Novel absorption tower

An adsorption tower and a new type of technology, applied in the field of adsorption towers, can solve the problems of low gas flow rate, increased adsorbent loading, easy pulverization, etc., and achieve the effect of uniform flow rate in the outlet section and improved utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention will be described in detail below in conjunction with accompanying drawing:

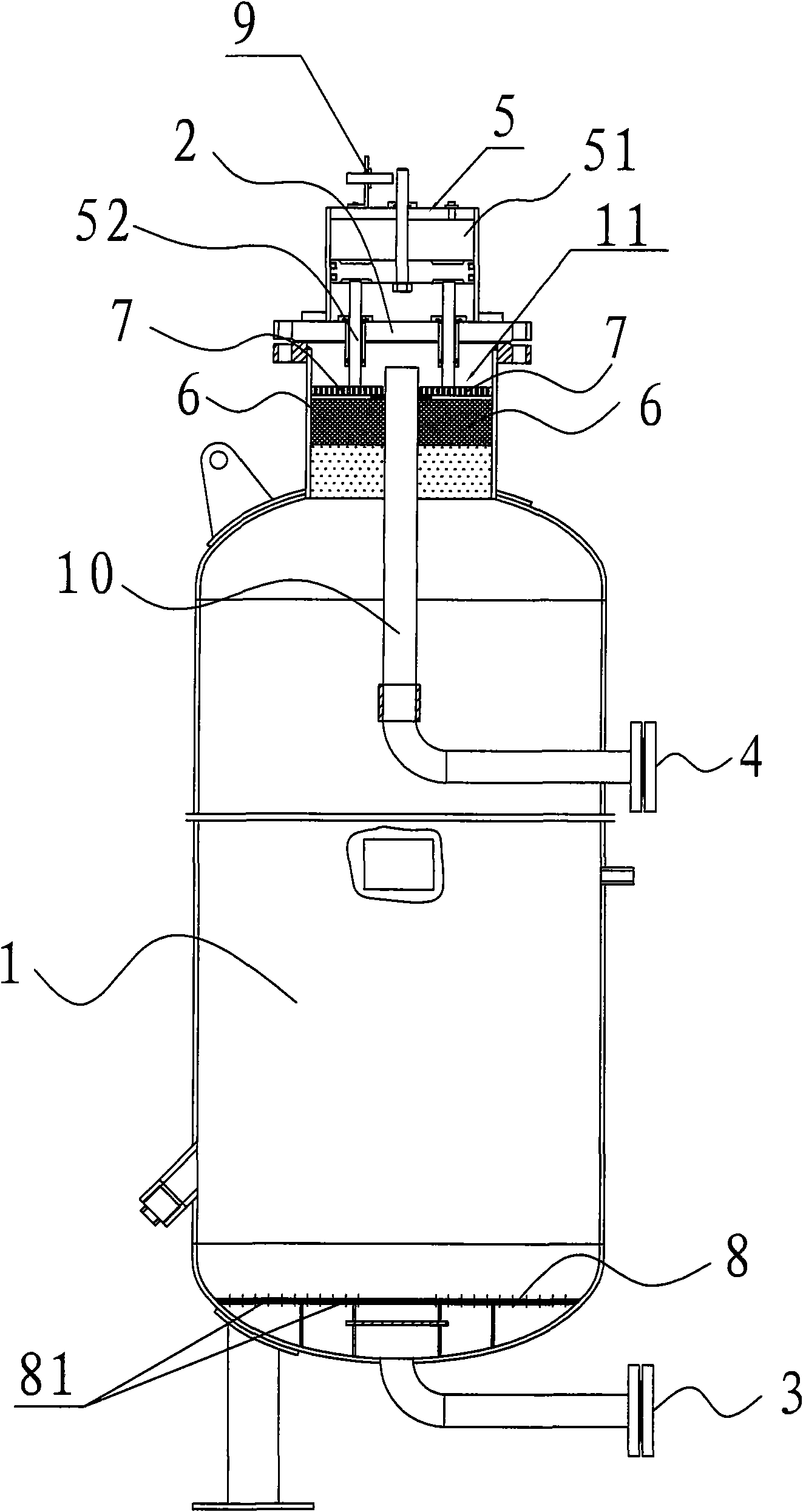

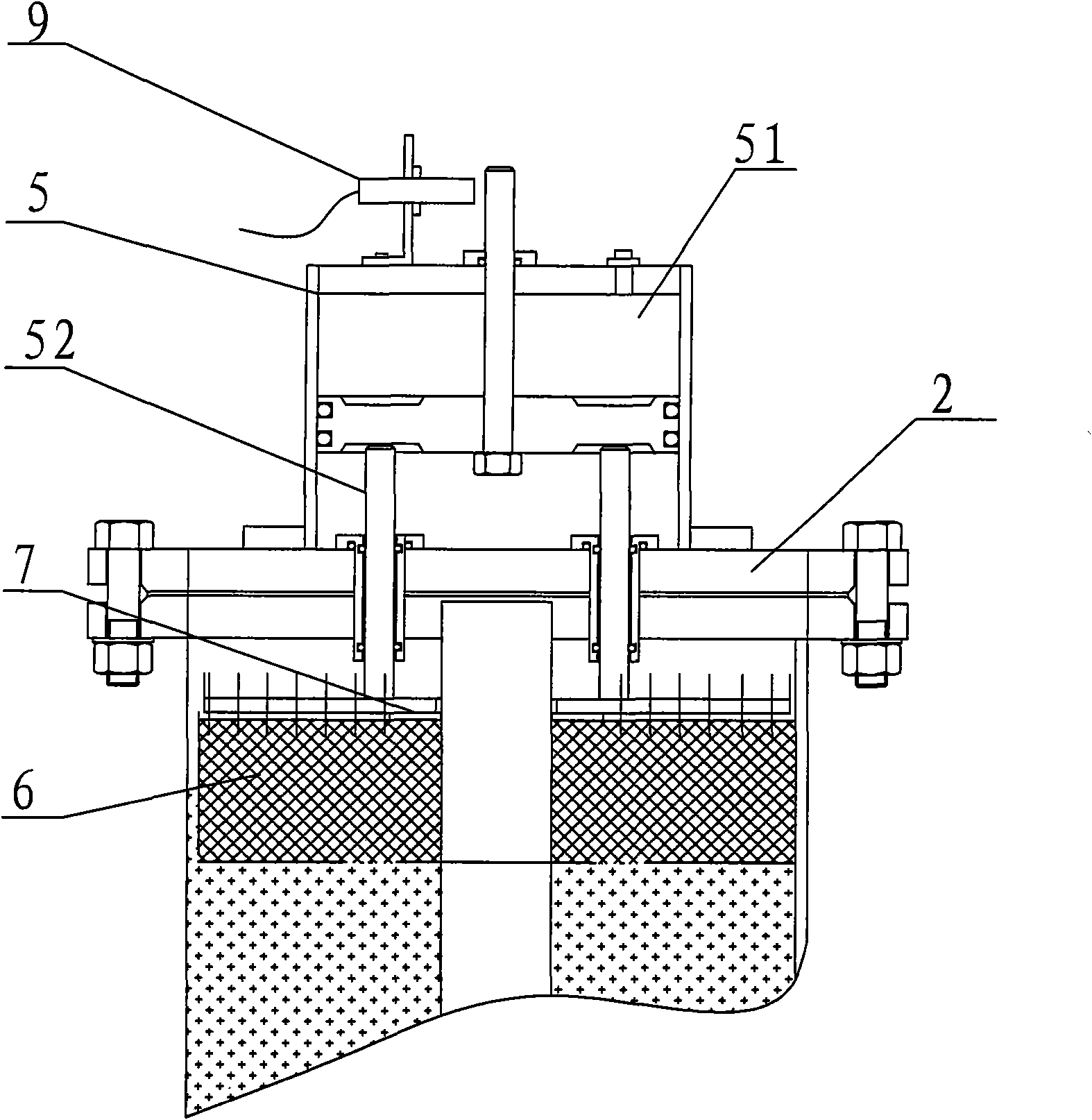

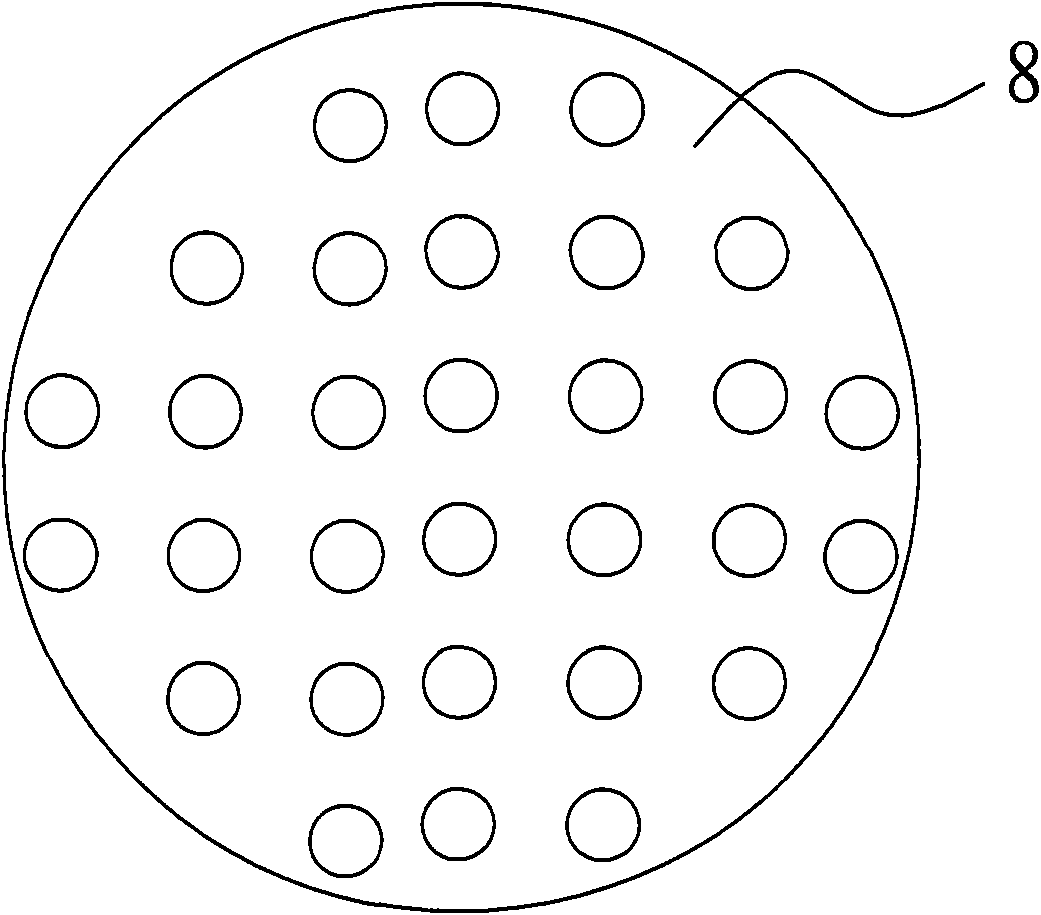

[0022] as attached figure 1 And attached figure 2 As shown, a new type of adsorption tower, which includes a tower body 1 for placing an adsorbent bed, a sealing cover 2 arranged on the top of the tower body 1, and an air inlet opened on the tower body 1 3 and air outlet 4. The sealing cover 2 is provided with a cylinder pressing device 5 for pressing down the adsorbent bed. The mixed gas after compression, oil removal and water removal enters from the air inlet 3 at the bottom of the tower body 1, and after passing through the gas flow distribution plate 8 and the carbon molecular sieve bed, the mixed gas such as nitrogen and impurity gases such as oxygen in a certain pressure state After being adsorbed into the micropores of the carbon molecular sieve, the nitrogen gas directly passes through the carbon molecular sieve bed and is sent to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com