The installation structure of Rubik's cube center block

A technology of installation structure and center block, which is applied in the Rubik's Cube field, can solve problems such as difficult adjustment, uneven tightness of the Rubik's Cube, and inaccurate installation position, and achieve the effects of high assembly accuracy, consistent tightness, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

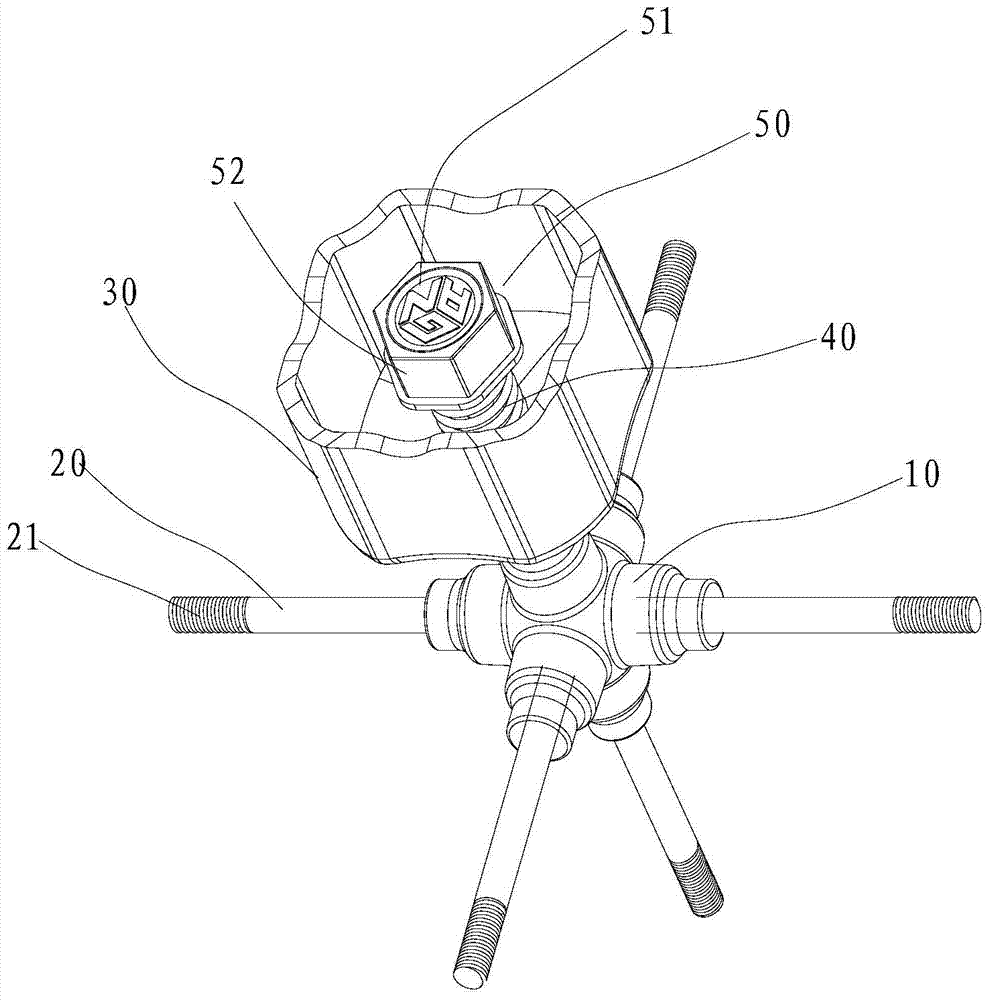

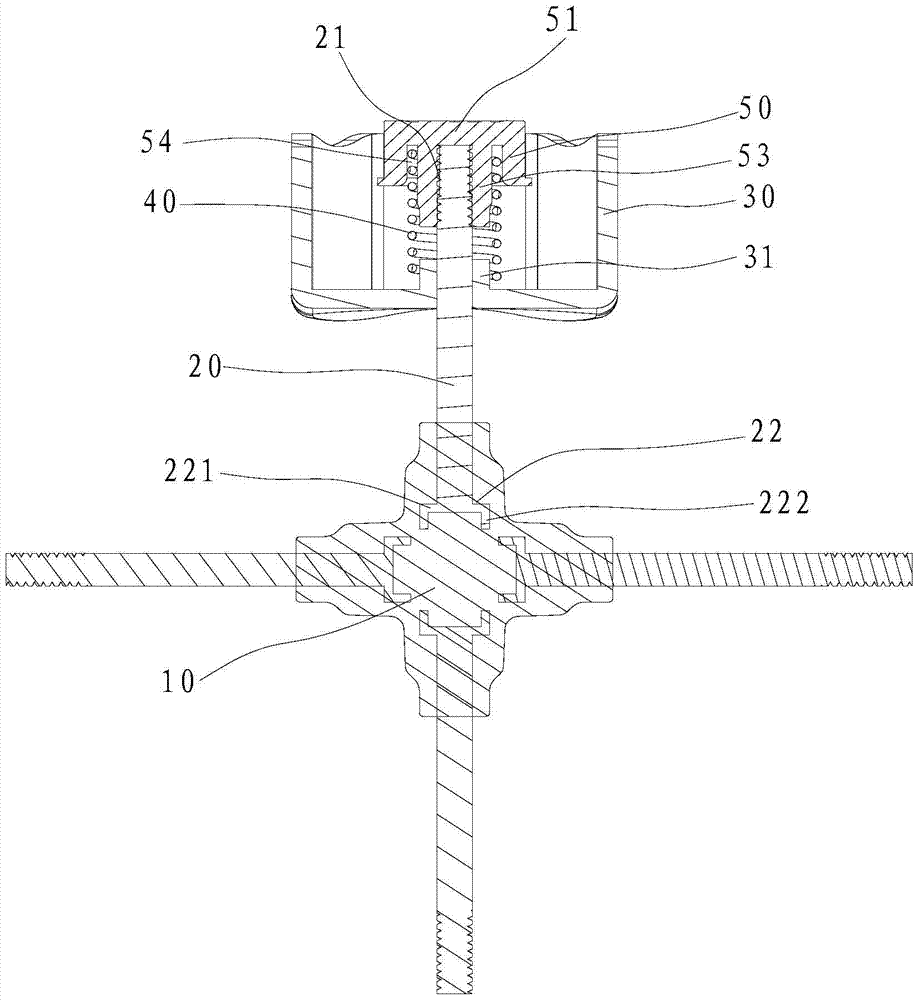

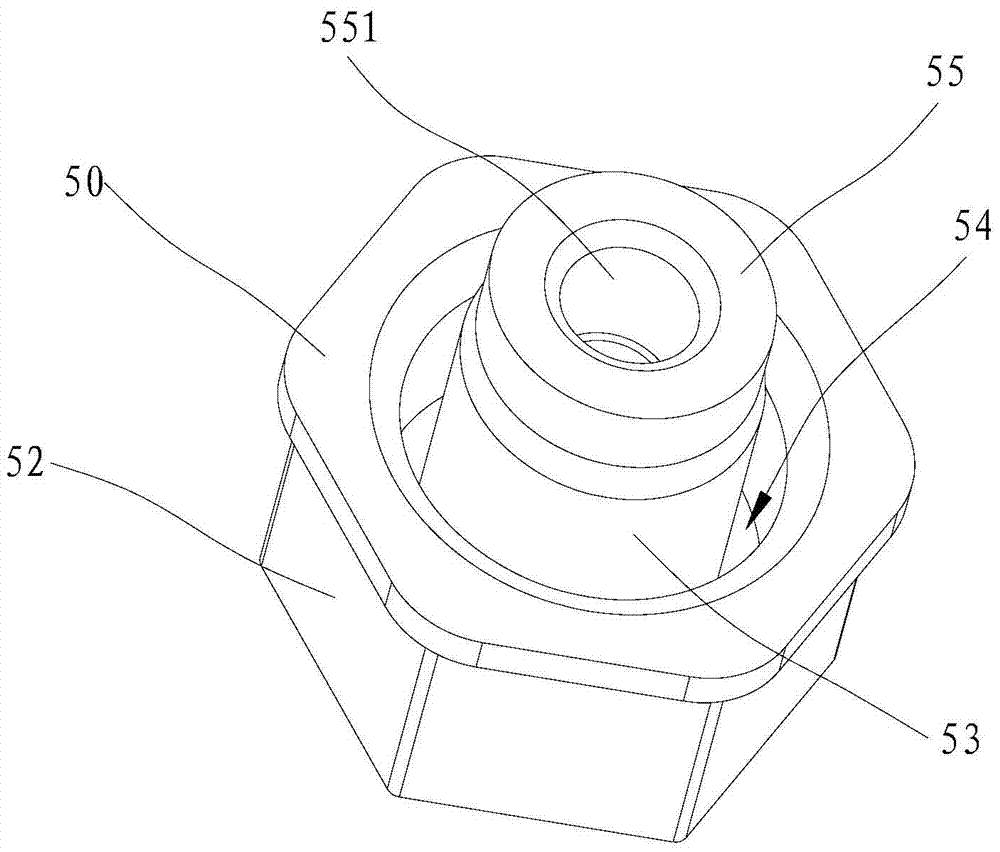

[0018] Such as figure 1 , 2 as well as image 3 The mounting structure of the shown Rubik's Cube center block, in this embodiment, takes the traditional third-order Rubik's Cube as an example, including the axis 10, the connecting rod 20, the center block 30 and the elastic member 40, so that one end of the connecting rod 20 is connected to the In the center block 30, the other end of the connecting rod 20 is provided with an embedding part 22 embedded in the shaft center. The embedding part 22 includes an extension part 221 and an insertion part 222. Specifically, the extension part 221 is located at the lower end of the connecting rod 20 and Extending outward along the radial direction of the connecting rod 20, and the insertion part 222 is formed by extending downward from the edge of the extending part 221. This structure increases the contact are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com