Dedicated jig for numerical control knife machine

A CNC sharpening machine and special fixture technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of insufficient locking force, easy wear, and difficulty in meeting the requirements of drawings, etc., and achieve the effect of high repeat positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

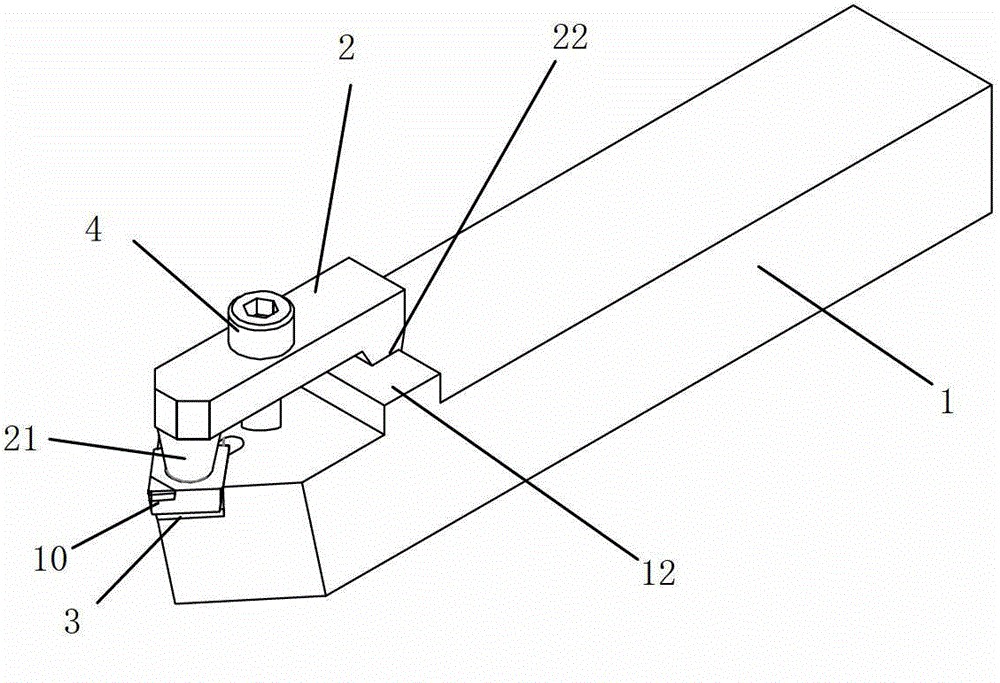

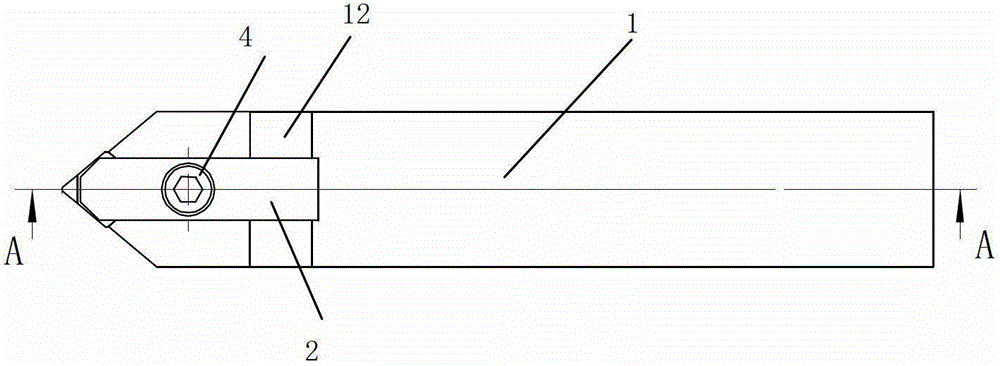

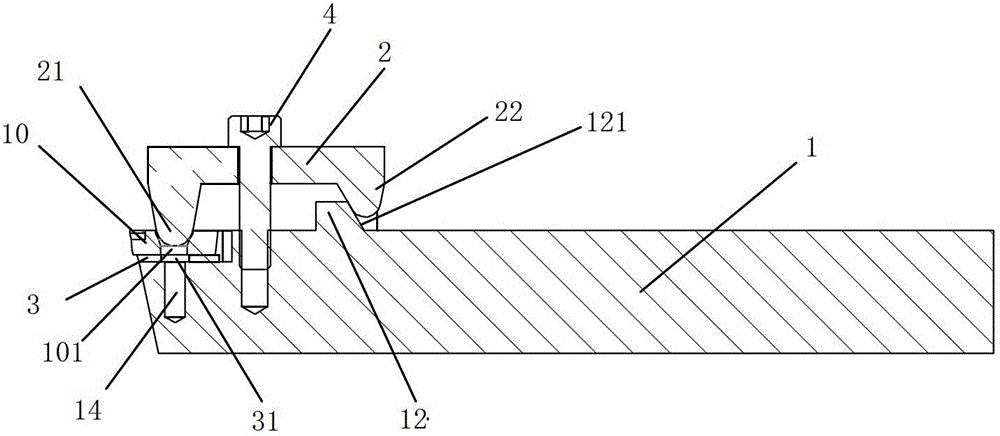

[0026] Embodiment, referring to the accompanying drawings, a special clamp for a CNC knife grinder of the present invention includes a turning handle 1 and a pressing plate 2; the pressing plate 2 is in the shape of a door frame; one end of the turning handle 1 is provided with a blade groove 11, and the blade Groove 11 contains vertical surface 111 and bottom surface 112; The middle of pressing plate 2 is fixed on the turning handle 1 by screw, and one end 21 of pressing plate 2 can press against the numerical control blade 10 of packing into blade groove 11; There is a boss 12 on the top, and the inner hook of the other end 22 of the pressing plate 2 leans against the boss 12 of the turning tool handle. One end 21 of the pressing plate is set as a spherical structure, and one end 21 of the pressing plate is pressed and attached to the insert groove through the spherical structure. CNC blade 10 on.

[0027] It further includes a polycrystalline diamond composite sheet 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com