Three-core terminal fixing device

A sizing device, three-core cable technology, applied in the direction of circuits, electrical components, conductive connections, etc., can solve the problems of easy-to-spread core wires, loose power supply of core wires, and short circuits of lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

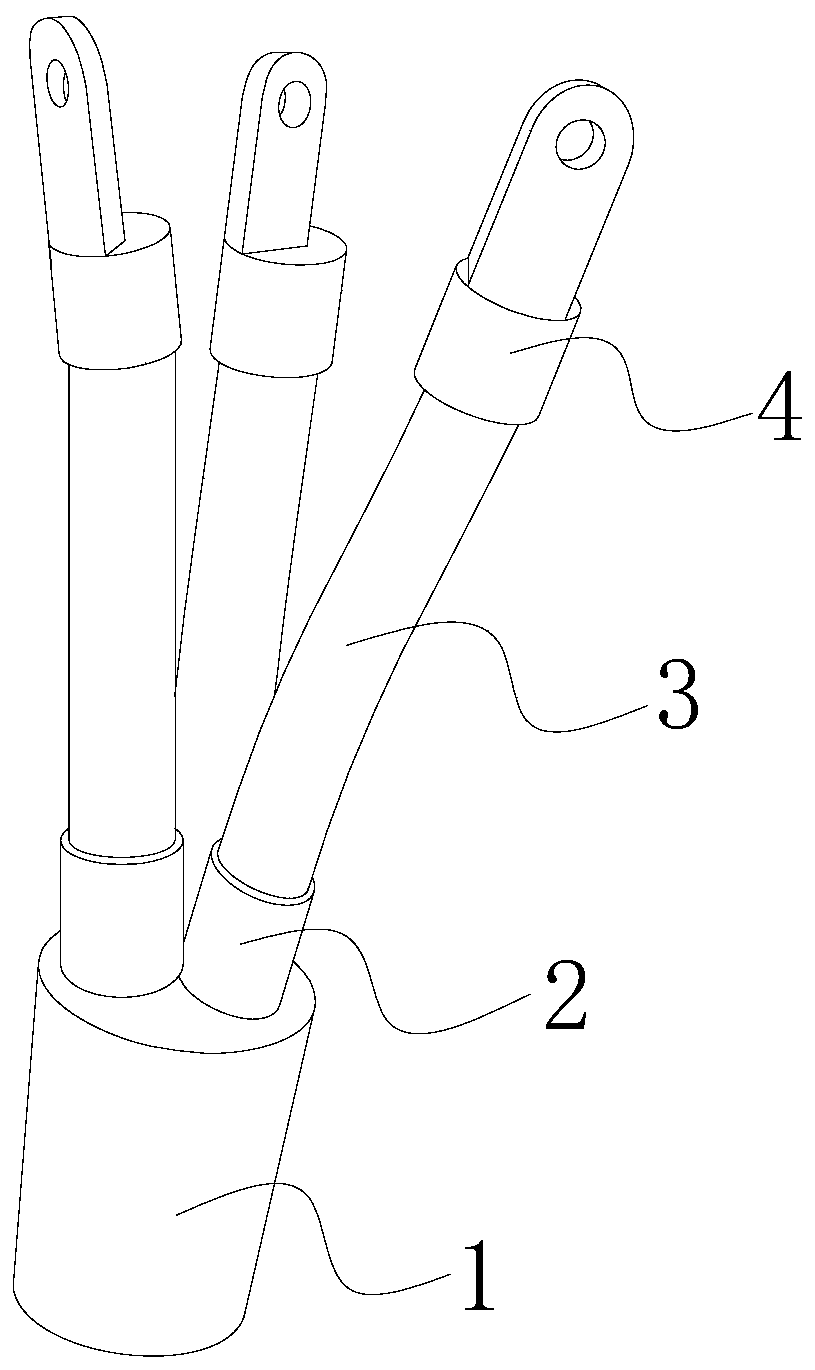

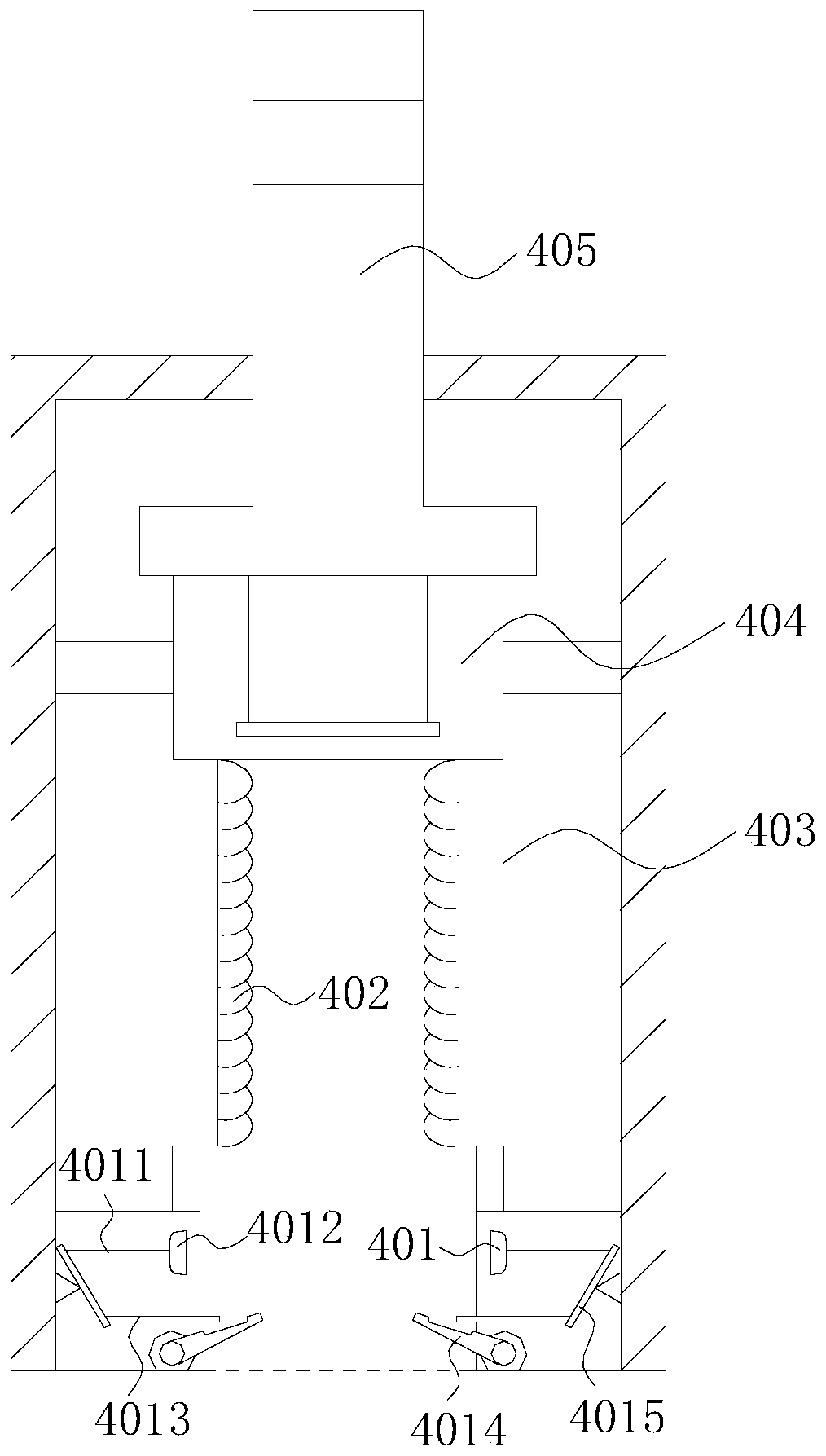

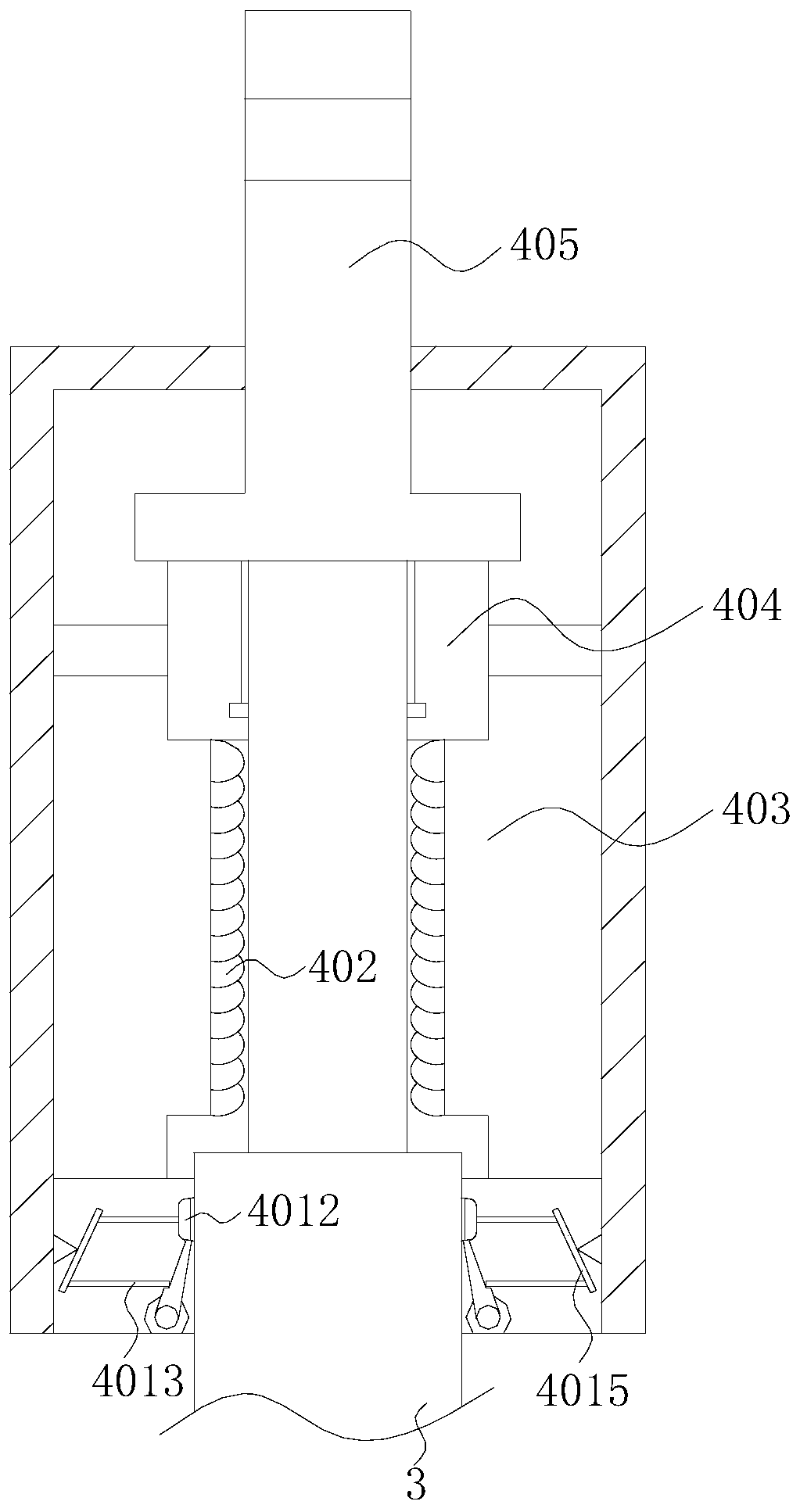

[0026] see Figure 1-Figure 5 , the present invention provides a three-core cable terminal shaping device, its structure includes a terminal 1, a connecting ring 2, a cable 3, and a cable connector 4, the cable 3 is connected to the connecting ring 2, and the connecting ring 2 is provided with three, so The connection ring 2 is fixedly installed on the terminal 1, the terminal 1 is electrically connected to the cable 3 through the connection ring 2, the cable connector 4 is electrically connected to the cable 3, and the cable connector 4 is arranged on the cable 3 away from the connection ring 2, the cable connector 4 is composed of an insulating layer fixing mechanism 401, a spiral guide rod 402, a working chamber 403, an adsorption mechanism 404, and a conductive plate 405. The insulating layer fixing mechanism 401 is set up opposite to the conductive plate 405. The spiral guide rod 402 is arranged in the working chamber 403, the spiral guide rod 402 connects the adsorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com