Large-stroke friction-free take-up and pay-off mechanism for spindle of knitter

A frictionless, unwinding and unwinding technology, applied in woven fabrics, textiles and papermaking, etc., can solve the problems of easy breakage of fine yarns, short strokes of thread drop, large spindle friction, etc., to improve product quality and production volume, Increase the pay-off stroke and the effect of constant tension and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

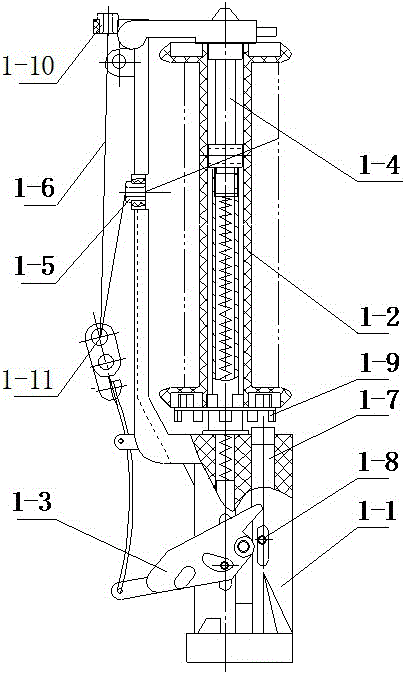

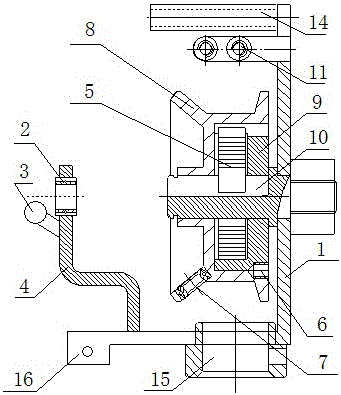

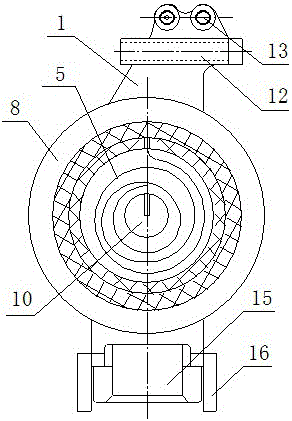

[0024] Embodiment 1: The take-up and pay-off mechanism includes: a wire passer, a bracket 1, a reel wire take-up device and a wire pass roller device; The thread device keeps the yarn in a tensioned state of appropriate force throughout the entire weaving cycle, which increases the spindle pay-off stroke; a thread passing roller device is connected to the bracket 1 at the upper end of the reel take-up device, and the thread is taken up on the reel A thread passer is connected to the bracket 1 on one side of the device, and the thread passer and the thread passer roller device have a rotating function, and there is no friction with the yarn surface, which reduces the wear of the output yarn; The connecting hole sleeve 15 and the support plate 16 that are connected with the spindle shaft are arranged on the support 1 of the.

[0025] The reel take-up device includes: a reel 8, a reel shaft 10, a cover 9, a coil spring 5, a fastening connector 6 and a reel wire passer 7; the reel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com