High-current connector

A high-current connector and connector technology, applied in the direction of conductive connection, electrical component connection, connection, etc., can solve the problems of battery electric shock, troublesome installation, large operating space, etc., saving materials and space, easy installation, and volume. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

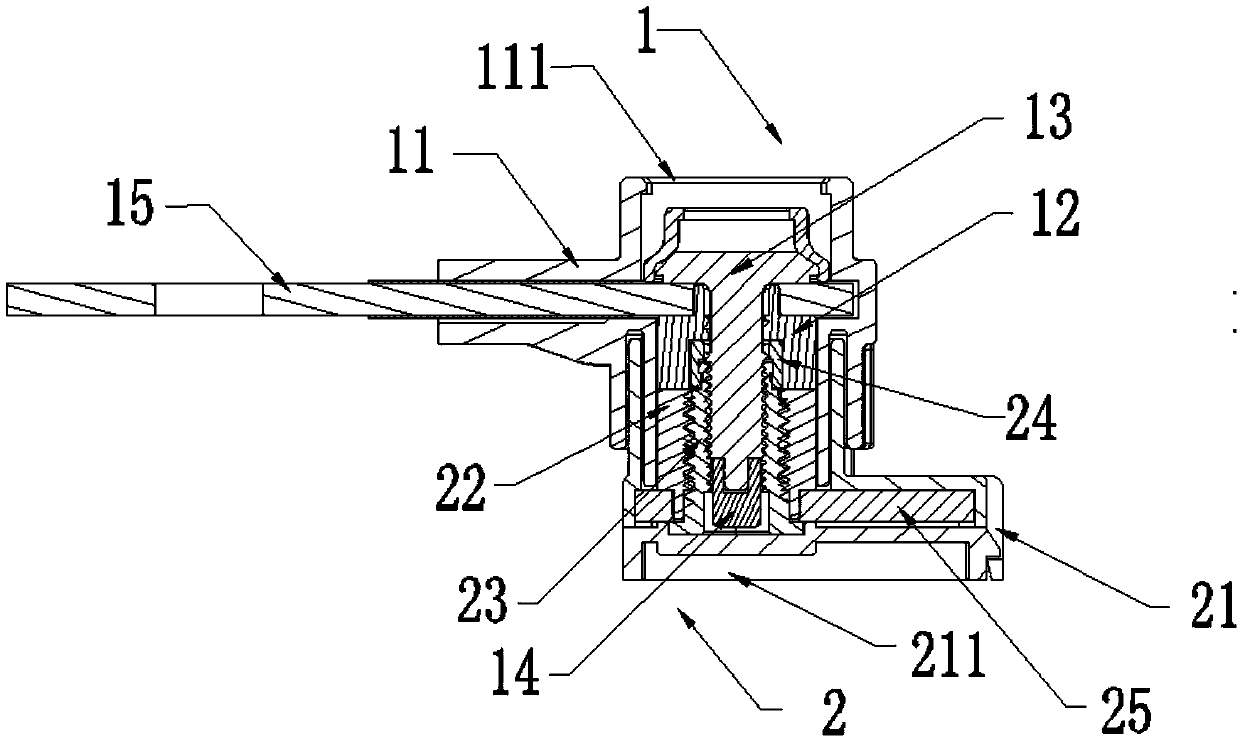

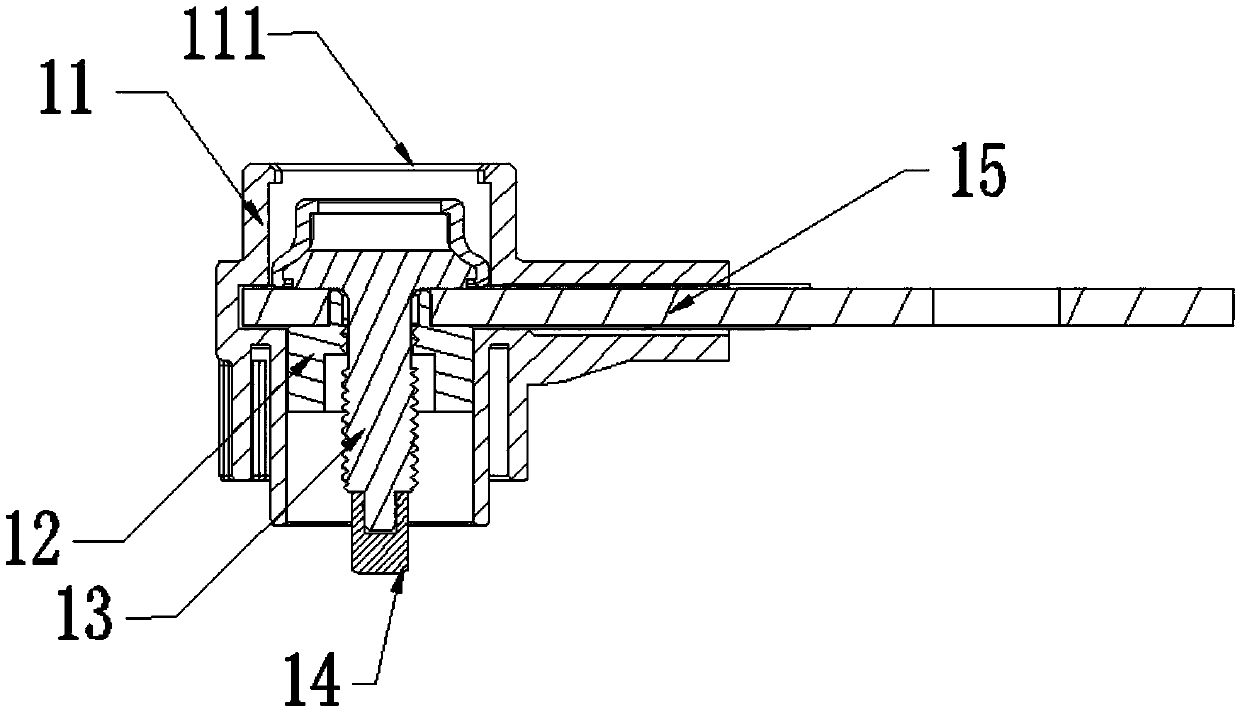

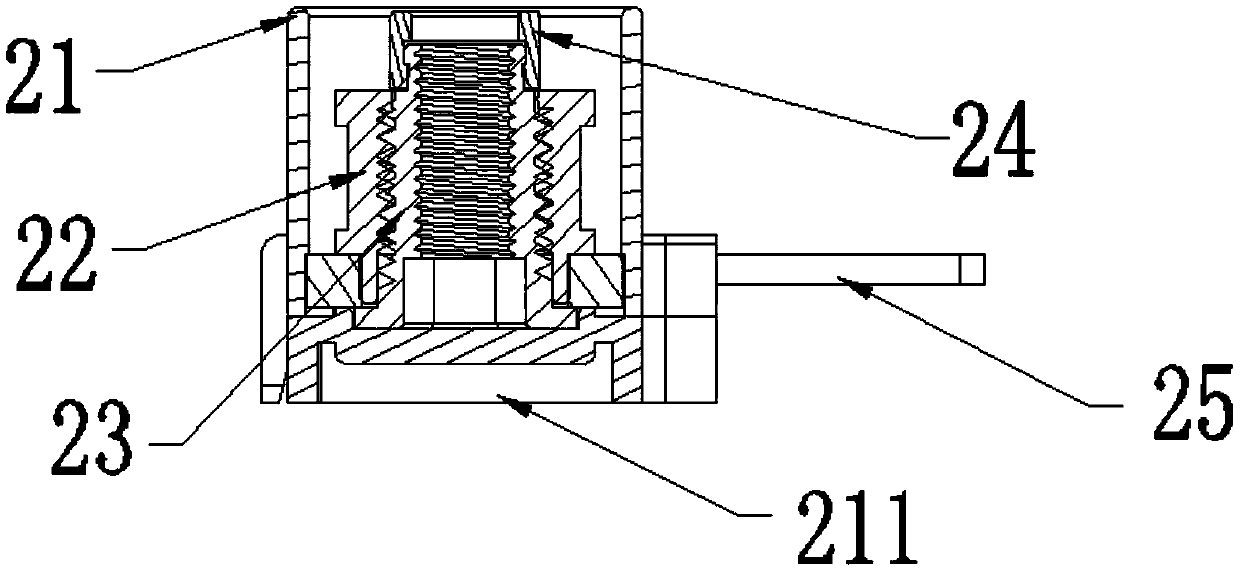

[0030] Such as Figure 1-7 As shown, according to this embodiment, a high-current connector is provided, including an input part 1 and an output part 2. The input part 1 includes a first housing 11, an input contact 12 and a fastener 13, and the input contact 12 is provided with There is a connection hole, the output part 2 includes a second housing 21, an output contact 22 and a connection seat 23, and the output contact 22 is sleeved on the connection seat 23; when the input part and the output part are connected, one end of the fastener 13 passes through The connection hole is fixed on the connection seat 23 , and the other end is limited on the first housing 11 or the input contact 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com