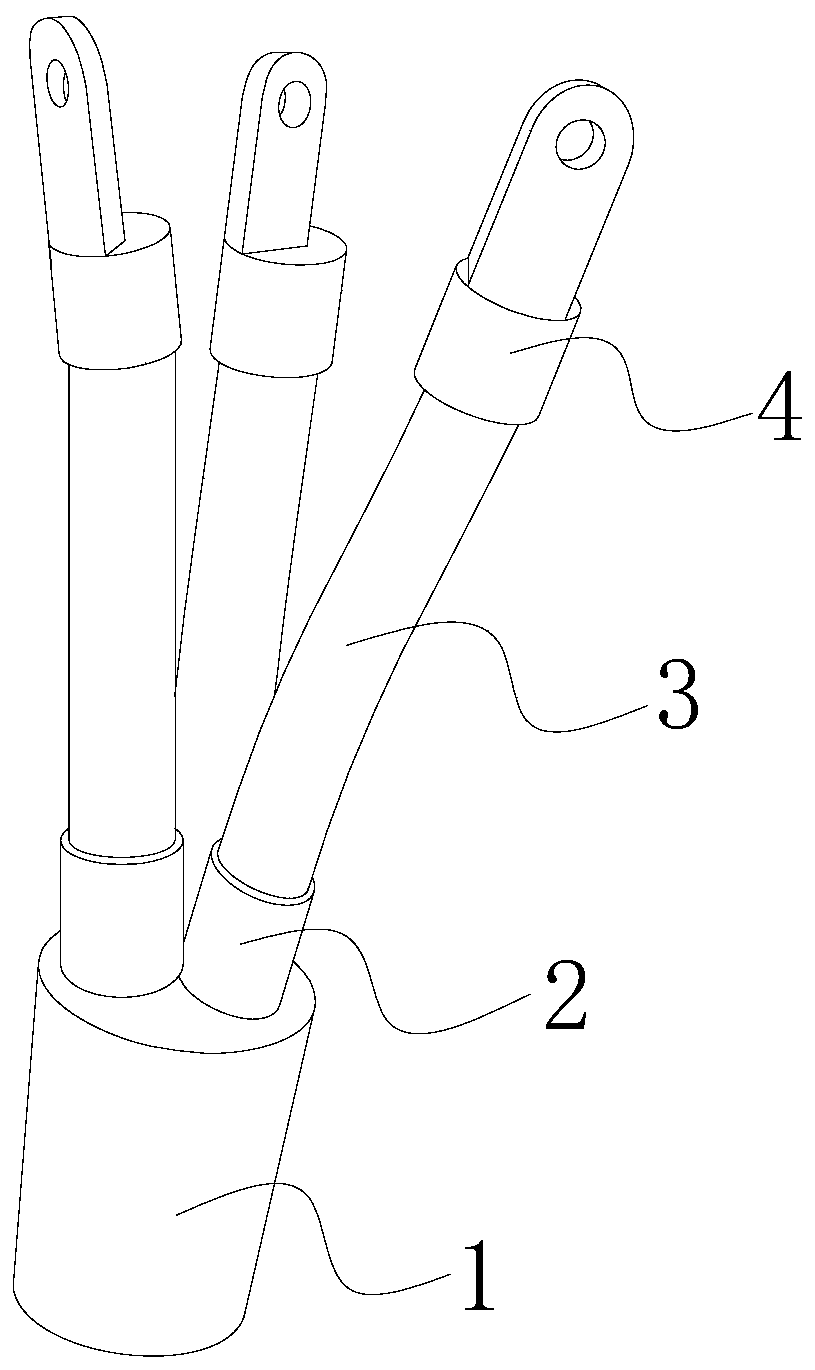

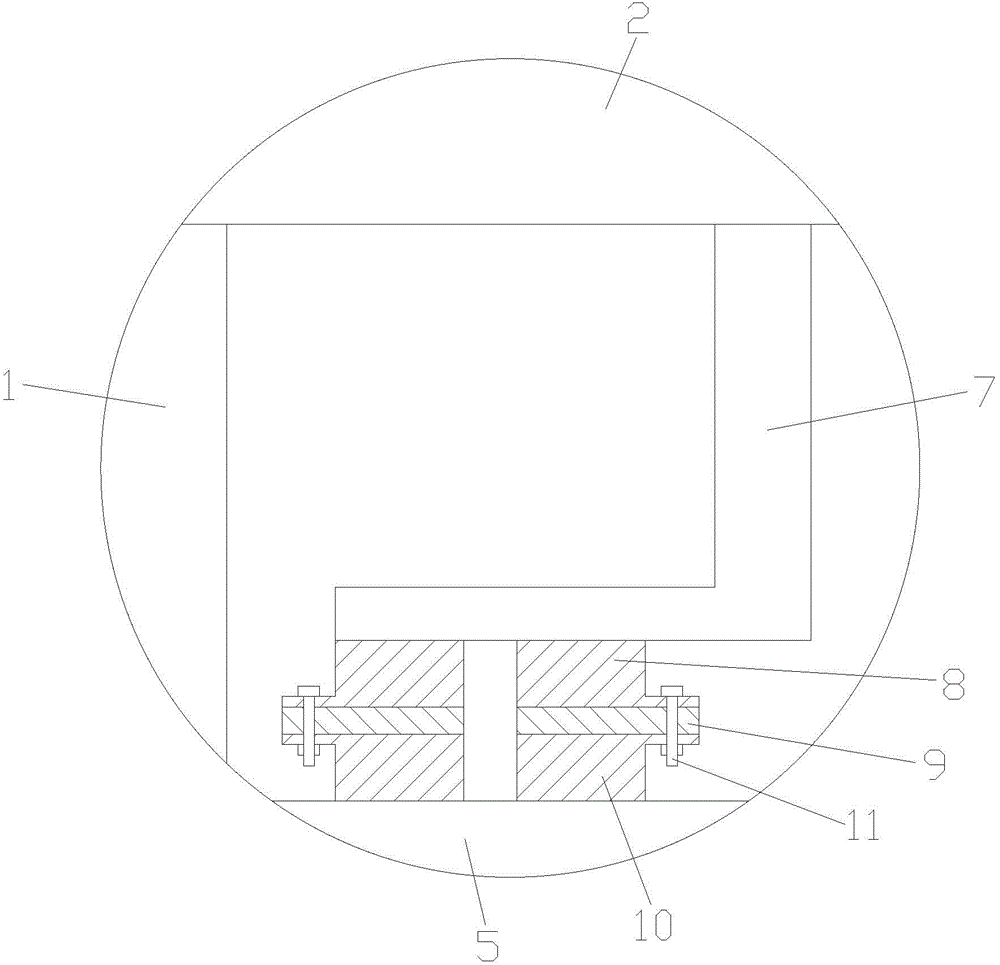

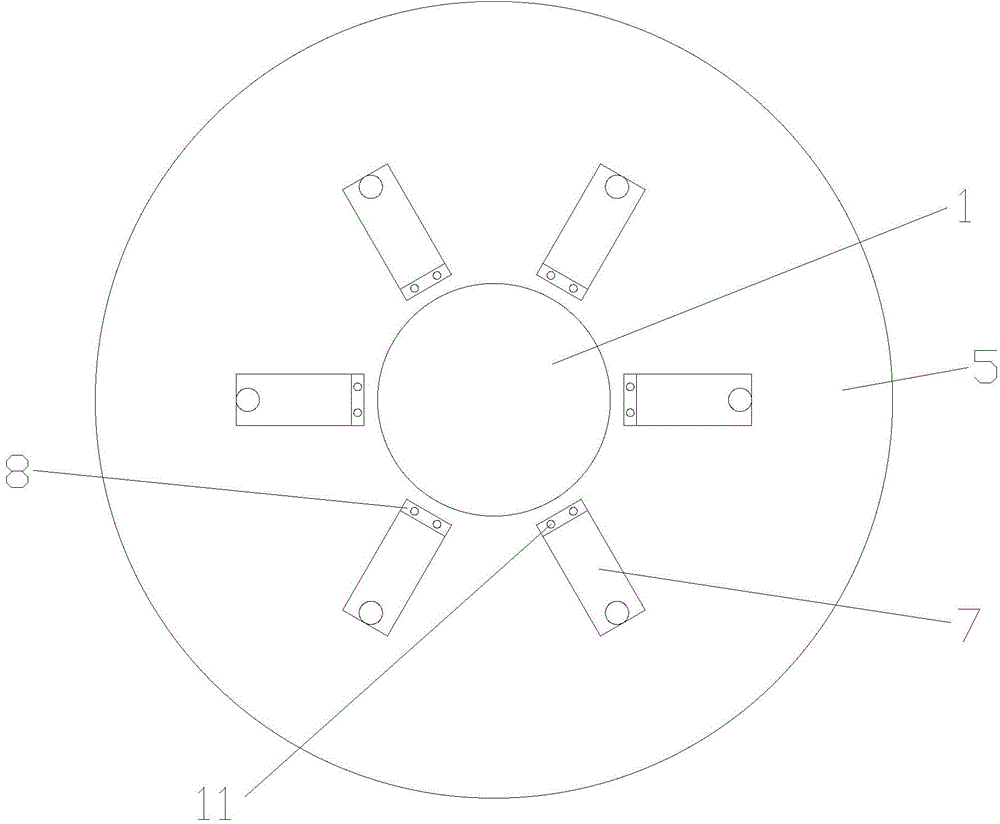

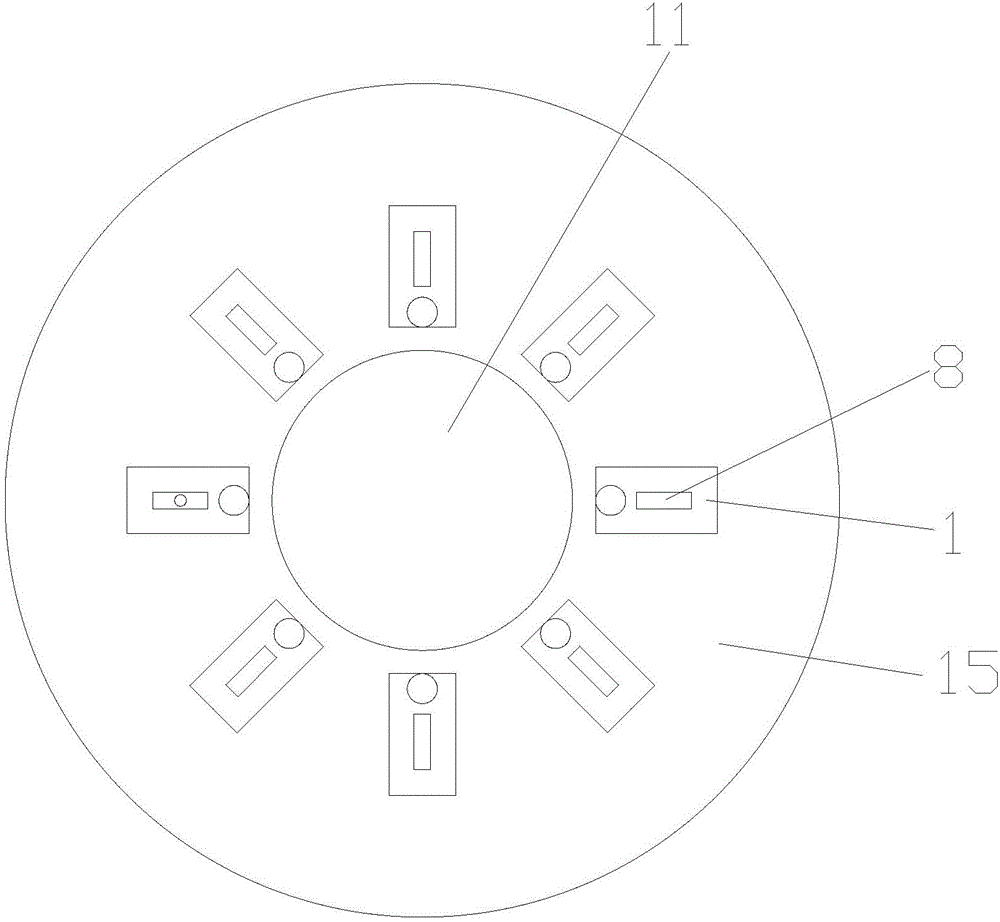

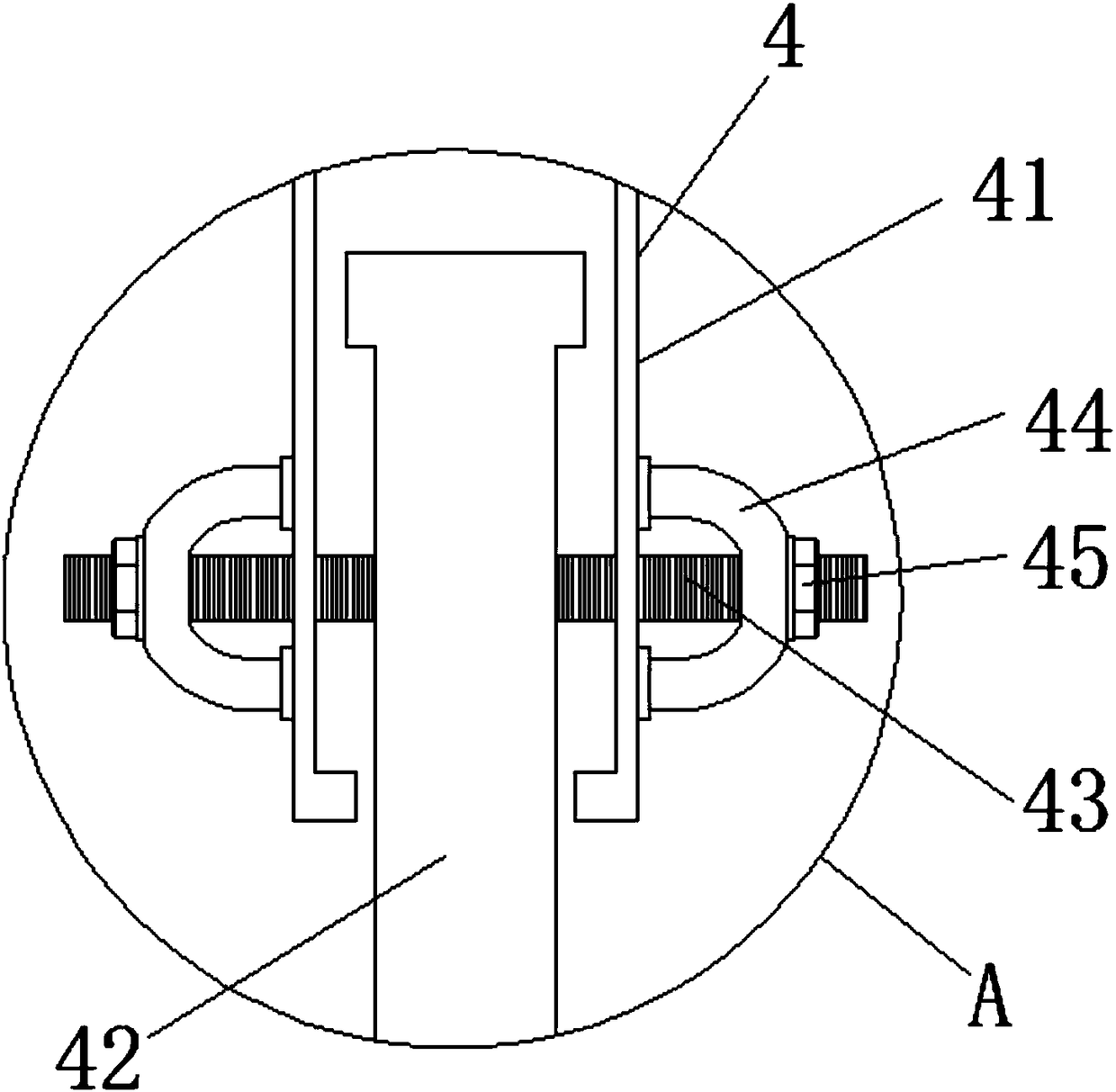

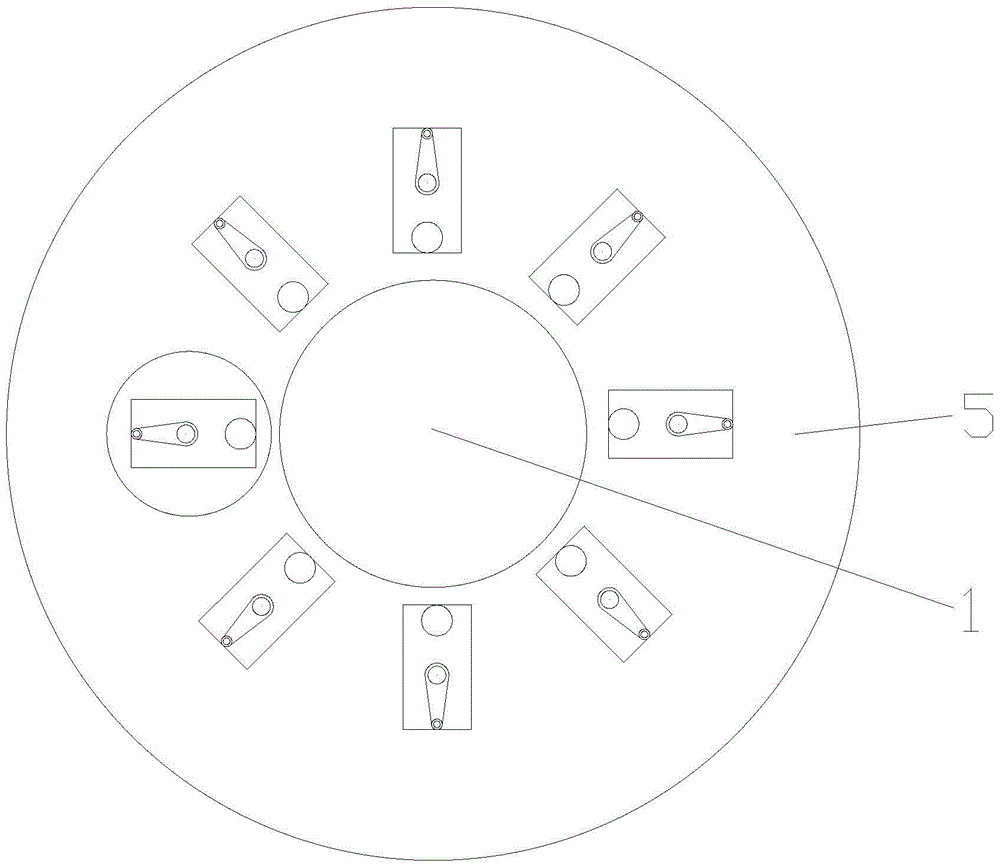

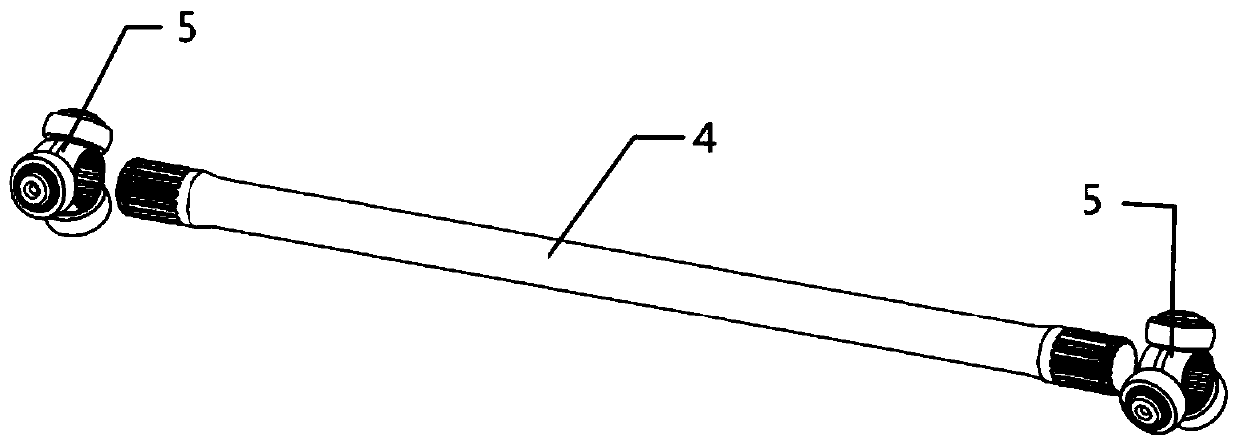

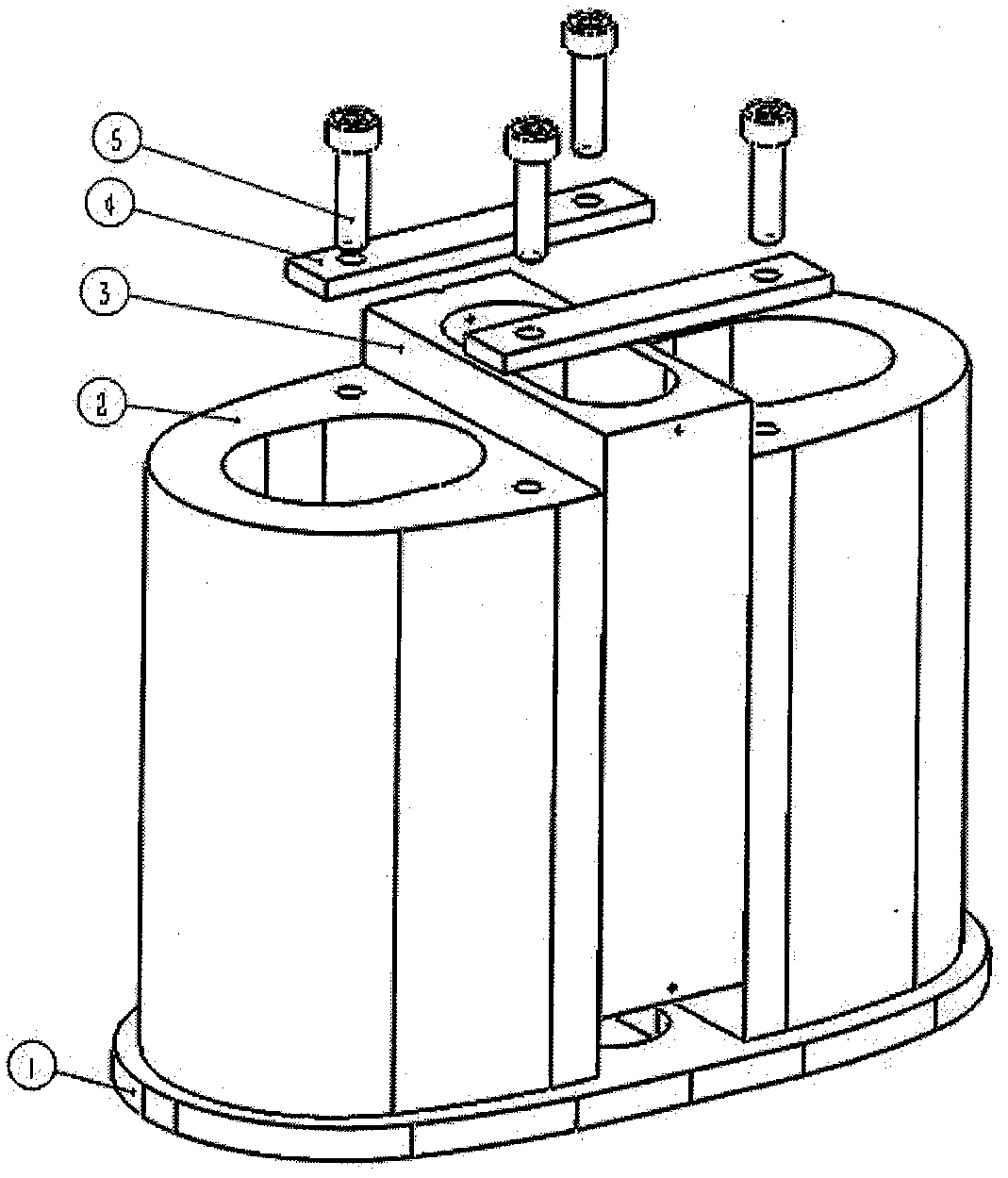

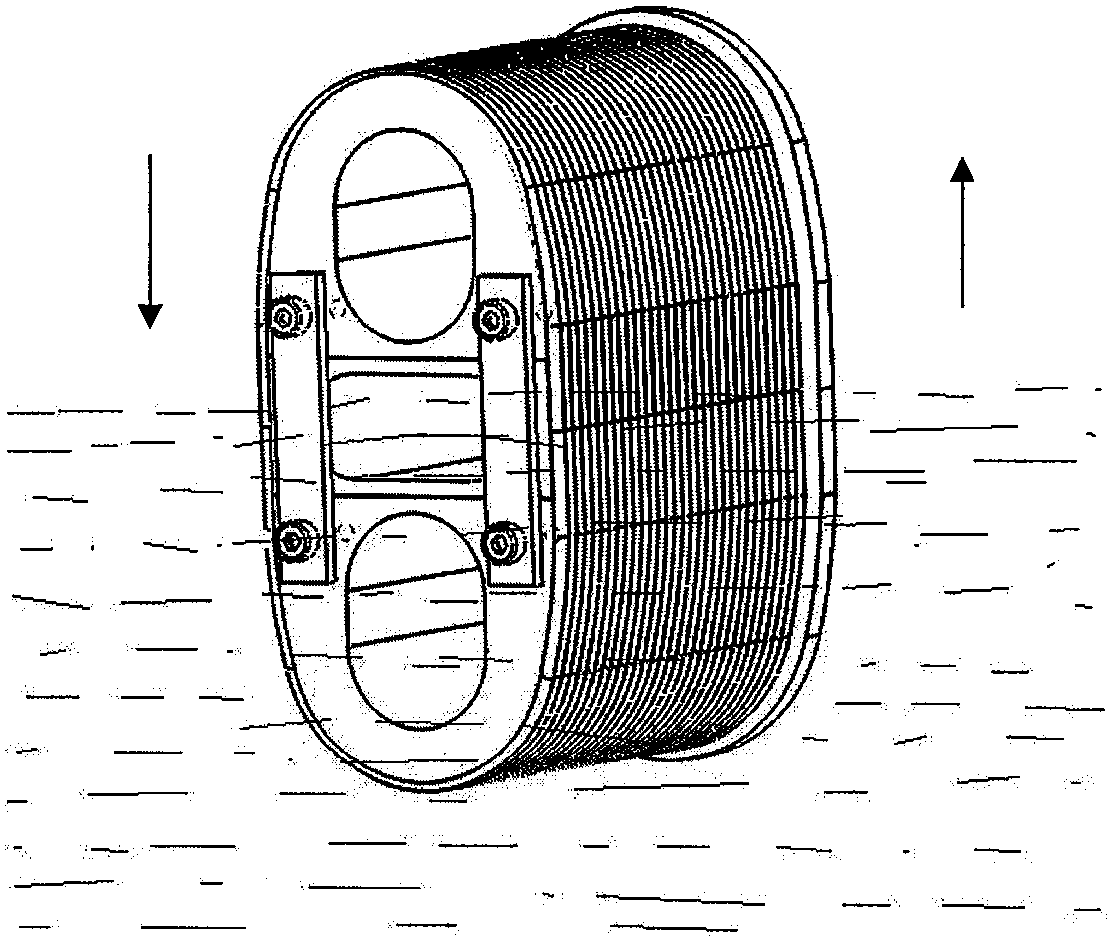

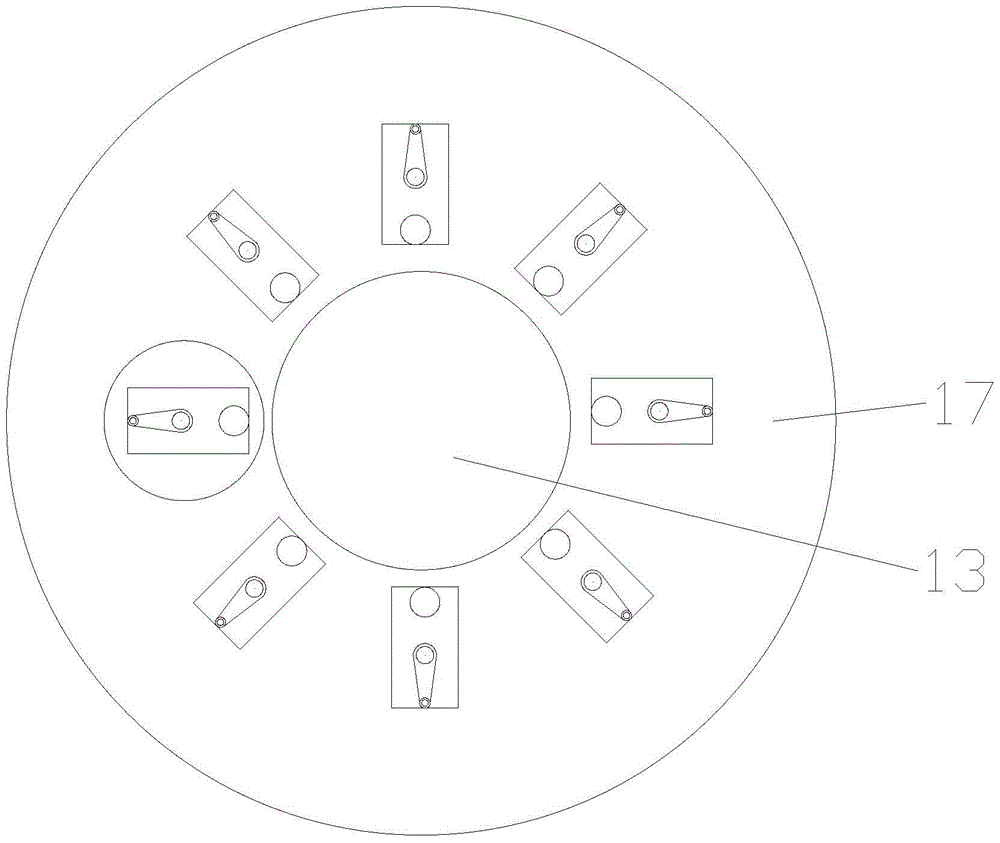

Single-layer bidirectional double-rope curtain wall support structure

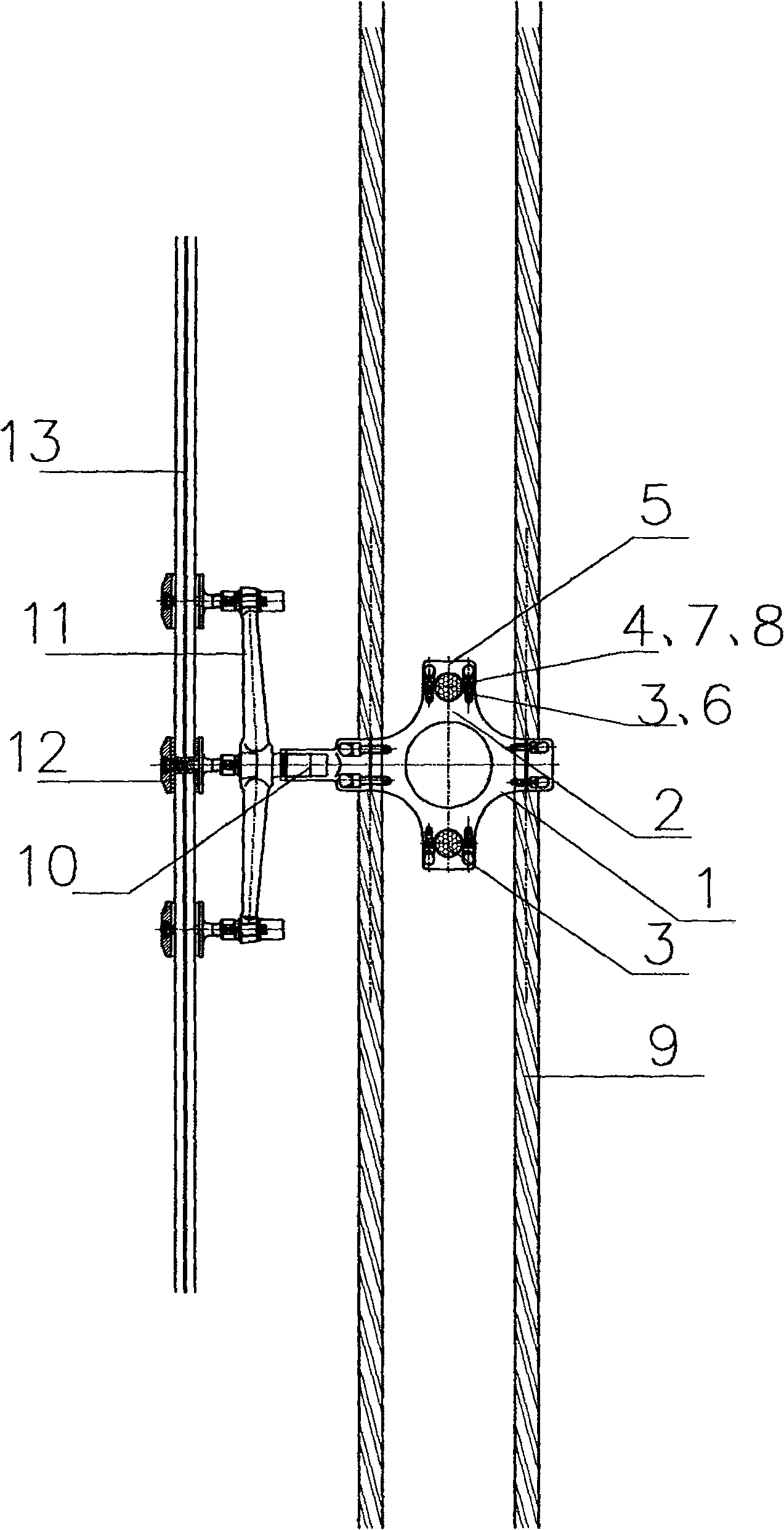

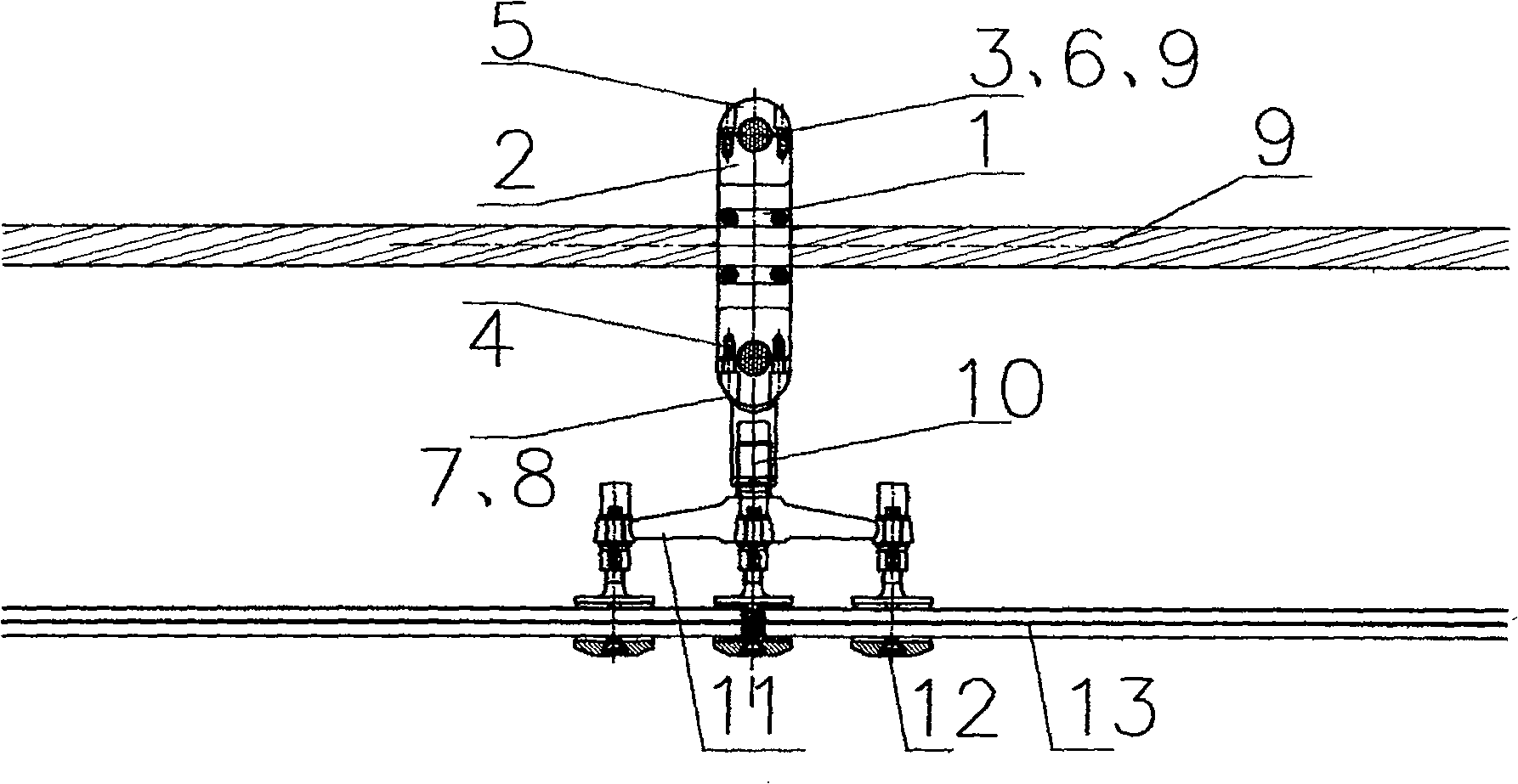

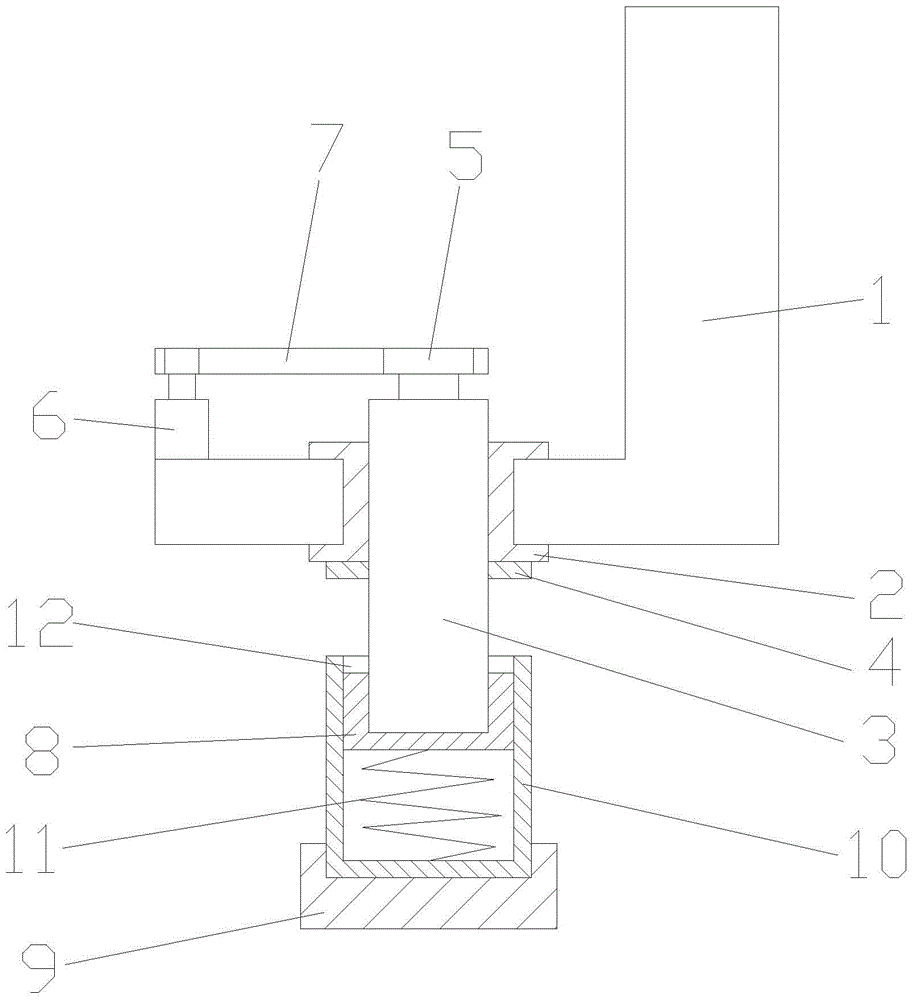

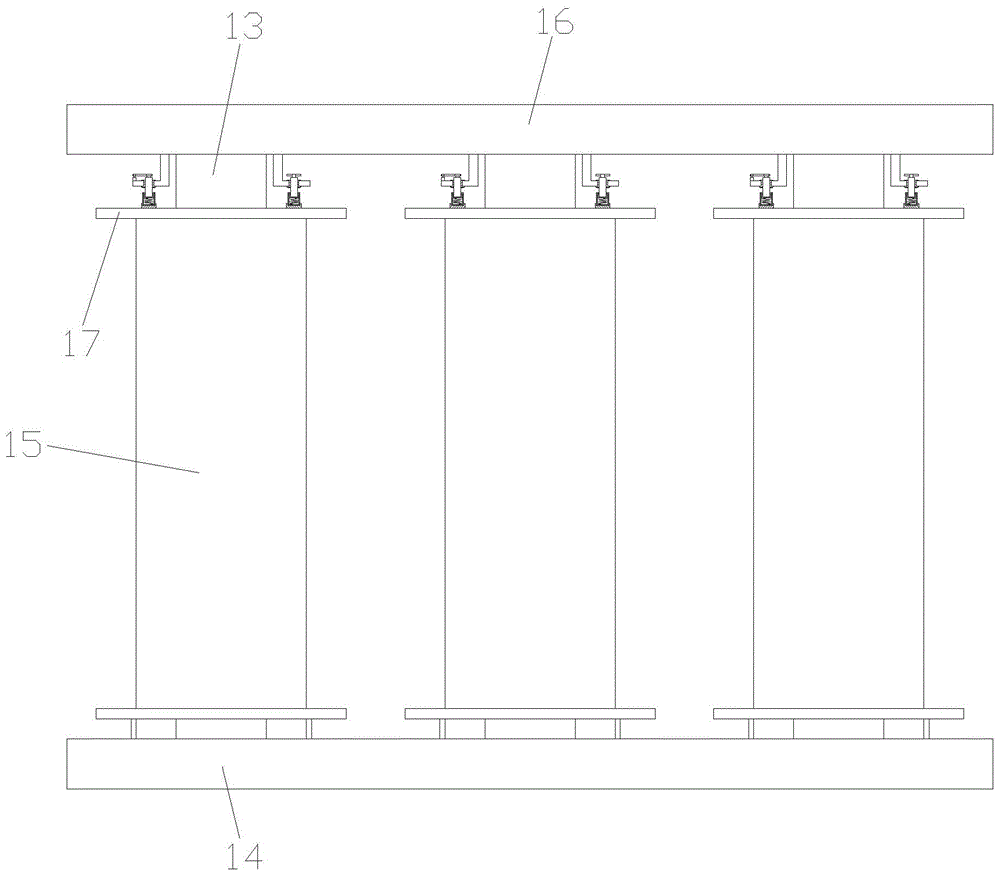

The invention relates to a single-layer bi-directional double-rope curtain wall support, which comprises a dragline clamp in form of a circular sheet, the middle of which is hollow and on which four abutments for fixing the dragline is provided. On each abutment, a semi-circle groove and an internal thread hole are provided. The four semi-circle grooves are distributed in cross way taking two as one group, the two groups of semi-circle grooves are vertical to each other in space. Each abutment is provided with a dragline-fastening end cover, on which also a semi-circle groove and a thread hole are provided. The fastening end cover is fixed on the abutment by a bolt. The abutment and the two semi-circle grooves for fastening the end cover coordinate each other to fix the dragline. The end of one fastening end cover is provided with an interface for connecting with the overlap connecting jaw. The invention makes possible adding no structural part in a space with a big span, and can guarantee the permeability of structures to the max. extent.

Owner:JANGHO GRP

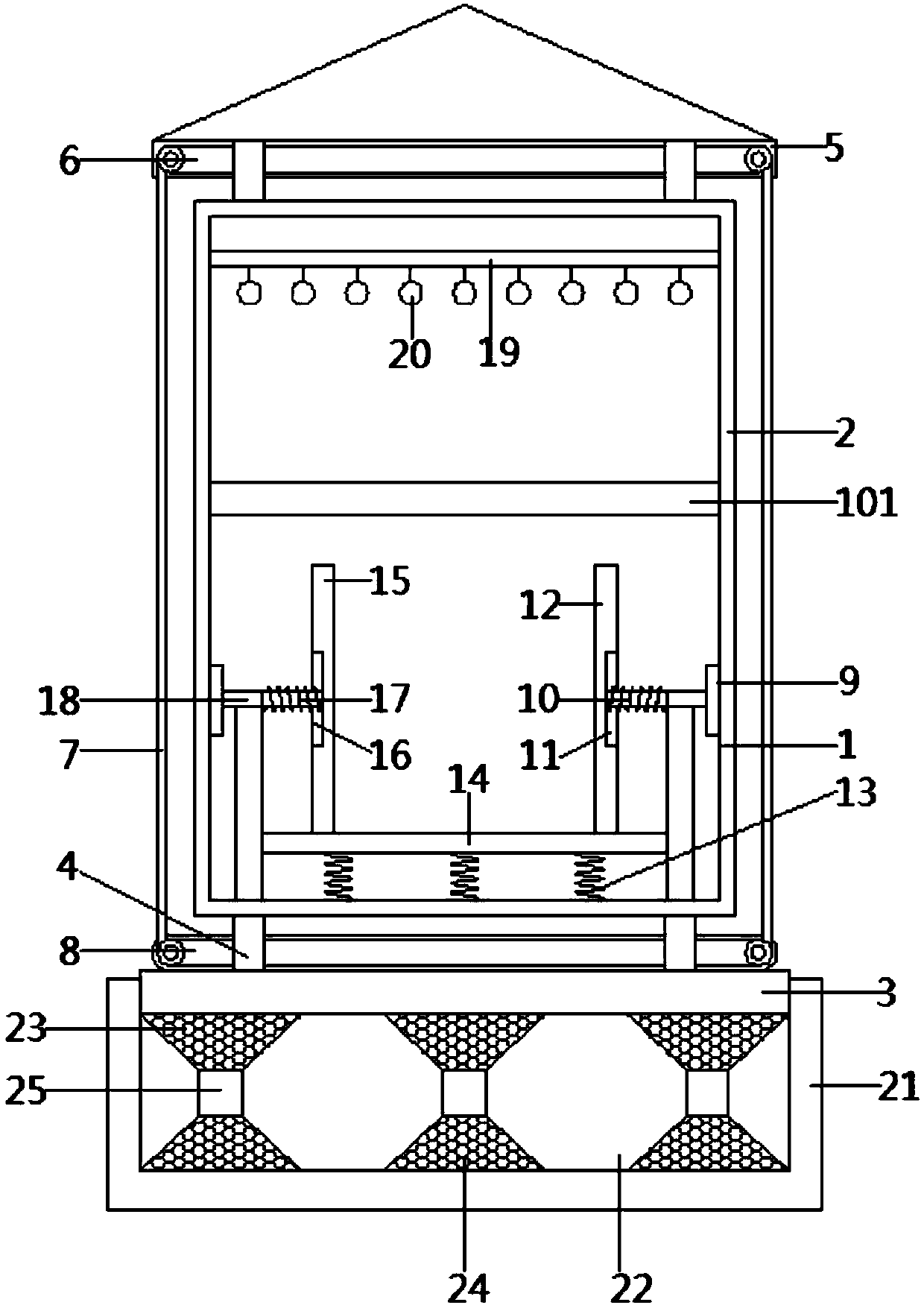

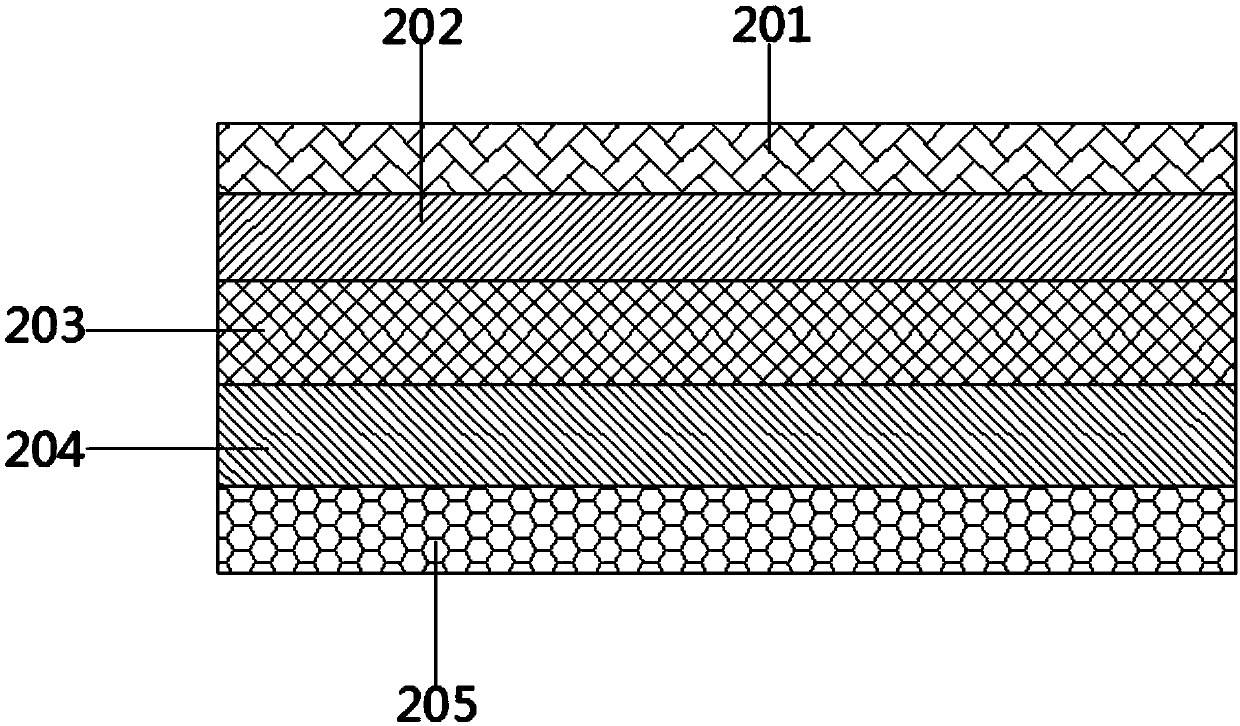

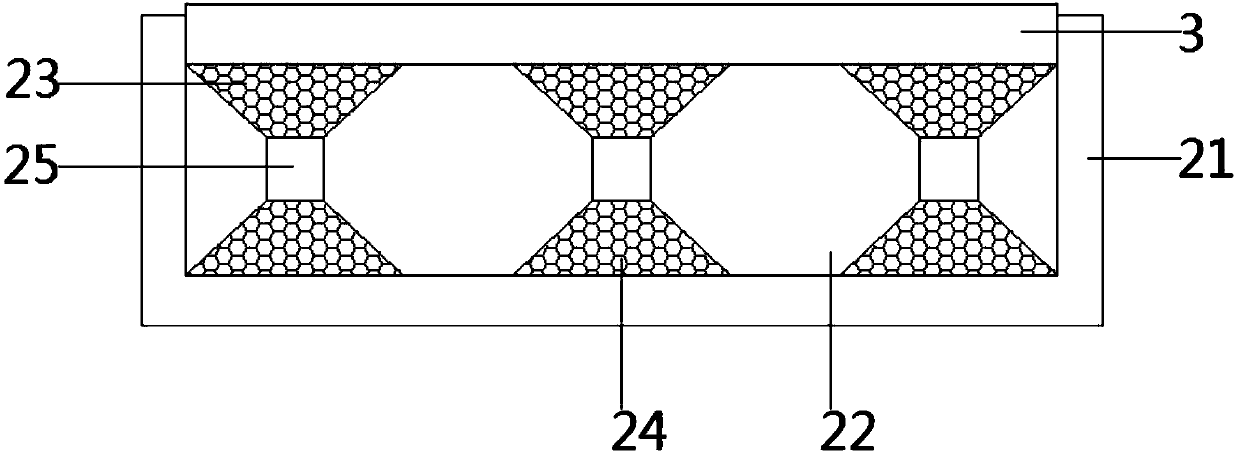

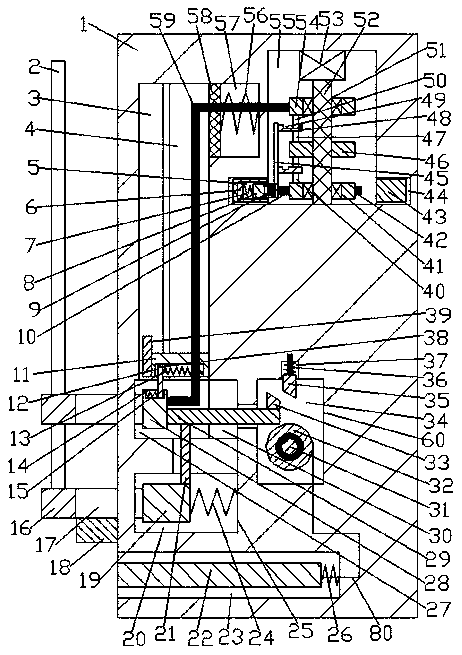

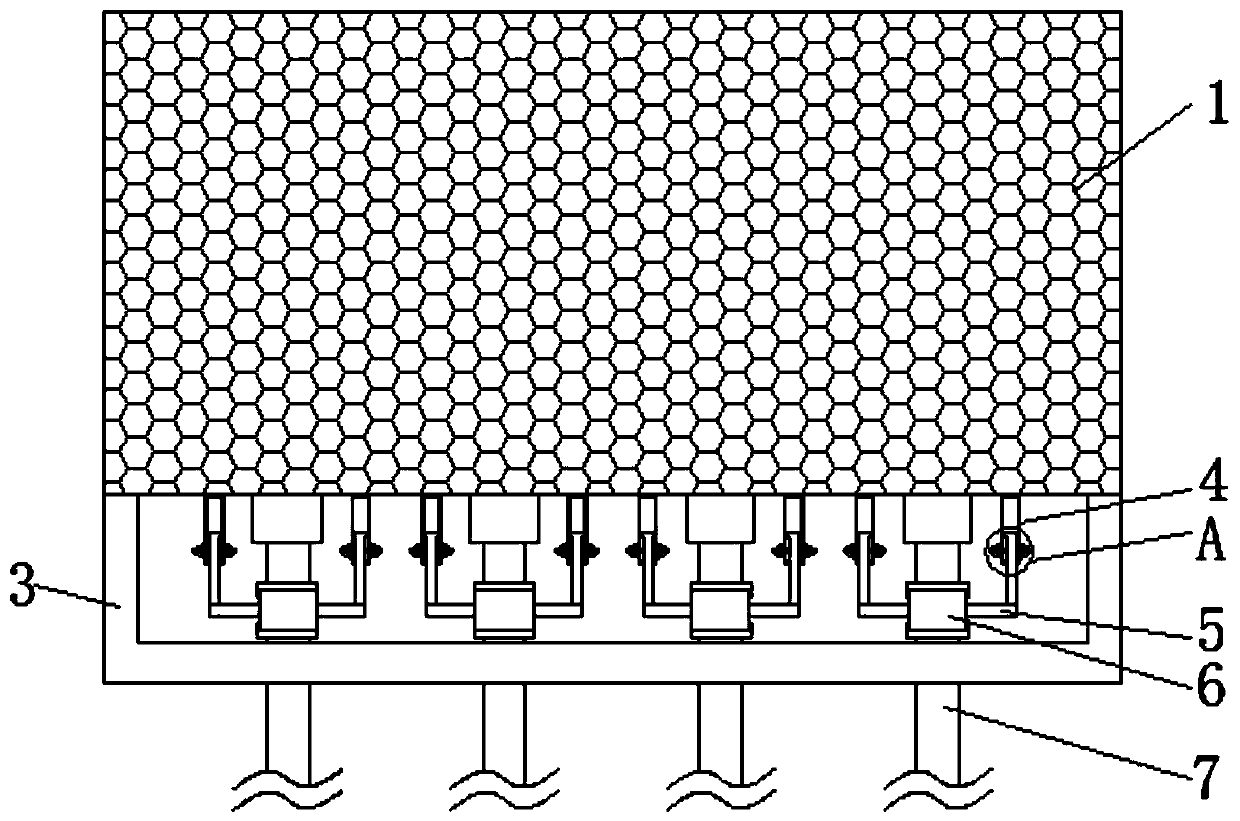

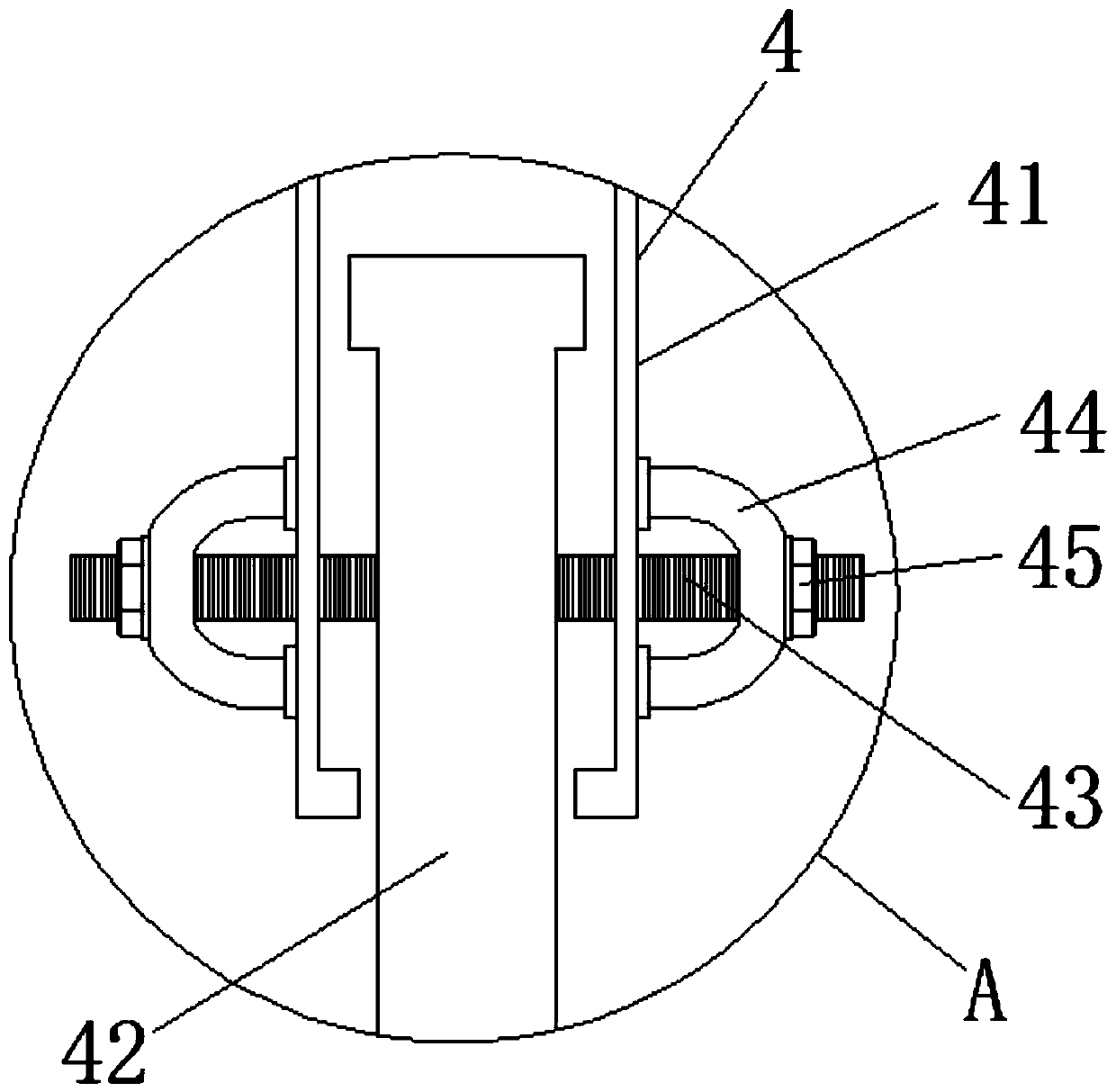

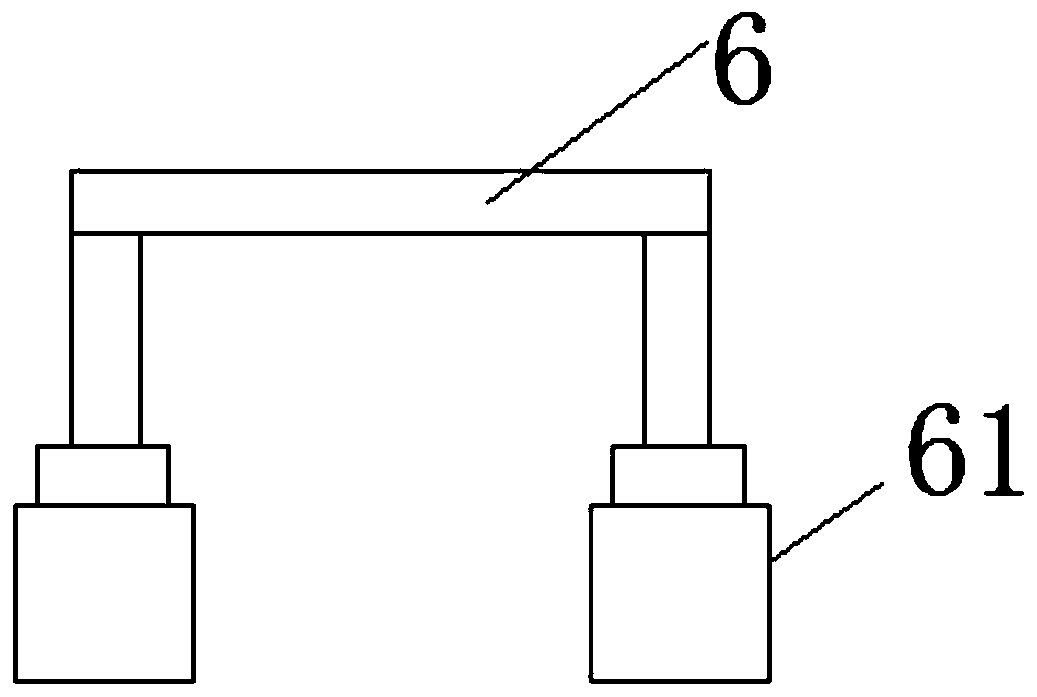

Outdoor power distribution cabinet with fire-proof and rain-proof functions

InactiveCN107634453AGood rain and sun protectionExtended service lifeSubstation/switching arrangement casingsAnti-seismic devicesEngineeringSun protection

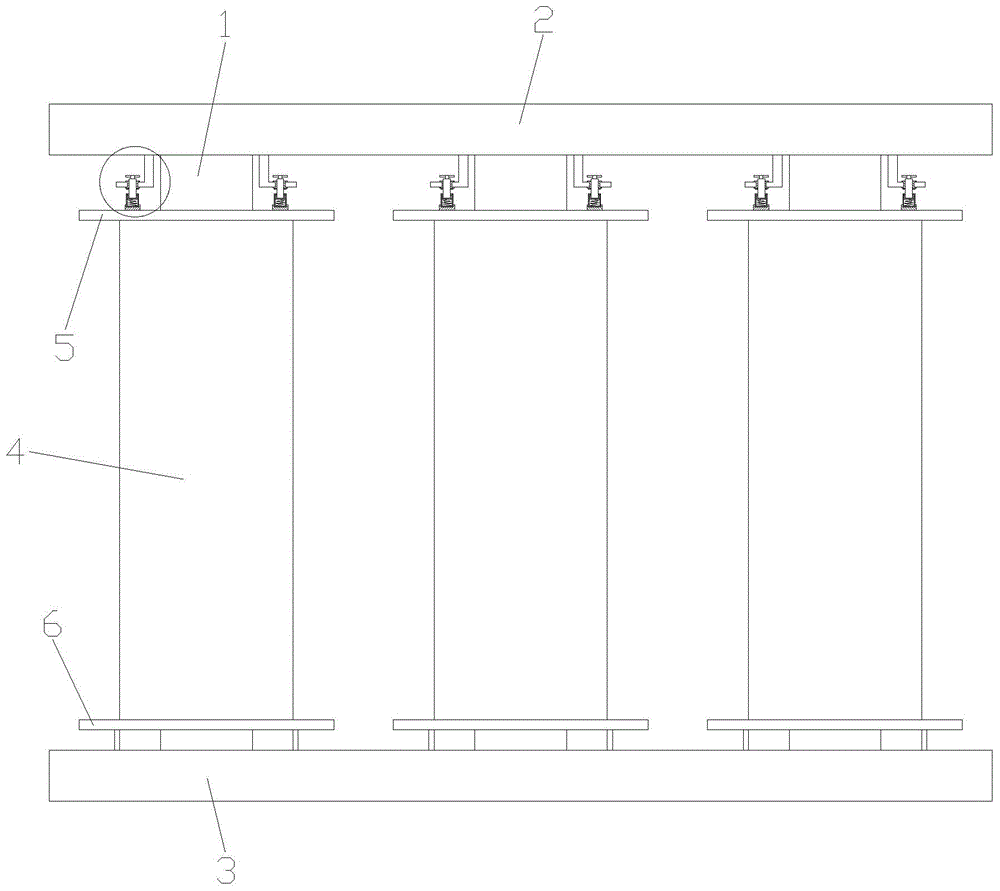

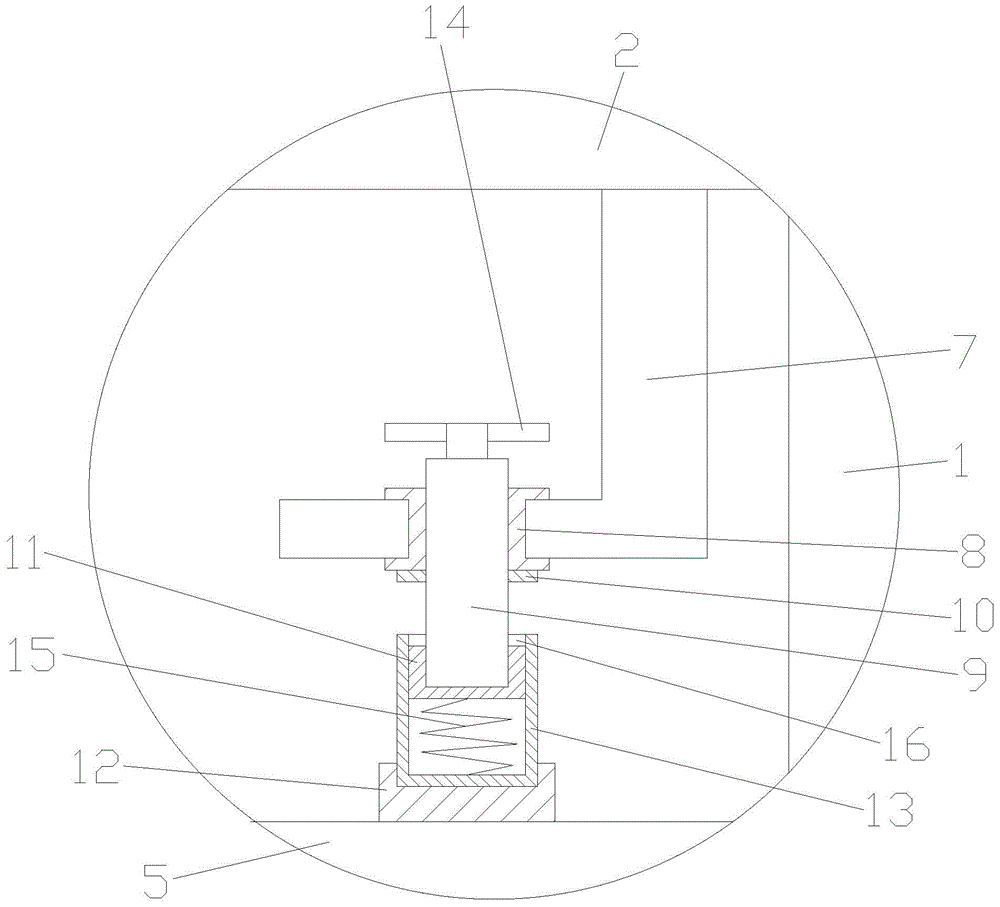

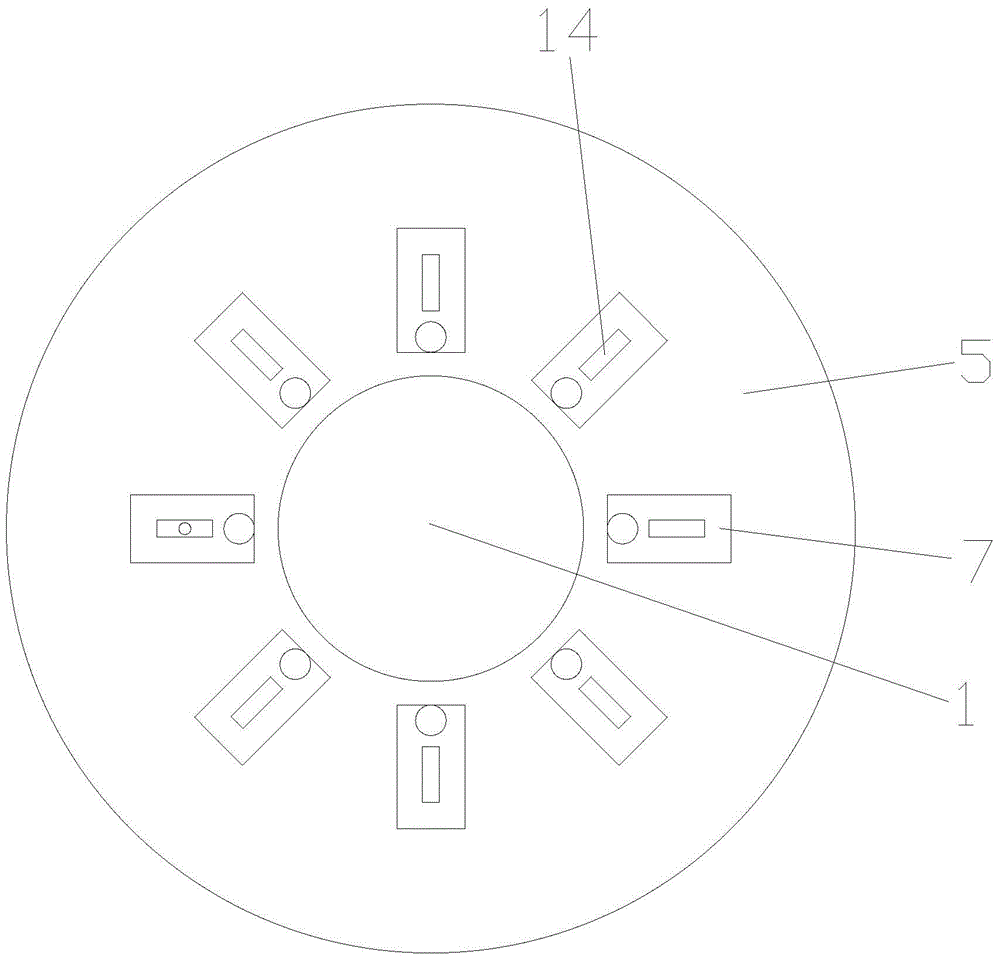

The invention discloses an outdoor power distribution cabinet with fire-proof and rain-proof functions, which comprises a cabinet body, and is characterized in that the outer wall of the cabinet bodyis provided with a fire-proof plate, the fire-proof plate is formed by sequentially laminating a waterproof layer, a first thermal insulating layer, a support layer, a second thermal insulating layerand a barrier layer, the first thermal insulating layer and the second thermal insulating layer are compact spongy expansion foam layers, and a base is horizontally arranged at the lower side of the cabinet body. The outdoor power distribution cabinet with fire-proof and rain-proof functions can effectively prevent a fire through wrapping the fire-proof plate at the outer side of the cabinet body,and the safety is improved. The vibration of electric power components can be greatly reduced through designing a lower damping spring, a left damping spring and a right damping spring, the electricpower components are ensured not to be loosened on an installation base plate, a rain-proof and sun protection cover improves the rain-proof and sun protection ability of the cabinet body, and the service life of the cabinet body is prolonged. In addition, buffering is performing through sand filled in a triangular funnel, so that the buffering effect is good, and the vibration of the power distribution cabinet is effectively reduced. The outdoor power distribution cabinet is simple in structure, stable in performance and long in service life.

Owner:CHANGSHA KEYUE ENTERPRISE MANAGEMENT CONSULTING CO LTD

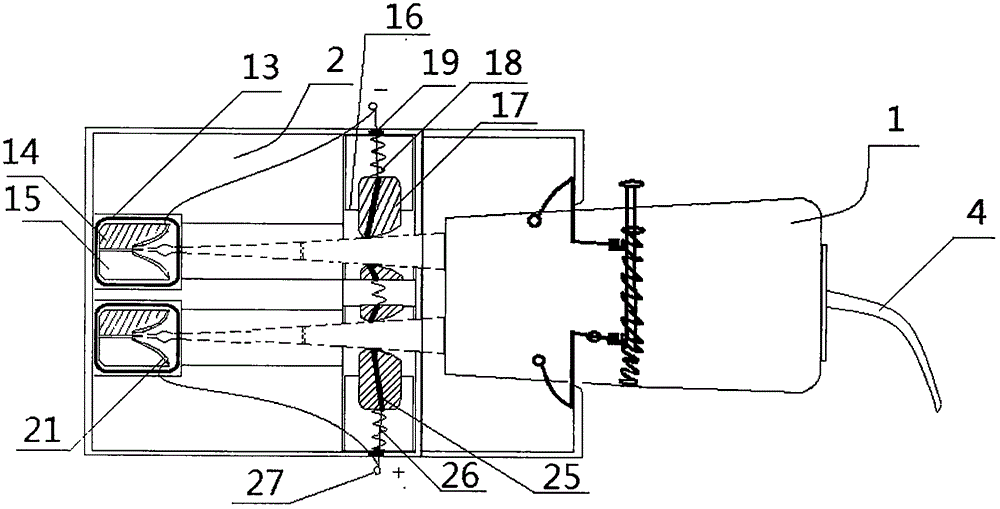

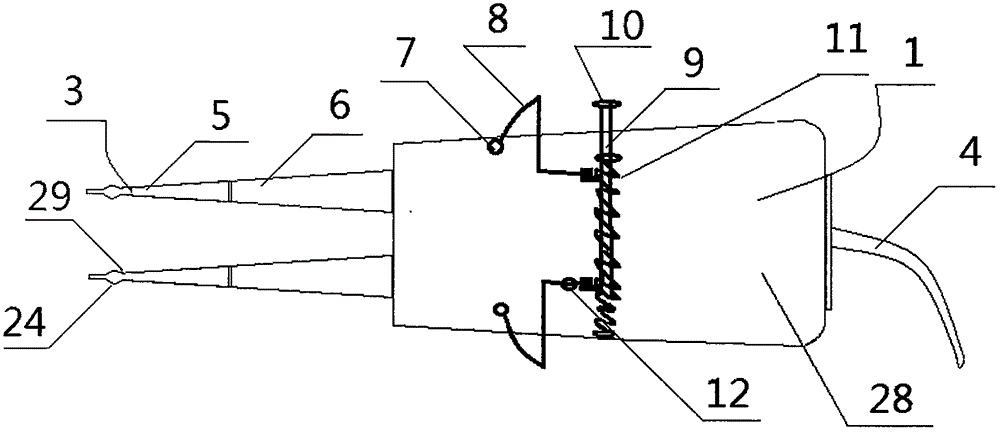

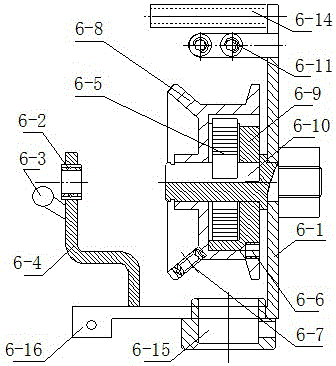

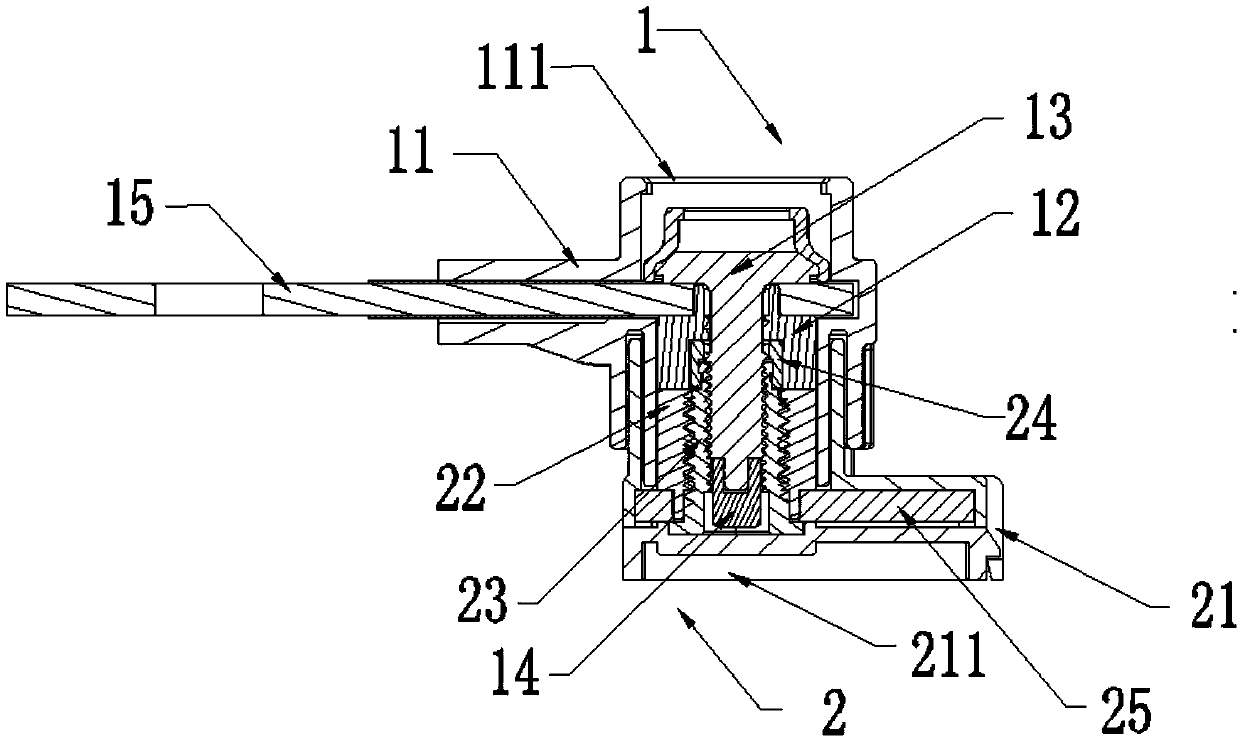

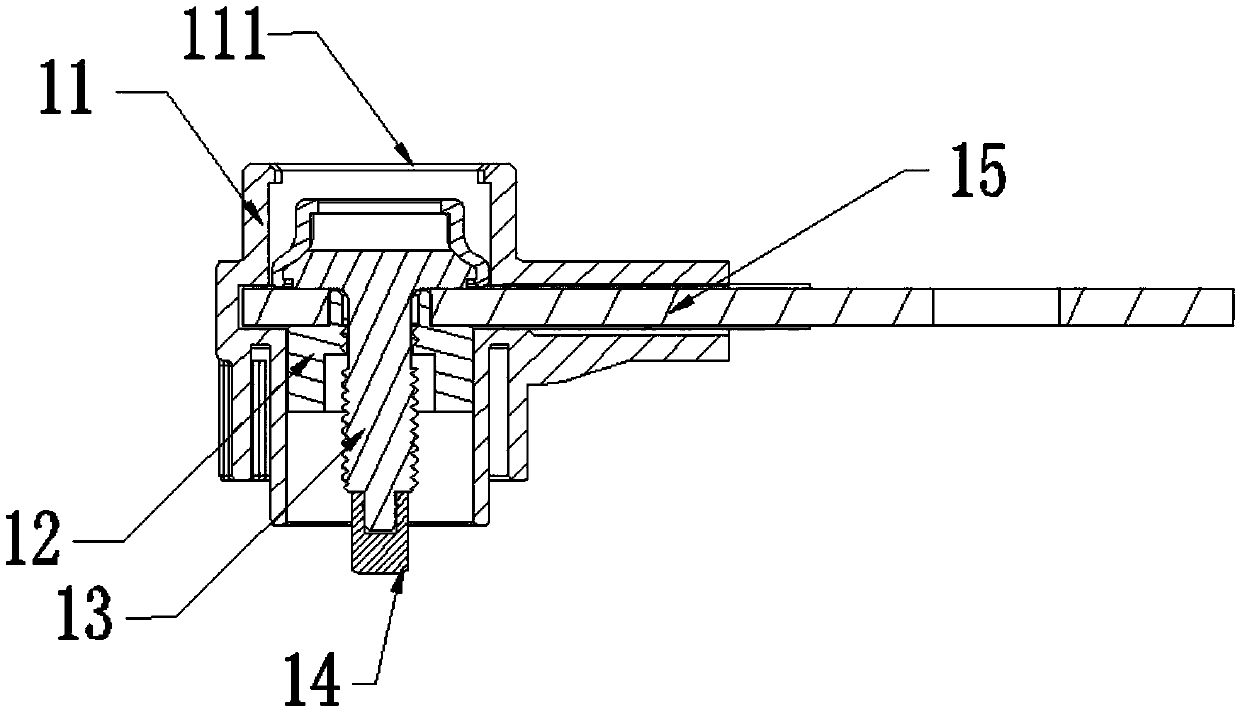

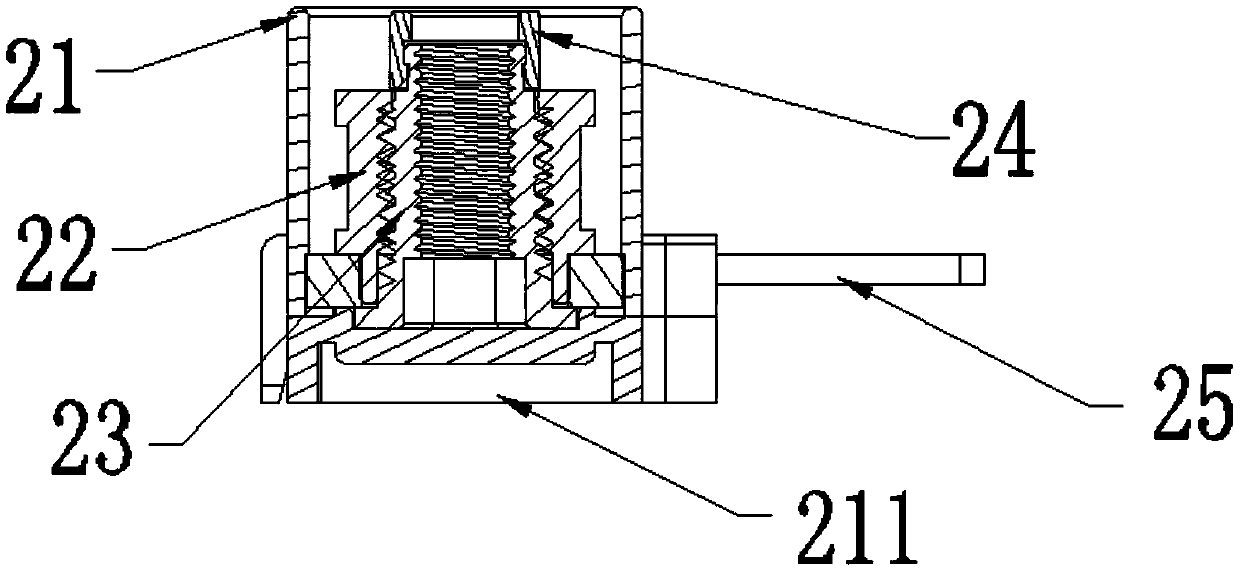

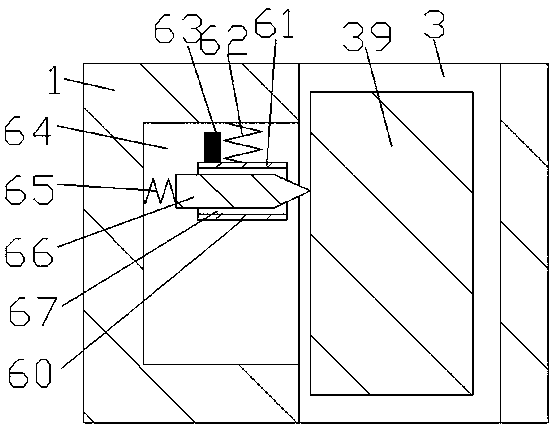

Graphene charging plug device for new-energy electric vehicles and method for graphene charging plug device

ActiveCN106299879AMeet the requirements of fast charging with high power and high currentExtended service lifeCharging stationsCoupling device detailsEngineeringBrush device

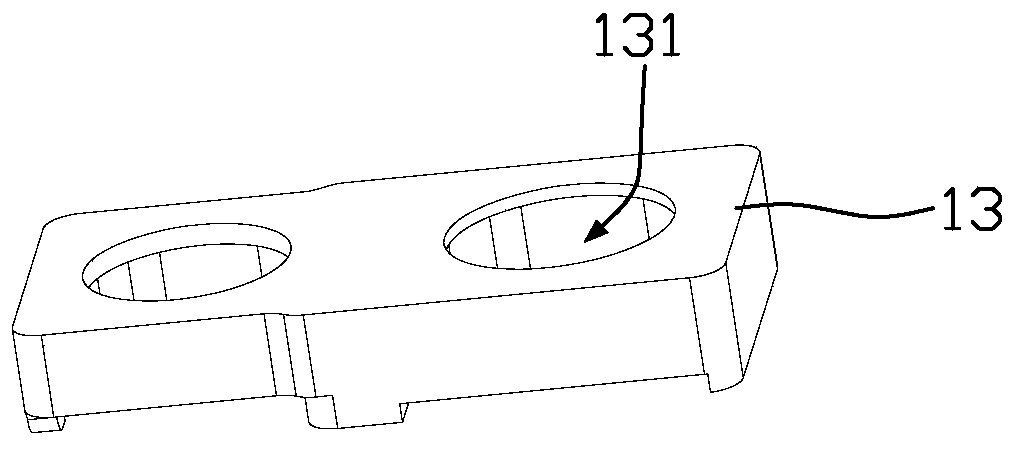

The invention discloses a graphene charging plug device for new-energy electric vehicles and a method for the graphene charging plug device. The graphene charging plug device comprises a plug device [1] and a socket device [2], and is characterized in that the plug device [1] comprises a plug handle [28], plugs [3] and a connecting wire [4], the socket device [2] comprises a ceramic socket [13], a magnet N (north) pole [14], a magnet S (south) pole [15], a carbon brush holder [16], a carbon brush device [17], a second spring [18] and a spring adjusting bolt [19], and the plug handle [28] is provided with a first movable end [7], a buckle device [8], a feed rod [9], a handle [10], a first spring [11] and a second movable fulcrum [12]. The graphene charging plug device and the method have the advantages that the graphene charging plug device is simple in arrangement and convenient to use, requirements on high power, currents and charging speeds in electric vehicle charging procedures can be met, heating or faults due to poor contact can be prevented, spark and electric arc can be effectively reduced, and the plugs can be guaranteed against being loosened or retreated.

Owner:李健

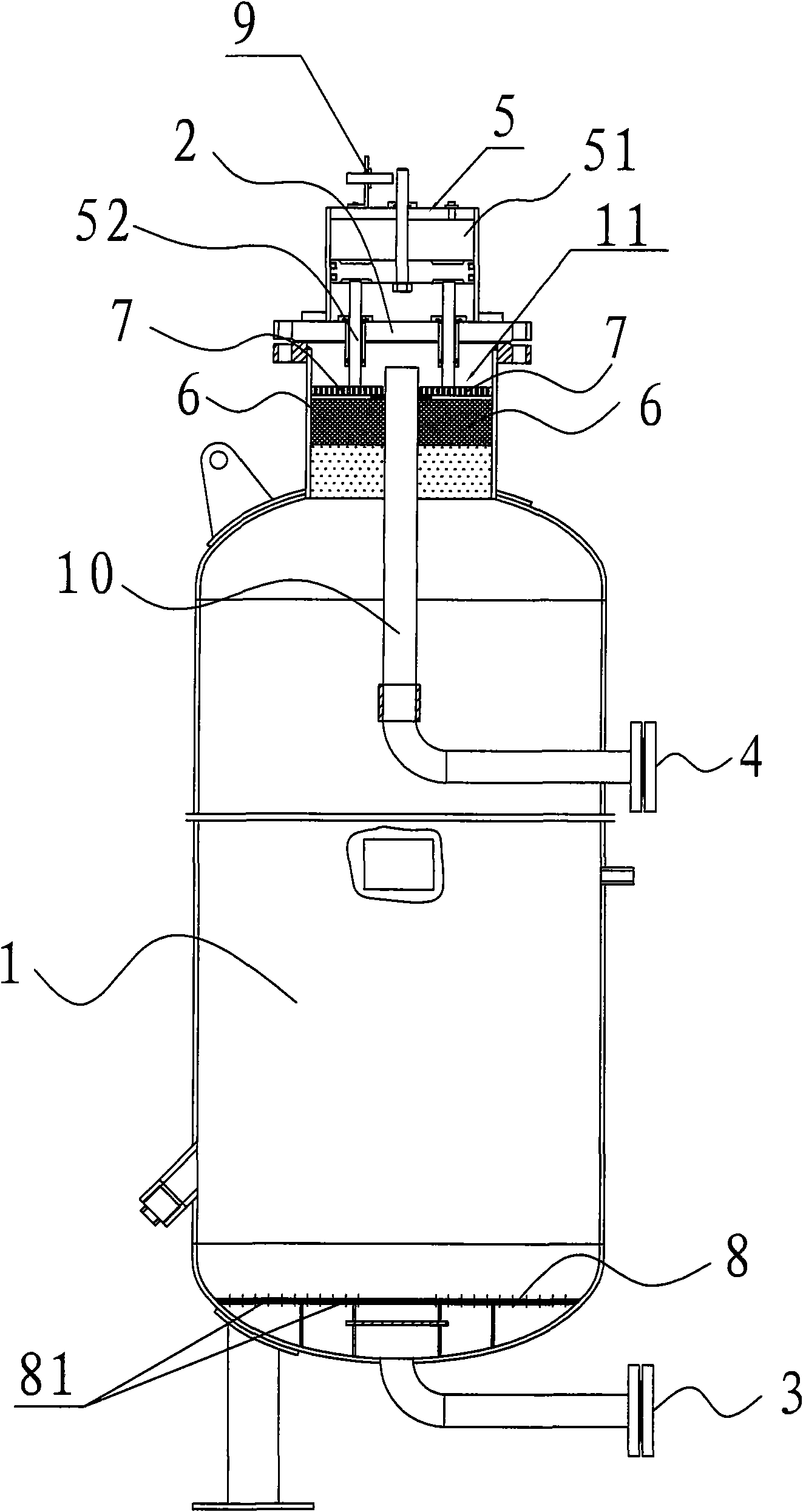

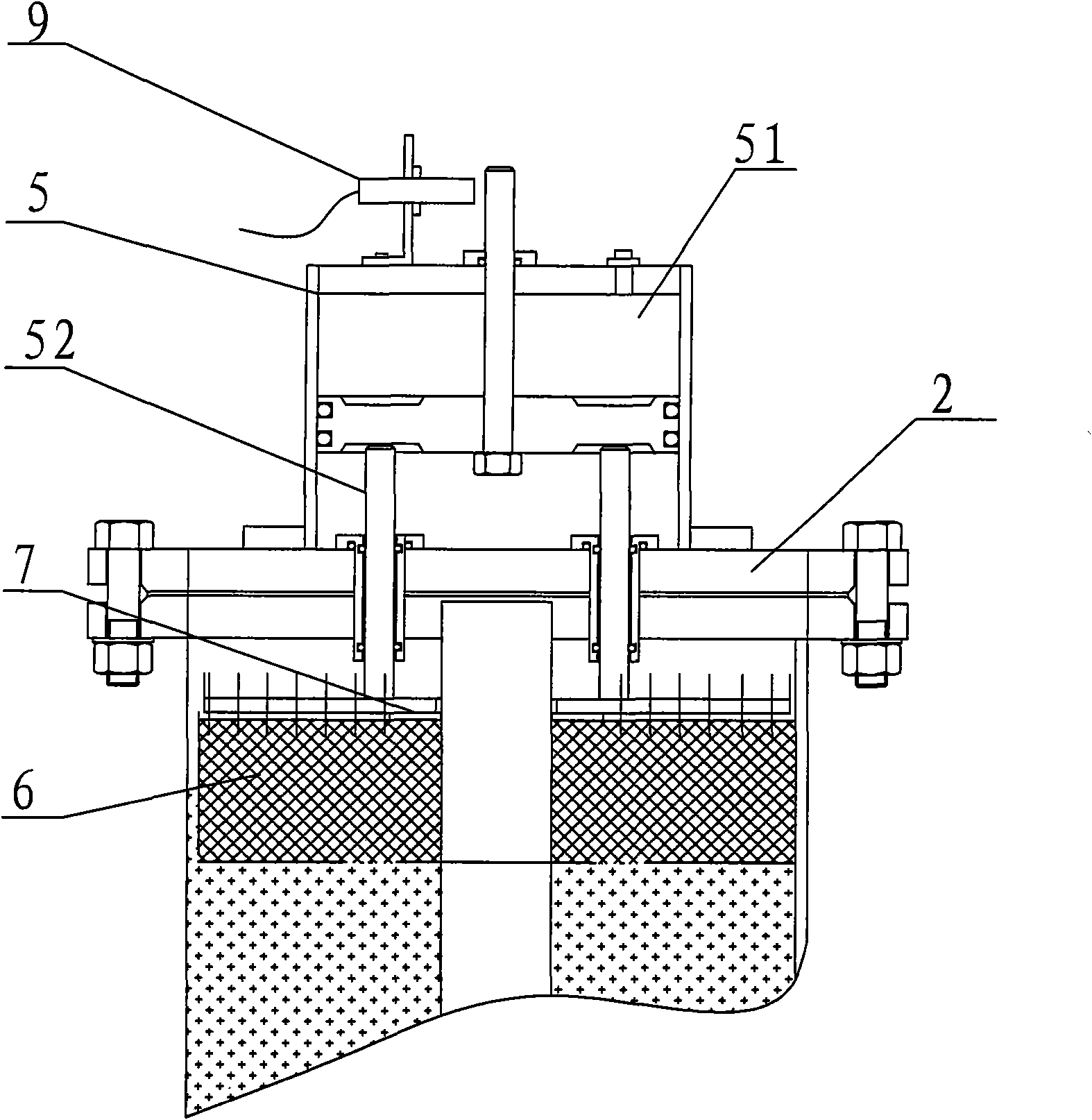

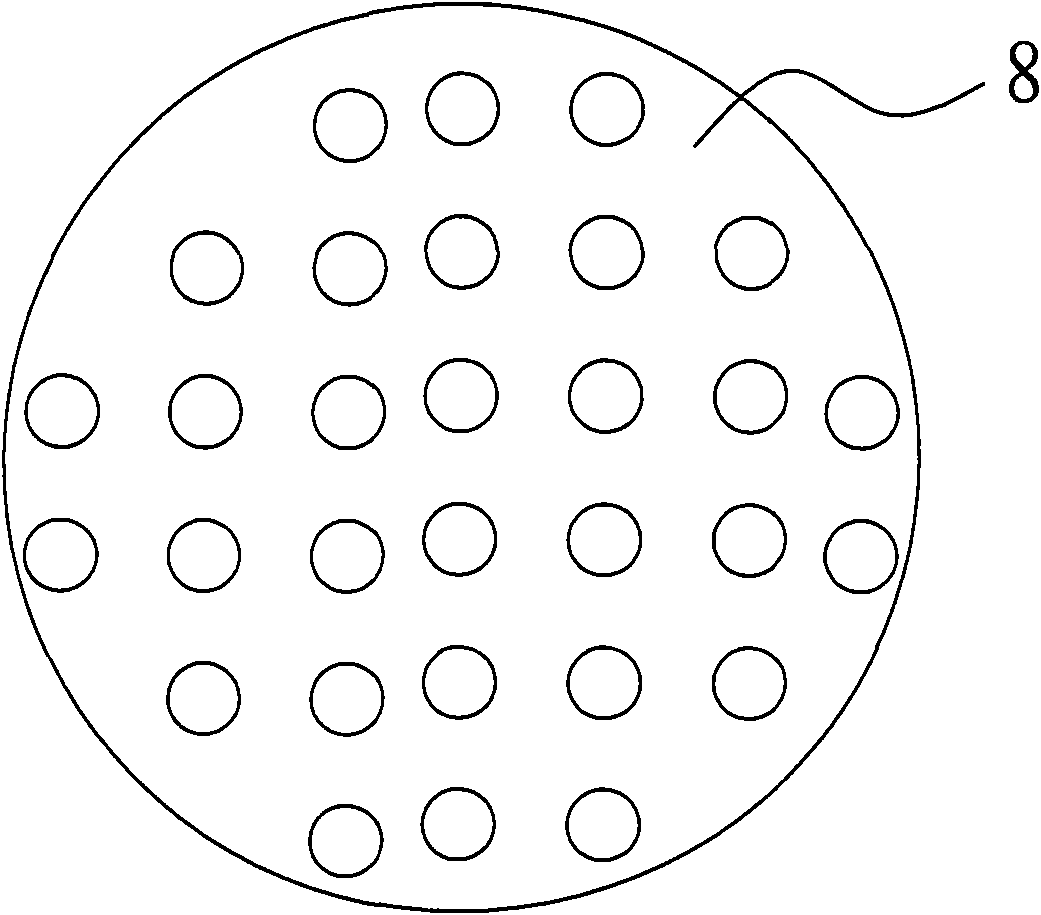

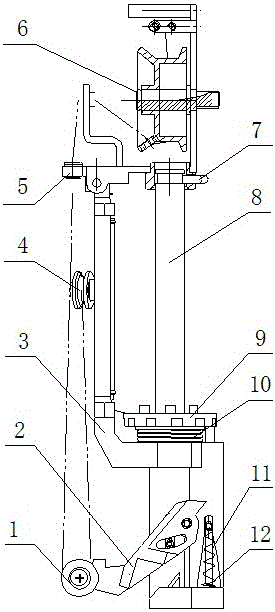

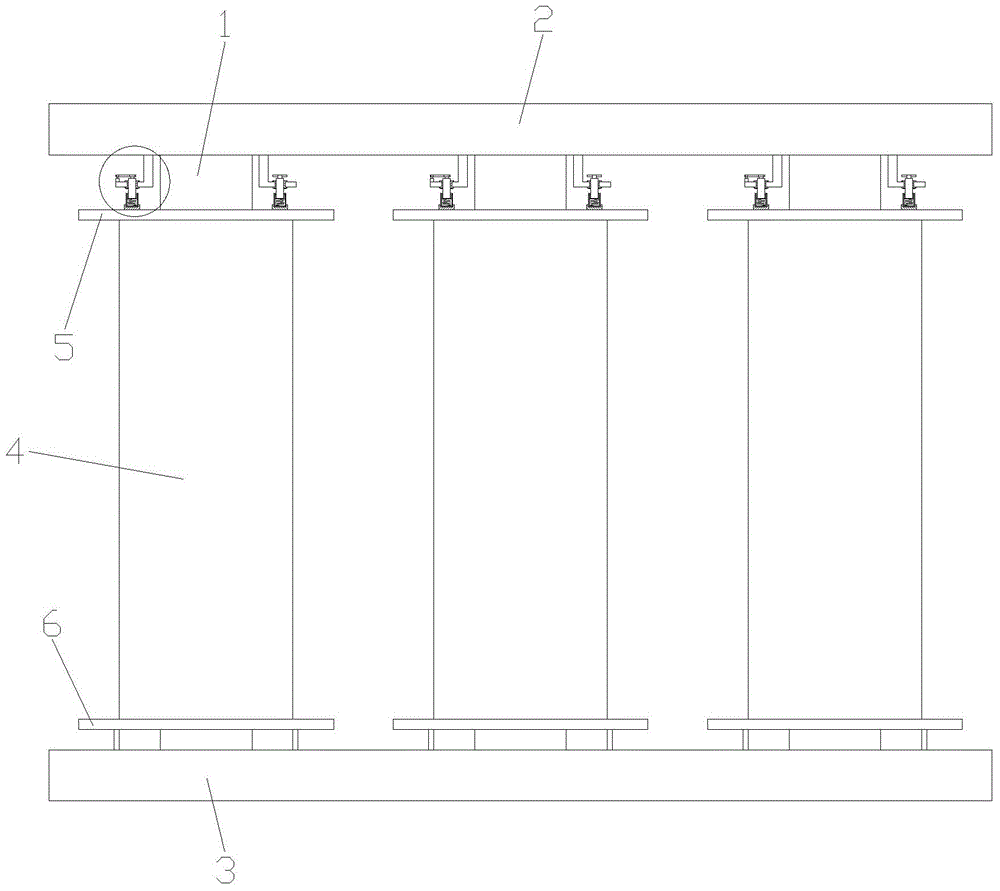

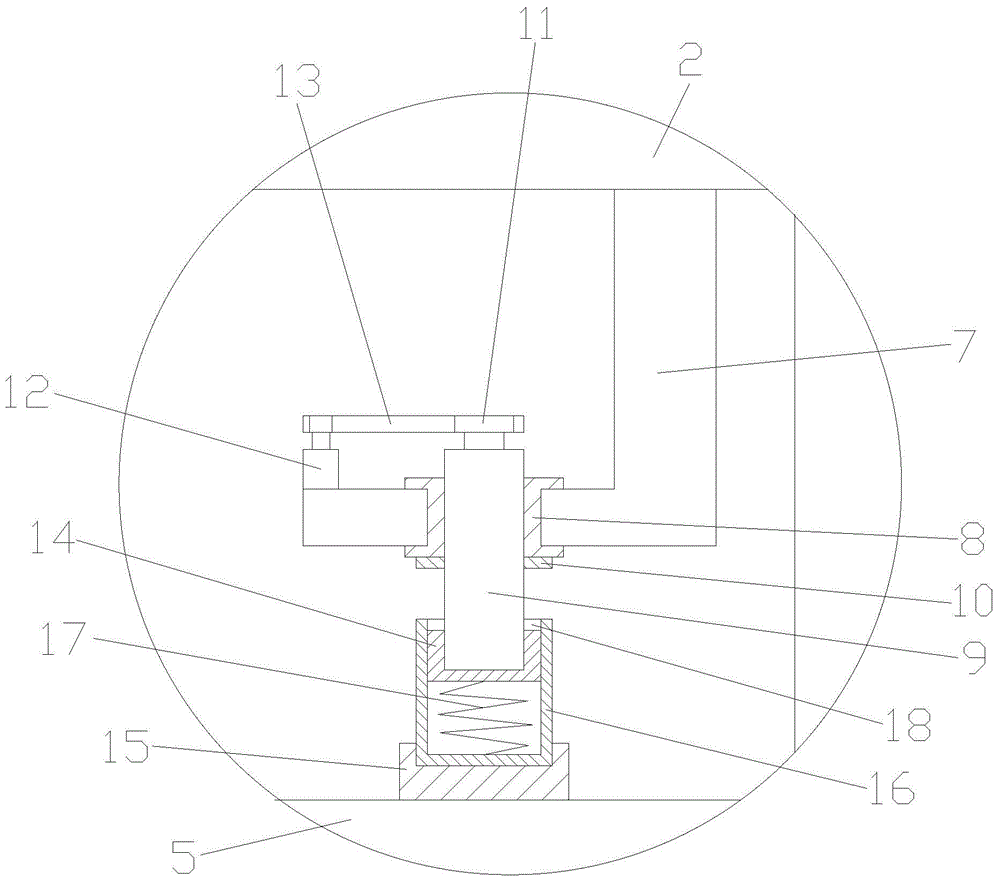

Novel absorption tower

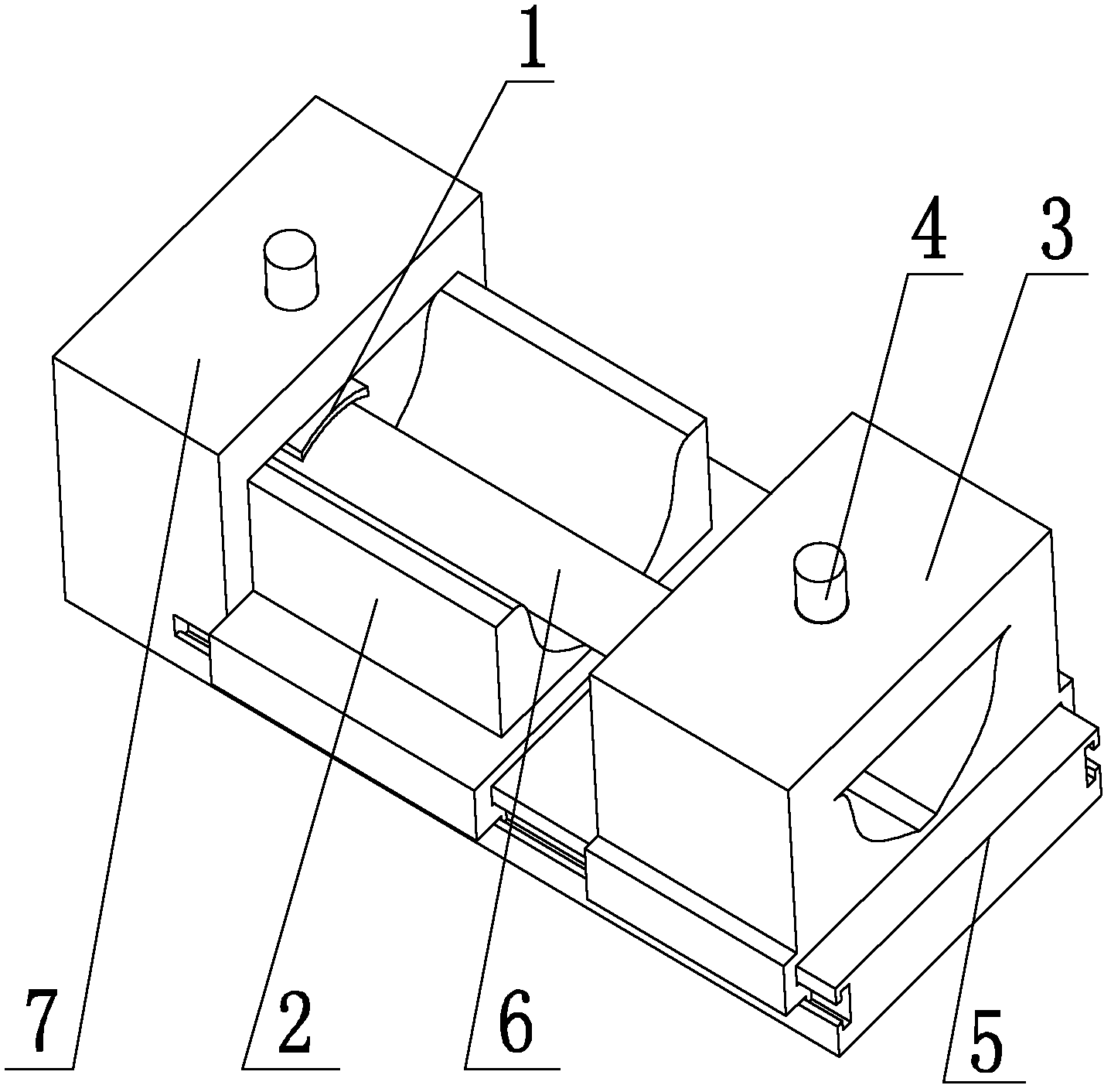

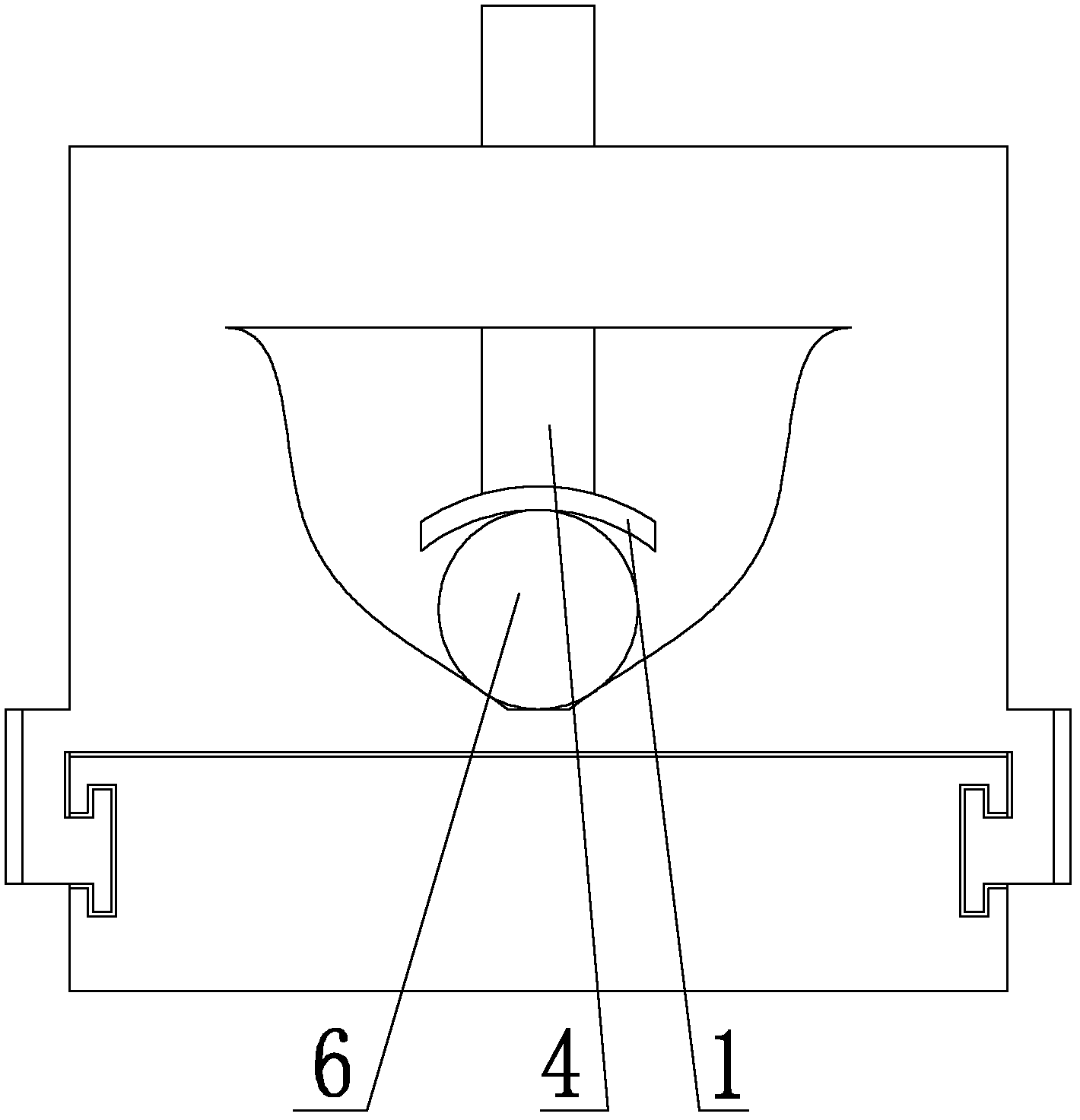

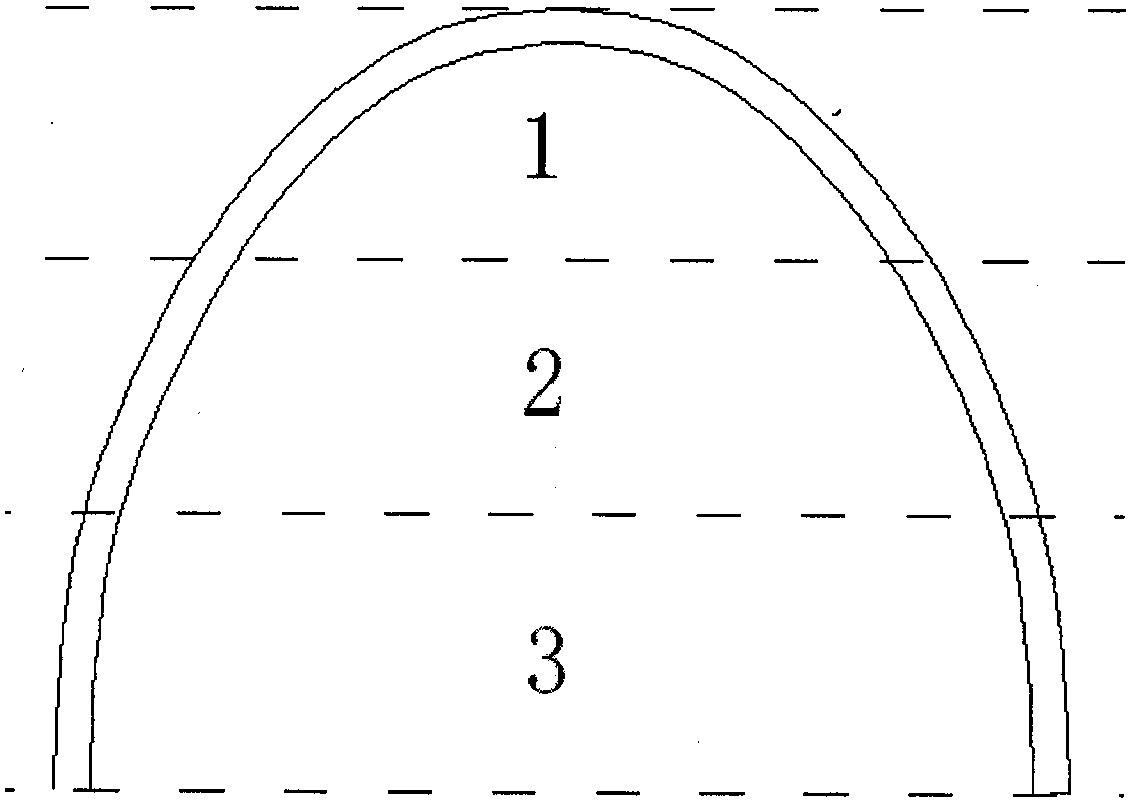

InactiveCN101992002AGuaranteed not to loosenAvoid chalkingDispersed particle separationMolecular sieveCompression device

The invention relates to a novel absorption tower which comprises a tower body, a sealing cover, an air inlet and an air outlet, wherein the tower body is used for placing an absorbing agent bed layer, the sealing cover is arranged at the top of the tower body, the air inlet and the air outlet are arranged on the tower body, an air cylinder compression device used for downwards compressing the absorbing agent bed layer is arranged on the sealing cover, an air flow distribution plate is arranged above the air inlet inside the tower body, a plurality of holes are arranged on the air flow distribution plate, and the hole diameters of the holes are gradually increased from the circle center of the air flow distribution plate in the radial direction. When a carbon molecular sieve bed layer downwards sinks, a piston rod of the air cylinder compression device pushes the hole plate and a cocoa pad to downwards move for tightly compressing the carbon molecular sieve bed layer, and the carbon molecular sieve bed layer is ensured not to get loose, so the pulverization phenomenon of the molecular sieve bed layer can be prevented. In addition, the hole diameters are gradually increased from the circle center of the air flow distribution plate in the radial direction, so the flow rate at the cross section of an air flow outlet can be uniform, and the utilization rate of the absorbing agent can be greatly improved.

Owner:张文波

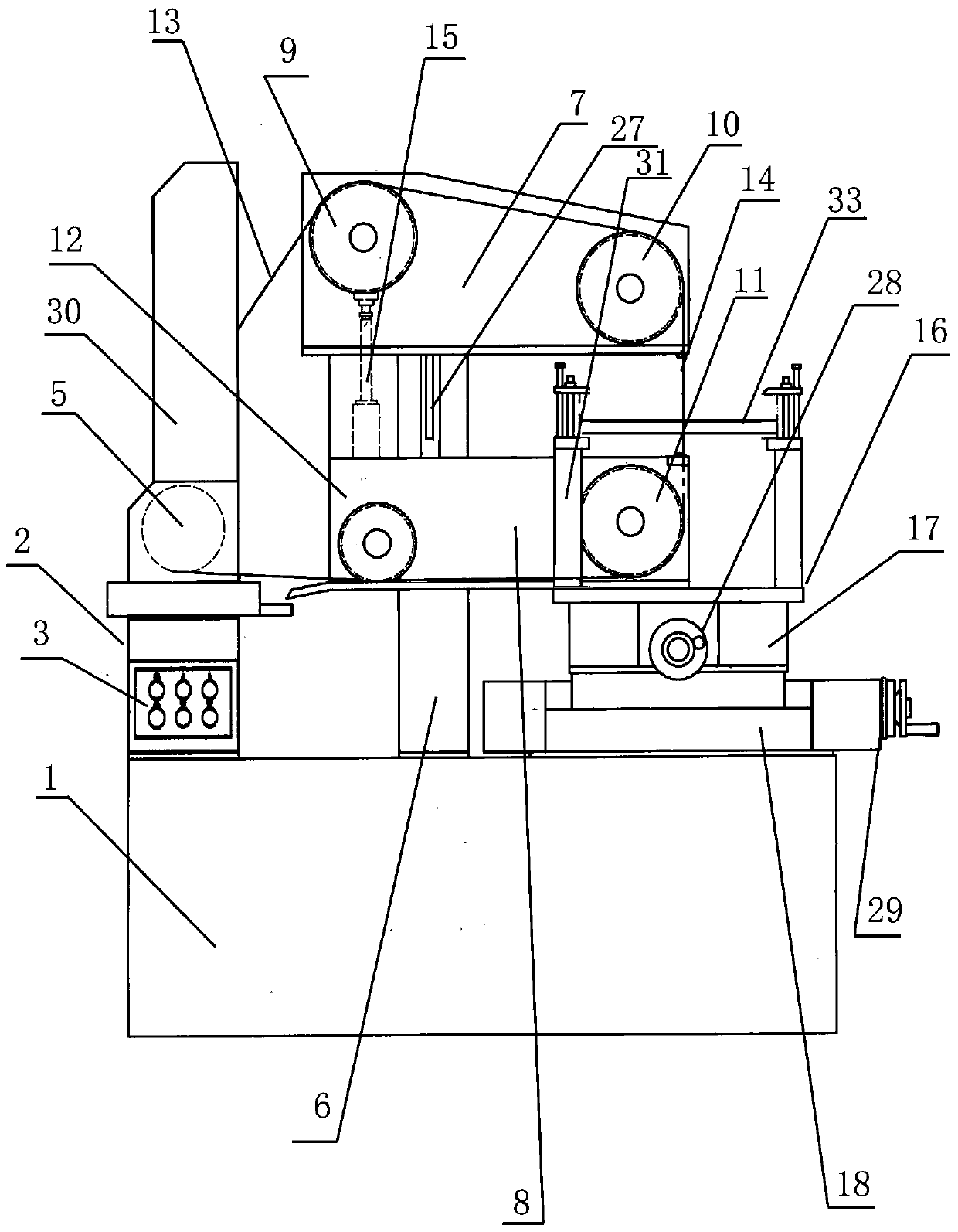

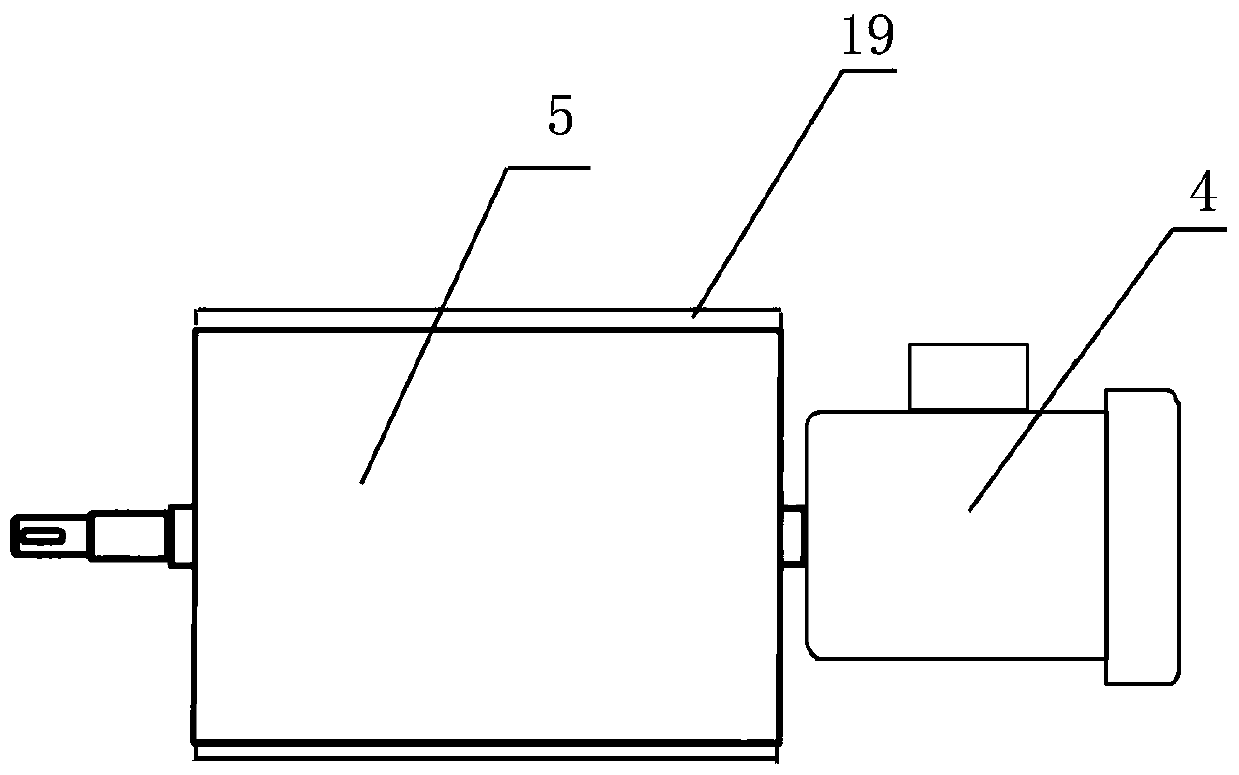

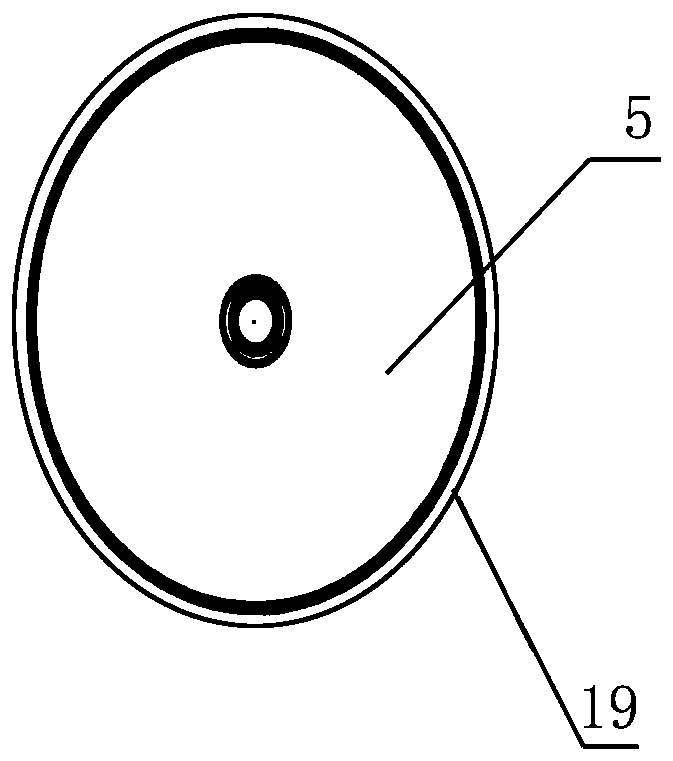

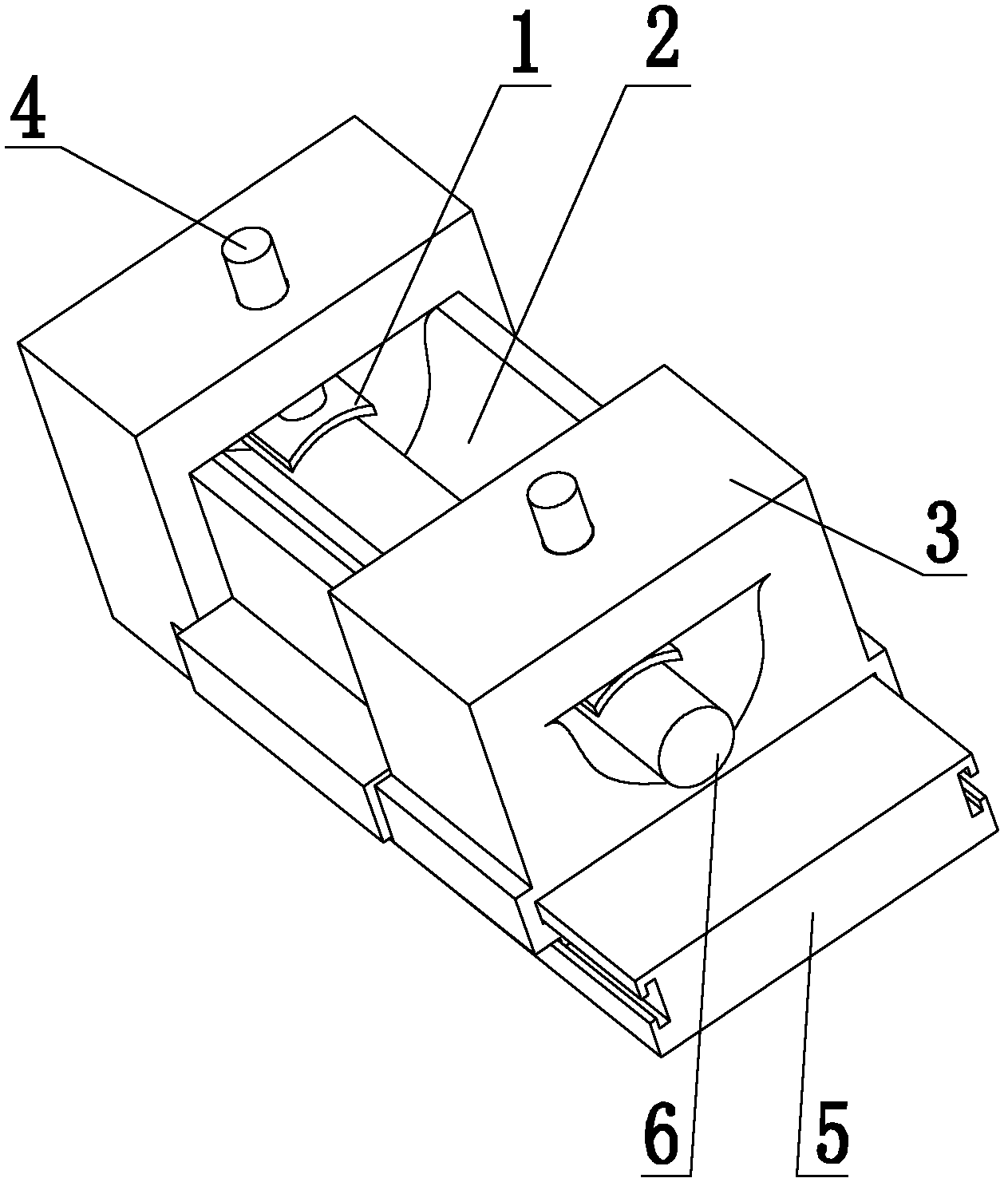

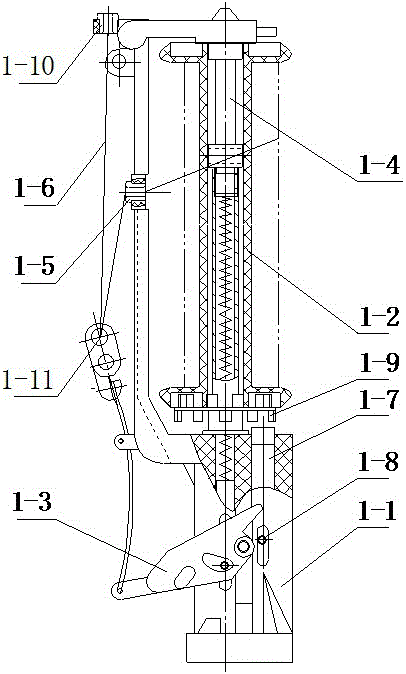

Numerical control diamond abrasive wire sawing machine

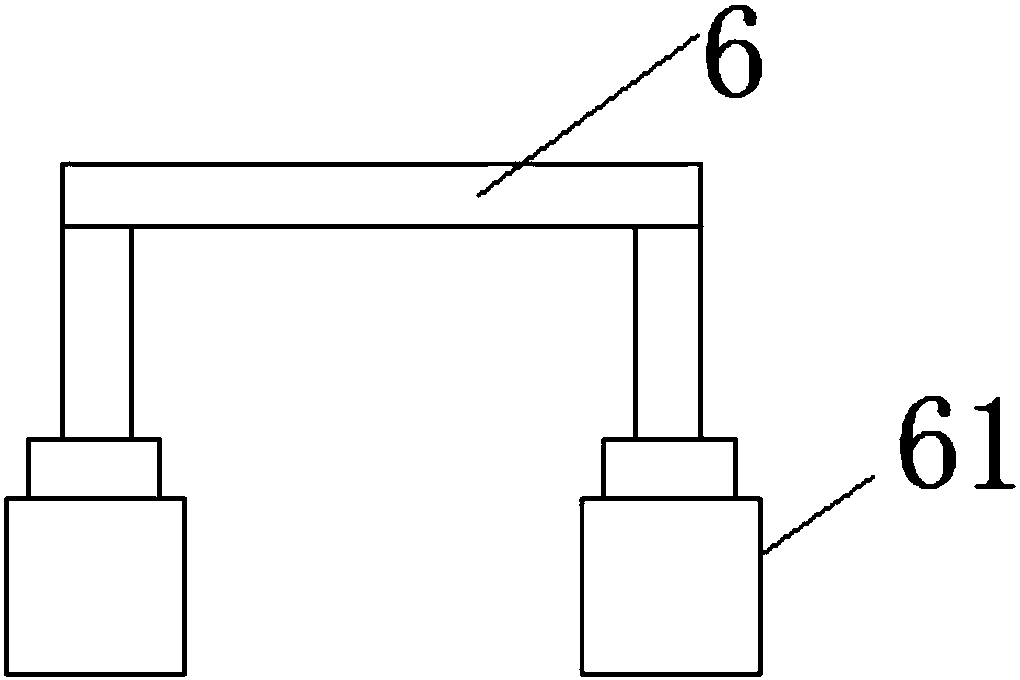

PendingCN107584396AImprove the tension effectImprove wear resistanceGrinding machinesNumerical controlDrive wheel

The invention discloses a numerical control diamond abrasive wire sawing machine. The outer surface of a wire storage barrel (5) of a wire transporting mechanism of the numerical control diamond abrasive wire sawing machine is covered with a wire barrel outer ring protecting glue layer, and an upper wire frame (7) and a lower wire frame (8) are arranged on a column (6) from top to bottom. An outerring of a tensioning wheel (9), an outer ring of a driving wheel I (10), an outer ring of a driving wheel II (11) and an outer ring of a transition wheel (12) are sleeved with protective sleeves, a diamond wire (13) is wound around the wire storage barrel (5), the driving wheel II (11) is vertically connected with a pneumatic tensioning device (15), the pneumatic tensioning device (15) pushes thetensioning wheel (9) to move up and down to adjust the position of the tensioning wheel (9) to enable the diamond wire to maintain a constant tension state, the other side of a lathe bed (1) is provided with a cutting working table (16), and the bottom of the cutting working table (16) is provided with a driving assembly. The numerical control diamond abrasive wire sawing machine not only is goodin use effect and wide in applied range, but also is resistant to abrasion and long in service life.

Owner:泰州市南光机械电子有限公司

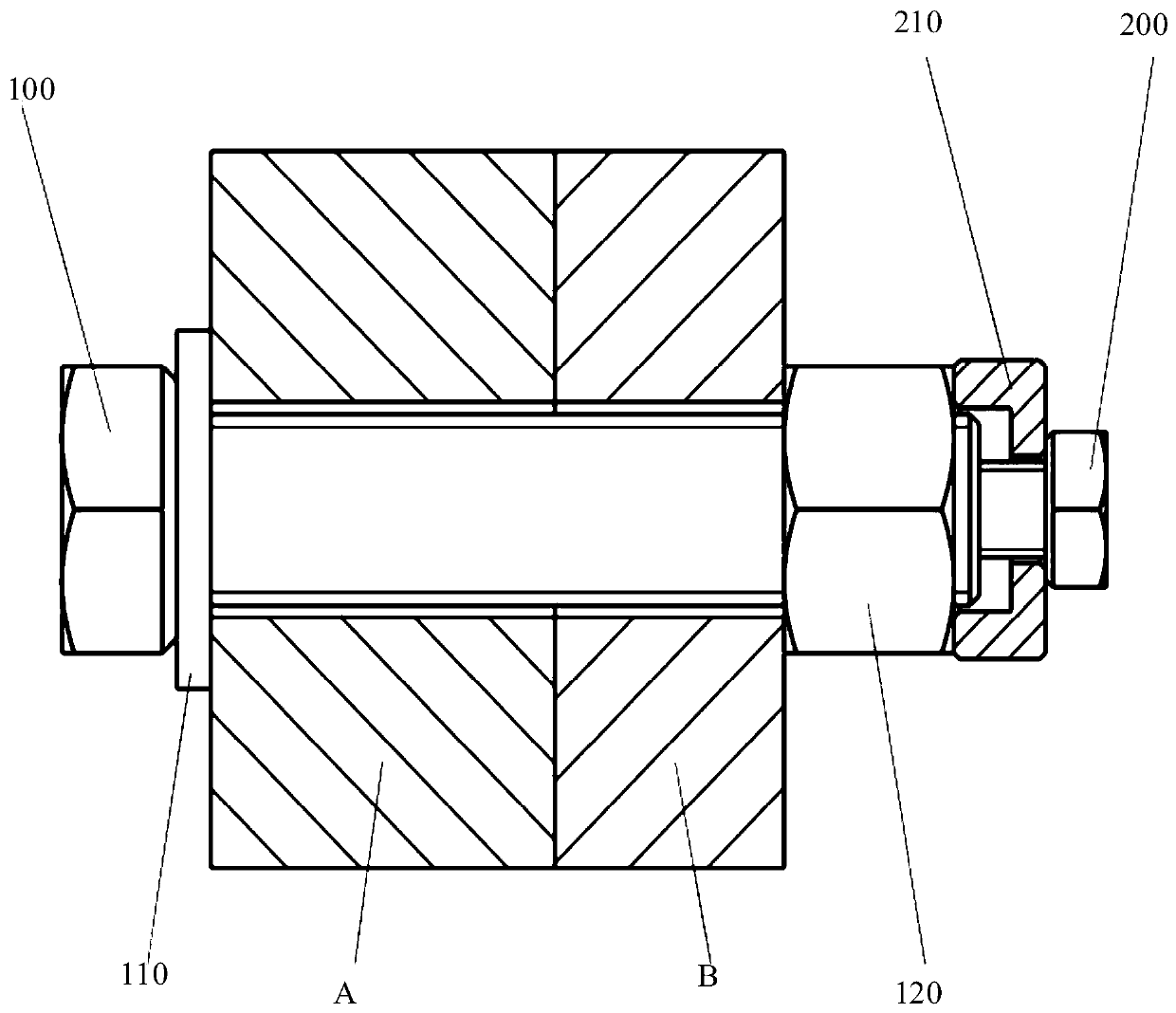

Clamping apparatus used for fixing revolving body

InactiveCN102554661AGuaranteed not to loosenHigh precisionPositioning apparatusBoring/drilling componentsHigh volume manufacturingEngineering

Owner:SUZHOU FUMAI PRECISION MACHINERY

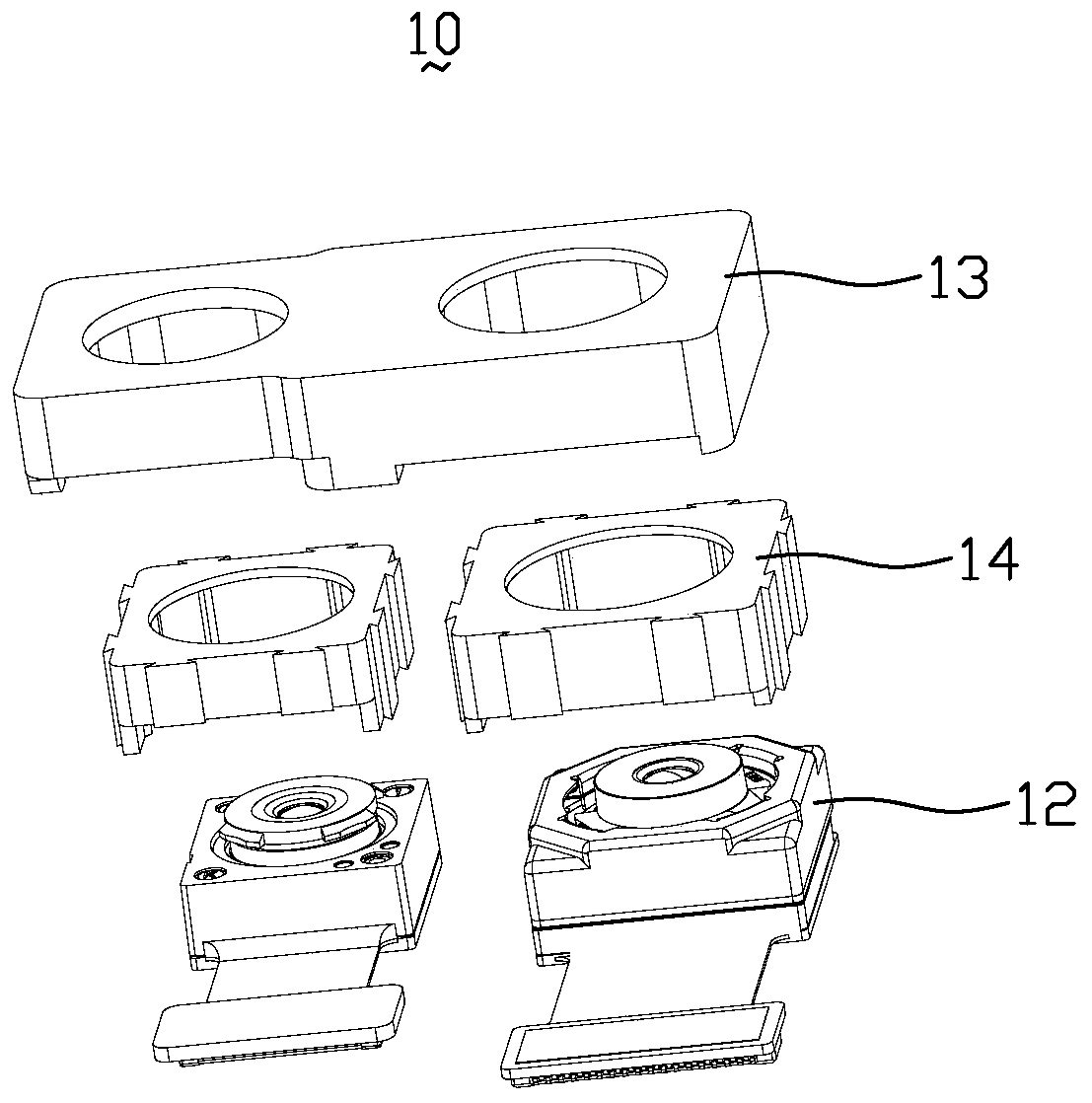

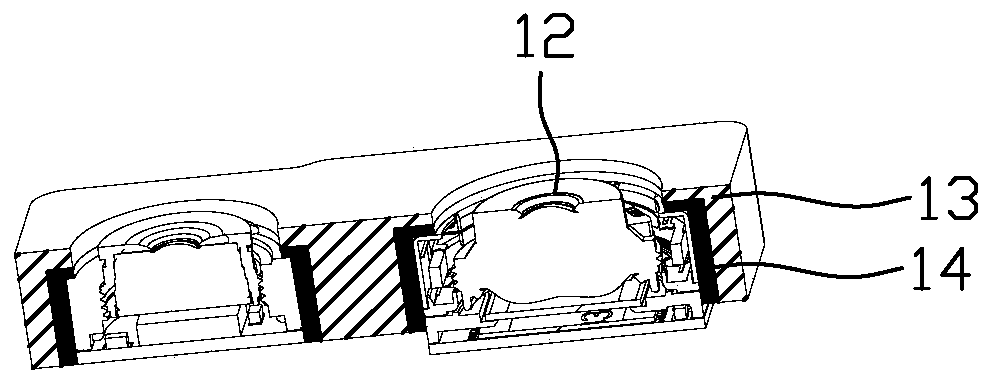

Camera module and terminal

PendingCN110035212AGuaranteed not to loosenEasy to assemble and disassembleTelevision system detailsColor television detailsCamera lensCamera module

A camera module includes a lens and also comprises a fixing bracket and an elastic element; the fixing bracket comprises a first containing space, the elastic element comprises a second containing space and a limiting protrusion, the elastic element is arranged in the first containing space and connected with the fixing bracket, the lens is fixed in the second containing space, and the limiting protrusion is arranged on the inner wall of the second containing space and makes contact with the outer wall of the lens. According to the camera module, dispensing equipment and glue curing equipmentcan be omitted, the production cost is reduced, and the fixing mode is convenient. The invention also relates to a terminal.

Owner:KUNSHAN Q TECH CO LTD

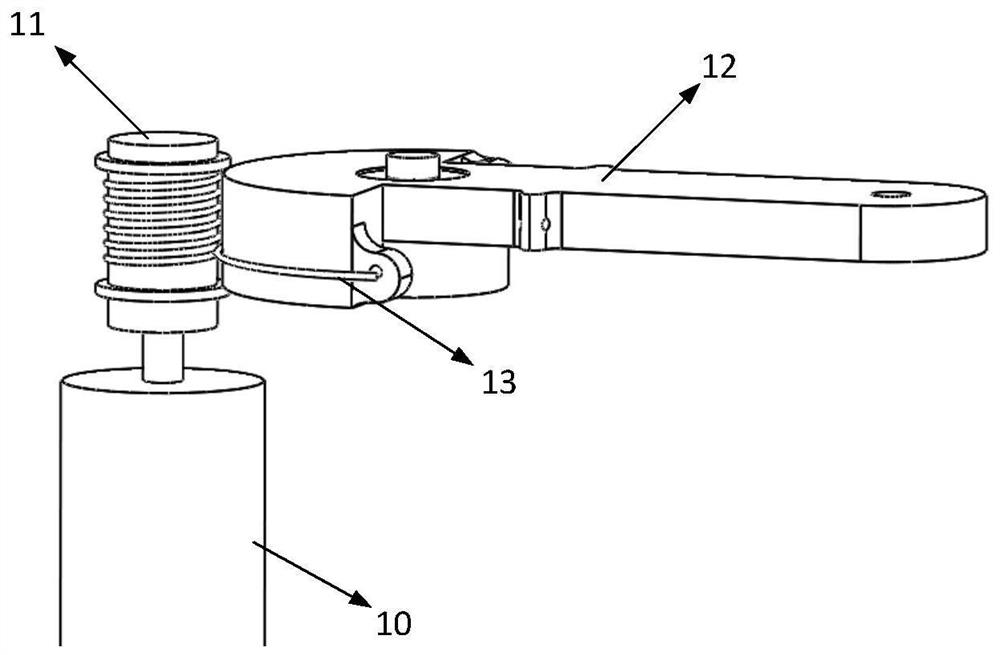

Large-stroke friction-free spindle of braider

The invention provides a large-stroke friction-free spindle mechanism of a braider, belonging to spindle mechanisms of braiders. The spindle comprises a lower yarn passing wheel, a plummet, a spindle blade, an upper yarn passing wheel, a threading sleeve, a take-up and pay-off device, a clamp spring, a bobbin shaft, a faceplate, a tensioner, a lifting pin and a pressure spring, wherein the plummet is connected below the spindle blade; the lifting pin and the pressure spring are connected to the spindle blade at one end of the plummet; the lower yarn passing wheel is connected at the other end of the plummet; the faceplate is arranged in the middle of the spindle blade; the bobbin shaft is arranged in the center of the faceplate and is connected with the spindle blade into a whole; the tensioner is connected between the faceplate and the spindle blade; the upper yarn passing wheel is connected in the middle of one side of the spindle blade; the threading sleeve is connected above one side of the spindle blade; one end of the take-up and pay-off device is connected to the bobbin shaft by the clamp spring and the other end of the take-up and pay-off device is hinged with the top end of the spindle blade. The spindle has the advantages that the pay-off stroke of the spindle is increased by adopting the rolling and take-up modes, so the spindle is suitable for two-dimensional and three-dimensional guide rail braiders; yarn surfaces are friction-free and yarn material surfaces are not damaged, thus increasing the product quality and yield.

Owner:XUZHOU HENGHUI BRAIDING MACHINE

High-current connector

PendingCN109524835AGuaranteed not to loosenEasy to installLive contact access preventionElectric connection structural associationsCarrying capacityPower flow

The present invention relates to a high-current connector comprising an input portion and an output portion. The input portion includes a first housing, an input contact and a fastener. The input contact is provided with a connection hole. The output portion includes a second housing, an output contact and a connection seat. The output contact sleeves the connection seat. When the input portion isconnected to the output portion, one end of the fastener passes through the connecting hole to be fixed to the connection seat, the other end of the fastener is restricted to the first housing or theinput contact, and the input contact is in conductive contact with the output contact. The input portion and the output portion are connected by a screw and a nut in an over-locking connection mode.The high-current connector is easy to install, saves material and space, and is not loose in the case of vehicle vibration, has an IPXXB anti-electric shock function under the premise of a small sizeand a large current carrying capacity. The output direction of the connector can be adjusted as required with in 360 degrees.

Owner:YUEQING BADA OPTICAL ELECTRICAL TECH CO LTD +1

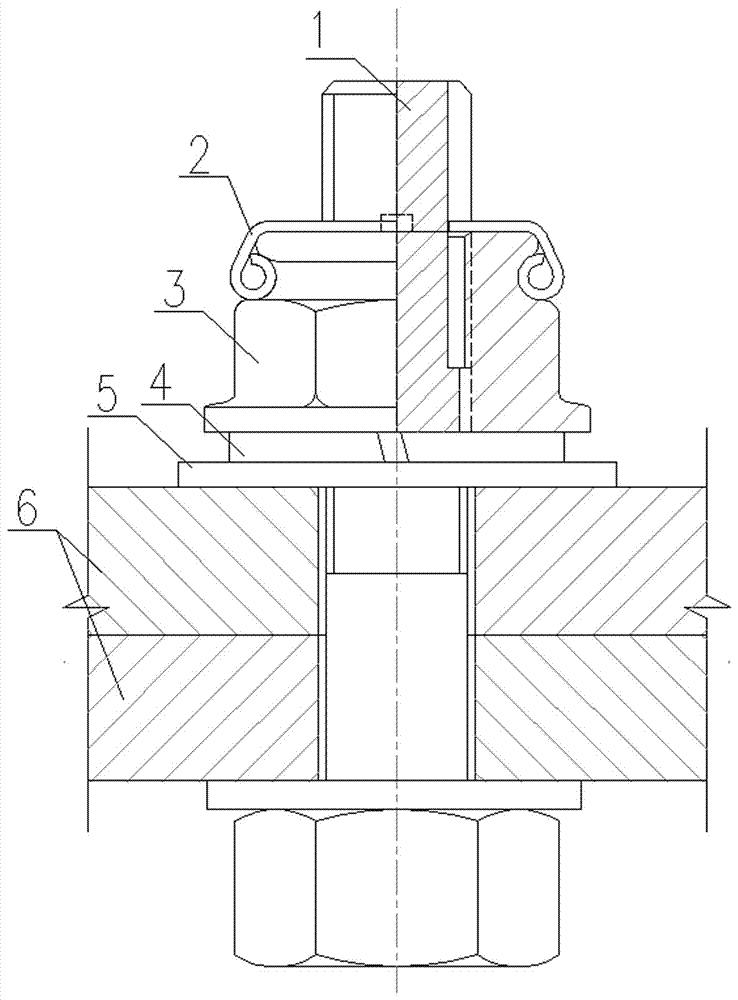

Bolt anti-loosening structure and anti-loosening method thereof

PendingCN106979212AEffective control of pressing forceControl the pressing forceNutsBoltsEngineeringMechanical engineering

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

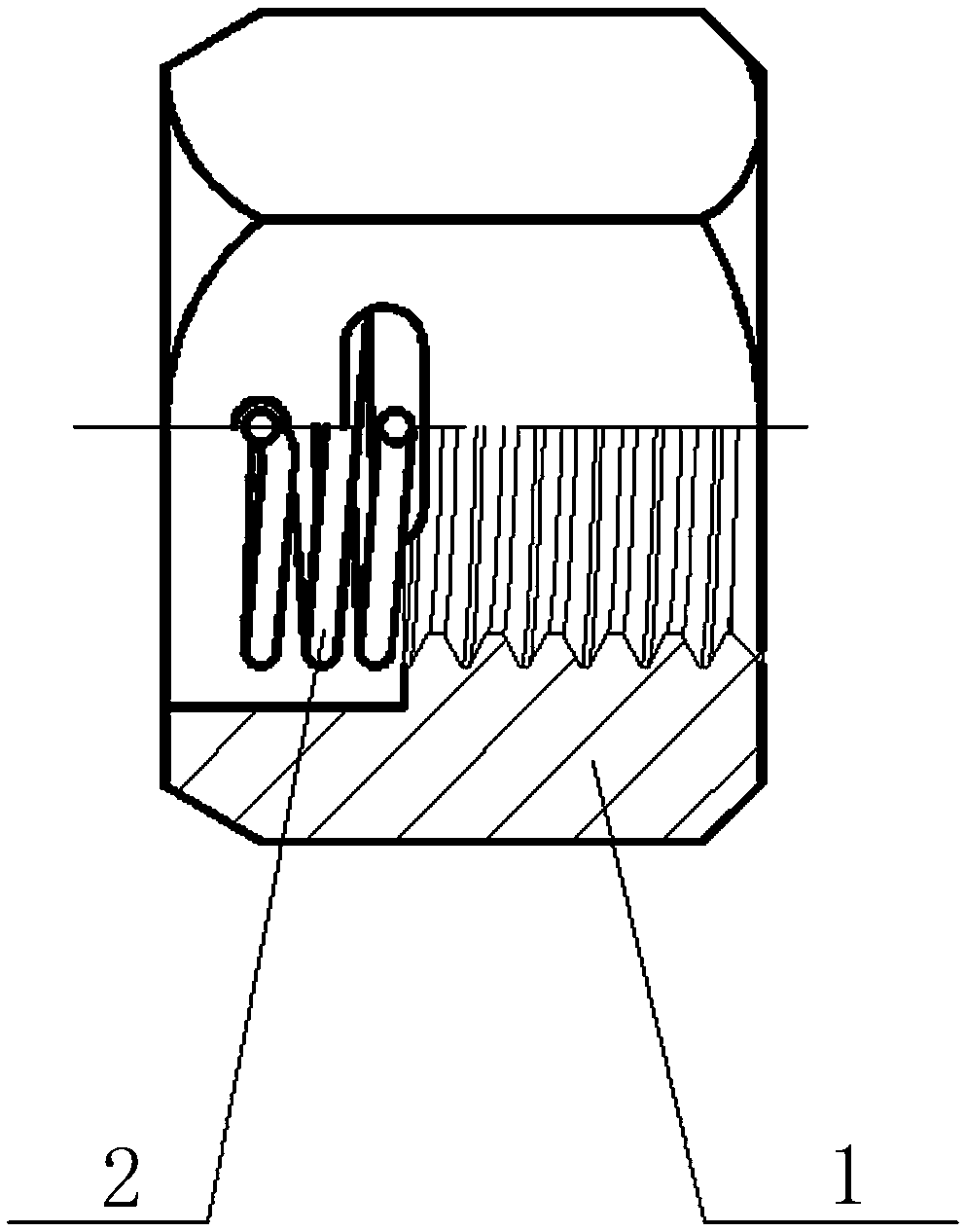

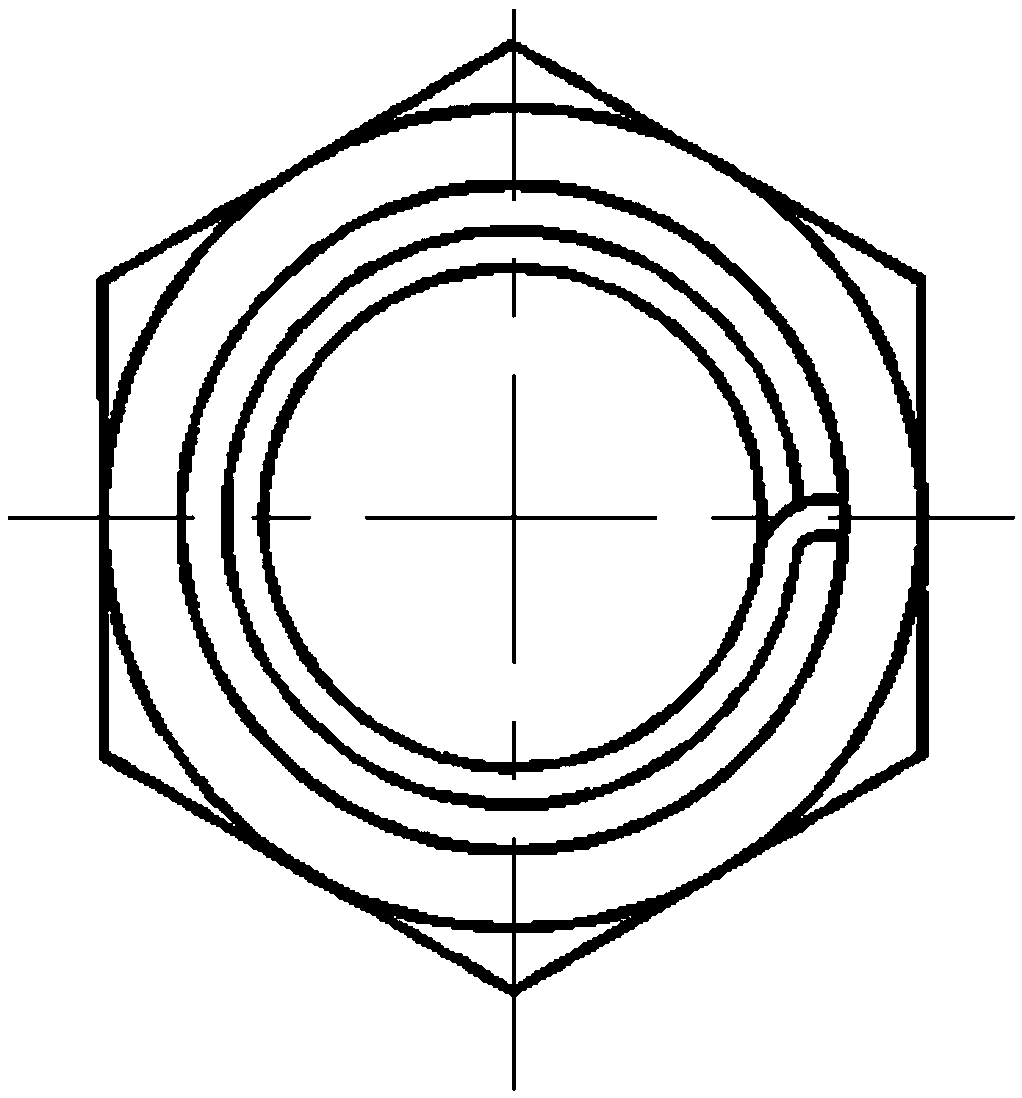

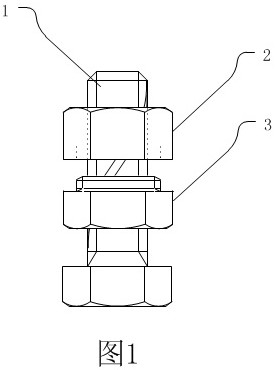

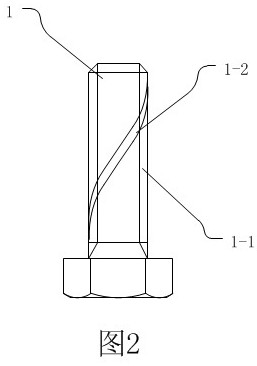

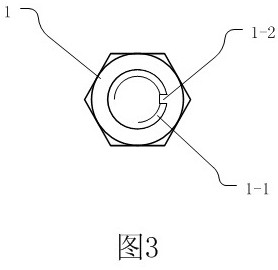

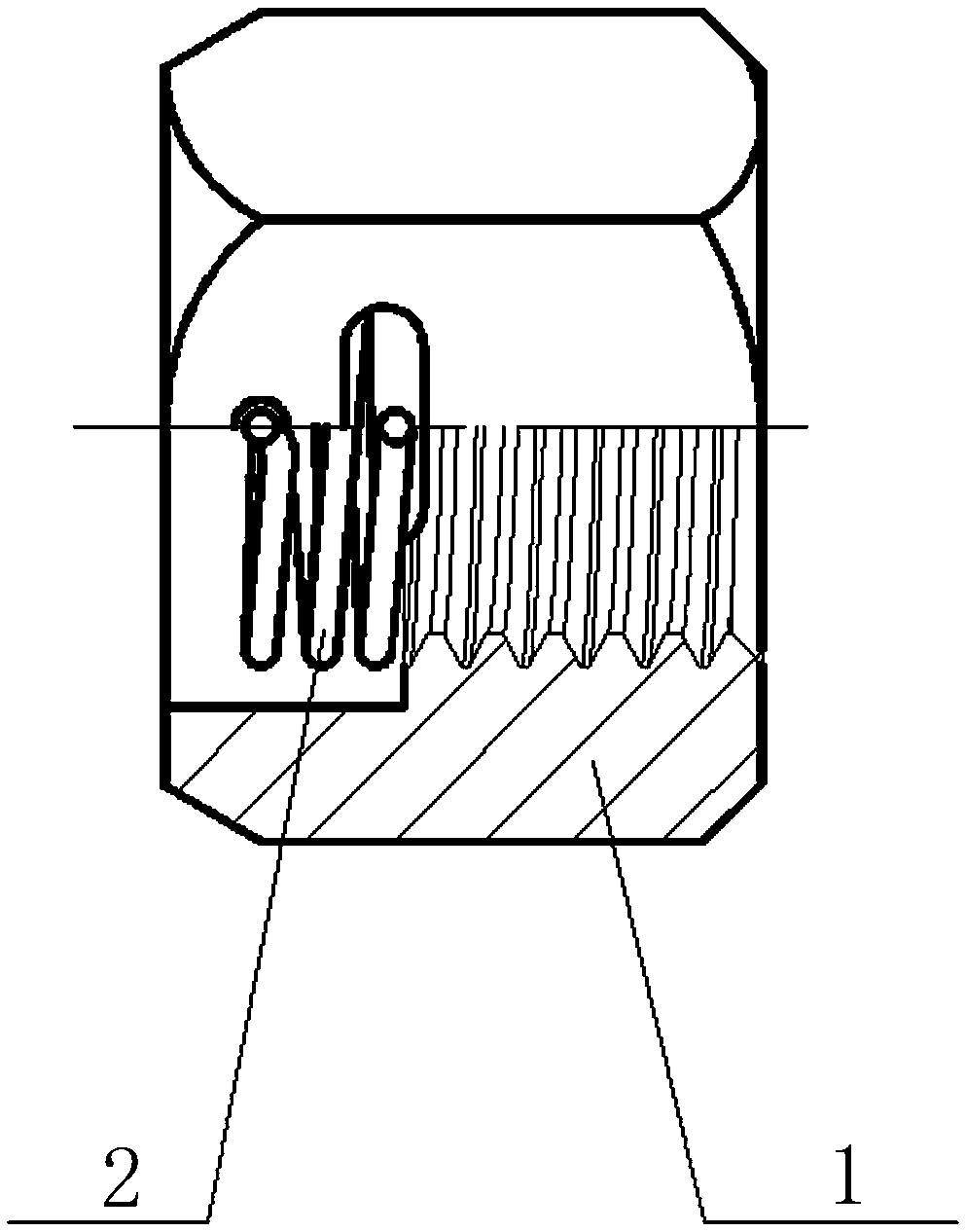

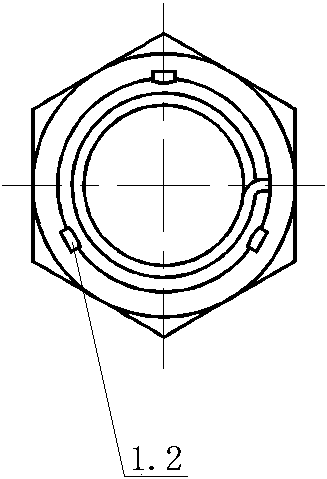

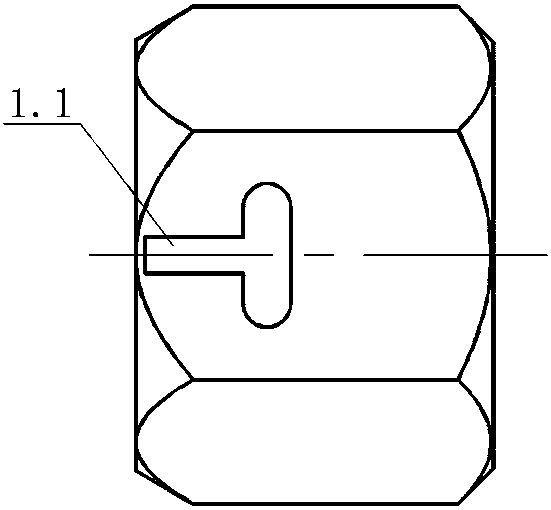

Self-locking nut with self-fixing spring

The invention provides a self-locking nut with a self-fixing spring and belongs to the technical field of rail transit equipment. The self-locking nut comprises a nut body and a spring, wherein the spring is arranged in the nut body; the screw pitch of the spring and the screw pitch of the nut body are the same; a round hole and a straight groove are formed in a hexagonal surface of the nut body;a first convex body and a second convex body are arranged at the front and rear ends of the spring respectively; the first convex body is arranged in the round hole and the second convex body is arranged in the straight groove. The self-locking nut provided by the invention has a simple structure; the spring is arranged in the nut body and has a fixing function; the spring has stretching and retracting performance so that the self-locking performance of the nut can be effectively improved; in a utilization process, a nut and bolt fastening system can be not loosened for a long time, and the number of times of repairing and the labor cost are effectively reduced.

Owner:四川艾尔诺航空金属器材有限公司

Bolt locking structure

InactiveCN111536131AGuaranteed not to loosenHigh reliability of anti-looseningNutsBoltsClassical mechanicsEngineering

The invention provides a bolt locking structure, and belongs to the technical field of fasteners. The bolt locking structure comprises a first bolt, a nut in threaded fit with the first bolt and a second bolt. A threaded hole in threaded fit with the second bolt is formed at the screw tail end of the first bolt. The thread turning directions of the second bolt and the first bolt are opposite. Thefirst bolt sequentially penetrates through two to-be-fastened workpieces. The nut and the first bolt are screwed from the opposite side, and the second bolt is screwed into the threaded hole from theopposite side so as to fasten the two to-be-fastened workpieces. The thread turning directions of the first bolt and the second bolt are opposite, and therefore the first bolt and the second bolt restrain each other to achieve the anti-loose locking aim.

Owner:SANY HEAVY MACHINERY

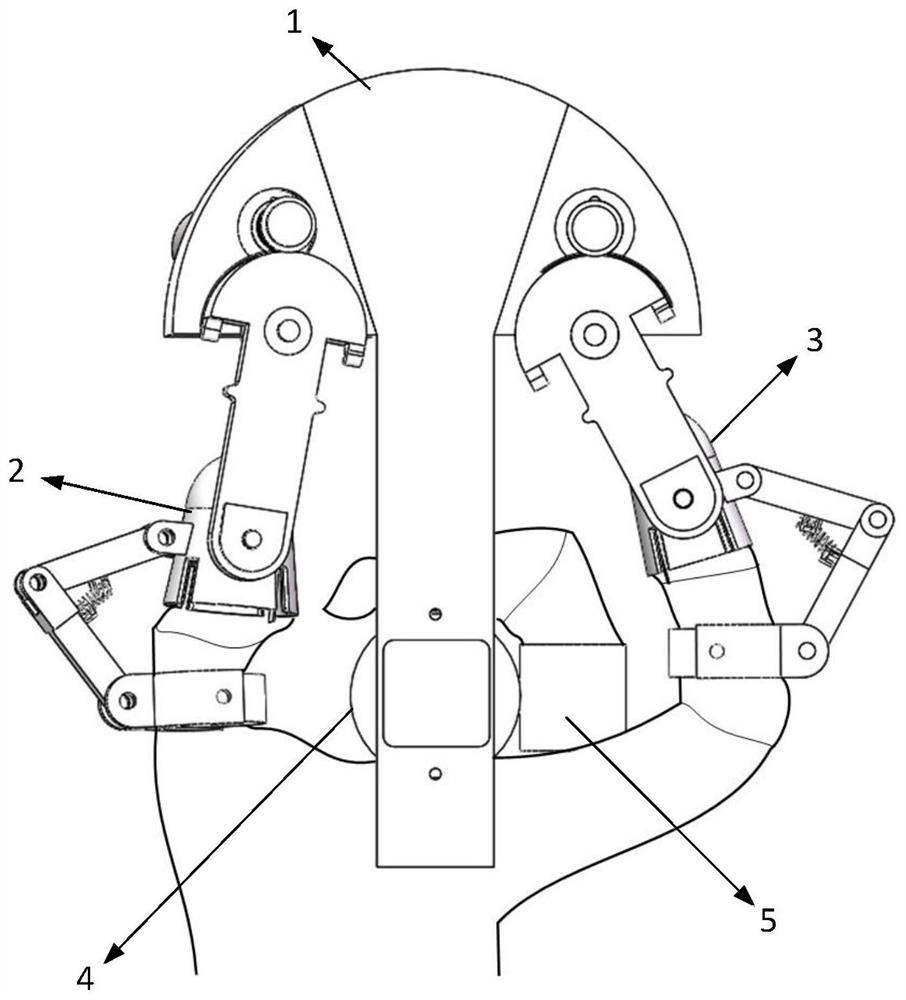

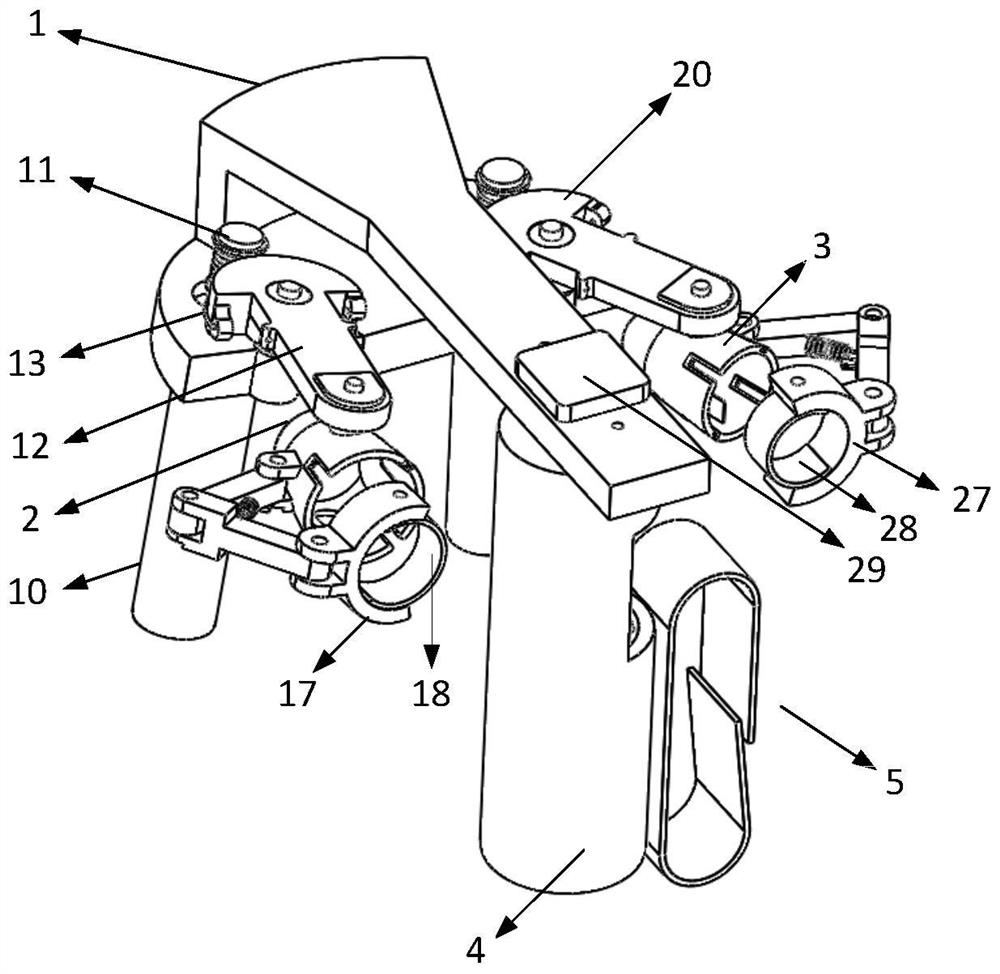

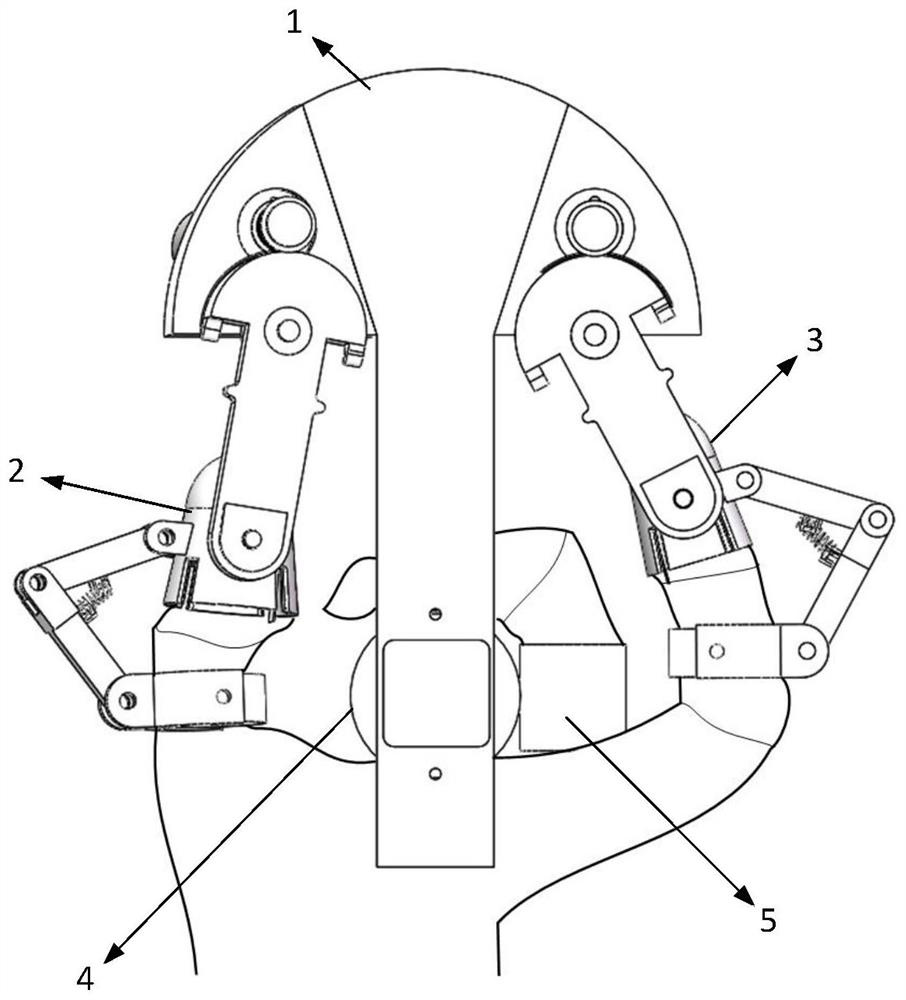

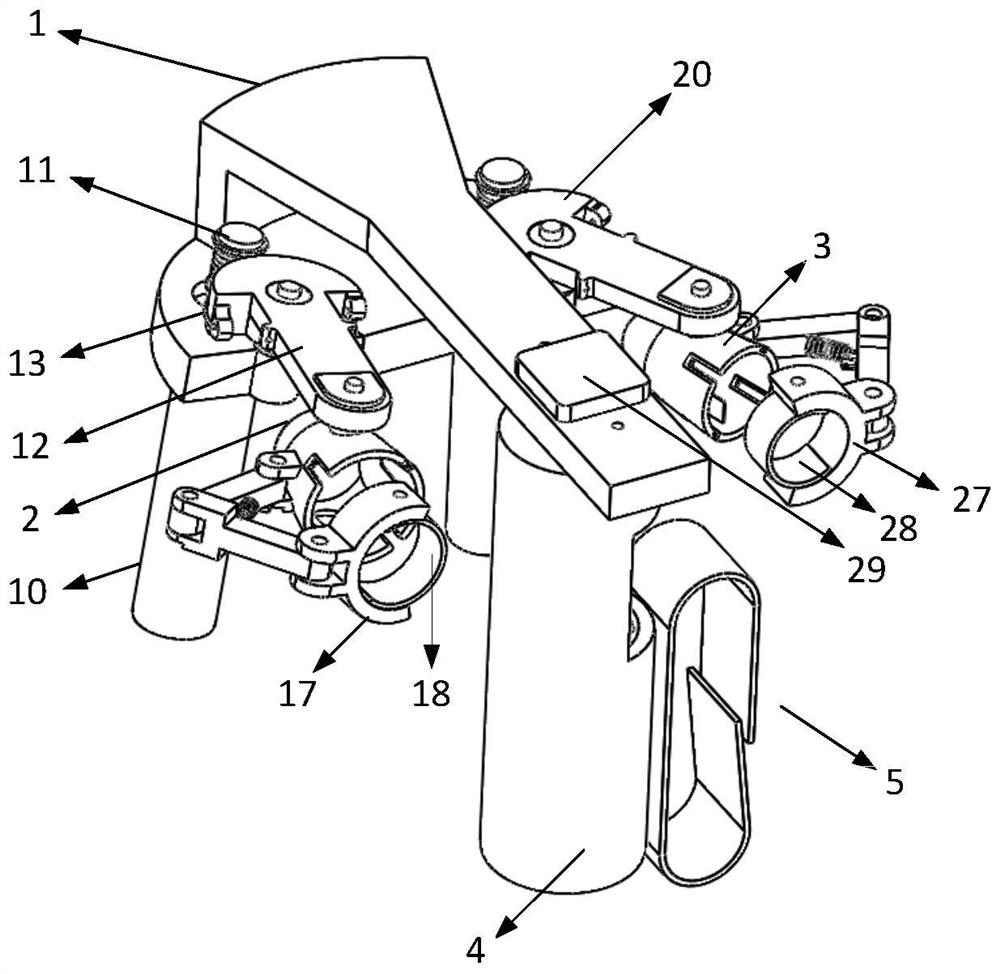

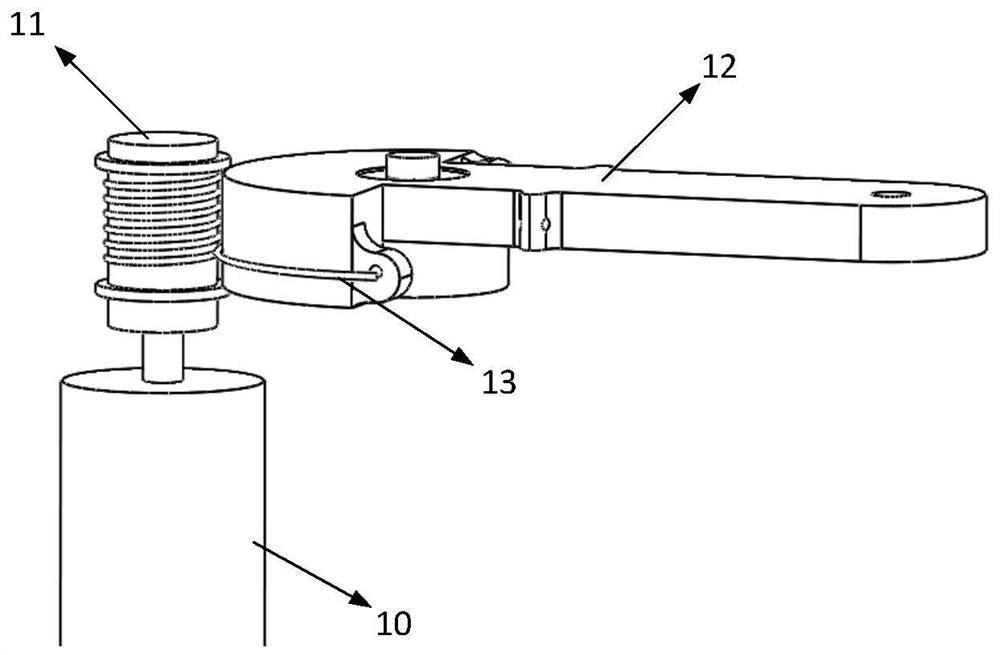

Two-degree-of-freedom rope transmission type finger force feedback device

ActiveCN112621790AThere will be no stuckImprove human-computer interactionAdditive manufacturing apparatusGripping headsHand partsIndex finger

The invention provides a two-degree-of-freedom rope transmission type finger force feedback device. The two-degree-of-freedom rope transmission type finger force feedback device comprises a hand support mechanism, a thumb movement mechanism, an index finger movement mechanism and a handle mechanism. The hand support mechanism comprises a motor, a motor shaft sleeve, a sliding rail and an IMU sensor. The thumb movement mechanism comprises a long rotating disc, a torque sensor, an angle sensor, a thumb sleeve, a pressure sensor, a two-bar linkage, a thumb bracket and a thumb fixing ring. The handle mechanism comprises a cylindrical grab handle, a pressure sensor, a flexible fixing band and a sliding block. Torque is transmitted between the rotating disc and the motor through a rope. The handle mechanism can move back and forth and self-reset. According to the two-degree-of-freedom rope transmission type finger force feedback device, the problems that traditional finger force feedback is high in cost and cannot be adjusted are solved, wearing is compact, and the self-adaptive freedom degree is achieved; rope transmission ensures that feedback force is smooth and real; and through the carried sensor, information such as hand postures, thumb and index finger rotating angles, grabbing force and middle finger contact force can be transmitted in real time.

Owner:SOUTHEAST UNIV

Double-thread lock bolt

PendingCN112780657AEffective control of pressing forceConstant pressure controlNutsBoltsComputer architectureEngineering

The invention discloses a double-thread lock bolt. The double-thread lock bolt is characterized by comprising a double-thread bolt body, a double-thread concave nut and a double-thread convex nut. A concave external thread is arranged on a thread section of the double-thread bolt body. The double-thread concave nut is provided with two sections of internal threads with different nominal diameters. A convex internal thread is arranged on the inner side of a central round hole of the double-thread convex nut, and an external thread is arranged on a boss portion of the double-thread convex nut. The double-thread convex nut and the double-thread concave nut are installed on a threaded section of the double-thread bolt, and a convex inner thread on the inner side of the double-thread convex nut is correspondingly screwed with a concave outer thread of the double-thread bolt body. A boss part external thread of the double-thread convex nut is correspondingly screwed with a large nominal diameter internal thread of the double-thread concave nut, and a small nominal diameter internal thread of the double-thread concave nut is correspondingly screwed with a thread of the double-thread bolt body. According to a locking method of the double-thread lock bolt, the pre-tightening force of the bolt can be effectively controlled within a constant and effective range, loosening of the bolt and the nut is prevented, and the state of the bolt and the state of the nut are locked.

Owner:陈建军

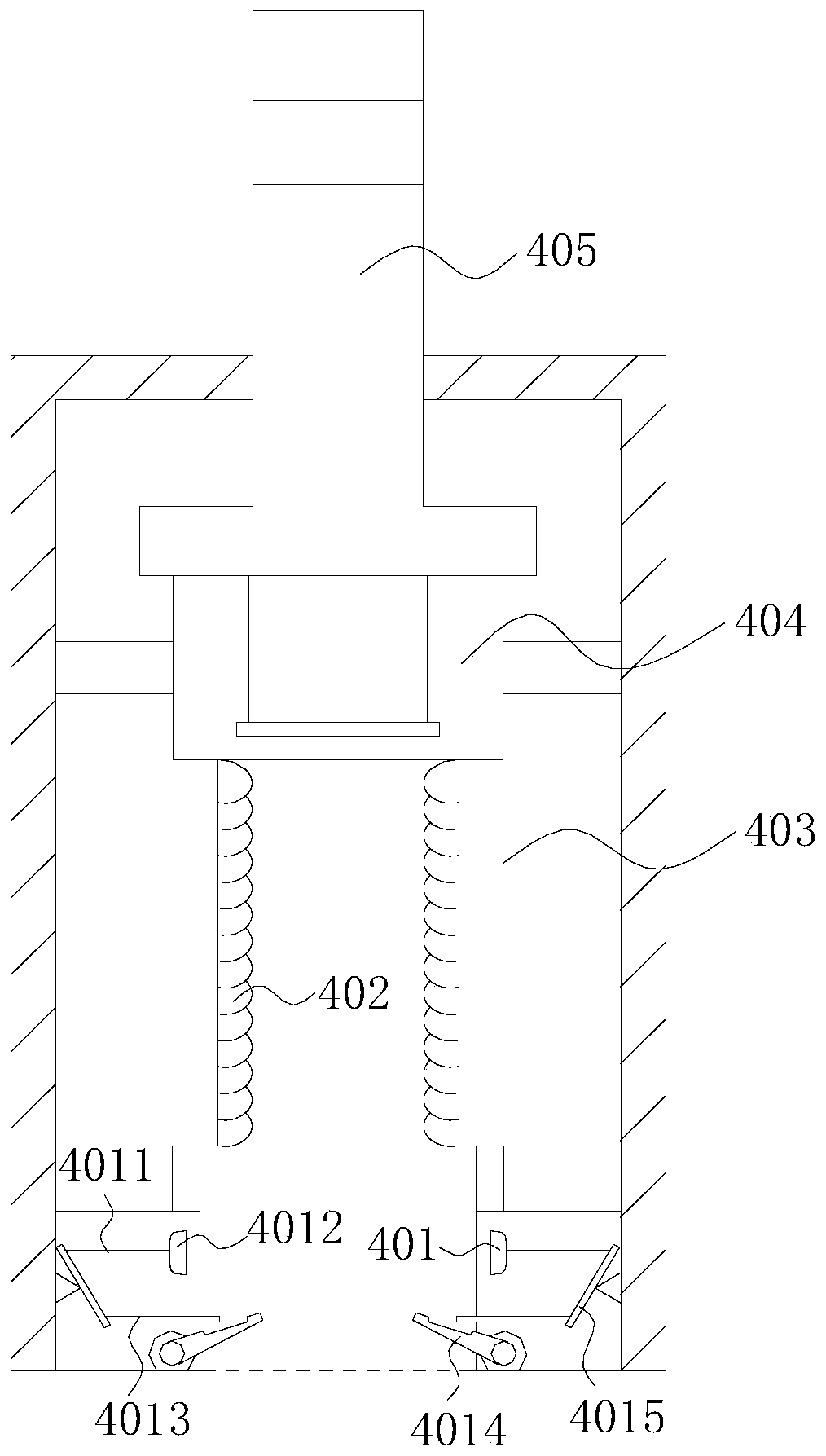

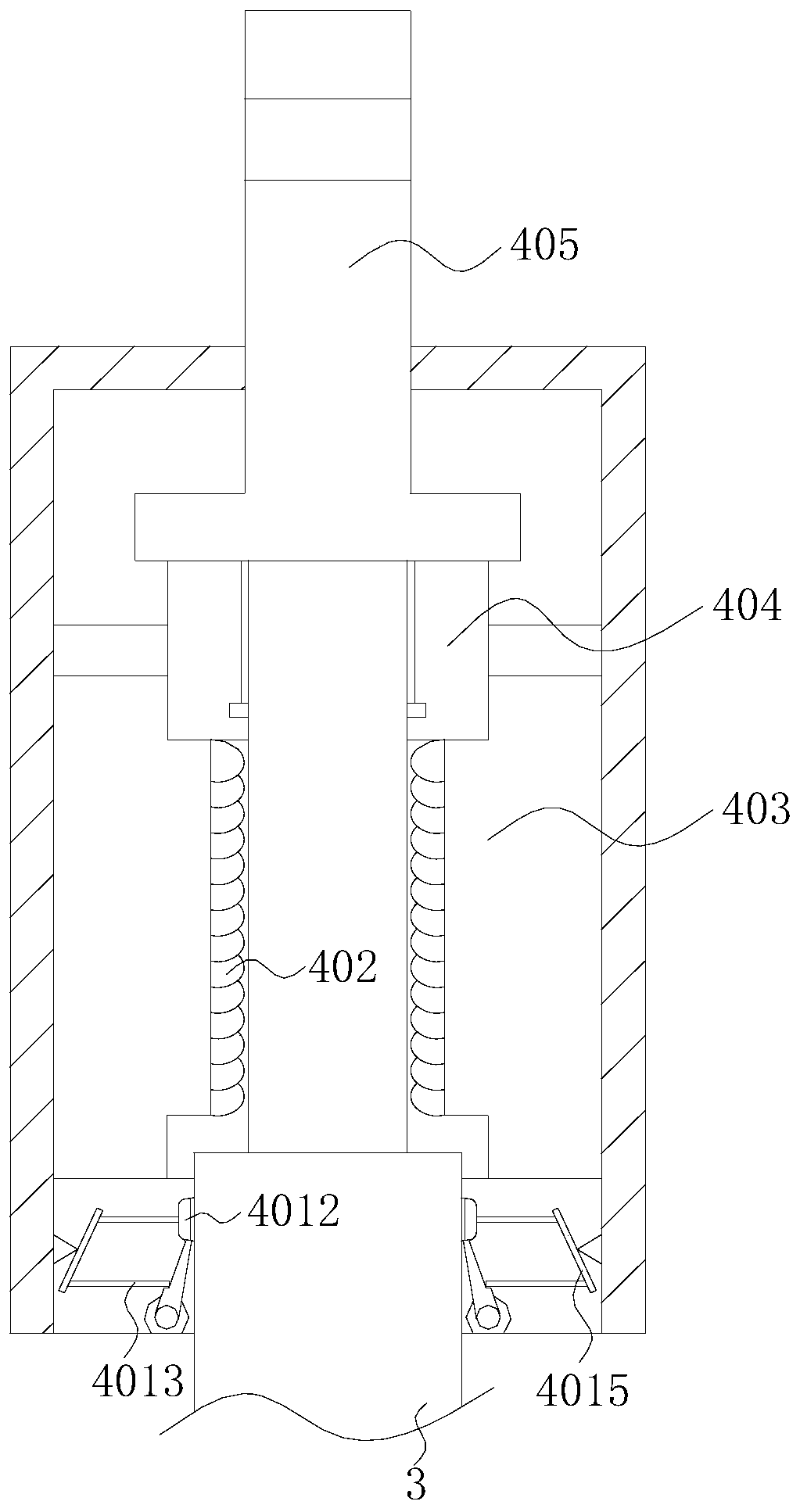

Three-core terminal fixing device

InactiveCN110086011ATo achieve the purpose of clampingGuaranteed not to loosenElectric connection structural associationsPetroleum engineering

Owner:益风电缆有限公司

Short-circuit prevention high voltage transformer

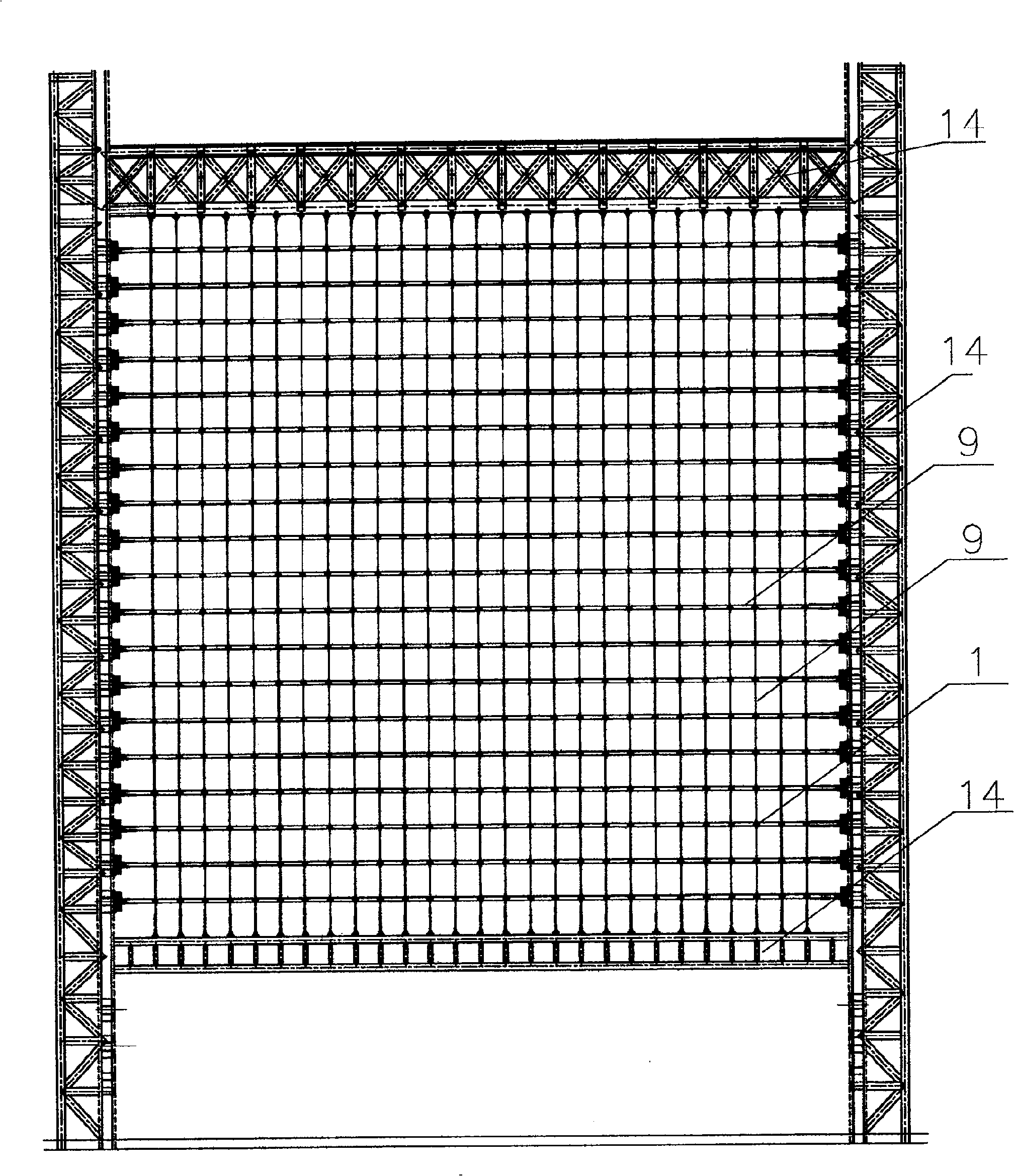

InactiveCN104376999AQuality assuranceImprove short circuit resistanceTransformers/inductances coils/windings/connectionsCushionFastener

The invention discloses a short circuit prevention high voltage transformer. The short circuit prevention high voltage transformer comprises an iron core, an upper iron yoke, a lower iron yoke and a winding. The winding comprises a coil, an upper pressing plate, a lower pressing plate and a compression cushion block device. The compression cushion block device comprises a fixing frame and a cushion block assembly. The cushion block assembly comprises an upper bakelite cushion block, a lower bakelite cushion block, an insulation adjusting sheet and a bakelite fastener. The fixing frame and the lower surface of the upper iron yoke are fixed. The upper bakelite cushion block and the lower surface of the fixing frame are fixed. The lower surface of the lower bakelite cushion block makes contact with the upper surface of the upper pressing plate. The insulation adjusting sheet is arranged between the upper bakelite cushion block and the lower bakelite cushion block. The upper bakelite cushion block, the lower bakelite cushion block and the insulation adjusting sheet are fixed through the bakelite fastener. According to the short circuit prevention high voltage transformer, the compression cushion block device can continuously apply pressure on the upper pressing plate; on the one hand, it is ensured that the whole winding does not loosen between the upper iron yoke and the lower iron yoke; on the other hand, it is ensured that the coil is not disengaged between the upper pressing plate and the lower pressing plate.

Owner:SUZHOU WUZHONG DISTRICT DALU ELECTRIC EQUIP FACTORY

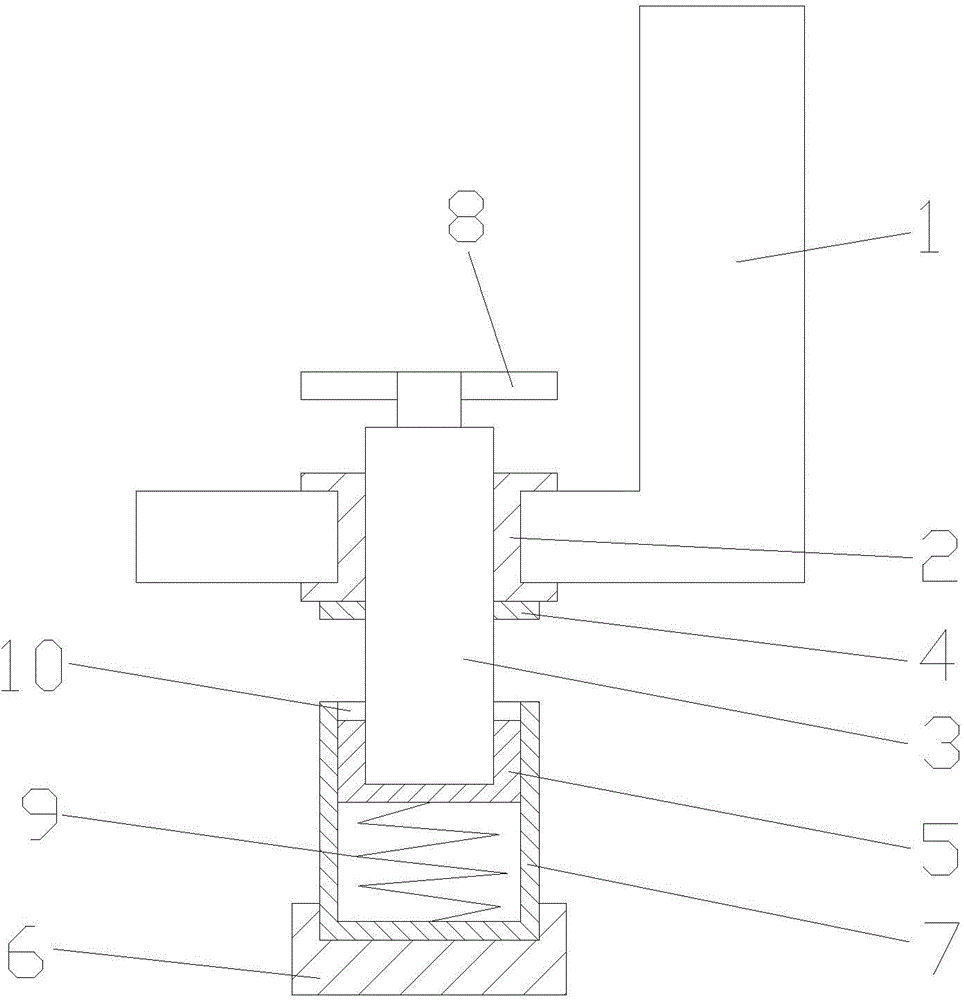

Pressing device

InactiveCN104377005AImprove short-circuit resistanceGuaranteed uptimeTransformers/inductances coils/windings/connectionsElastic componentEngineering

The invention discloses a pressing device. The pressing device comprises a fixing frame, a threaded sleeve, a lead screw, a locking nut, a sliding block, a fixed block, a sliding sleeve, an elastic component and a handle, wherein the threaded sleeve is arranged in the fixing frame, the lead screw penetrates through the threaded sleeve, the lead screw is sleeved with the locking nut, the locking nut is located under the threaded sleeve, the sliding block is arranged at the bottom of the lead screw, the sliding block slides in the sliding sleeve, the sliding sleeve is fixed in the fixed block, the elastic component is arranged between the bottom of the sliding block and the bottom surface inside the sliding sleeve, and the handle is arranged at the top of the lead screw. The pressing device can continuously apply pressure on an object under the fixed block.

Owner:SUZHOU WUZHONG DISTRICT DALU ELECTRIC EQUIP FACTORY

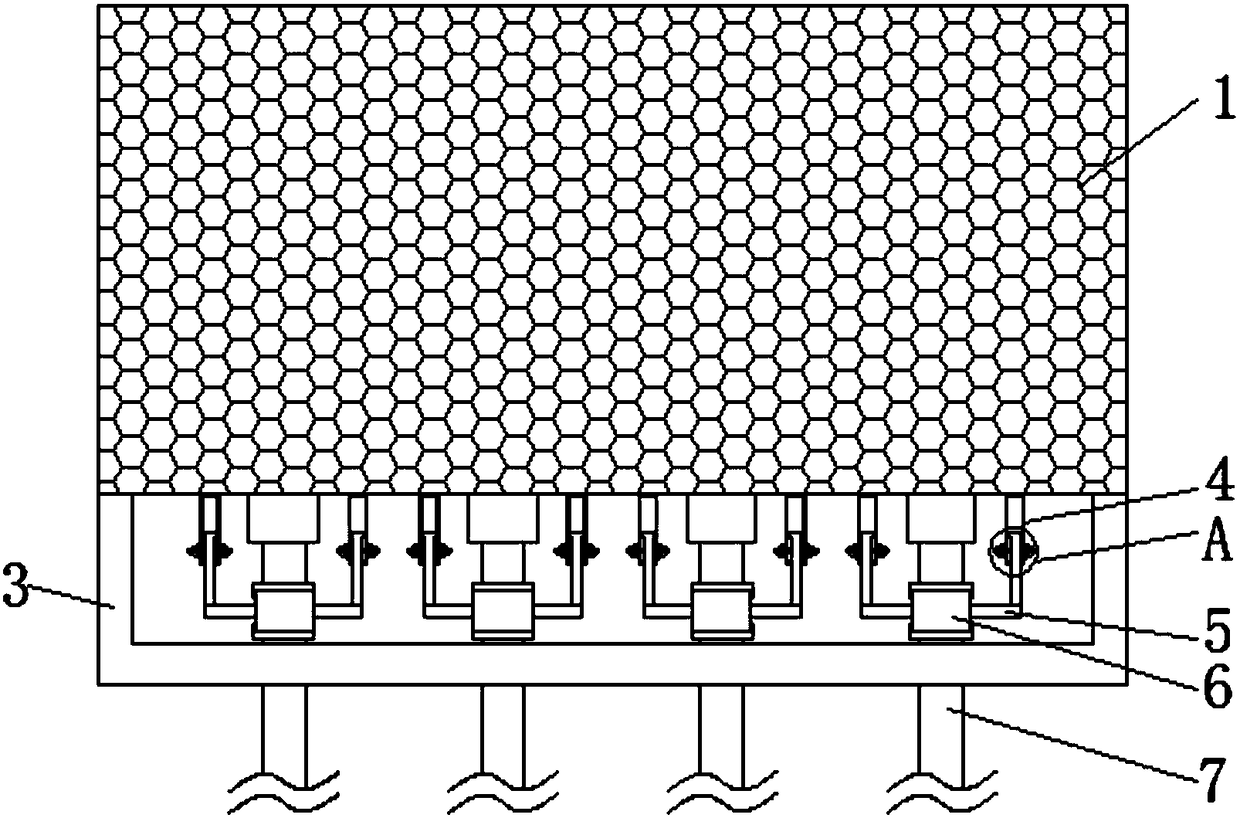

Interference extrusion and rigid fixation combined piezoelectric fan

ActiveCN113431794AGuaranteed not to loosenEasy to fixPump componentsPiezoelectric/electrostriction/magnetostriction machinesCantilevered beamPiezoelectric fan

The invention discloses an interference extrusion and rigid fixation combined piezoelectric fan. The fan comprises piezoelectric fan blades, blade clamping seats, a fan base and an embedded intelligent driving circuit; the piezoelectric fan blades are of cantilever beam structures, the bottom ends of the piezoelectric fan blades are cantilever beam fixing ends, and the top ends of the piezoelectric fan blades are cantilever beam free end; and the bottom ends of the piezoelectric fan blades are fixed to the blade clamping seats, the blade clamping seats are extruded on the fan base in an interference mode, and the embedded intelligent piezoelectric fan driving circuit is embedded into the piezoelectric fan base and used for driving the piezoelectric fan blades to vibrate. The combined piezoelectric fan can stably work in a good state with high reliability for a long time in a severe environment, has no electromagnetic interference on electronic equipment needing heat dissipation, and meets the requirements.

Owner:CHENGDU HUITONG WEST ELECTRONIC CO LTD

Time synchronization device with data line fastening function

ActiveCN108156774AWith fastening functionAvoid churnCasings/cabinets/drawers detailsData connectionData loss

The invention discloses a time synchronization device with a data line fastening function. The device comprises a time synchronization device body with the data line fastening function. A data line jack is arranged in the back of the time synchronization device body with the data line fastening function. A protection frame is fixedly arranged on the back of the time synchronization device body with the data line fastening function. Adjusting rods are arranged on both sides of the data line jack on the back of the time synchronization device body with the data line fastening function. The telescopic ends of two adjusting rods are fixedly connected through a connecting cross plate. A line clamp plate is fixedly arranged at the top of the connecting cross plate. A line clamp buckle is fixedlyarranged at the bottom of the line clamp plate. A data connection line is inserted into a line insertion slot on the surface of the protection frame. The line clamp plate is in clamp connection withthe surface of the data connection line. One end of the data connection line is inserted into the data line jack. According to the time synchronization device with the data line fastening function, the data connection line is not loosened; normal operation of the time synchronization device with the data line fastening function is ensured; the time synchronization device with the data line fastening function is prevented from data loss caused by the loose data connection line; and the device facilitates the work of people.

Owner:湖北中科亿能科技有限公司

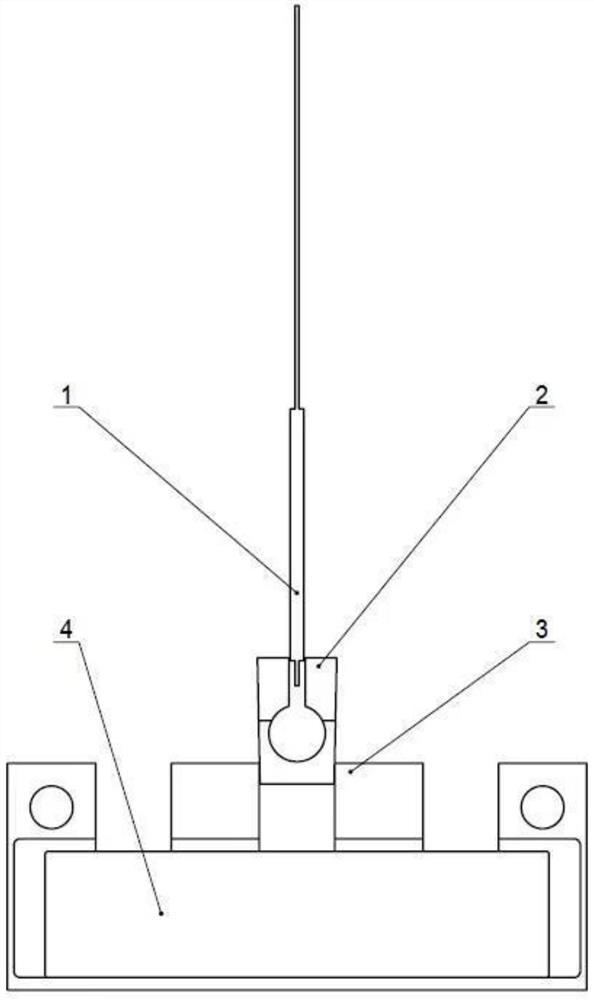

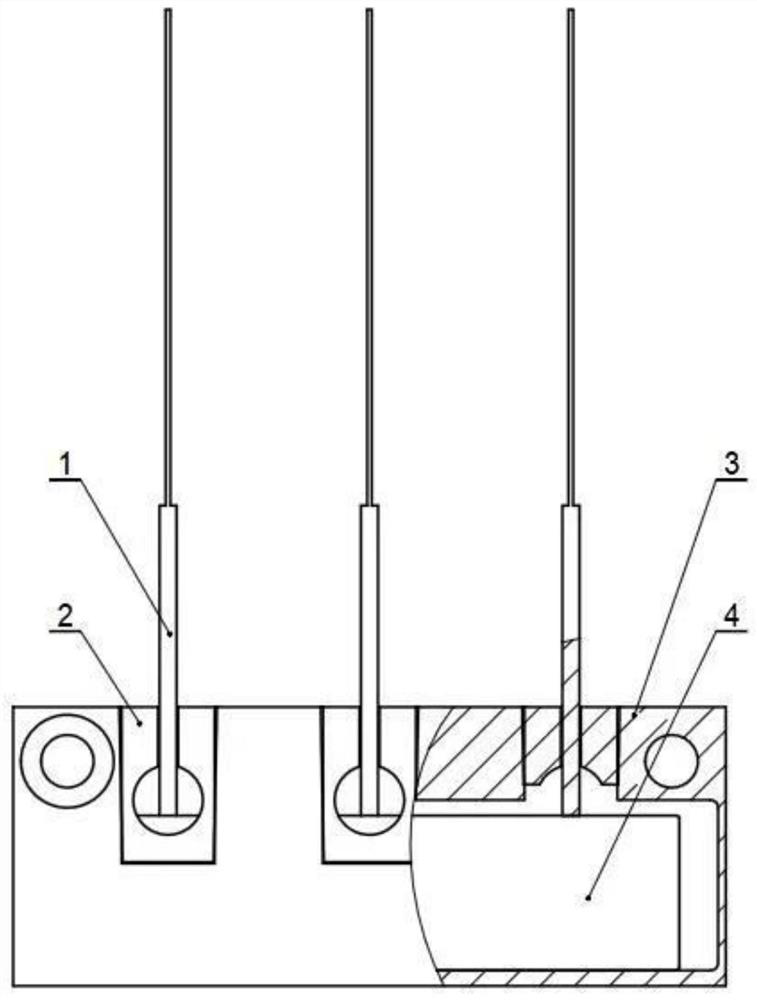

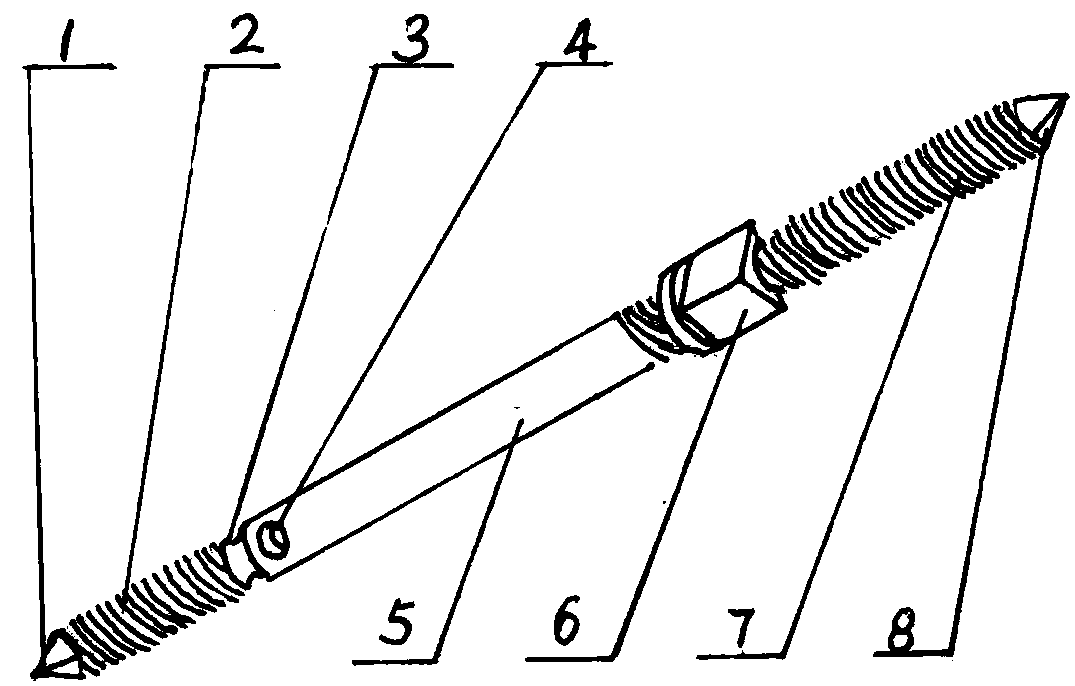

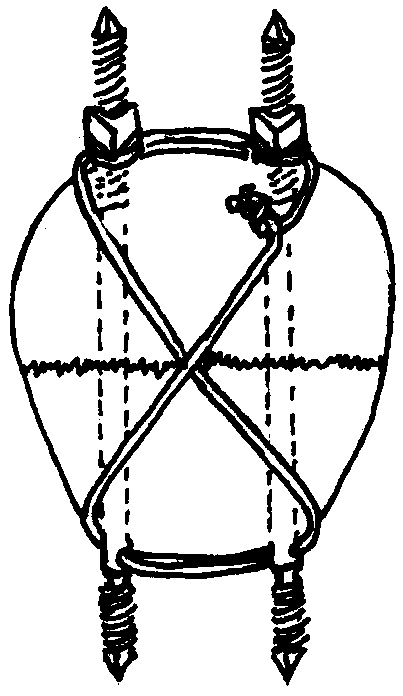

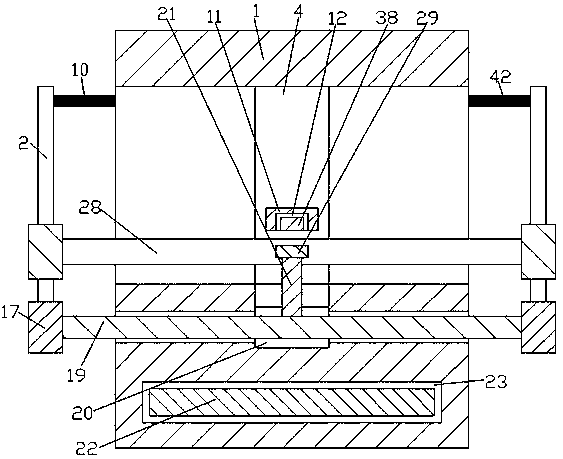

Spicule pressurizing system

PendingCN108175490APrevent slipping outGuaranteed not to loosenInternal osteosythesisFastenersEngineeringLower pole

A spicule pressurizing system capable of preventing loosening is composed of circular spicules and matched pressurizing nuts, wherein the two ends of the circular spicules are each provided with a thread and a pointed cone. Each front end thread is short, a through hole for a steel wire to penetrate through transversely runs through the rear end of each circular spicule, and a retreating groove easy to break is formed between the thread and the through groove; each rear end thread is long, and the large diameter of the thread is equal to the diameter of a polished rod of the corresponding spicule. During the internal fixation of a tension band steel wire for a patella fracture, the steel wire can penetrate through the through holes of the front ends of the two spicules on a patella lower pole and then be folded back and crossed to be wound around the spicule of a patella upper pole to be screwed and fixed in an 8-shaped mode; in addition, the fixed steel wire and the patella upper poleare squeezed by the two pressurizing nuts, the two ends of the spicules are broken or cut off, and then the firm fixation free of spicule tip stimulation and looseness and beneficial for spicule taking can be achieved; when the spicule pressurizing system is used for the internal fixation of a clavicle fracture intramedullary needle or the humerus pl humeri medial malleolus fracture fixation or other fixation modes where the front end of a spicule does not need to penetrate through opposite side bone cortex, through the combination of the rear pressurizing nuts and the front end threads, it can be avoided that the spicules get loose and slip out forward or backward.

Owner:董谢平

Auxiliary device for drawing or artistic drawing

ActiveCN110039945AAutomatic and accurate clampingGuaranteed not to loosenOther artistic work equipmentsDrive shaftDrive motor

The invention discloses an auxiliary device for drawing or artistic drawing. The auxiliary device for drawing or artistic drawing comprises a drawing board, a driving cavity is formed in the drawing board, a driving mechanism is arranged in the driving cavity, the driving mechanism comprises a driving motor, the driving motor is in power connection with a driving shaft, and the lower end wall of the driving cavity is provided with a rotating cavity for communicating the inner wall with the driving cavity. In the working process, any selection can be carried out in an automatic or manual mode,a pressing block is controlled to clamp the paper according to the size of the paper, so that the manual fine clamping paper is achieved, the paper can be clamped automatically and accurately, therefore the paper can be prevented from being loosened under the condition that the paper is ensured to be flat, the use space of the paper is not excessively occupied, the author can make better creation,the working efficiency of running of the auxiliary device is higher through mechanical transmission, the clamping degree is higher, and looseness during drawing is avoided.

Owner:义乌市锐超相框有限公司

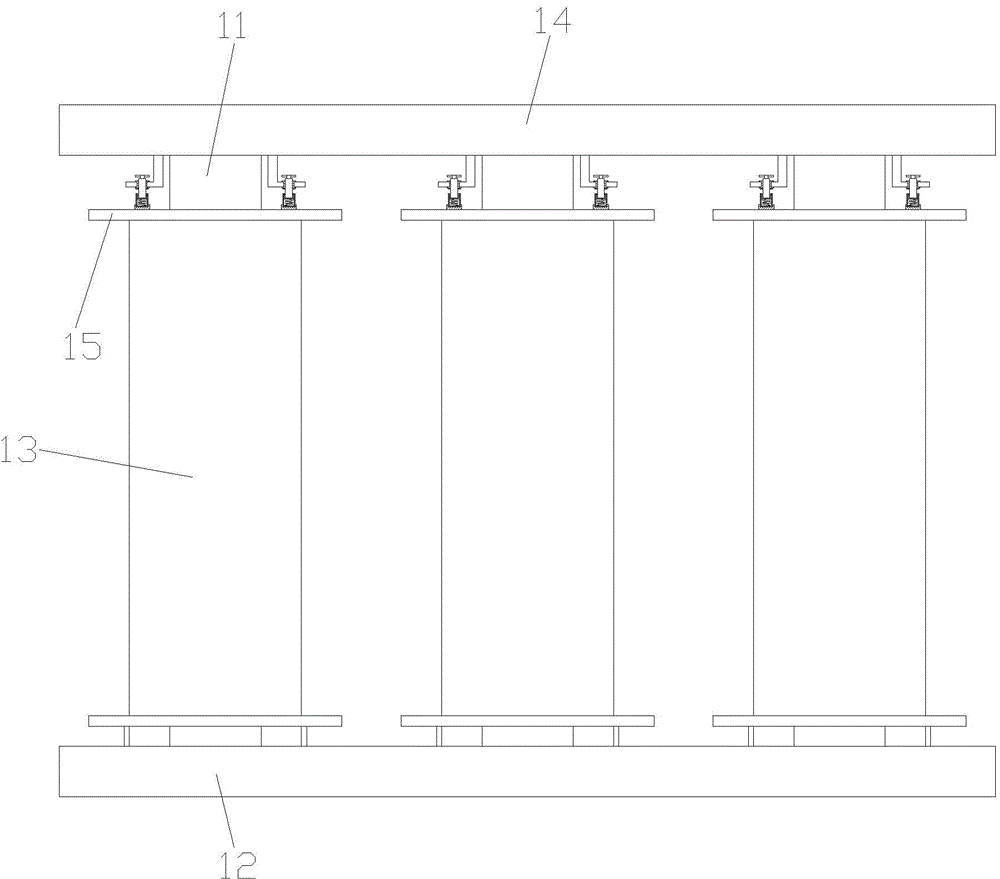

A high voltage transformer

ActiveCN104376996BQuality assuranceImprove short-circuit resistanceTransformers/inductances coils/windings/connectionsEngineeringMechanical engineering

The invention discloses a high-voltage transformer. Fixing frames are fixed to the lower surface of an upper iron yoke. Threaded sleeves are arranged in the fixing frames, and threaded rods penetrate through the threaded sleeves. The threaded rods are sleeved with locking nuts, and the locking nuts are located below the threaded sleeves. Driving discs are arranged at the tops of the threaded rods. Driving devices are arranged on the fixing frames. The output ends of the driving devices are connected with the driving discs through belts. Sliding blocks are arranged at the bottoms of the threaded rods. The upper surfaces of upper pressing plates make contact with the lower surfaces of fixing blocks. Sliding sleeves are fixed in the fixing blocks. The sliding blocks slide in the sliding sleeves. Elastic components are arranged between the bottoms of the sliding blocks and the bottom surfaces inside the sliding sleeves. According to the high-voltage transformer, automatic pressing devices can exert pressure on the upper pressing plates continuously, so that it is guaranteed that a whole winding will not become loose between the upper iron yoke and a lower iron yoke, and it is also guaranteed that coils will not get loose between the upper pressing plates and lower pressing plates.

Owner:ZHONGBIAN GRP SHANGHAI TRANSFORMER CO LTD

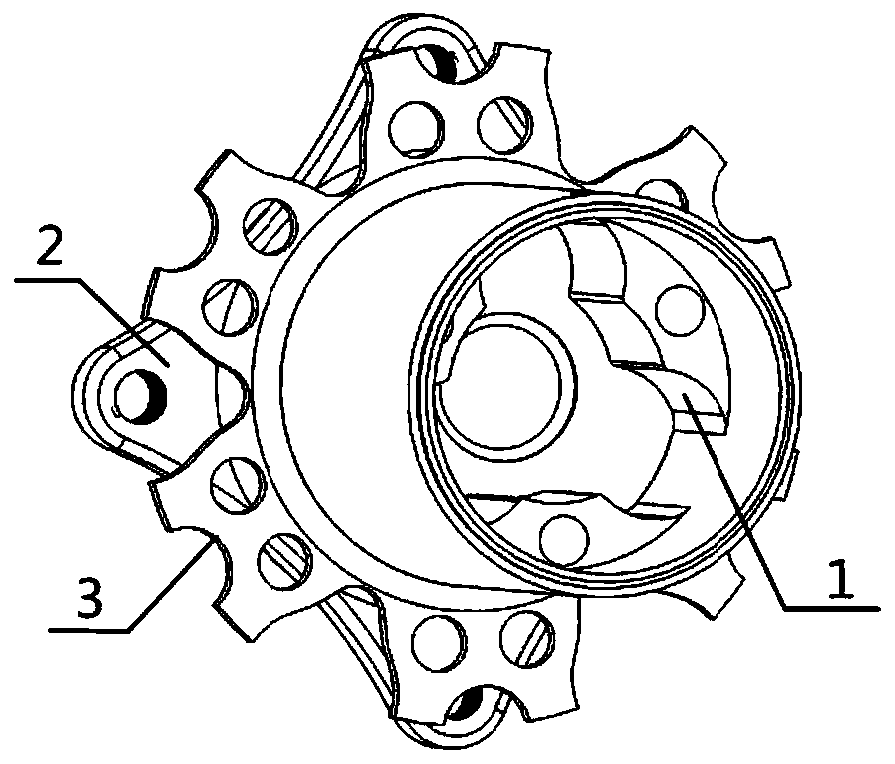

T-shaped split ring self-locking nut

The invention relates to a T-shaped split ring self-locking nut which is applied to the technical field of railway transportation equipment. The T-shaped split ring self-locking nut comprises a nut body and a spring, wherein the spring is arranged in the nut body; a screw pitch of the spring is consistent to a screw pitch of a screw thread of the nut; a T-shaped slot is formed in one hexagonal surface of the nut body; three closing ports are formed in one threadless end in the nut body; a first convex body and a second convex body are arranged at the head end and the tail end of the spring, and stretch out of an opening of the T-shaped slot from the inner part of the nut body; and the spring is clamped into the T-shaped slot. The T-shaped split ring self-locking nut provided by the invention is simple in structure; the spring is arranged in the nut body, so that a fixing function is realized; and the spring has stretchability and contractibility, so that a self-locking performance of the nut can be effectively improved, a nut-bolt fastening system cannot be loosened after a long time during a use process, and the maintenance times and the labor cost are effectively reduced.

Owner:四川艾尔诺航空金属器材有限公司

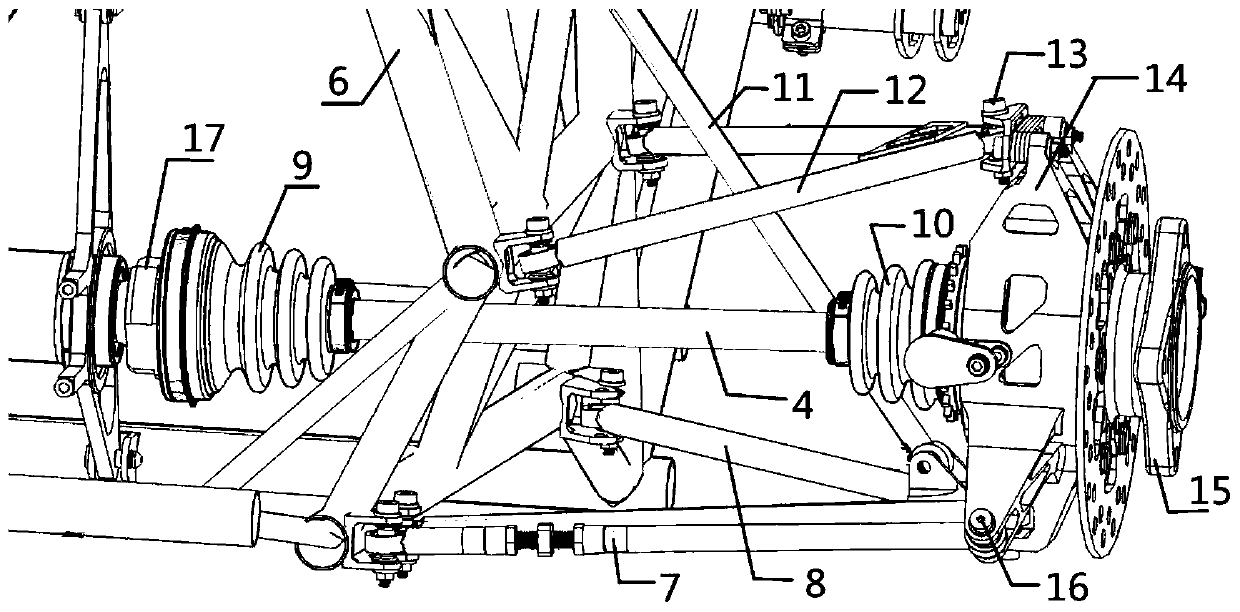

A kind of FSAA racing car rear wheel hub and disassembly method that realizes quick disassembly and assembly of half shaft

The invention discloses an FSAE racing car rear wheel hub capable of realizing quick disassembling and assembling of an axle shaft and a disassembling and assembling method. The rear wheel hub comprises a three-column-groove shell and a sealing device. A through cavity is formed in the center of the three-column groove shell. The through cavity is sealed by the sealing device. The sealing device comprises an end cover, an end cover gasket, a sealing circular ring and a sealing circular ring gasket. The end cover and the sealing circular ring are correspondingly matched with the through cavity.The sealing circular ring is pressed on the through cavity by the end cover. An annular stepped table is arranged on the center of one end of the sealing circular ring, and the end cover gasket is pressed on the annular stepped table by the end cover. A circular groove which is concentric with the sealing circular ring is formed in an outer cylinder surface of the sealing circular ring, the sealing circular ring gasket is arranged in the circular groove, and the outer surface of the sealing circular ring gasket is in tight contact with the inner surface of a rear wheel hub body after assembling. When the axle shaft is disassembled, one end of the axle shaft impacts the sealing circular ring to enable the sealing circular ring and the axle shaft to move towards the outer side of a vehicleuntil the other end of the axle shaft falls from a differential mechanism groove shell to achieve the disassembling of the axle shaft. The rear wheel hub simplifies the disassembling and assembling process of the axle shaft and shortens the maintenance time.

Owner:HUNAN UNIV

A two-degree-of-freedom rope-driven finger force feedback device

ActiveCN112621790BThere will be no stuckImprove human-computer interactionAdditive manufacturing apparatusGripping headsGrip forceHand parts

The invention provides a two-degree-of-freedom rope-driven finger force feedback device, which includes a hand support mechanism, a thumb movement mechanism, an index finger movement mechanism and a handle mechanism. The hand support mechanism includes a motor, a motor shaft sleeve, a slide rail and an IMU sensor. The thumb movement mechanism comprises a long rotating disc, a torque sensor, an angle sensor, a thumb sleeve, a pressure sensor, two connecting rods, a thumb bracket and a thumb fixing ring. The handle mechanism consists of a cylindrical grip, a pressure sensor, a flexible retaining strap, and a slider. The torque is transmitted between the rotating disk and the motor through a rope. The handle mechanism can move back and forth and reset itself. The invention overcomes the problems of high cost and non-adjustable traditional finger force feedback, and is compact to wear and has self-adaptive freedom; the rope transmission ensures that the feedback force is soft and real; through the mounted sensor, the hand posture, thumb and forefinger rotation angle and Grip force, middle finger contact force and other information.

Owner:SOUTHEAST UNIV

Orthodontic arch wire with gradient correction force value and its forming process and device

ActiveCN104546162BGuaranteed not to loosenThe nickel content of the matrix is reducedArch wiresPeriodontiumArch wires

The invention relates to an orthodontic arch wire with gradually changing orthodontic force value and its forming process and device. This kind of orthodontic arch wire gradually changes the orthodontic force value and elastic modulus from the front teeth to the posterior teeth, so that it can provide more reasonable orthodontic force values for different teeth and different patients, and reduces the impact of the orthodontic force on the periodontal ligament. tissue damage. The present invention realizes the gradual change of the orthodontic force value of different parts on a single orthodontic arch wire by changing the cross-sectional shape of different parts of the orthodontic arch wire and adjusting the value of the orthodontic force by means of aging heat treatment.

Owner:INNOVATIVE MATERIAL & DEVICES

Single-layer bidirectional double-rope curtain wall support structure and installing method thereof

The invention relates to a single-layer bi-directional double-rope curtain wall support, which comprises a dragline clamp in form of a circular sheet, the middle of which is hollow and on which four abutments for fixing the dragline is provided. On each abutment, a semi-circle groove and an internal thread hole are provided. The four semi-circle grooves are distributed in cross way taking two as one group, the two groups of semi-circle grooves are vertical to each other in space. Each abutment is provided with a dragline-fastening end cover, on which also a semi-circle groove and a thread hole are provided. The fastening end cover is fixed on the abutment by a bolt. The abutment and the two semi-circle grooves for fastening the end cover coordinate each other to fix the dragline. The end of one fastening end cover is provided with an interface for connecting with the overlap connecting jaw. The invention makes possible adding no structural part in a space with a big span, and can guarantee the permeability of structures to the max. extent.

Owner:JANGHO GRP

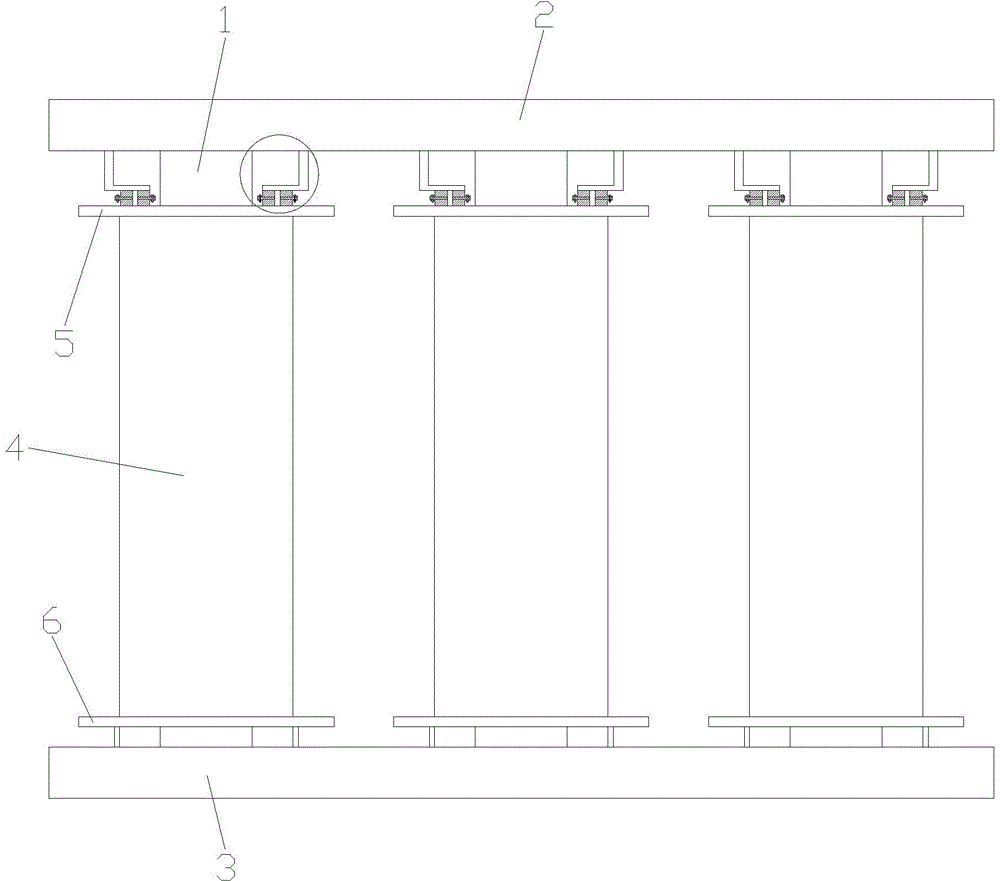

An automatic pressing device

ActiveCN104376994BImprove short-circuit resistanceGuaranteed uptimeTransformers/inductances coils/windings/connectionsFixed frameSemi automatic

The invention discloses an automatic pressing device which comprises a fixed frame, a thread bushing, a screw rod, a locknut, a drive plate, a drive device, a belt, a sliding block, a fixed block, a sliding sleeve and a flexible assembly. The thread bushing is arranged in the fixed frame; the screw rod penetrates through the thread bushing; the screw rod is sleeved with the locknut; the locknut is located on the lower side of the thread bushing; the drive plate is arranged on the top of the screw rod; the drive device is arranged on the fixed frame; the output end of the drive device is connected with the drive plate through the belt; the sliding block is arranged at the bottom of the screw rod; the sliding block slides in the sliding sleeve; the sliding sleeve is fixed in the fixed block; the flexible assembly is arranged between the bottom of the sliding block and the internal bottom surface of the sliding sleeve. The automatic pressing device can apply pressure to an object below the fixed block continuously, semi-automatic operation is achieved, no manual operation is needed, and convenience and rapidness are achieved.

Owner:SUZHOU ZHONGTUO PATENT OPERATION MANAGEMENT CO LTD

A time synchronization device with data line fastening function

ActiveCN108156774BWith fastening functionAvoid churnCasings/cabinets/drawers detailsData connectionData stream

The invention discloses a time synchronization device with a data line fastening function. The device comprises a time synchronization device body with the data line fastening function. A data line jack is arranged in the back of the time synchronization device body with the data line fastening function. A protection frame is fixedly arranged on the back of the time synchronization device body with the data line fastening function. Adjusting rods are arranged on both sides of the data line jack on the back of the time synchronization device body with the data line fastening function. The telescopic ends of two adjusting rods are fixedly connected through a connecting cross plate. A line clamp plate is fixedly arranged at the top of the connecting cross plate. A line clamp buckle is fixedlyarranged at the bottom of the line clamp plate. A data connection line is inserted into a line insertion slot on the surface of the protection frame. The line clamp plate is in clamp connection withthe surface of the data connection line. One end of the data connection line is inserted into the data line jack. According to the time synchronization device with the data line fastening function, the data connection line is not loosened; normal operation of the time synchronization device with the data line fastening function is ensured; the time synchronization device with the data line fastening function is prevented from data loss caused by the loose data connection line; and the device facilitates the work of people.

Owner:湖北中科亿能科技有限公司

Short circuit prevention high-voltage transformer

InactiveCN104377004AQuality assuranceImprove short-circuit resistanceTransformers/inductances coils/windings/connectionsElastic componentFixed frame

The invention discloses a short circuit prevention high-voltage transformer. Iron cores are axially arranged between an upper iron yoke and a lower iron yoke; windings are arranged around the iron cores; a compression device is arranged between the upper iron yoke and each upper pressing board. Each compression device comprises a fixing frame, a threaded sleeve, a screw rod, a locking nut, a sliding block, a fixed block, a sliding sleeve, an elastic component and a handle, wherein the fixing frame and the lower surface of the upper iron yoke are fixed; the threaded sleeve is arranged in the fixing frame; the screw rod penetrates through the threaded sleeve and is sleeved with the locking nut; the locking nut is located below the threaded sleeve; the sliding block is arranged at the bottom of the screw rod; the upper surface of each upper pressing board makes contact with the lower surface of the corresponding fixed block; the sliding sleeve is fixed in the fixed block; the sliding block slides in the sliding sleeve; the elastic component is arranged between the bottom of the sliding block and the inner bottom face of the sliding sleeve; the handle is arranged on the top of the screw rod. The quality of the short circuit prevention high-voltage transformer is effectively ensured, the short circuit prevention capacity of the short circuit prevention high-voltage transformer is improved, and market requirements are met.

Owner:SUZHOU WUZHONG DISTRICT DALU ELECTRIC EQUIP FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com