Pipe discharge mechanism

A discharge mechanism and pipe technology, applied in the direction of conveyor objects, transportation and packaging, rollers, etc., can solve the problems of inconvenient discharge and transportation, easy rolling of pipes, and unfixable positions, etc., so as to achieve convenient and flexible use and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

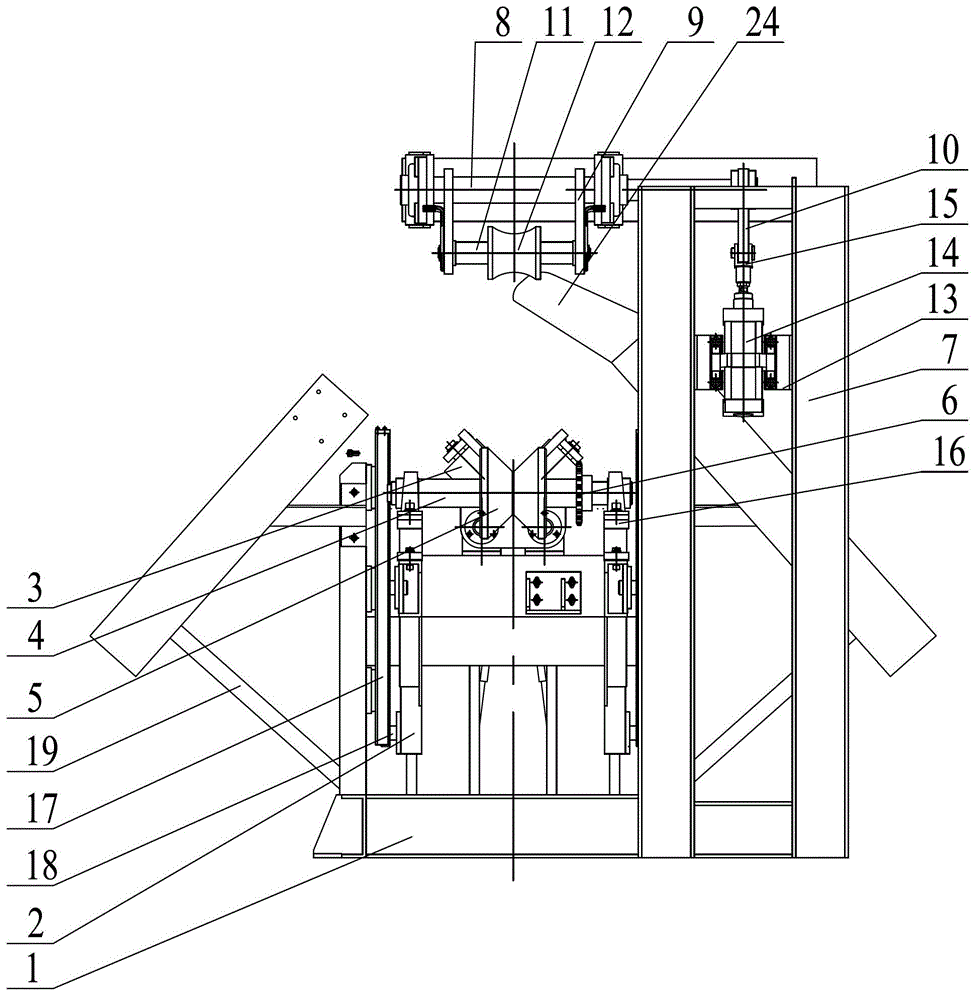

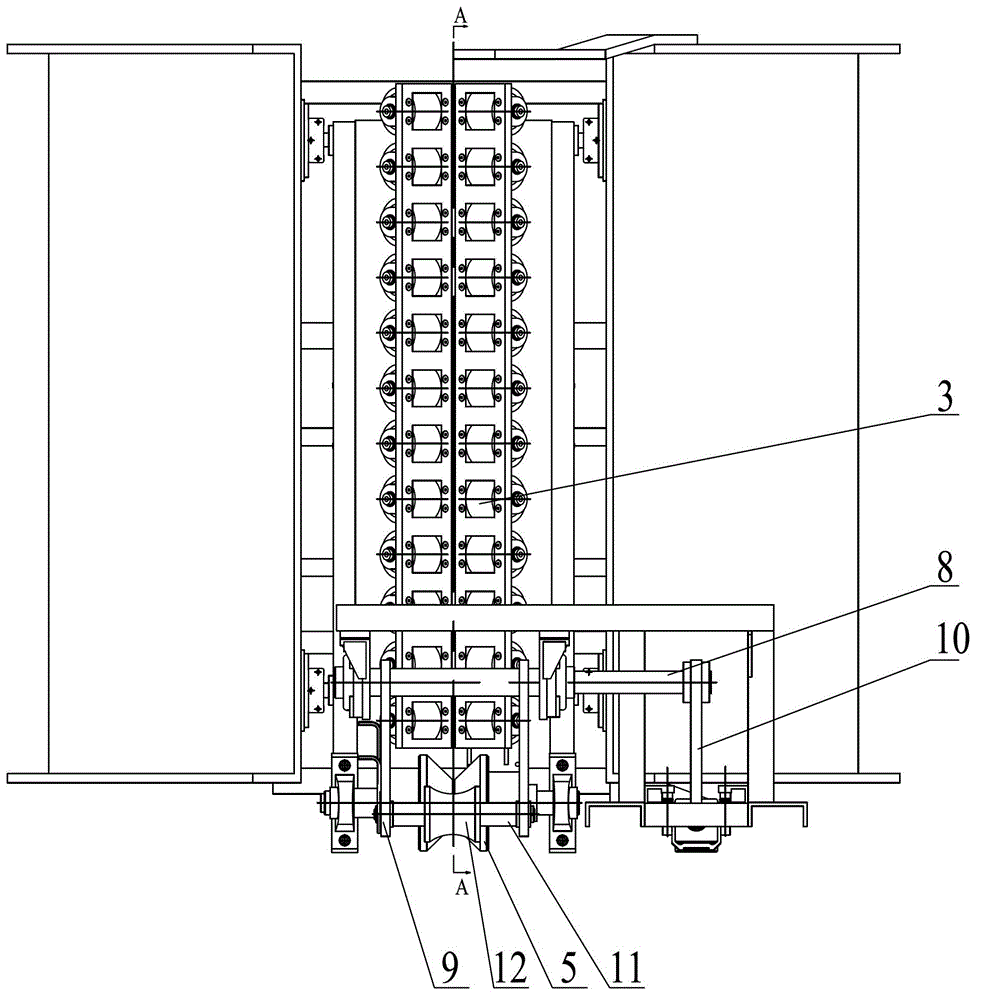

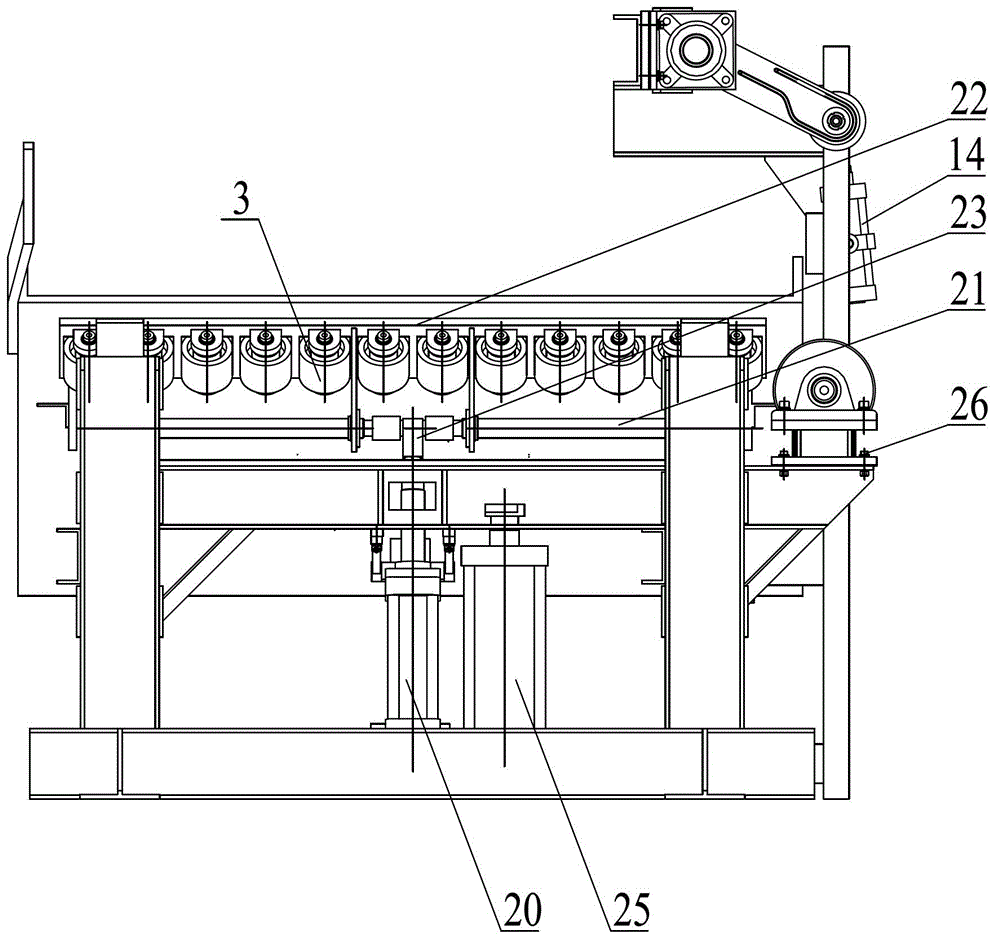

[0015] As shown in the figure: the pipe discharge mechanism is vertically slid on the installation seat 1 and installed with a lifting frame 2, and the rotating frame on the lifting frame 2 is provided with a roller shaft 4, and a conveying roller 5 and a drive are fixed on the roller shaft 4. Sprocket 6, two rows of driven rollers 3 on the left and right are installed in the rotation of lifting frame 2 on the rear side of conveying roller 5, and left and right two rows of driven rollers 3 form a V-shaped conveying groove, and driven roller 3 cooperates with conveying roller 5; Mounting seat 1 is fixed with hold-down frame 7, is provided with hold-down pivot 8 at the top end portion rotatable frame of hold-down frame 7, is fixed with pivot frame 9 and cylinder lever 10 on hold-down pivot 8, on pivot frame Rotate on 9 and be equipped with compression wheel shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com