Belt collecting and winding machine structure

A technology of coiling machine and barrel, which is applied in the structural field of coiling machine for strip material rewinding, can solve the problems affecting the tightness of the strip material, the deposition of the strip material, and the effect of the coil material, and achieve a good tensioning effect of the strip material Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

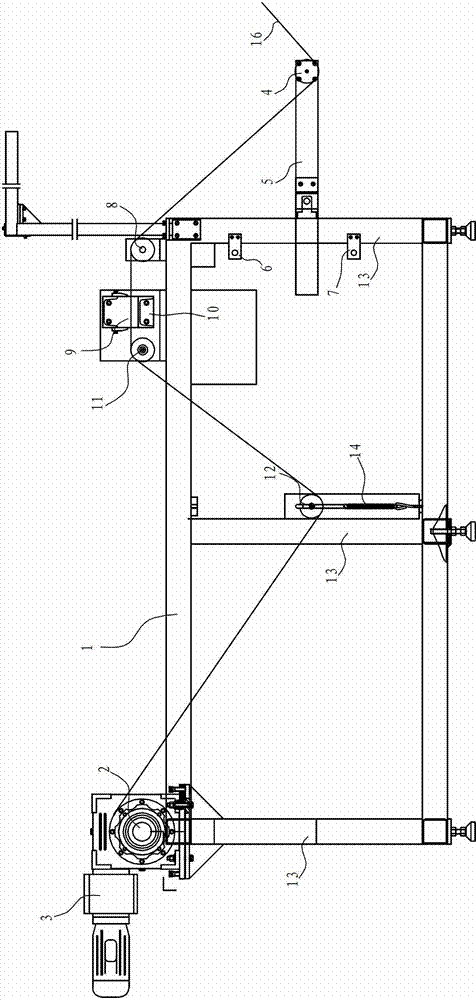

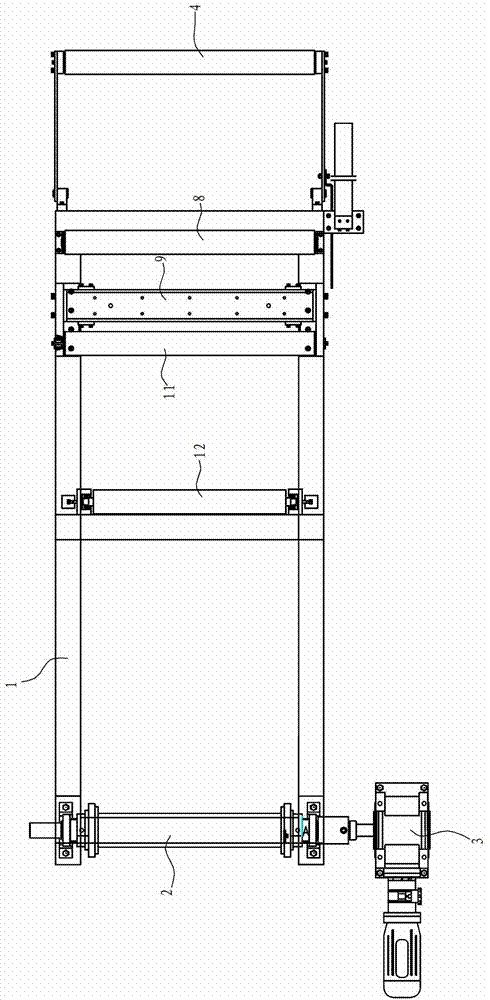

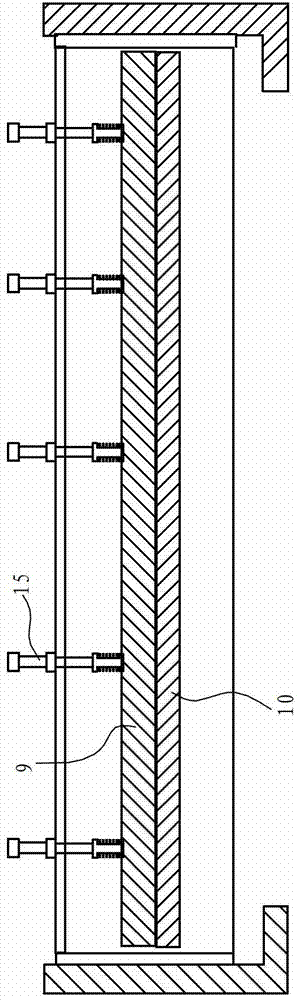

[0024] Such as figure 1 with 2 The structure of the tape rewinding and reeling machine shown includes:

[0025] Support frame, the support frame includes a support table 1 and a support foot 13;

[0026] The receiving barrel 2 set on the support table 1,

[0027] The receiving drive mechanism 3 that controls the rotation of the receiving barrel,

[0028] The first roller 4, the first roller is fixed at the first end of the pendulum rod 5, the middle part of the pendulum rod 5 is rotatably arranged on the supporting foot 13, and the conveyed belt material 16 first bypasses the first roller 4, The axis position of a roller 4 is lower than the axis position of the receiving drum 2;

[0029] The first limit switch 6 is arranged on the support foot 13 and is located above the pendulum rod 5, which can contact the second end of the pendulum rod 5 after rotating;

[0030...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com