High-strength built reinforced concrete block and manufacturing mold thereof

A reinforced concrete block, high-strength technology, applied in the direction of manufacturing tools, building structures, building components, etc., can solve the problems of strength reduction, insufficient strength, and damage to the internal structure of concrete blocks, so as to improve the anti-seepage performance and good intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

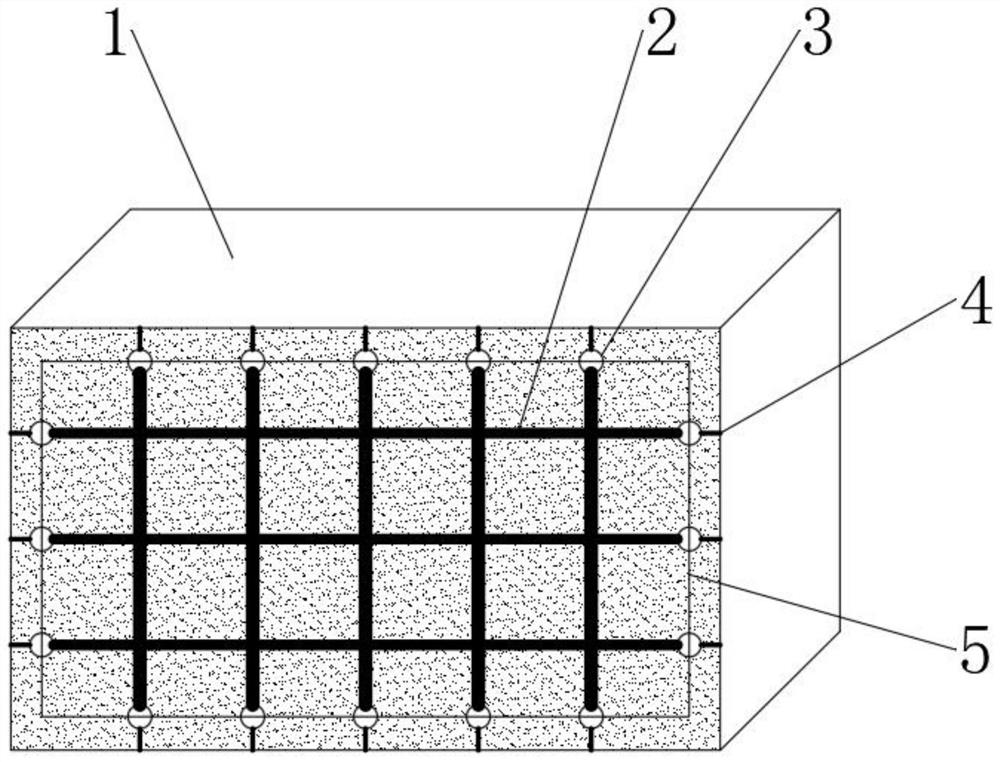

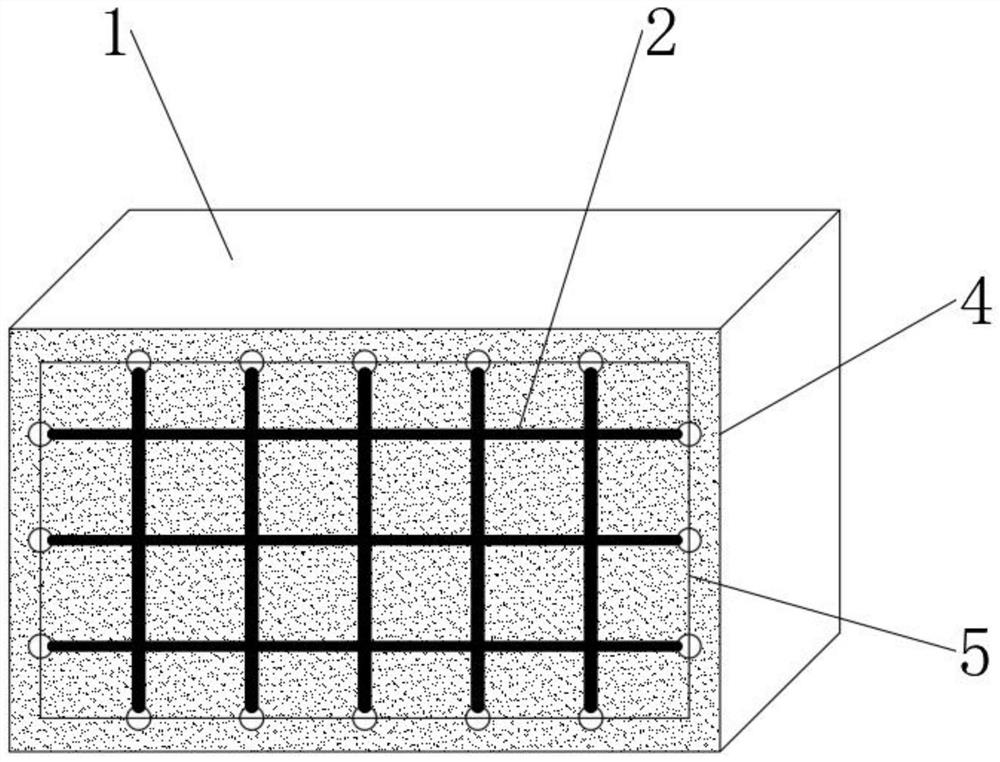

[0043] see Figure 1-2 , a high-strength added reinforced concrete block, comprising a block body 1, a steel grid frame 2 is inlaid and connected to the block body 1, and anti-seepage balls 3 are connected to multiple ends of the steel grid frame 2, and the anti-seepage balls 3 An air pressure rod 4 is inserted at one end away from the steel grid frame 2, and a water guide fiber pipe 5 is connected between the air pressure rods 4.

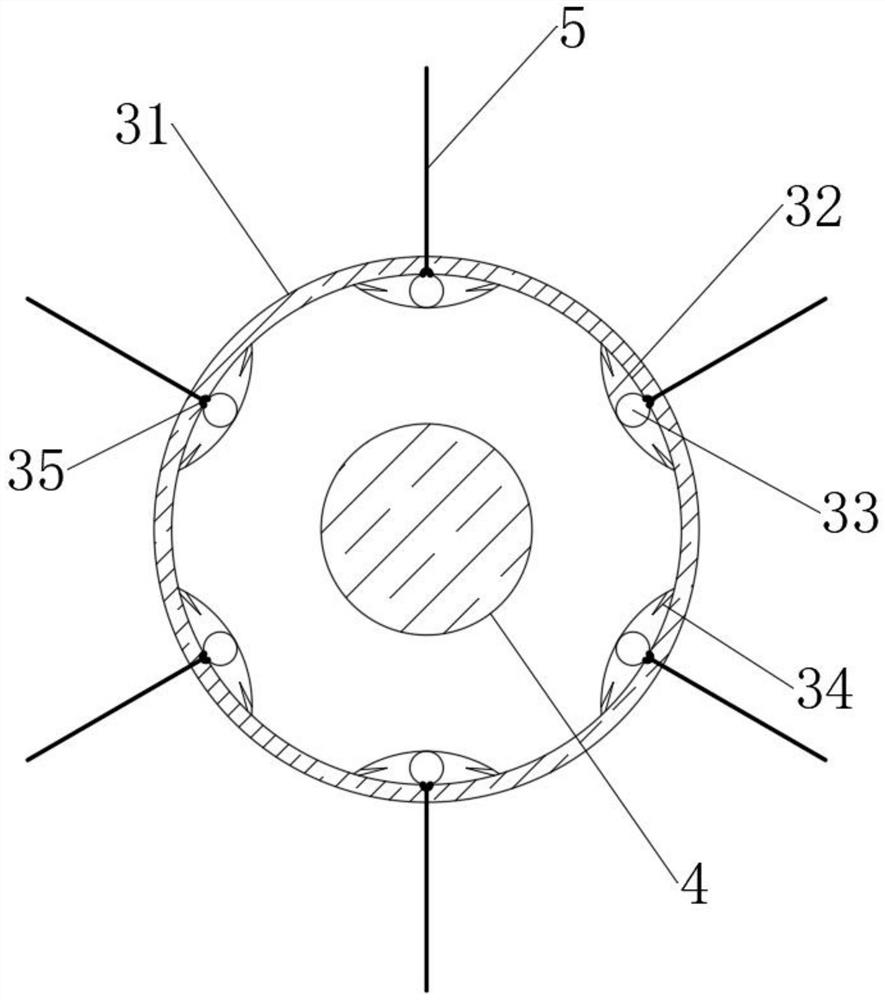

[0044] see image 3 The anti-seepage ball 3 includes a basic sphere 31 and a plurality of extension packages, and the plurality of extension packages are uniformly connected to the inner surface of the basic sphere 31, and the delay package includes a gas-sensitive tympanic membrane 32, an isolation bag 33 and a plurality of trigger pins 34, and the gas-sensitive The tympanic membrane 32 is connected to the inner surface of the basic sphere 31, and the isolation bag 33 is connected between the basic sphere 31 and the air-sensitive tympanic membran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com