Scrap iron cleaning and collecting processing device for machinery works

A processing device and a technology of a machinery factory, applied in cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of inconvenient release of iron filings, inconvenient iron filings shoveling, and inability to absorb and collect iron filings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

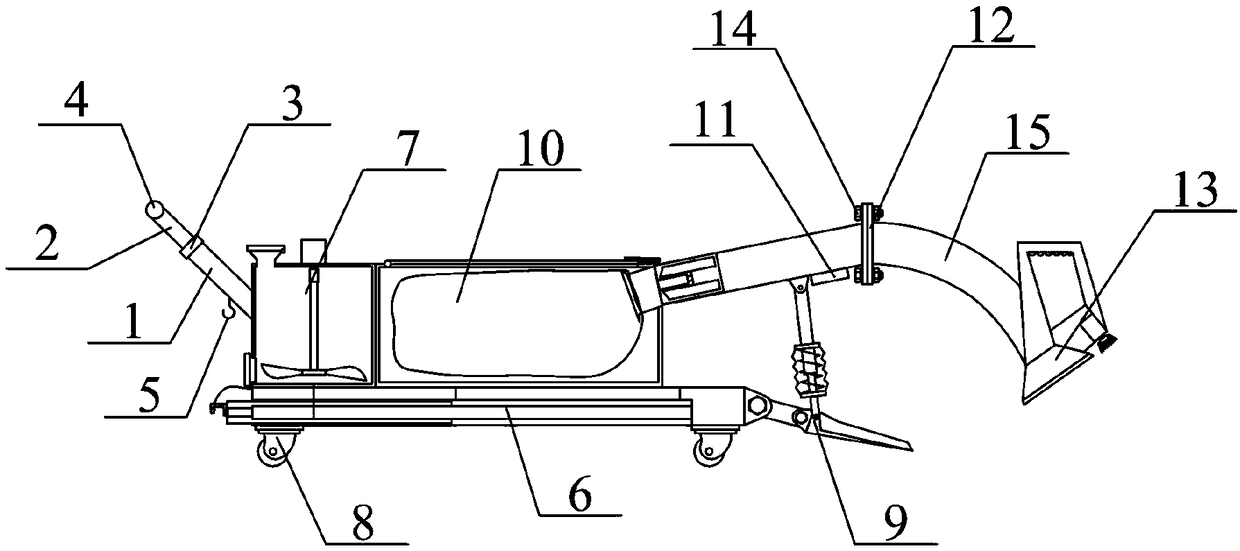

[0041] As attached figure 1 And figure 2 Shown

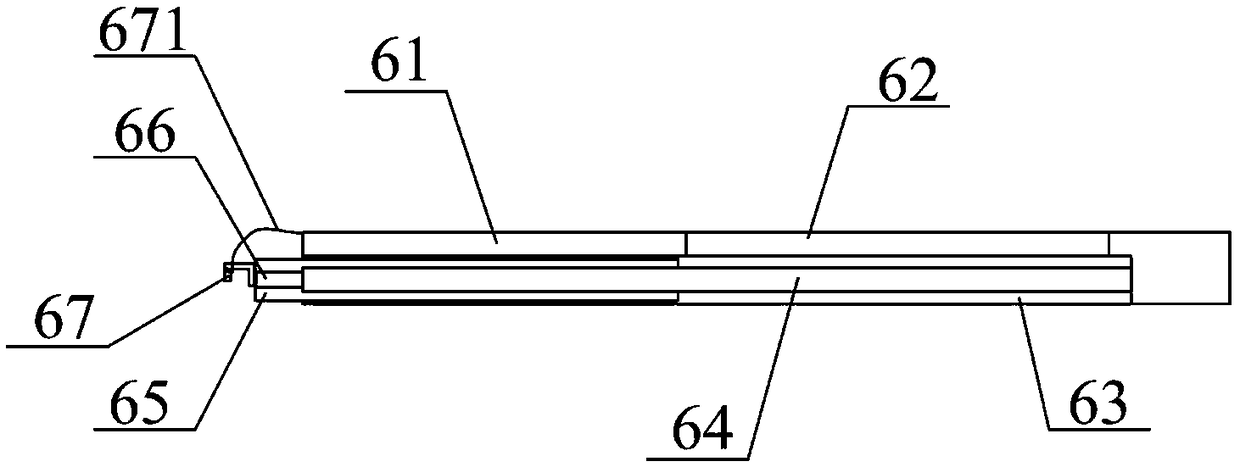

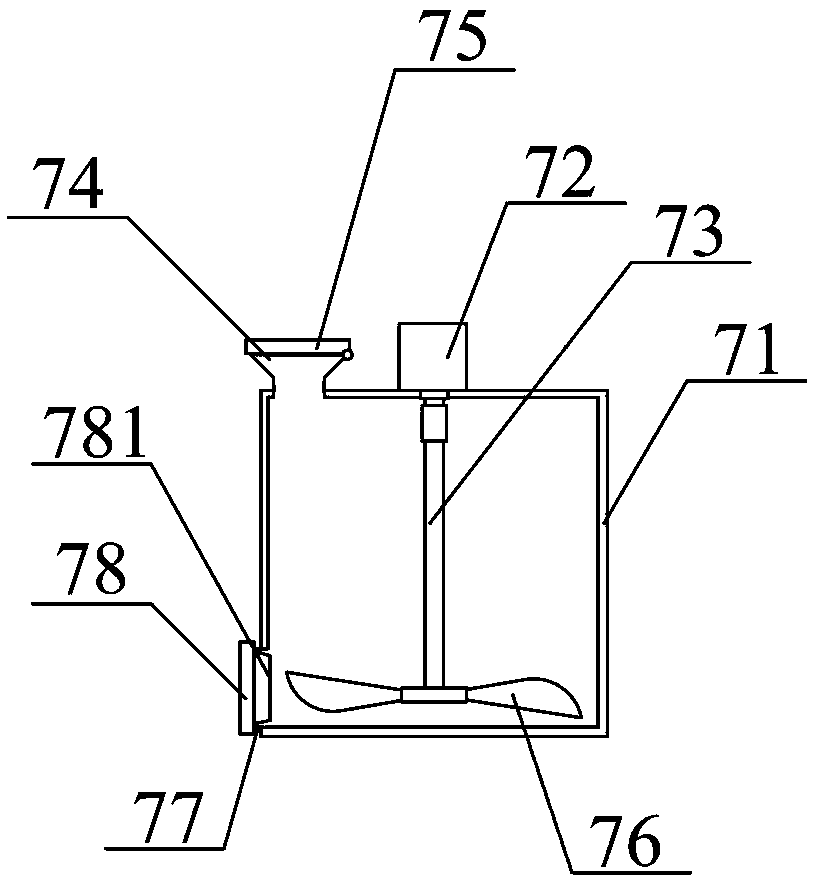

[0042] The invention provides an iron filings cleaning collection and processing device for machinery factories, which includes an elongated sleeve 1, an elongated support rod 2, a quick release buckle 3, a push-pull grip 4, a tool hook 5, a bottom iron filings suction collection frame structure 6, and iron Chip crushing box structure 7, universal bottom wheel 8, iron chip production shovel bucket structure 9, iron chip extraction box structure 10, lighting 11, flange connection plate 12, cleaning extraction head structure 13, bolts and nuts 14 and metal soft Tube 15, the extended sleeve 1 is installed on the upper left side of the iron filings crushing box structure 7; the extended support rod 2 is inserted into the left side of the extended sleeve 1; the quick release buckle 3 Sleeve at the junction of the extension sleeve 1 and the extension pole 2; the push-pull grip 4 is glued to the left end of the extension pole 2; the tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com