Protection belt winding device for petroleum transport pipeline

A technology of winding device and transportation pipe is applied in the field of protective belt winding device of petroleum transportation pipeline and double-layer protective belt winding device, which can solve the problems of affecting protective effect, low winding efficiency, thin protective layer thickness, etc. effect, improved winding effect, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

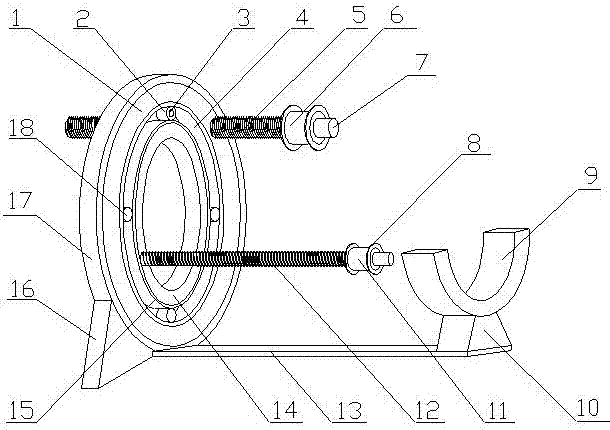

[0021] A protective belt winding device for oil transportation pipelines of the present invention is realized in this way. When using, when winding the protective belts for oil transportation pipelines, firstly place one end of the oil pipeline in the inner fixing ring (14), and place the other end On the arc-shaped bracket (9), separate a roll of protective tape from the middle and wind it on the main winding roller (6) and the auxiliary winding roller (11) respectively, and make the protective tape pass through the bottom of the oil pipeline, drive the motor ( 3) Work, the motor shaft drives the driving gear (2) to rotate, the driving gear (2) drives the inner gear (4) and the outer gear (15) to rotate respectively, and the inner gear (4) and the outer gear (15) turn On the contrary, the three driven gears follow the rotation of the inner ring gear (4) and the outer ring gear (15) to maintain the stability of the rotation of the inner ring gear (4), and the inner ring gear (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com