An automatic pressing device

A technology of pressing device and driving device, applied in the direction of transformer/inductor coil/winding/connection, etc., can solve the problems of easy loosening of windings, poor short-circuit resistance of transformers, easy loosening of coils, etc. Short-circuit capability, the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

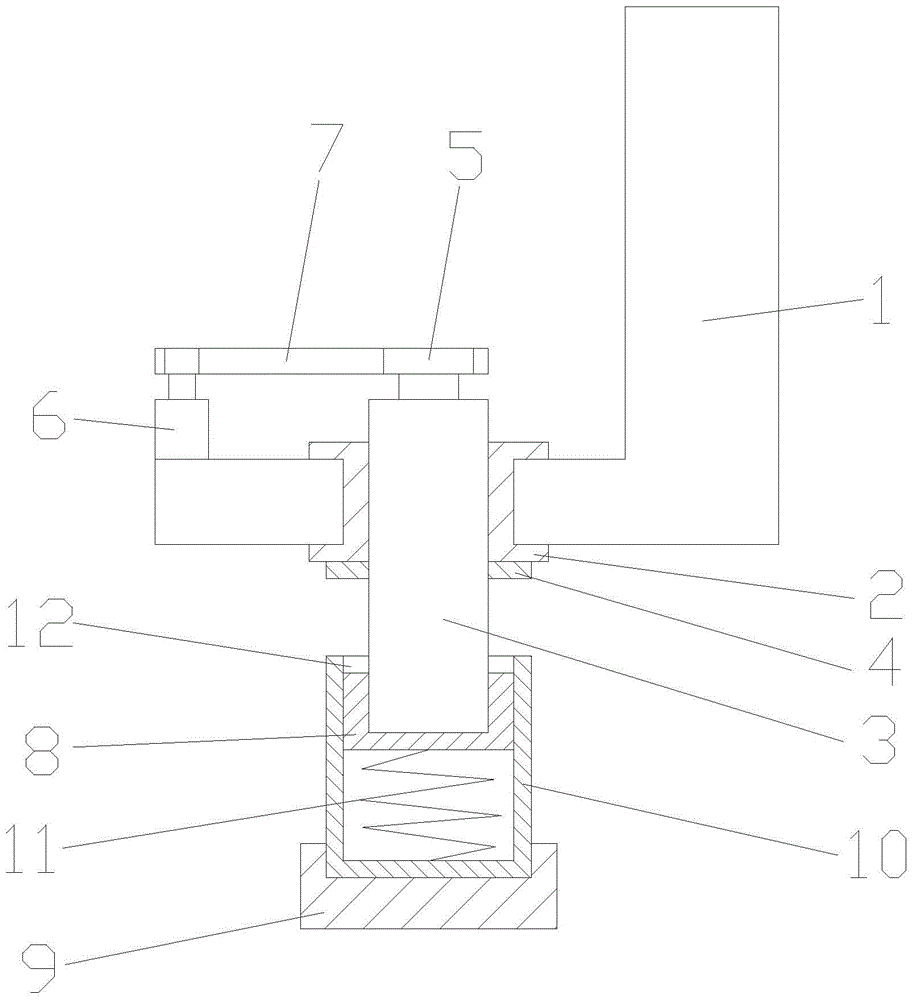

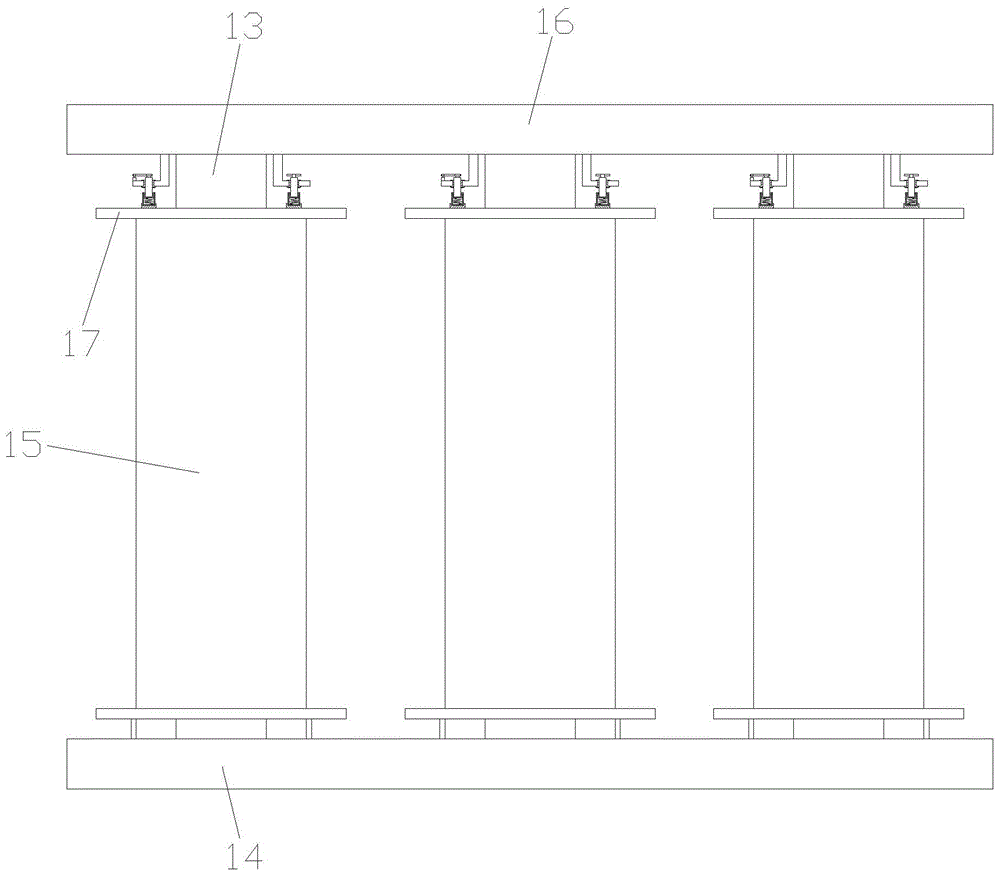

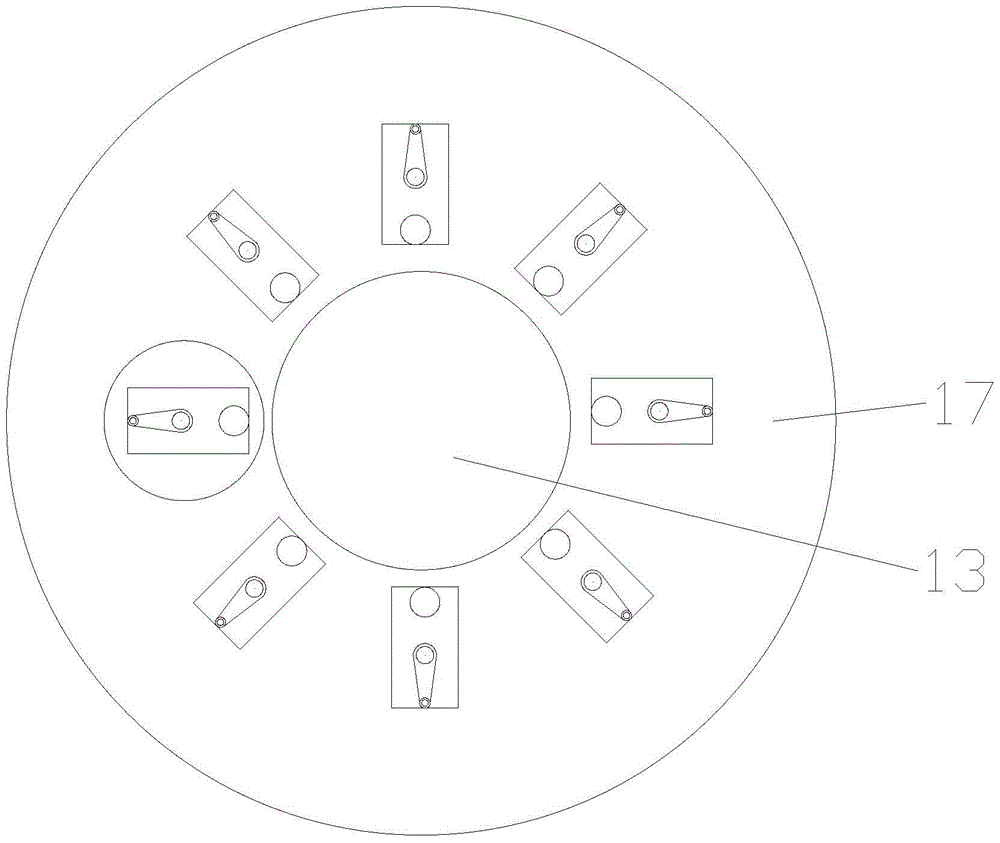

[0015] The present invention is described below in conjunction with accompanying drawing.

[0016] as attached figure 1 The shown automatic pressing device of the present invention includes a fixed frame 1, a threaded sleeve 2, a screw rod 3, a lock nut 4, a driving disc 5, a driving device 6, a belt 7, a slider 8, and a fixed block 9 , sliding sleeve 10 and elastic parts; the fixed frame 1 is provided with a threaded sleeve 2; the screw 3 passes through the threaded sleeve 2; the screw 3 is covered with a lock nut 4; the lock nut 4 is located on the thread Below the cover 2; the top of the screw 3 is provided with a driving disc 5; the driving device 6 is arranged on the fixed frame 1; the output end of the driving device 6 is connected with the driving disc 5 through a belt 7; The bottom is provided with a slider 8; the slider 8 slides on the sliding sleeve 10; the sliding sleeve 10 is fixed in the fixed block 9; an elastic member is provided between the bottom of the slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com