Finishing and ironing device for knitted fabrics

A knitwear and processing box technology, which is applied in textiles and papermaking, textile material treatment, fabric surface trimming, etc., can solve the problems of knitwear such as wrinkles, achieve the effect of improving the quality of ironing and strengthening the effect of steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

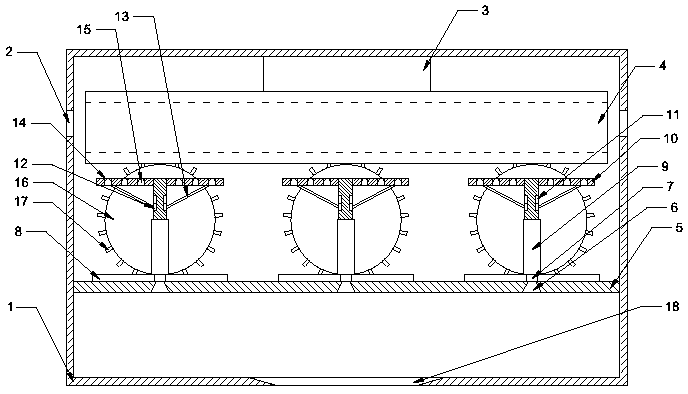

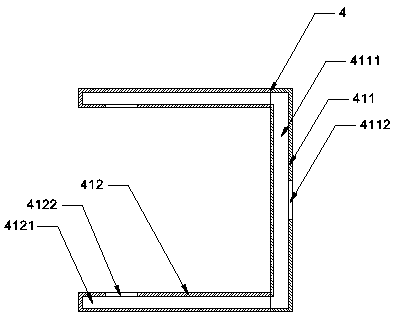

[0018] The reference signs in the accompanying drawings of the specification include: processing box 1, feed port 2, auxiliary arm 3, limit block 4, vertical section 411, vertical hole 4111, first auxiliary hole 41112, transverse section 412, and transverse hole 4121 , the second auxiliary hole 4122, the partition plate 5, the through hole 6, the first support shaft 7, the gear 8, the telescopic rod 9, the cross bar 10, the chute 11, the slider 12, the movable rod 13, the air inlet 14, Inflatable bag 15, disk 16, transmission tooth 17, steam inlet 18.

[0019] The embodiment is basically as attached figure 1 And attached figure 2 Shown: the ironing device used for knitwear, including a hollow processing box 1, the left and right sides of the processing box 1 are provided with feed ports 2; Positioning mechanism, the limiting mechanism includes an auxiliary arm 3 affix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com