Orthodontic arch wire with gradient correction force value and its forming process and device

A molding process, a technology for dental arch wires, applied in the direction of arch wires, etc., can solve the problems of high cost, no products and reports, no breakthrough progress, etc., to increase lateral displacement, improve orthodontic efficiency, and reduce wire replacement. The effect of frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

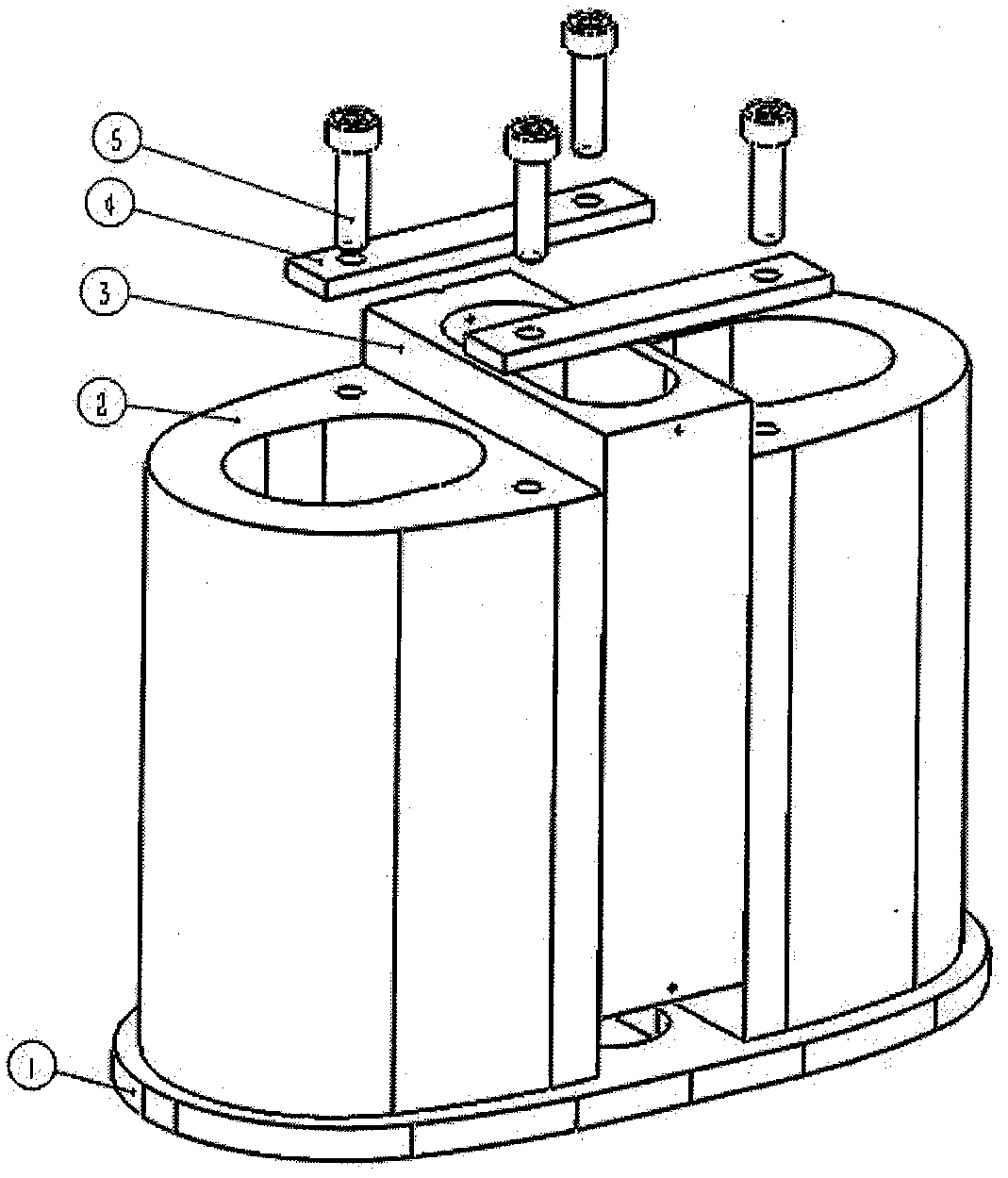

[0022] The gradient orthodontic force value orthodontic arch wire graded aging heat treatment molding process of the present invention is carried out according to the following steps:

[0023] 1. The upper mold, closely arrange the nickel-titanium round wires of Φ0.41 on the device of the present invention, and the distance of the wire arrangement is 0.3;

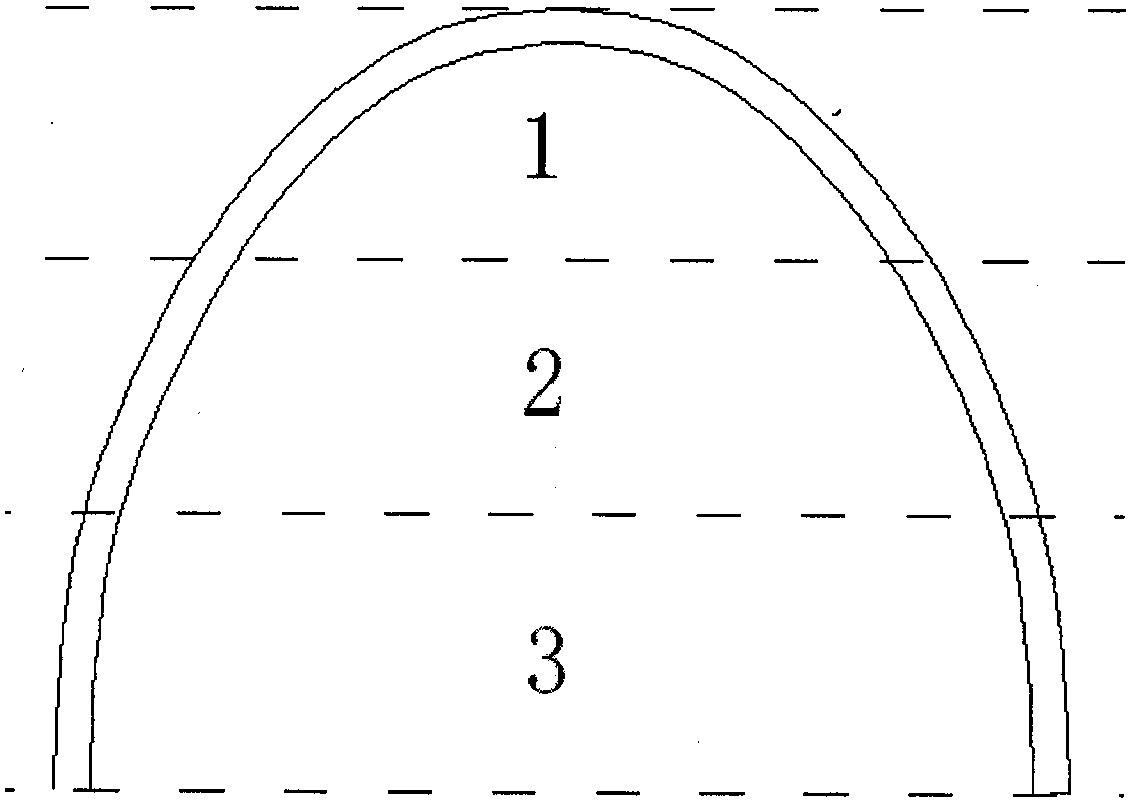

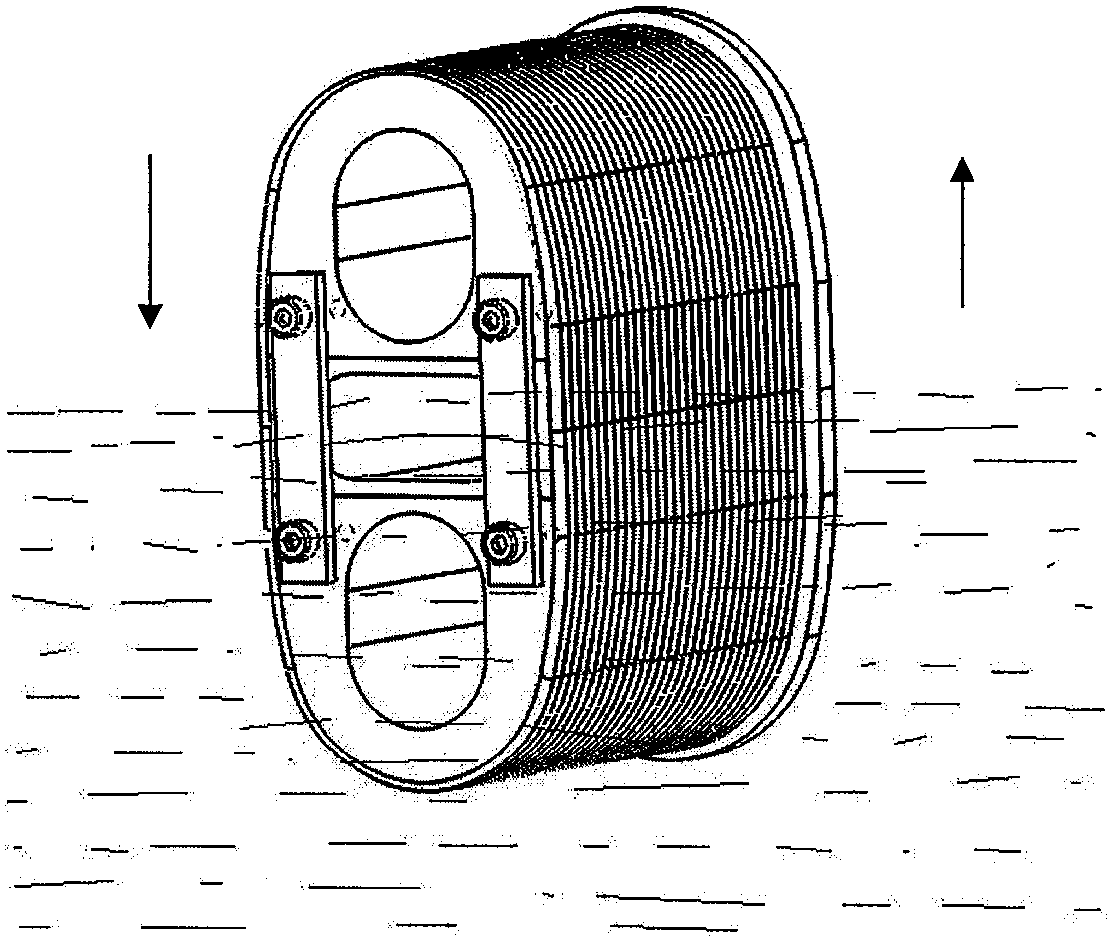

[0024] 2. Graded aging heat treatment, the temperature of the salt bath furnace is set to 540°C, and the mold and the wire are put together as figure 1 The anterior part of the area shown in area 1 is first immersed in the salt bath furnace with the front teeth facing down, and the overall decline is at a constant speed of 5mm / min. When the mold is half immersed in the salt bath, it stops falling. After 15 minutes of static heat preservation, the salt bath is quickly taken out, and after 5 minutes of air cooling Rotate the mold 180° and carry out the other half according to the above method. After completion, take out the ...

specific Embodiment approach 2

[0026] The difference between this embodiment and Embodiment 1 is that the graded aging heat treatment described in step 2 is to quickly immerse the orthodontic arch wire 1 area in the salt bath furnace to the centerline of the mold, and then heat it for 20 minutes at a rate of 5 mm / min. Elevate the mold at a constant speed at a constant speed, rotate 180° after being out of the oven for 5 minutes and then perform the above steps, and the rest of the steps are the same as in Embodiment 1.

specific Embodiment approach 3

[0027] The difference between this embodiment and Embodiment 1 is that the staged aging heat treatment in step 2 is a stepwise descending method, such as figure 1 The quick immersion is divided into three stages as shown, the 1st area is quickly immersed and then kept for 7 minutes, the 2nd area is soaked and then kept for 7 minutes, the 3rd area is immersed for 10 minutes, and the air is cooled after being out of the oven. The rest of the steps are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com