Pearl wool winding treatment method and system

A processing method and technology of pearl cotton, which can be applied in the direction of thin material processing, coiling strips, transportation and packaging, etc., and can solve problems such as uneven stress on pearl cotton

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

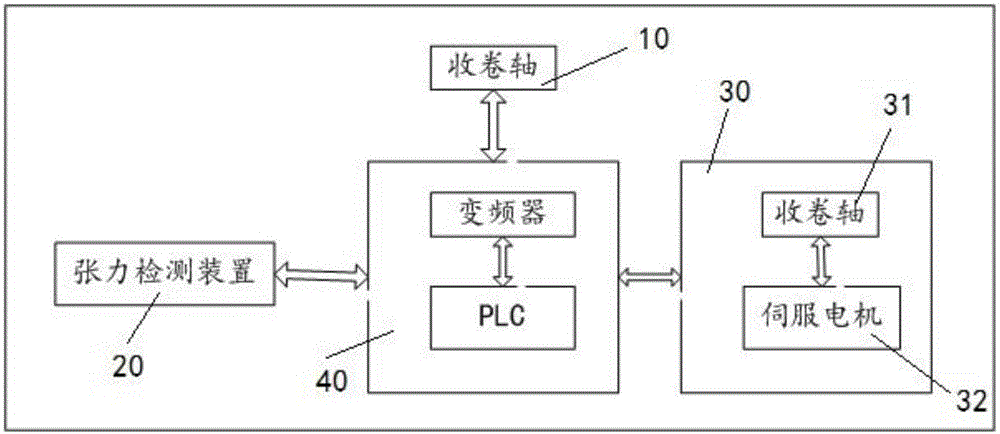

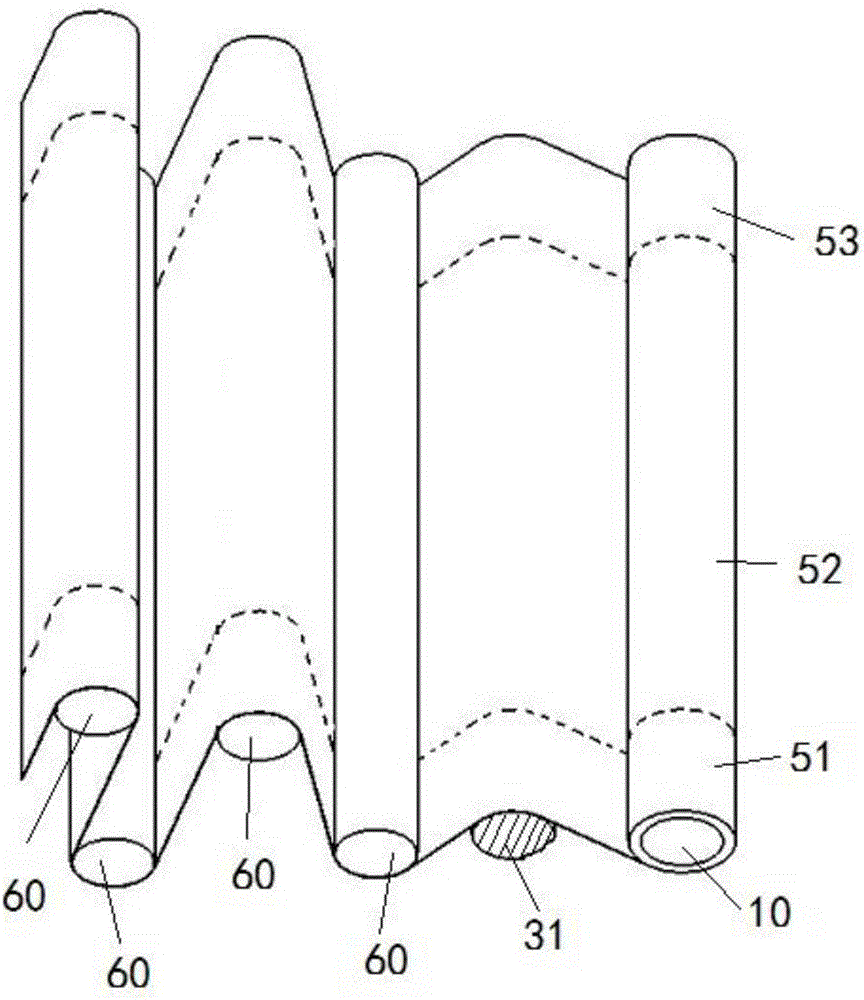

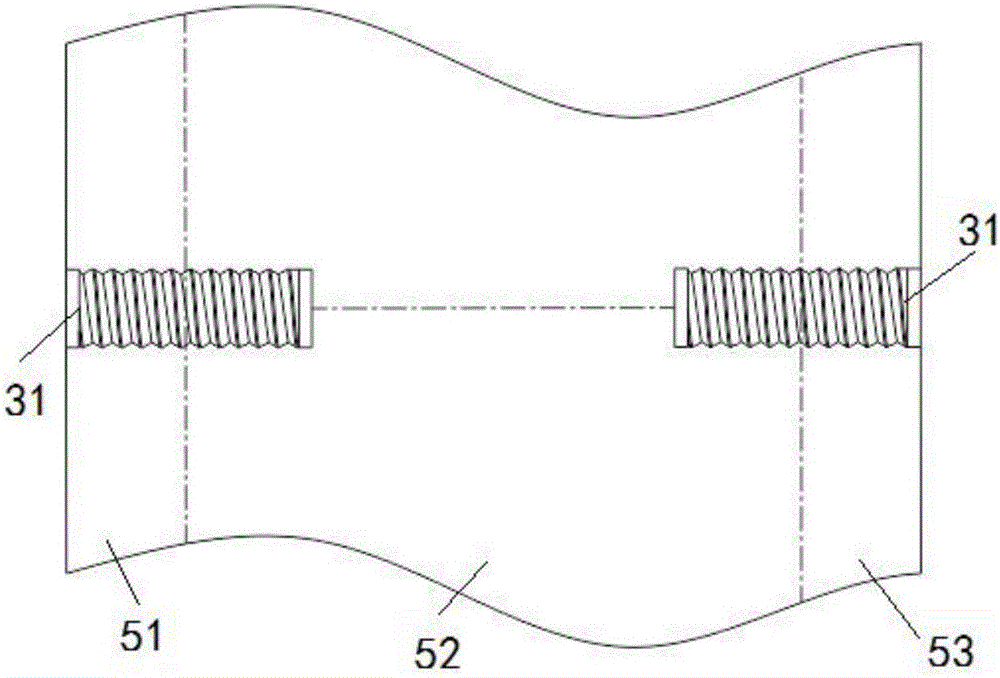

[0035] The pearl cotton winding treatment method of the present invention includes: dividing the pearl cotton into three areas along the width direction according to the properties of the pearl cotton, namely, the left edge area, the middle area and the right edge area, and the left Tension detection is performed on the side edge area, the middle area and the right edge area, and the tension values of the three areas are obtained; the instantaneous radius of the winding shaft is obtained according to the volume of the rolled pearl cotton on the winding shaft, combined with the initial tension detected in the middle area Adjust the winding shaft torque in real time to keep the pearl cotton in the middle area constant; compare the pearl cotton tension values detected in the left and right edge areas with the pearl cotton tension values detected in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com