Pressing device

A compression device and locking nut technology, applied in the direction of transformer/inductor coil/winding/connection, etc., can solve the problems of poor short-circuit resistance of transformers, easy loosening of coils, easy loosening of windings, etc., to improve short-circuit resistance, Guarantee the quality and ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described below with reference to the drawings.

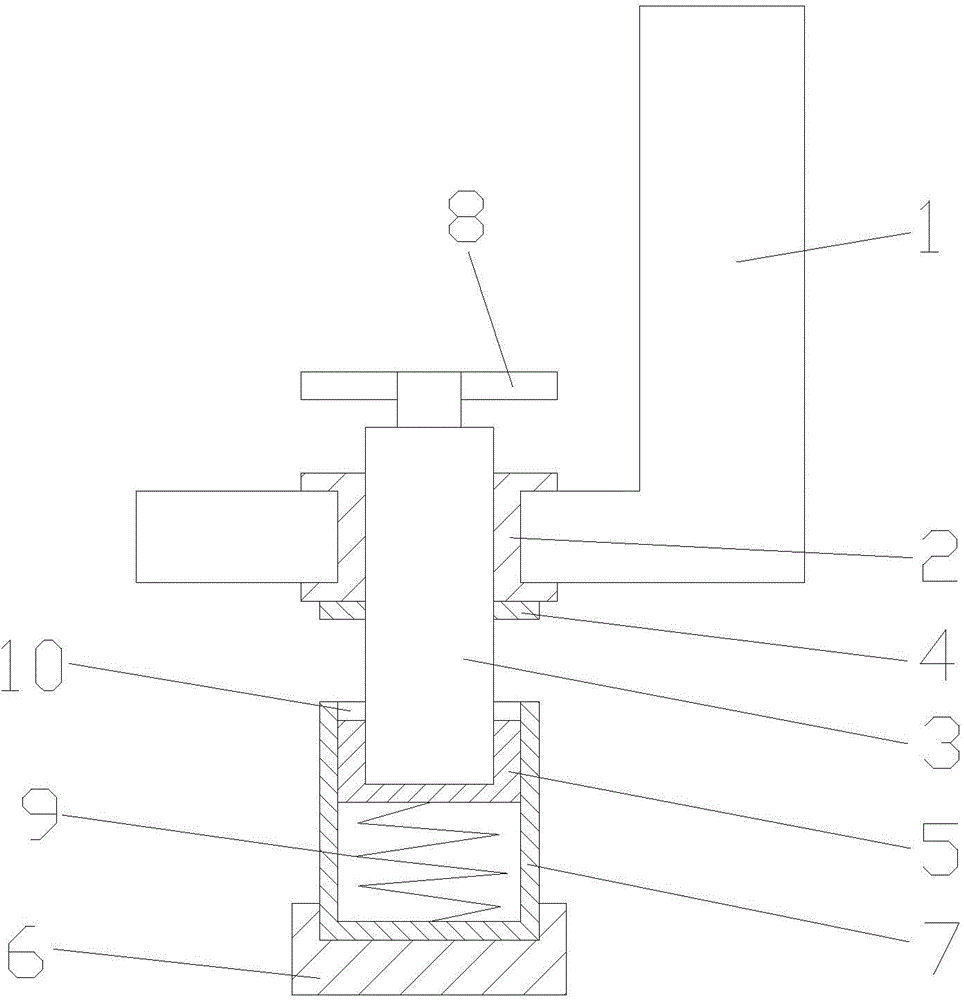

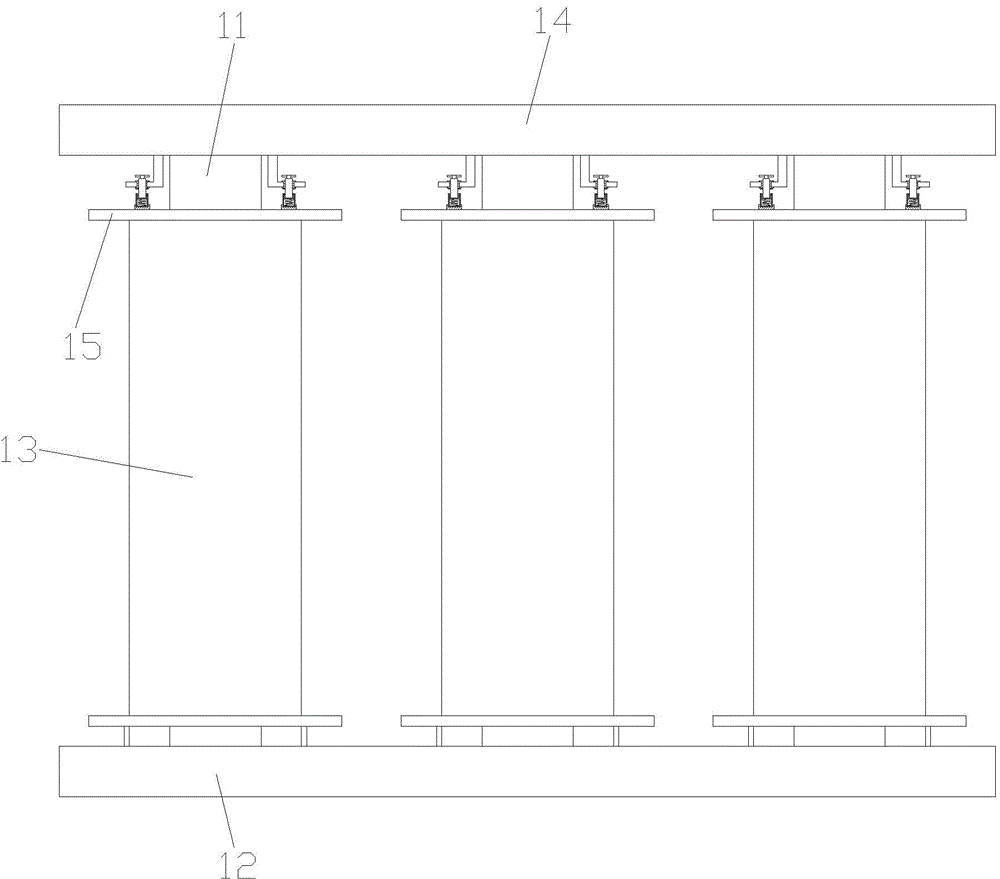

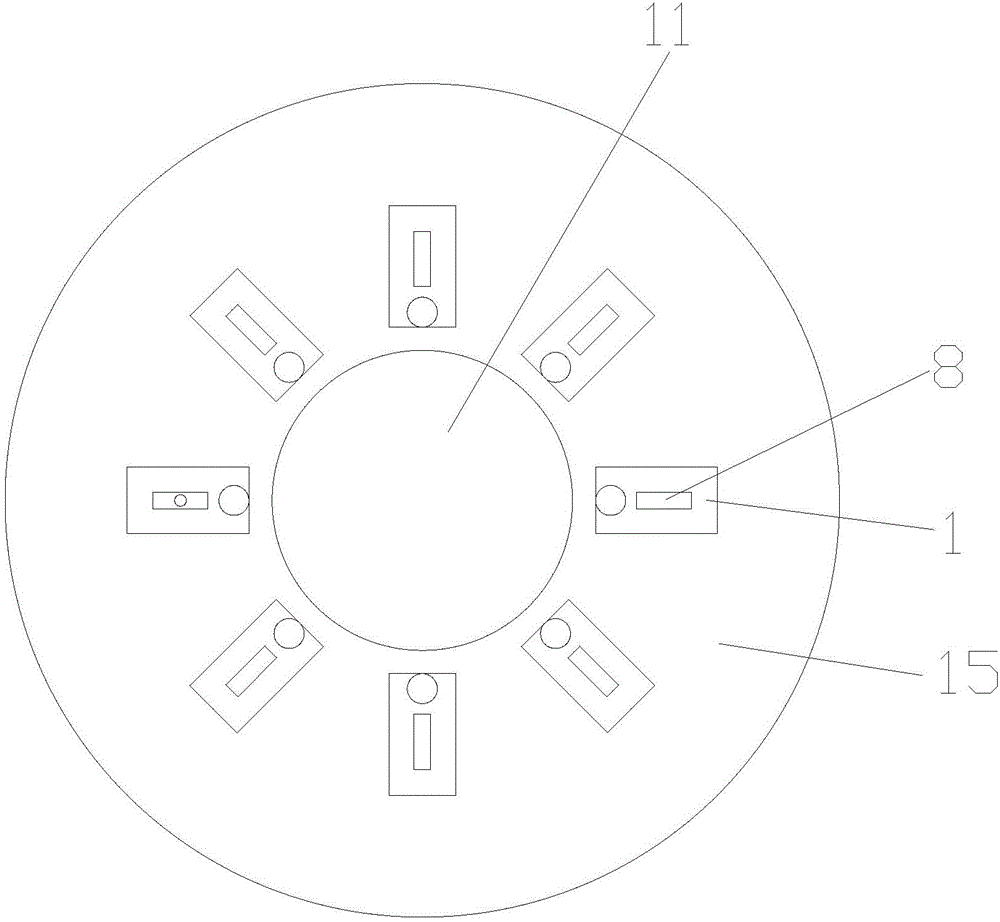

[0015] As attached figure 1 The shown pressing device according to the present invention includes a fixing frame 1, a threaded sleeve 2, a screw 3, a lock nut 4, a sliding block 5, a fixing block 6, a sliding sleeve 7, an elastic component and a handle 8; The fixing frame 1 is provided with a threaded sleeve 2; the screw 3 passes through the threaded sleeve 2; the screw 3 is sleeved with a locking nut 4; the locking nut 4 is located below the threaded sleeve 2; A sliding block 5 is provided at the bottom; the sliding block 5 slides on the sliding sleeve 7; the sliding sleeve 7 is fixed in the fixed block 6; an elastic component is arranged between the bottom of the sliding block 5 and the inner bottom surface of the sliding sleeve 7; The elastic component is preferably a spring 9; the top of the sliding sleeve 7 is provided with a limit ring 10 to prevent the sliding block 5 from falling out; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com