Large-stroke friction-free spindle of braider

A frictionless, long-stroke technology, used in knitted fabrics, textiles and papermaking, etc., can solve the problems of short thread weight stroke, easy breakage of fine yarns, and easy wear on the surface of yarns, so as to increase the payoff stroke and reduce Wear, increase stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

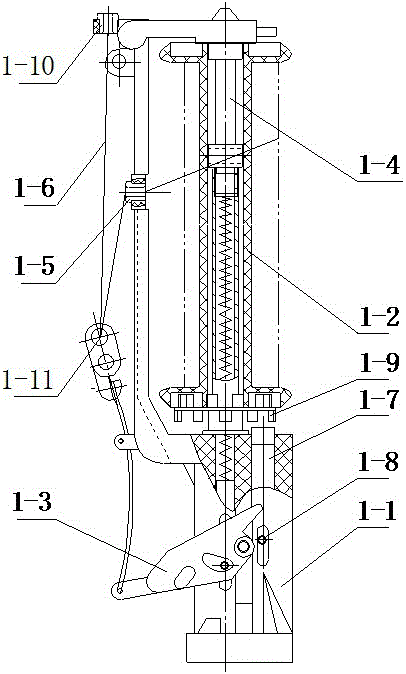

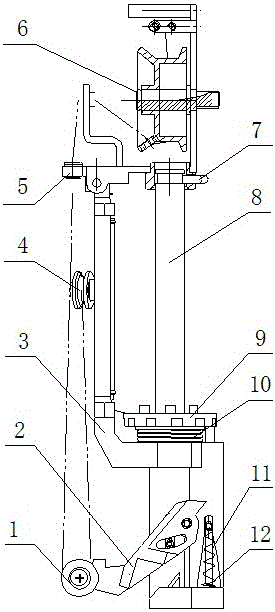

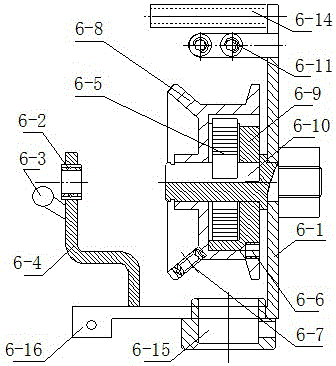

[0027] Embodiment 1: The spindle includes: the lower thread wheel 1, the thread pendant 2, the spindle rod 3, the upper thread wheel 4, the threading sleeve 5, the take-up and take-off device 6, the circlip 7, the bobbin shaft 8, the face plate 9, Tensioner 10, top pin 11 and compression spring 12; a wire dropper 3 is connected to the lower part of the spindle bar 3, a top pin 11 and a compression spring 12 are connected to the spindle bar 3 at one end of the line dropper 3, and the other end of the line dropper 3 is connected There is a lower wire wheel 1; there is a faceplate 9 in the middle of the spindle bar 3, and a bobbin shaft 8 is arranged in the center of the faceplate 9, and the bobbin shaft 8 is connected with the spindle bar as a whole, and a tensioner is connected between the faceplate 9 and the spindle bar 10. The tensioner 10 is synchronized with the pay-off to prevent loosening of the pay-off; the upper wire pulley 4 is connected to the middle part of one side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com